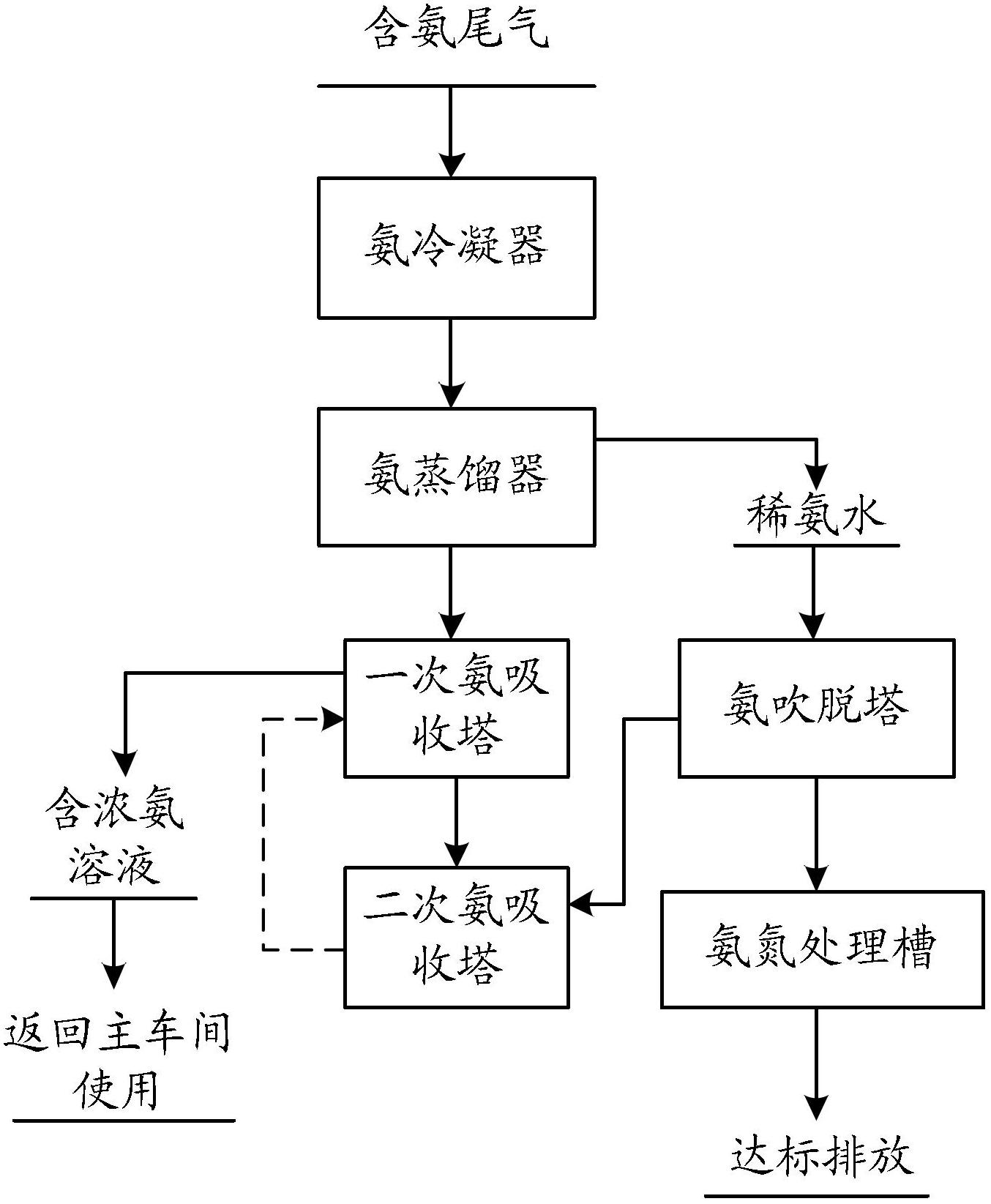

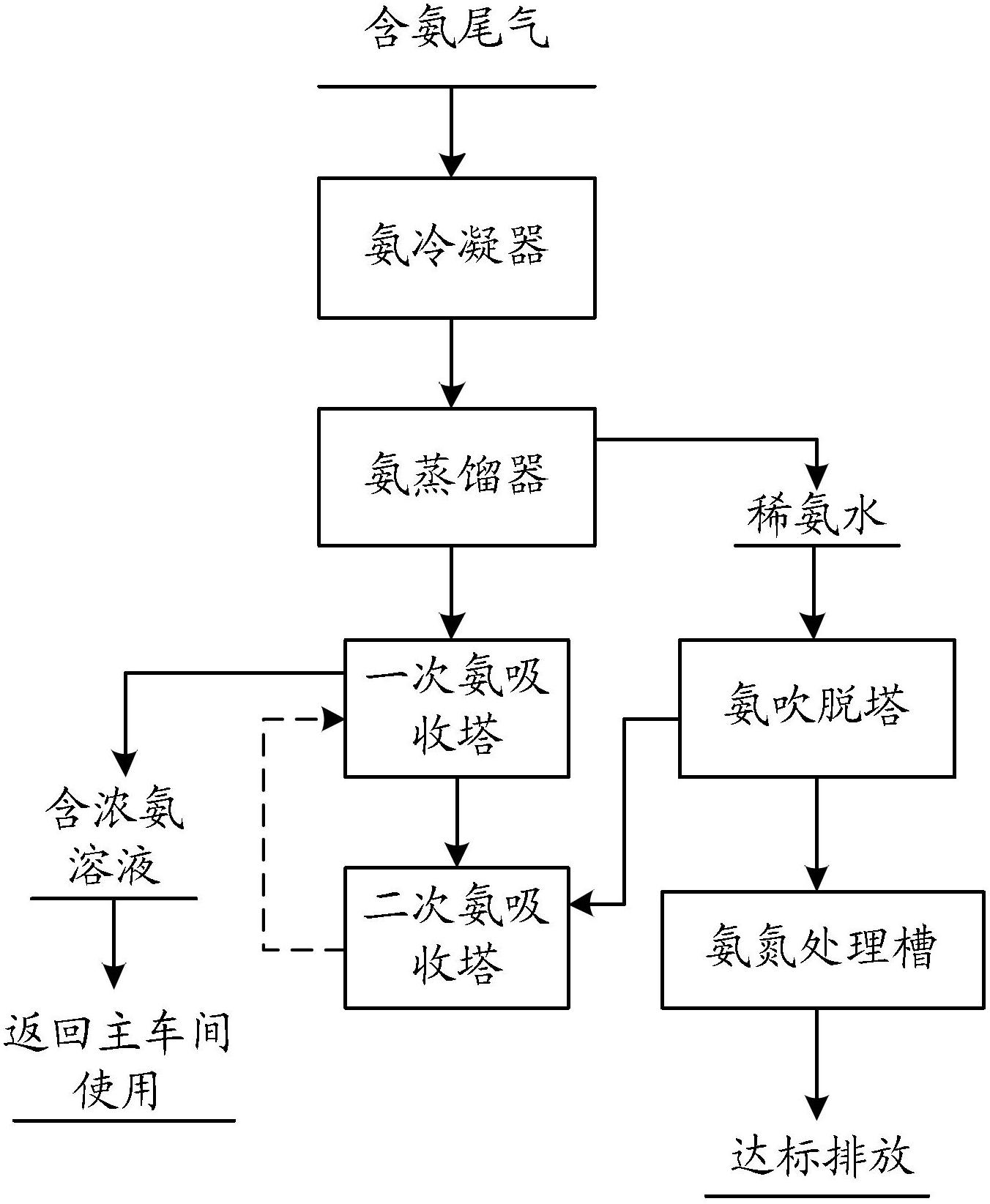

Ammonia tail gas recycling method and system

A recovery method and tail gas technology, which is applied in the field of ammonia tail gas recovery and utilization, can solve problems such as the need for improvement in the recovery method of ammonia-containing tail gas, difficult treatment costs of dilute ammonia water, and low concentration of ammonia water, so as to maintain ammonia recovery rate and equipment operation stability The effect of high and high ammonia recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 10m 3 Evaporation and crystallization pot (feed volume is 4m 3 ~7m 3 ), the feed ammonium tungstate solution is 6m 3 , WO 3 =250g / L, OH - =2mol / L. Condensation by condenser gives 3.4m 3 Dilute ammonia water, the ammonia nitrogen concentration is 8g / L; Dilute ammonia water is distilled under pressure at 100°C in a distillation pot, and the volume of the distilled liquid is 3.2m 3 , the concentration of liquid ammonia nitrogen after distillation is 4g / L; after distillation, the liquid is blown off by a dissolved air pump, and the concentration of ammonia nitrogen after blowing off is 900mg / L, and the blowing off rate is 77.5%; Deep removal, the concentration of ammonia nitrogen after removal is 7mg / L, and the removal rate is 99.22%.

