Patents

Literature

44results about How to "Continuous and stable preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of vanadium containing solution

ActiveCN108359815AHigh recovery rateSolve the pollution of the environmentVanadium oxidesCeramic materials productionResource utilizationAluminum ammonium sulfate

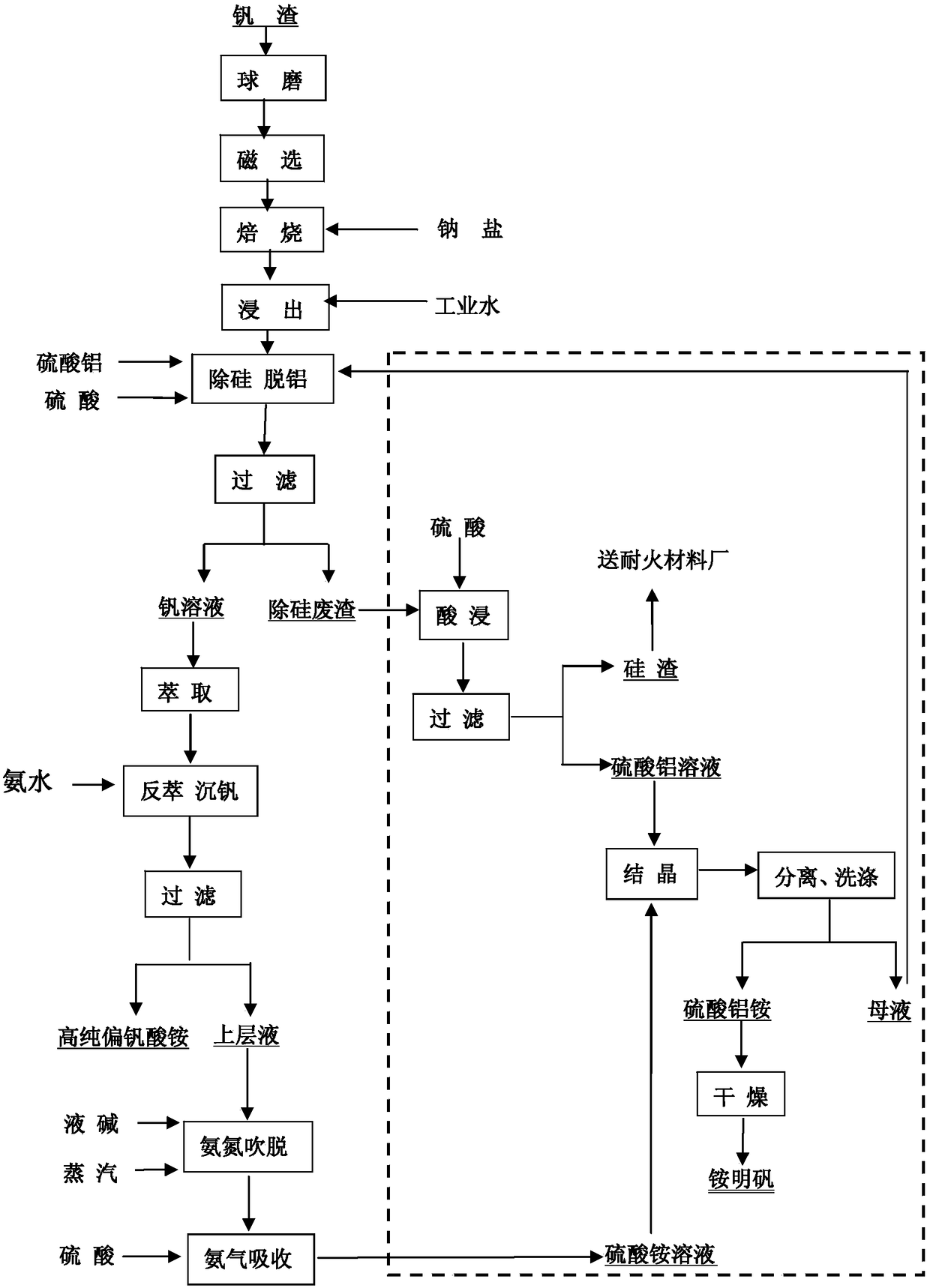

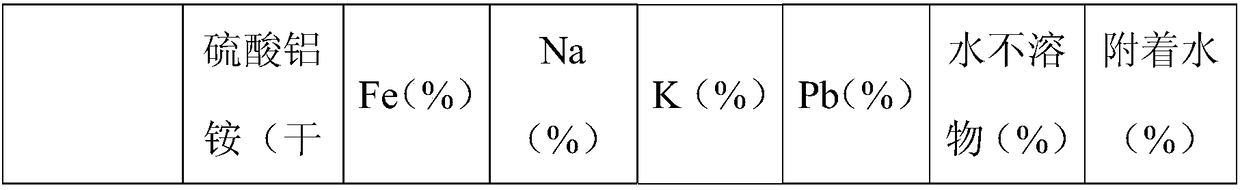

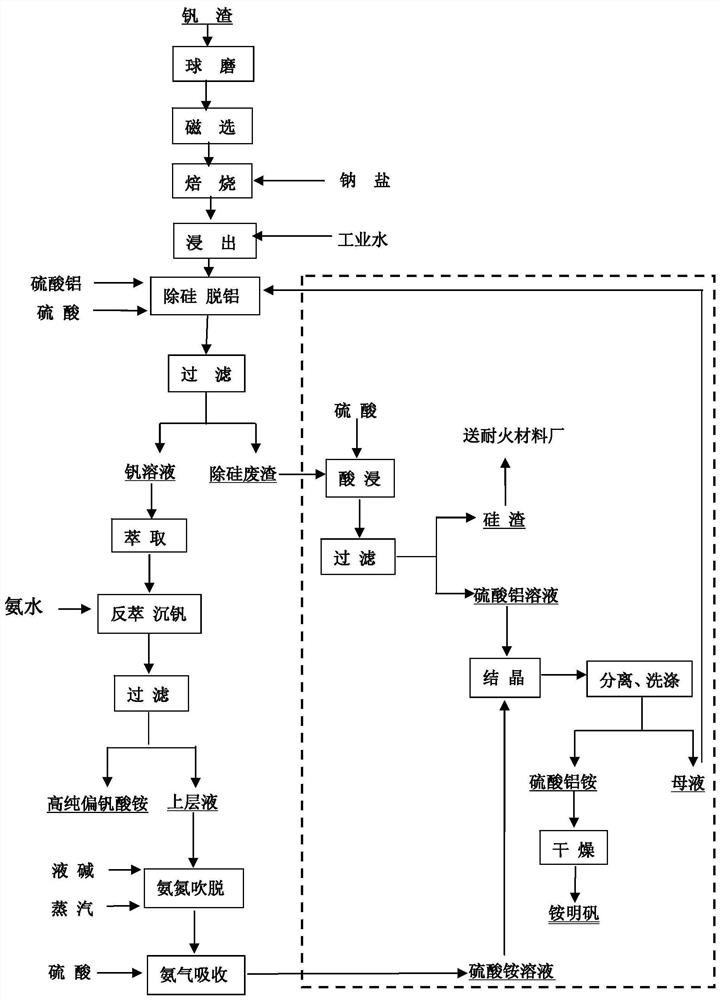

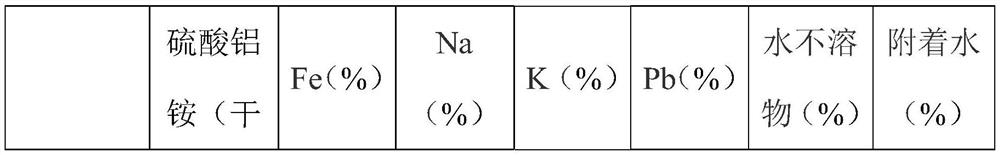

The invention provides a preparation method of a vanadium containing solution. The preparation method comprises the following steps that vanadium containing lixivium is subjected to silicon removal and dealumination to obtain the vanadium containing solution and silicon removal waste residues; the silicon removal waste residues are leached through concentrated sulfuric acid to obtain an acid leaching solution; after the acid leaching solution is precisely filtered, silicon residues and an aluminum sulfate solution are obtained; and the aluminum sulfate solution and an ammonium sulfate solutionare mixed, recooling crystallization is carried out after reacting, aluminum ammonium sulfate crystals and crystallization mother liquor are obtained through second solid-liquid separation, and the crystallization mother liquor is used for replacing part or all of aluminum salt to be mixed with a silicon-chrome-silicon containing solution for silicon removal. According to the method, the siliconremoval waste residues can be subjected to resource utilization, and an aluminum ammonium sulfate product high in additional value can be obtained; meanwhile, the consumption of the aluminum salt canbe reduced, high-purity ammonium metavanadate can be prepared continuously and stably, and therefore a high-purity vanadium pentoxide product with the purity not smaller than 99.9% is prepared, and the vanadium recovery rate is increased; and the process is simple, the cost is low, and energy consumption is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing diethylacetonitrile in imino group

