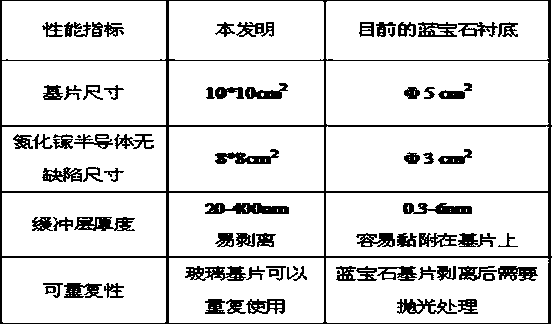

A kind of preparation method of large-scale gallium nitride semiconductor chip for LED

A gallium nitride and semiconductor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as high density, mismatched lattice, small size, etc., and achieve simple preparation process, easy storage and transportation, and wide sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add ethyl orthosilicate to methanol solvent, control the temperature at 25°C, and stir at 300 rpm, then add deionized water and 7% hydrochloric acid in sequence, and adjust the pH value to between 3-4 Between, obtain silica airgel precursor liquid, the ratio of described ethyl orthosilicate, methyl alcohol, deionized water, 7% hydrochloric acid is 1:5:2:1 in molar ratio;

[0035] (2) After the silica airgel precursor solution was left to stand at a temperature of 30°C for 0.1 hour, the temperature was adjusted to 60°C, and the drying control additive formamide was added under the condition of a stirring speed of 200 rpm Stir for 10-20 minutes, the molar ratio of tetraethyl orthosilicate and formamide is 1:0.25;

[0036] (3) Add alumina with a particle size of 100nm to the silica airgel obtained in step (2), stir for 5 minutes at a stirring speed of 300 rpm, then add ammonia water, and stir for 5 minutes to obtain Aluminum-silica airgel composite sol;

[0037] (4) Sp...

Embodiment 2

[0041] (1) Add methyl orthosilicate to ethanol, set the temperature of ethanol at 35°C, and stir at 350 rpm, then add distilled water and 10% hydrochloric acid in turn to adjust the pH value to between 3-4 Between, obtain silica airgel precursor solution, the ratio of described methyl orthosilicate, ethanol, distilled water, 10% hydrochloric acid is 1:6:4:2 in molar ratio;

[0042] (2) After the silica airgel precursor solution was allowed to stand at 40°C for 1 hour, the temperature was adjusted to 65°C, and the drying control additive acetamide was added at a stirring speed of 350 rpm Stir for 10-20 minutes, the molar ratio of the silicon alkoxide and acetamide is 1:0.35;

[0043] (3) Add alumina with a particle size of 300nm to the silica airgel obtained in step (2), stir for 20 minutes at a stirring speed of 350 rpm, then add sodium hydroxide, and stir for 15 minutes. Obtain alumina-silica airgel composite sol;

[0044] (4) Spin the alumina-silica airgel composite sol on...

Embodiment 3

[0048] (1) Add propyl silicate to isopropanol, set the temperature of isopropanol solvent to 35°C, and stir at 500 rpm, then add deionized water and 15% hydrochloric acid in turn to adjust its pH Value is between 3-4, obtains silica airgel precursor liquid, and the ratio of described propyl silicate, isopropanol, deionized water, 15% hydrochloric acid is 1:5:4:3 in molar ratio ;

[0049] (2) After the silica airgel precursor solution was left to stand at a temperature of 50°C for 5 hours, the temperature was adjusted to 70°C, and the drying control additive acetamide was added at a stirring speed of 300 rpm Stir for 15 minutes, the molar ratio of propyl silicate and N,N-dimethylformamide is 1:0.3;

[0050] (3) Add alumina with a particle size of 400nm to the silica airgel obtained in step (2), stir for 25 minutes at a stirring speed of 400 rpm, then add ammonium fluoride, and stir for 25 minutes , to obtain alumina-silica airgel composite sol;

[0051] (4) Spin the alumina-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com