Construction technology of large high-altitude assembled steel member

A construction technology and steel component technology, which is applied in the construction of steel components and the construction of large-scale assembled steel components, can solve the problems of heavy welding workload, high cost, and difficulty in erecting high-altitude tire assembly frames, etc., to reduce hoisting time , The effect of reducing the difficulty of installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be further explained by taking the steel structure project of the secondary reflection tower of the 50 thousand kilowatt solar thermal power generation module of the molten salt tower in a certain place as an example.

[0023] 1. Engineering requirements:

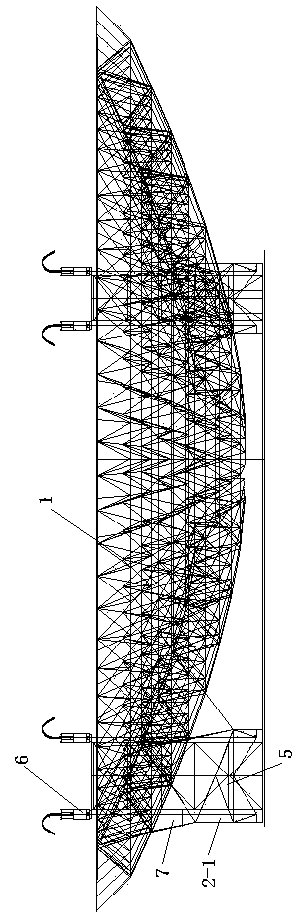

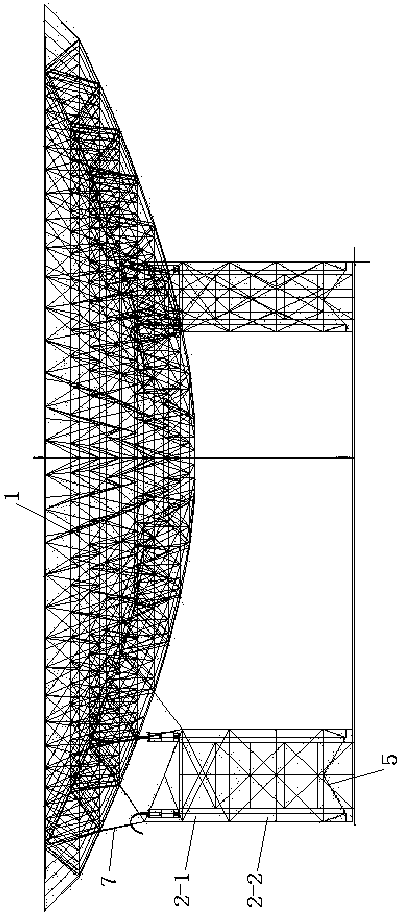

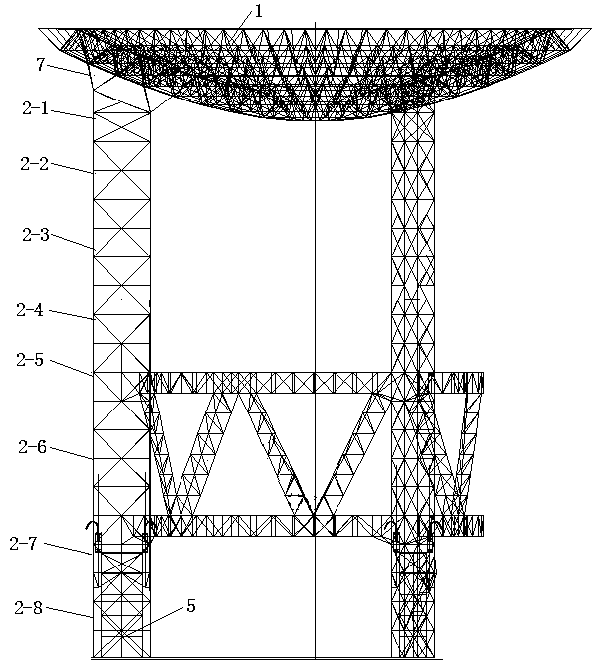

[0024] Such as figure 1 As shown, the designed steel structure of the reflecting tower is composed of a secondary reflecting structure 1 at the top and three groups of lattice columns 2 at the bottom. A waist truss 3 and a supporting truss 4 between the three groups of lattice columns 2 are also required.

[0025] Among them, the secondary reflection structure is the above-mentioned steel member of the present invention, which is composed of a square pyramid grid frame and a mirror secondary structure. The main structure of the secondary reflection tower is a steel structure, and the upper structure is a rotating hyperboloid grid supported by three lattice columns. The maximum ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com