InactiveCN101050191AHigh yieldQuality improvementCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrilePhotochemistry

This invention provides a method for preparing iminodiacetonitrile. The method comprises: reacting hydroxyacetonitrile and 95-100 wt. % liquid ammonia to obtain iminodiacetonitrile. The method has such advantages as high yield, high product quality, and continuous and stable process.

Owner:四川省天然气化工研究院

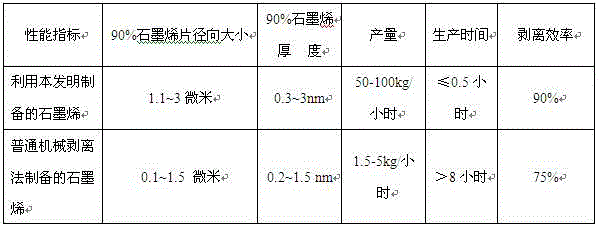

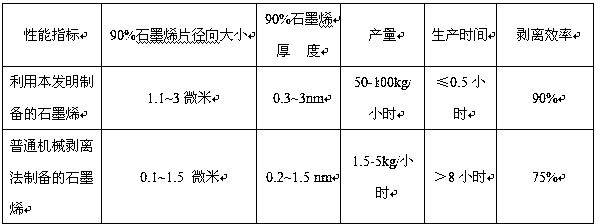

Method for large-scale clean graphene preparation

ActiveCN105819437AGood effectContinuous and stable preparationGrapheneEnvironmental resistanceGraphite

The invention provides a method for large-scale clean graphene preparation. Graphite is used as a raw material, spray drying equipment is used, mechanical peeling and powder drying are integrated in the spray drying machine, a graphene material is continuously, stably, and cleanly produced in an environment-friendly mode, nano graphene powder or micron grapheme powder is limited in a drying chamber to be processed, and the technical defects that the prior art is only used for preparing graphene powder in a drying mode, dust pollution is serious in the production process, and graphene cannot be produced continuously are overcome. The technical effects of continuous, clean and environment-friendly graphene preparation are achieved, and industrial production of graphene dry powder is promoted. Furthermore, shearing and peeling are completed in the spray drying machine in one step, uniform dispersion is achieved, the layered structure of graphene is reserved to the maximum, the graphene material is continuously and stably prepared, surface electric topological symmetry of graphene is not destroyed, and the quality of graphene finished product is further ensured.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

