Method based on extensional rheology for stripping graphene and application of graphene

A technology of exfoliating graphene and extensional rheology, applied in the field of material processing, can solve the problems of limited exfoliation efficiency of graphene size uniformity, and achieve the effect of avoiding lattice damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Mix graphite flake graphite with a particle size of 0.5 mm, glucose and water according to a mass ratio of 1:5:2 and stir evenly to prepare a viscous paste-like graphite mixture;

[0045] (2) Put the paste graphite mixture into the feeding port of the stretching machine, enter the stretching mechanism after adding the feeding mechanism, connect the power transmission mechanism, control the working temperature to 50°C, and set the speed to 500r / min , in the process of continuously passing through the central shaft, the eccentric rotation of the cam rotor during the rotation process periodically compresses and stretches the cavity space, the paste graphite mixture is continuously compressed and stretched, and the During the stretching process, the graphite is stripped into graphene, and the graphene is collected by the collection mechanism.

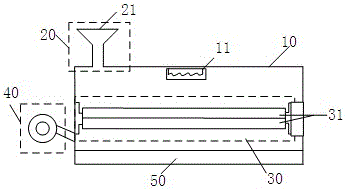

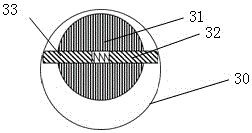

[0046] like figure 1 shown and figure 2 As shown, the stretching machine includes a barrel 10, and a temperature control de...

Embodiment 2

[0050] (1) Mix and stir the expanded graphite with graphite raw material particle size of 0.3 mm, EVA hot melt adhesive and methanol according to the mass ratio of 1:6:3, and prepare a viscous paste-like graphite mixture;

[0051] (2) Put the paste-like graphite mixture into the feeding port of the stretching machine, enter the stretching mechanism after adding the feeding mechanism, connect the power transmission mechanism, control the working temperature to 60°C, and set the speed to 700r / min , in the process of continuously passing through the central shaft, the eccentric rotation of the cam rotor during the rotation process periodically compresses and stretches the cavity space, the paste graphite mixture is continuously compressed and stretched, and the During the stretching process, the graphite is stripped into graphene, and the graphene is collected by the collection mechanism.

[0052] like figure 1 shown and figure 2 As shown, the stretching machine includes a ba...

Embodiment 3

[0056] (1) Mix and stir the highly oriented graphite with a graphite raw material particle size of 0.2mm, PA hot melt adhesive and n-propanol according to the mass ratio of 1:7:2, and prepare a viscous paste-like graphite mixture;

[0057] (2) Put the paste graphite mixture into the feeding port of the stretching machine, enter the stretching mechanism after adding the feeding mechanism, connect the power transmission mechanism, control the working temperature to 60°C, and set the speed to 800r / min , the cam rotors rotate in the same direction. In the process of passing through the central shaft continuously, the two cam rotors generate compressive force and tensile force during the rotation process, and the paste graphite mixture is continuously compressed and stretched. During the stretching process, the graphite is exfoliated into graphene, and the graphene is collected by the collection mechanism.

[0058] like figure 1 shown and figure 2 As shown, the stretching machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com