A small tension anti-winding slow-release rope retractable mechanism

A retractable mechanism and anti-winding technology, which is applied in the field of space debris cleaning, can solve the problems of no cable arrangement mechanism, system impact, and low operational reliability, so as to increase work stability and reliability, reduce the number of engine startups, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below with reference to the accompanying drawings.

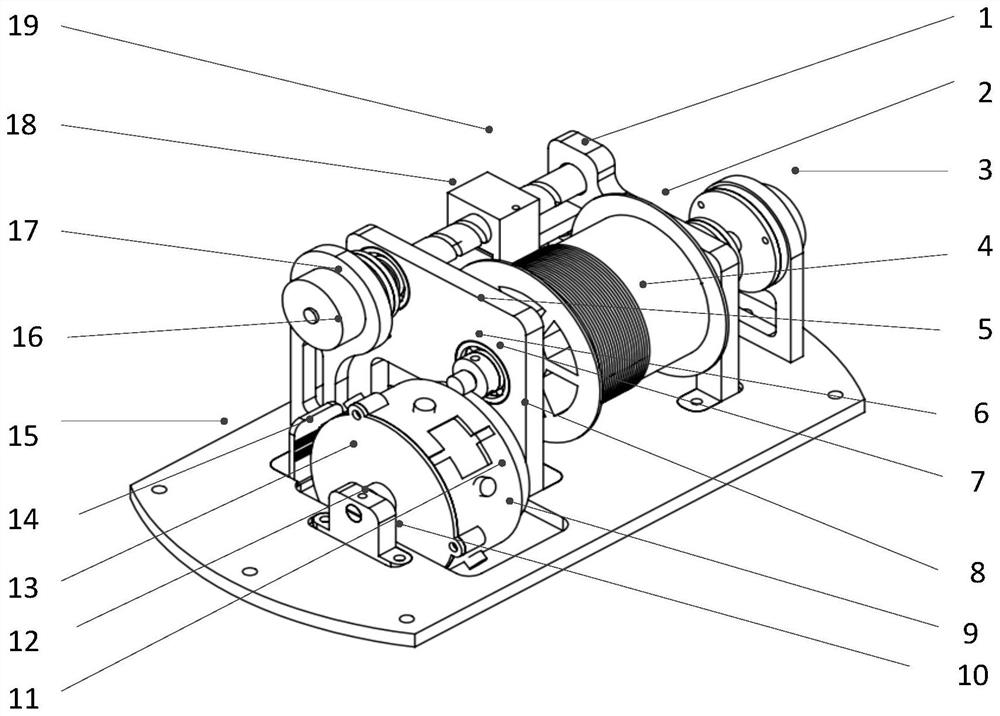

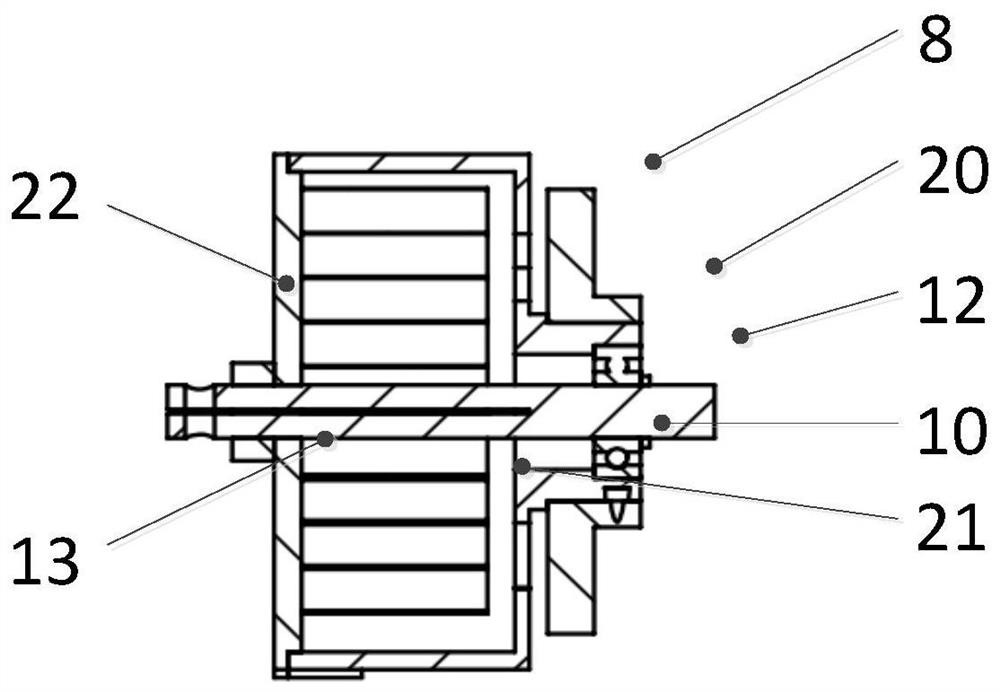

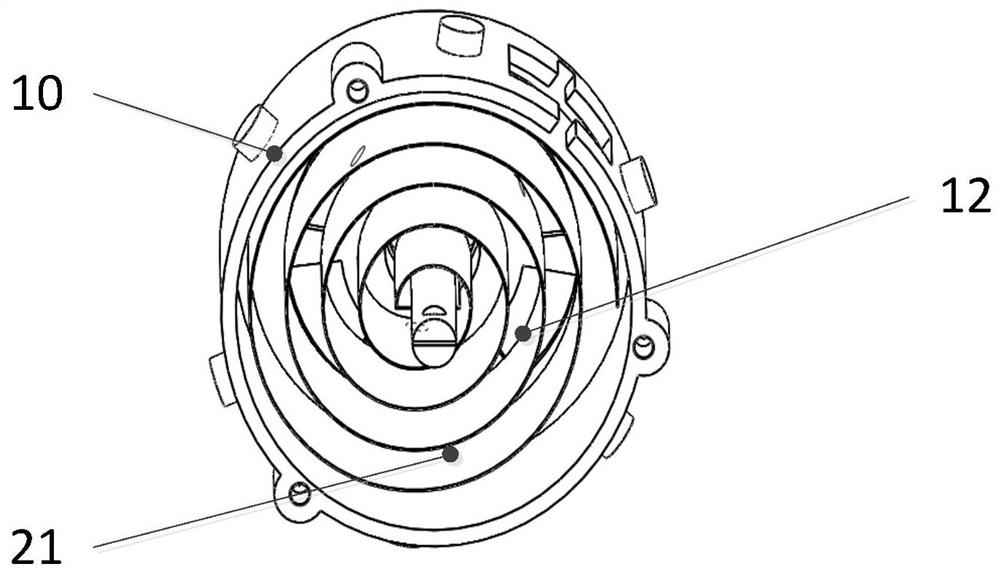

[0050] like Figure 1-7 As shown, the rope 4 is evenly wound on the spool 2, the entire rope retraction mechanism is placed on the space tugboat, and the rope head is connected to the target. When the space tugboat starts the engine and accelerates, the rope 4 is pulled out, and at the same time, the spool 2 is driven to rotate. The rotation of the spool 2 drives the spool shaft 7 and the spool shaft gear 6 fixed on the spool shaft to rotate. The rotation of the spool shaft gear 6 drives the barrel gear 8 and the slow release mechanism 3 to rotate.

[0051]The motor 17 drives the lead screw 18 to rotate forward or reverse. There is a single thread in the cable nut 19 that engages with the lead screw thread, so the lead screw 18 that rotates in both directions can drive the cable nut 19 to move back and forth. The rotation direction of the motor 17 is determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com