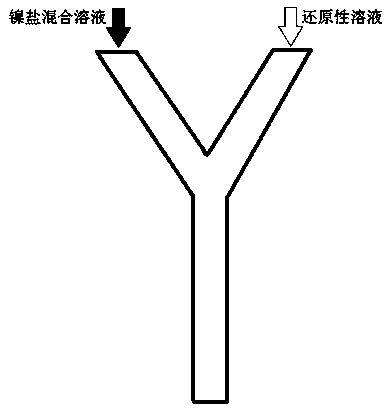

Method for continuous and rapid preparation of nano nickel by microfluidics technology

InactiveCN103737018AUniform preparationUniform particle size distributionNanotechnologyNickel saltActive agent

The invention relates to a method for continuous and rapid preparation of nano nickel by the microfluidics technology and belongs to the technical field of synthesis of nanomaterial by microfluidics and microreactor technology. The method includes: dissolving NiS04.6H21 into distilled water, regulating PH (power of Hydrogen) of a solution, adding a surfactant, and mixing well for configuration to obtain a nickel salt mixed solution; dissolving a reducing agent into the distilled water for configuration to obtain a reducing solution; pumping the nickel salt mixed solution and the reducing solution obtained in the above steps into a Y-shaped microreactor channel for micro-mixing reaction, and subjecting the mixed solution to cleaning, separating and vacuum low-temperature drying treatment to obtain black nickel nanoparticles. The method has the advantages of being high in mixed mass transfer rate, even in reaction, continuously stable and the like by combining the microfluidics technology; featuring in wet reduction, the nano nickel is subjected to micro-mixing in the Y-shaped microreactor channel, so that the continuous and rapid preparation of the nano nickel is realized.

Owner:KUNMING UNIV OF SCI & TECH

Method of controlling halogen substitution site in halogenated butyl rubber

The invention discloses a method of controlling a halogen substitution site in halogenated butyl rubber, belonging to the technical field of chemistry and chemical engineering. The method comprises the following steps of: firstly, adding a certain amount of water into alkane liquor of butyl rubber, uniformly mixing to form emulsion; then, mixing the emulsion with a halogen to carry out halogenation reaction, in-situ extracting and halogenating haloid acid generated in the halogenation reaction process by utilizing water in the system to achieve the effect of lowering acid concentration in an organic phase to inhibit halogen substitution site transformation (transforming a secondary site into a primary site); and finally, ending the reaction process by using alkaline liquor to neutralize reaction liquid. The process is characterized in that a substitution site transformation phenomenon is effectively inhibited by introducing an appropriate amount of water (mass fraction of water being controlled to 0.5%-5.0%) into the reaction liquid, primary-site halogen mole fraction in a product is greater than 98%, halogenation degree (halogen mass fraction) can be regulated and controlled, degree of unsaturation and Mooney viscosity indexes are excellent, and conditions are provided for producing high-quality halogenated butyl rubber.