[0038] Perform a spray cycle absorption on the condensed ammonia tail gas and distilled ammonia water to obtain 3.1m 3 One-time absorption of ammonia nitrogen solution, the concentration of ammonia nitrogen is 80g / L, which is directl...

Embodiment 2

[0041] 10m 3 Evaporation and crystallization pot (feed volume is 4m 3 ~7m 3 ), the feed ammonium tungstate solution is 4m 3 , WO 3 =250g / L, OH - =2mol / L. Condensed by condenser to get 2.35m 3 Dilute ammonia water, the ammonia nitrogen concentration is 7g / L; the dilute ammonia water is distilled under pressure at 98°C in a distillation pot, and the volume of the distilled liquid is 2.2m 3 , the concentration of liquid ammonia nitrogen after distillation is 3.7g / L; the liquid after distillation is blown off by a dissolved air pump, the concentration of ammonia nitrogen after blowing off is 700mg / L, and the stripping rate is 81%; finally, the liquid after blowing off is treated with ammonia nitrogen remover Ammonia nitrogen is deeply removed, the concentration of ammonia nitrogen after removal is 5mg / L, and the removal rate is 99.28%.

[0042] Perform a spray cycle absorption on the condensed ammonia tail gas and distilled ammonia water to obtain 2.1m 3 One-time absorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com