Asymmetric installation and construction method for straddle type light rail special steel box extradosed cable-stayed bridge

A low-tower cable-stayed bridge and construction method technology, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of complicated installation procedures in the air, affecting the normal passage of waterways, and difficult precision control, etc., so as to shorten the time occupied by the waterway, The effect of reducing hoisting and alignment time and high accuracy of line control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

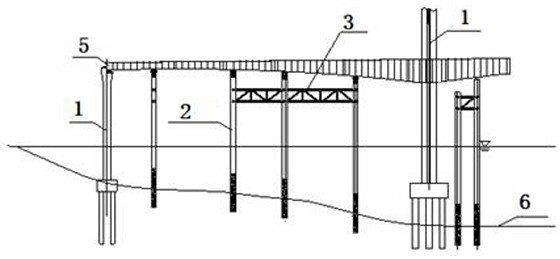

[0035] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following examples.

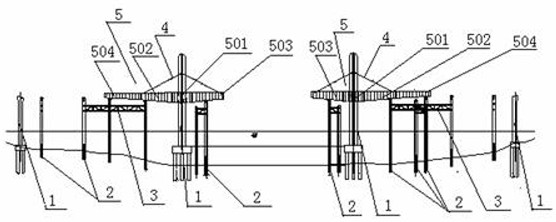

[0036] A straddle-type light rail dedicated steel box low-tower cable-stayed bridge asymmetrical installation and construction method, comprising the following steps:

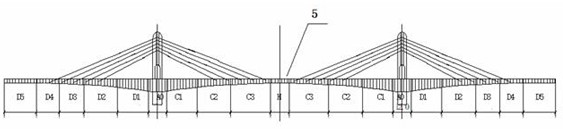

[0037] S1. Divide the steel box girder of the whole bridge into several girder sections, including: mid-span closing section H, mid-span section C symmetrically arranged relative to mid-span closing section H n ... mid-span C 2 , mid-span section C 1 , support section A 0 , side span D 1 , side span D 2 ... side span section D n , side-span closing section, side-span section D n+2 ; Among them, the mid-span section C n and midspan C 2 The part omitted between is also the corresponding mid-span segment, side span segment D 2 ... side span section D nThe part omitted between is also the corresponding side span se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com