Owner:TSINGHUA UNIV

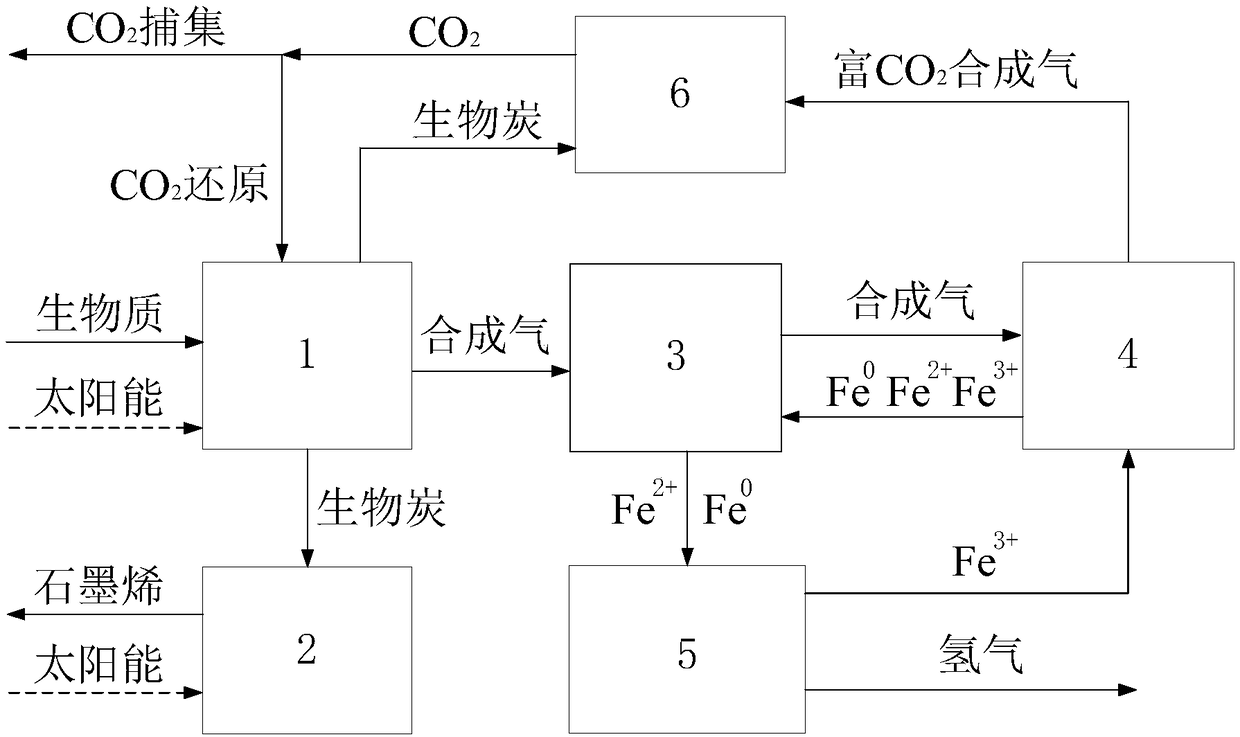

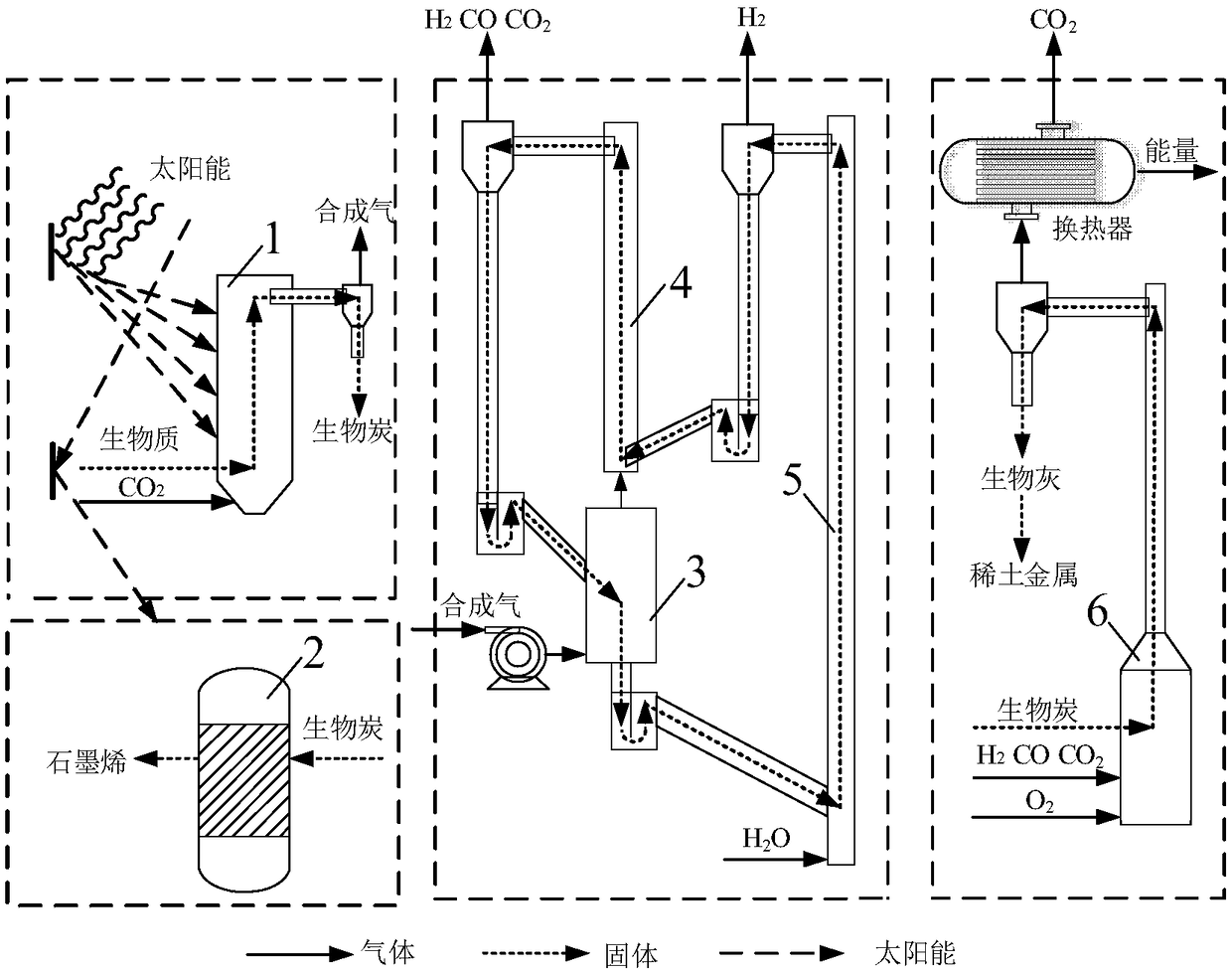

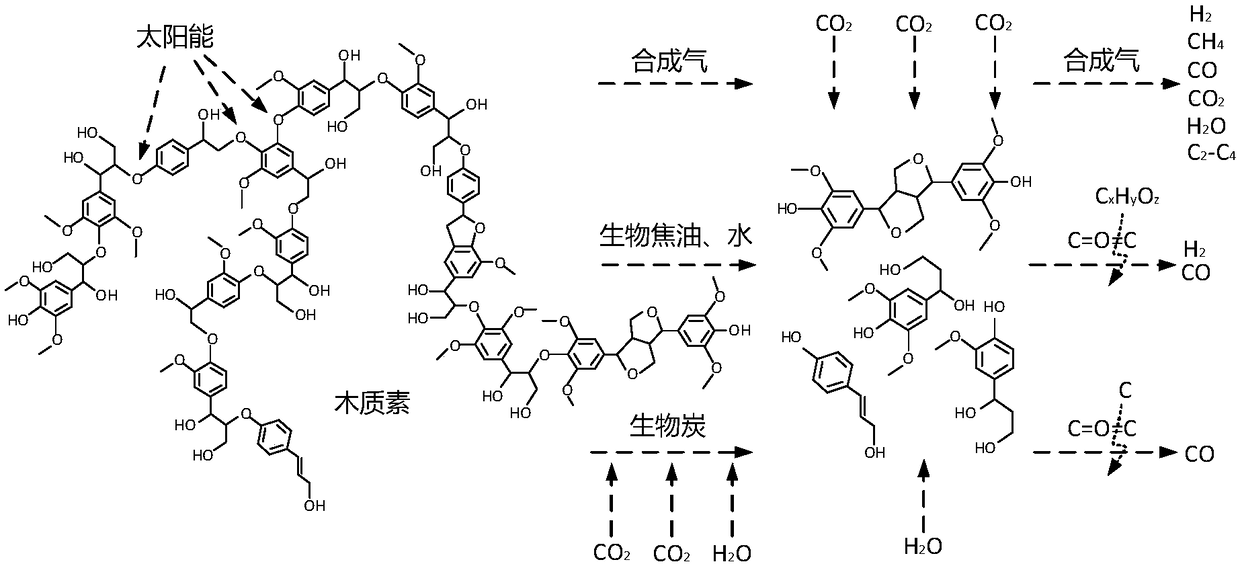

CO2 emission reduction system and method synergized with hydrogen production by step-by-step conversion of biomass energy

ActiveCN108840325ASpeed up preparationAchieve recyclingEnergy inputGrapheneCombustionRenewable biomass

The invention discloses a CO2 emission reduction system and method synergized with hydrogen production by step-by-step conversion of biomass energy. The system comprises a CO2 photothermal reduction device, a graphene photothermal reduction furnace, a chemical chain hydrogen production device and a combustion furnace auxiliary heating device. High-efficiency conversion of biomass energy into synthesis gas, preparation of reduced graphene oxide and continuous and stable preparation of high-quality hydrogen are realized respectively by adopting renewable biomass as a raw material and utilizing aconcentrating solar energy technology, a novel graphene oxide photothermal reduction technology and a multi-stage fuel reactor chemical chain hydrogen production technology. The energy input of the system is inexhaustible solar energy, renewable biomass energy with zero-carbon emission in a life cycle, and high-quality hydrogen and graphene materials are prepared continuously and efficiently on the premise of ensuring the system self-heating, and the step-by-step conversion and utilization of non-fossil energy as well as the continuous emission reduction, fixation and reuse of CO2 gas under self-heating conditions of the system are realized.

