Novel forming whole set wall (column) formworks and production method and on-site construction technique thereof

A new type of on-site construction technology, applied in formwork/formwork/work frame, on-site preparation of building components, formwork/formwork components, etc., to achieve the effects of easy management, strong bearing capacity, and low bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

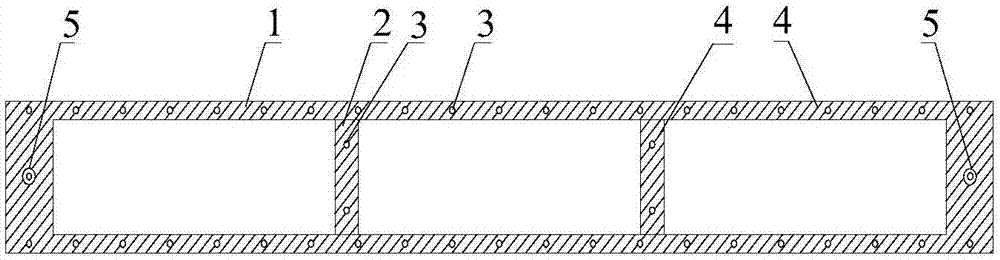

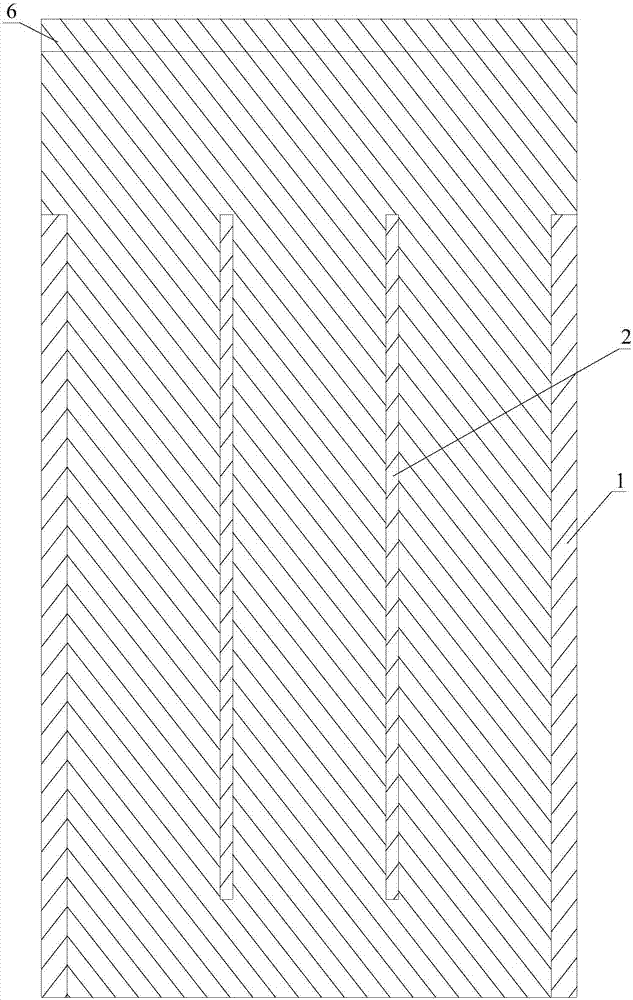

[0050] Such as figure 1 , figure 2 As shown, the present invention forms a complete set of new wall (column) molds. The wall (column) mold is a straight column frame mold structure. , the bottom end of the reinforcement plate 2 is higher than the bottom end of the frame formwork 1, and the upper end is flush with or lower than the upper end of the frame formwork 1. The frame formwork 1 and the reinforcement plate 2 are formed by pouring steel mesh 3 and concrete 4, and the frame The thickness of one side of the mold 1 is 30mm, the width of the frame mold is 2100mm, the thickness of the reinforcement plate is 50mm, the width of the reinforcement plate is 190mm, and the distance between the reinforcement plates is 600mm, and the left and right sides of the frame mold 1 are formed with suspension rings 5.

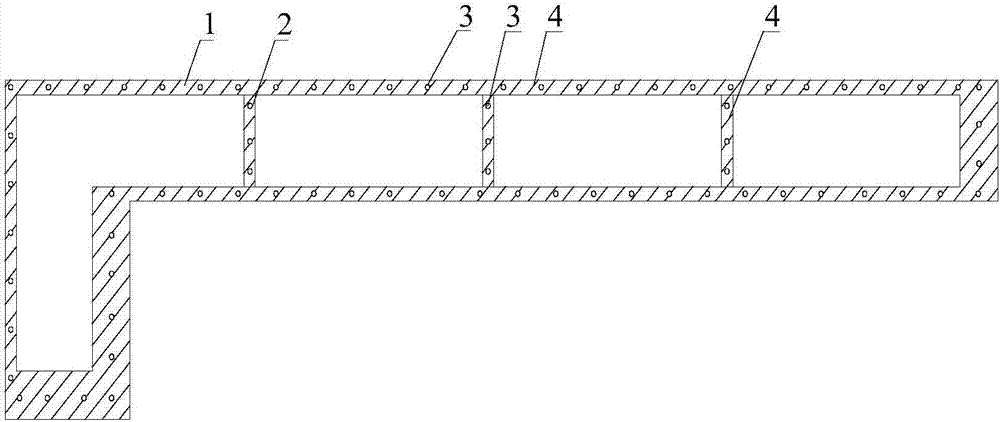

[0051] Such as image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com