Owner:SOUTHEAST UNIV

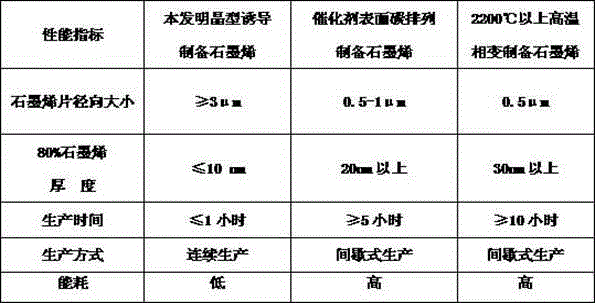

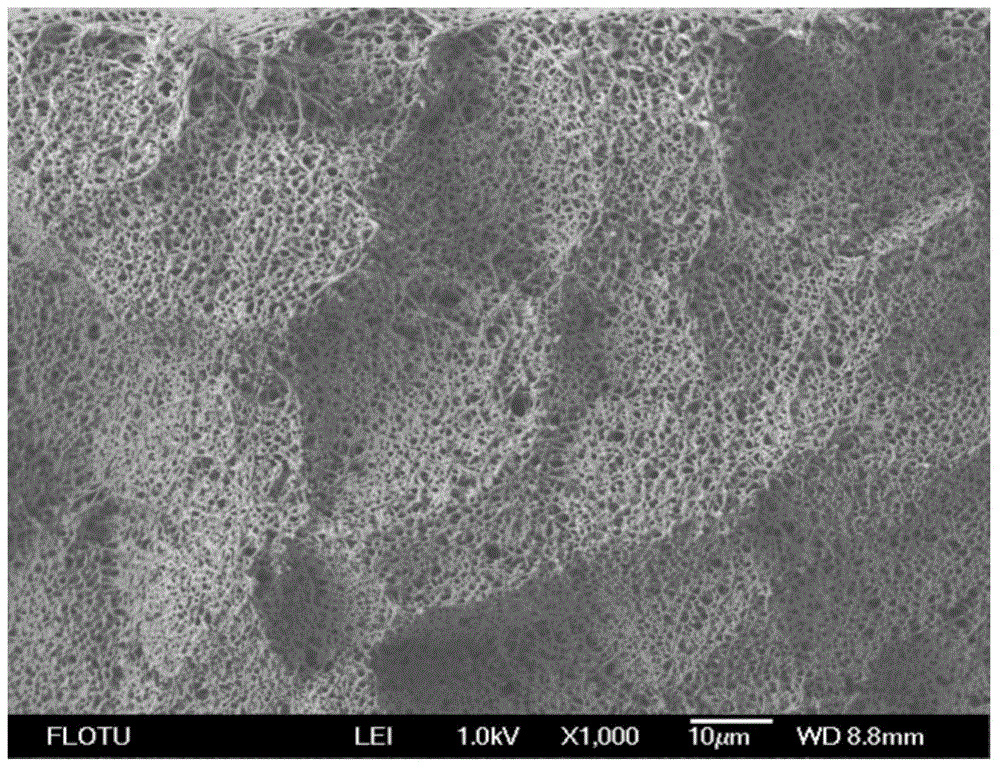

Method for preparing graphene in screw extruder through crystal form inducing

The invention provides a method for preparing graphene in a screw extruder through crystal form inducing. The method comprises the steps that shearing slicing is performed on a carbon source through the screw extruder, a crystal form inducing agent is utilized, the crystal form inducing agent generates a variant along with gradual increasing of the temperature to induce the carbon source to form crystals and enable the crystals to grow along layers, the layer structure of graphite is more obvious, the layer size of the graphite exceeds 1 mm, and finally the graphene is obtained through shearing stripping of the screw extruder. Accordingly, the defect of high-temperature long-time sintering of a catalyst used in the process of graphene preparation through the carbon source is overcome, therefore, the layer structure of the graphite is complete, and then the large-size graphene with the two-dimensional area is obtained. The method has the advantages that the technology is simple, the cheap and rich raw materials are used, a chemical reaction or high synthesizing temperature is effectively prevented from being adopted, and industrial production is achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

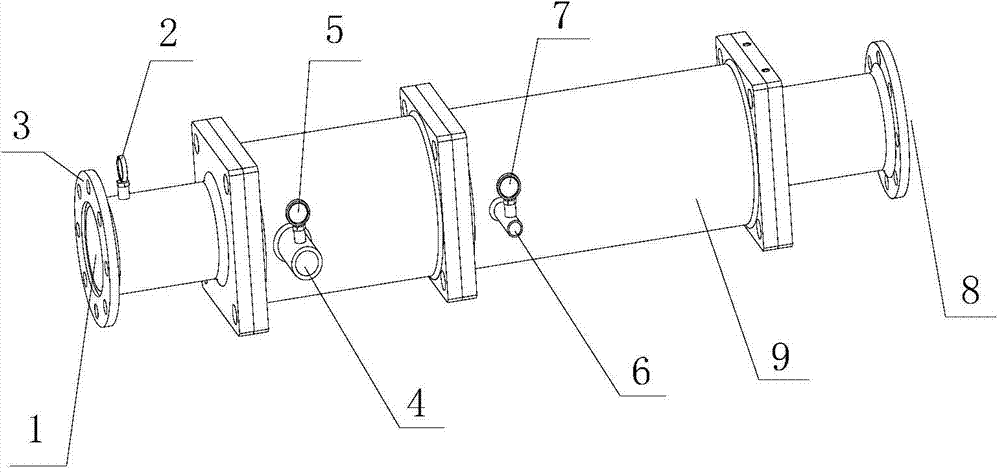

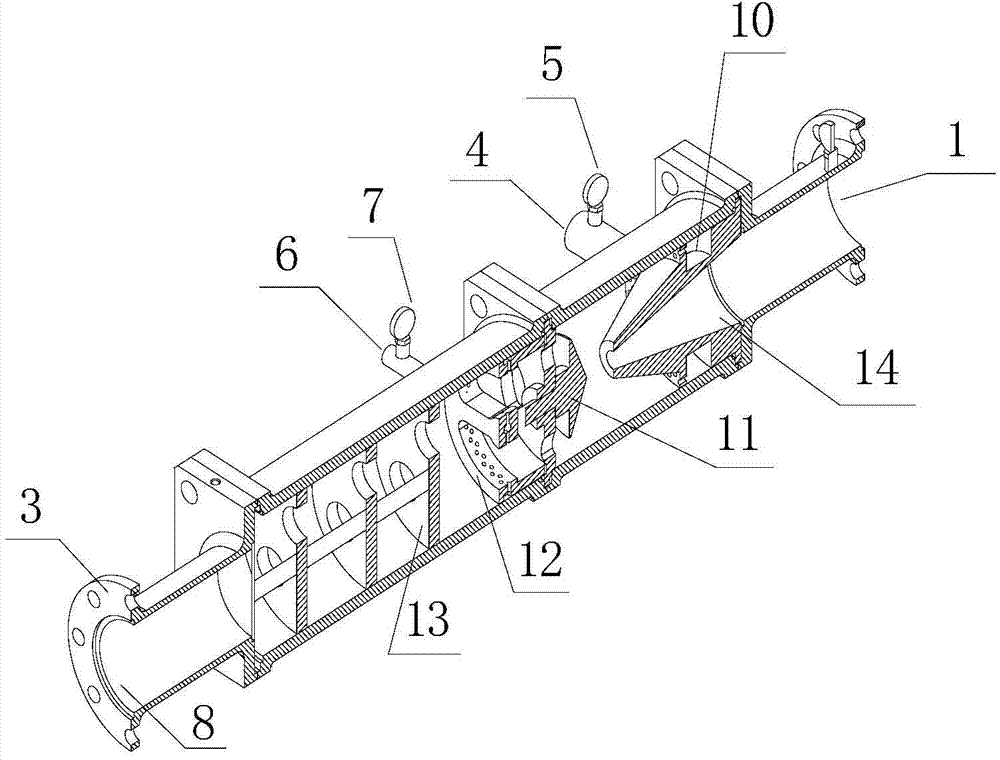

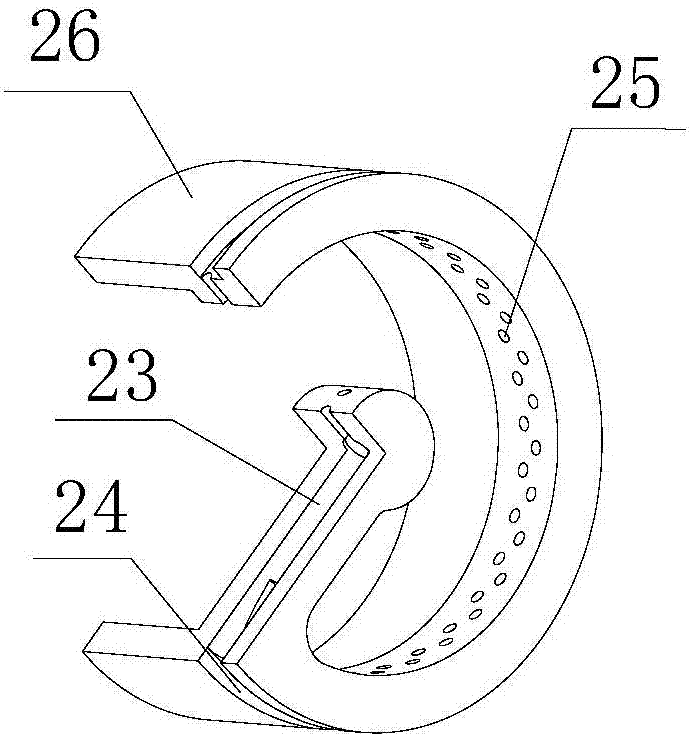

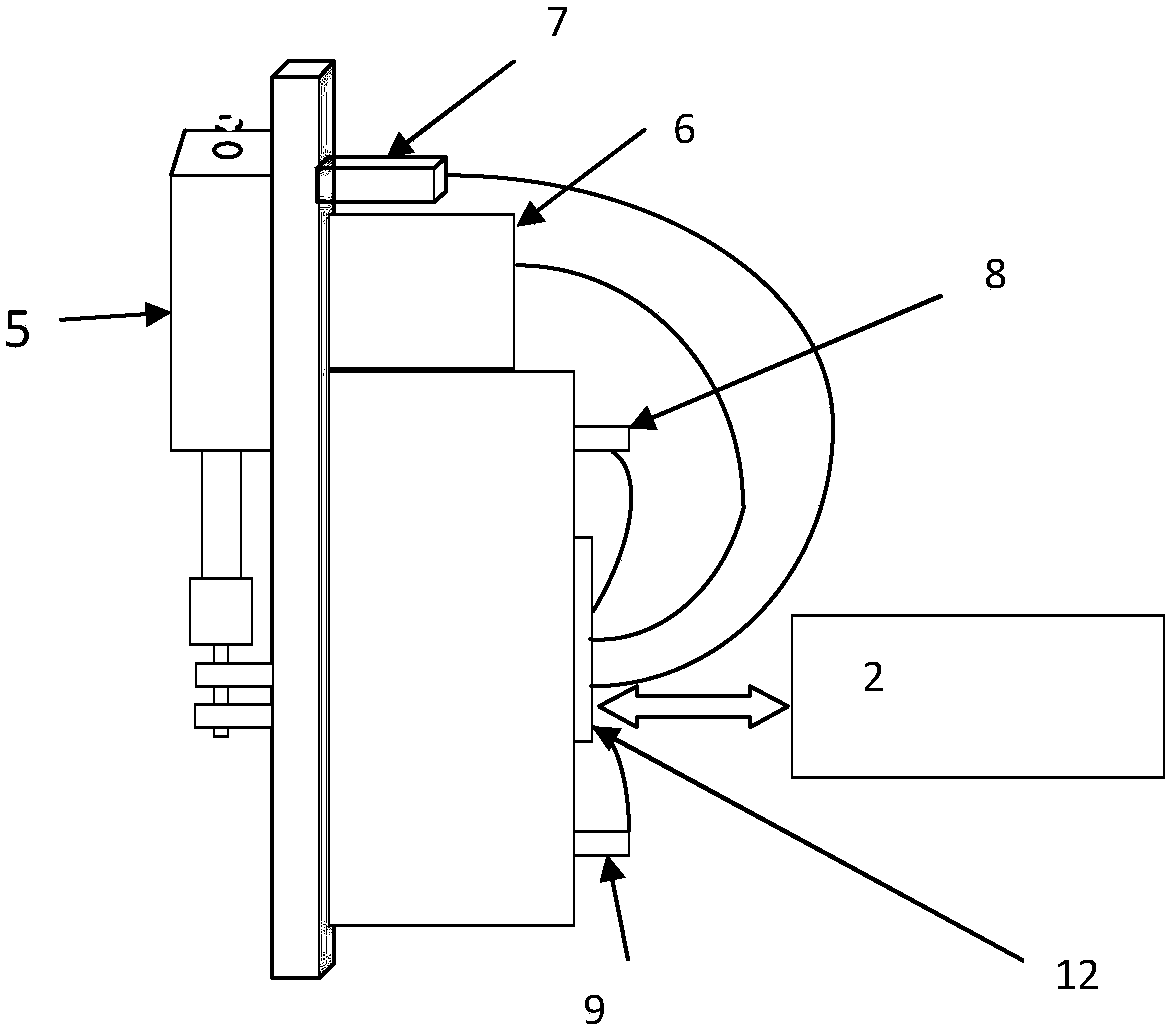

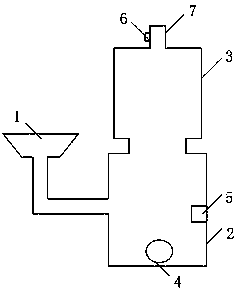

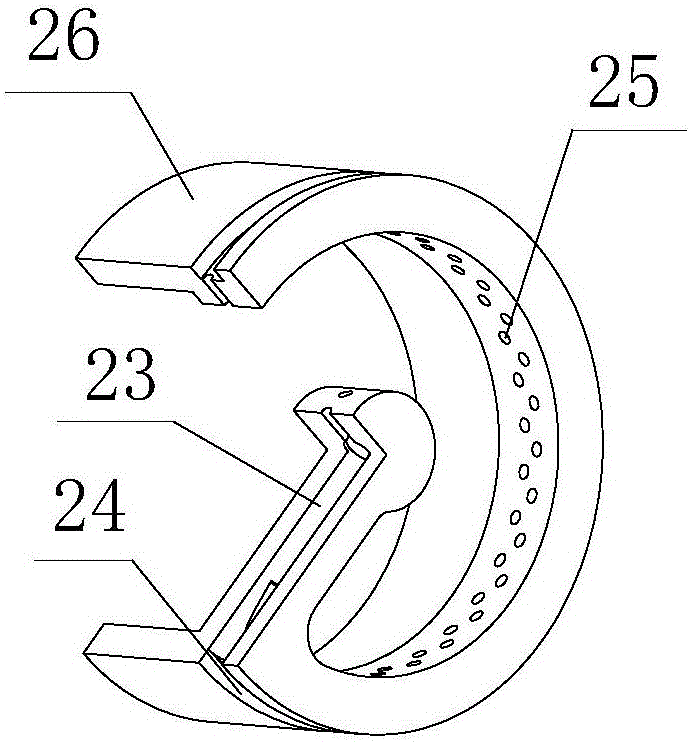

Foam gel preparing apparatus for mine fire preventing and extinguishing

ActiveCN103585726AExpand the scope of diffusionLong-lasting cooling coverageDust removalFire preventionEngineering

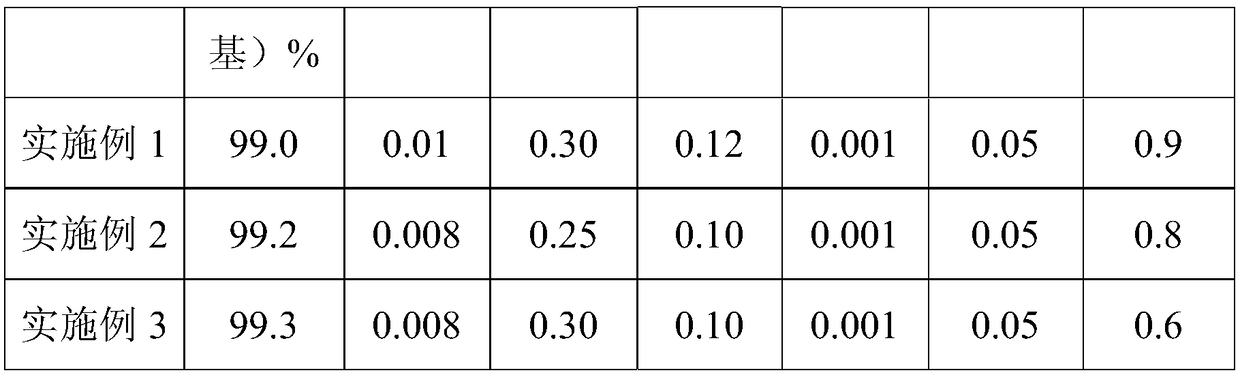

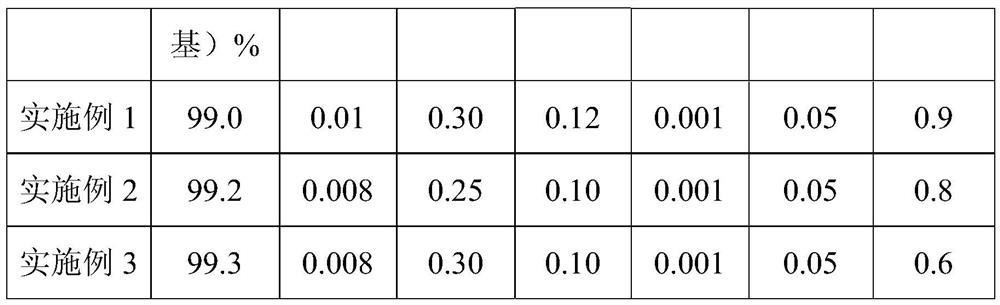

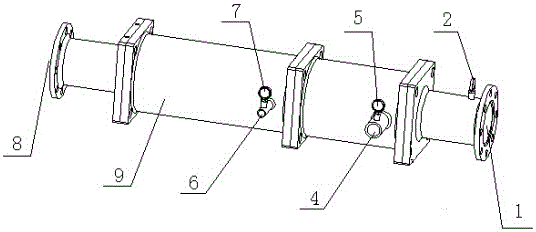

A disclosed foam gel preparing apparatus for mine fire preventing and extinguishing comprises a shell (9), a liquid inlet (1) and a foam gel outlet (8) respectively arranged at the two ends of the shell, a foaming device arranged in the shell, and an air inlet pipe (4) arranged on the outer wall of the shell and communicated with the foaming device. The foam gel preparing apparatus also comprises a gelatinizing agent charging pipe (6) and a gelatinizing agent adding device (12); the gelatinizing agent adding device (12) mainly consists of a peripheral-direction charging groove (24), a discharging hole (25) and a positioning barrel (26); the positioning barrel is fixedly disposed on the inner wall of the shell and at the rear of the foaming device; the inner circle of the positioning barrel forms the peripheral-direction charging groove which is communicated with the gelatinizing agent charging pipe; and the discharging hole is arranged on the peripheral-direction charging groove. The apparatus enables a large amount of liquid on a foam wall to form gel in the premise of no damage to foam structure, and by taking foams as a carrier, the diffusion scope of the gel in the fire preventing and extinguishing area is substantially improved, and also a large amount of water is concreted in gel and does not run off.

Owner:XUZHOU JIAN TECH

Preparation method and device of nitrogen oxide

The invention discloses a preparation method and device of nitrogen oxide. The preparation method includes following steps: preheating and mixing a nitric acid solution and a nitrite solution for reaction to generate nitrogen oxide gas, wherein nitrogen oxide is NOx, and x is greater than 1 and smaller than 2. The preparation method is easy-to-get in raw material, simple in process, easy in reaction, conducive to continuity of production operation and capable of ensuring continuous and stable supply and use of nitrogen oxide serving as an oxidant in a nuclear fuel aftertreatment plant.

Owner:CHINA NUCLEAR POWER ENG CO LTD

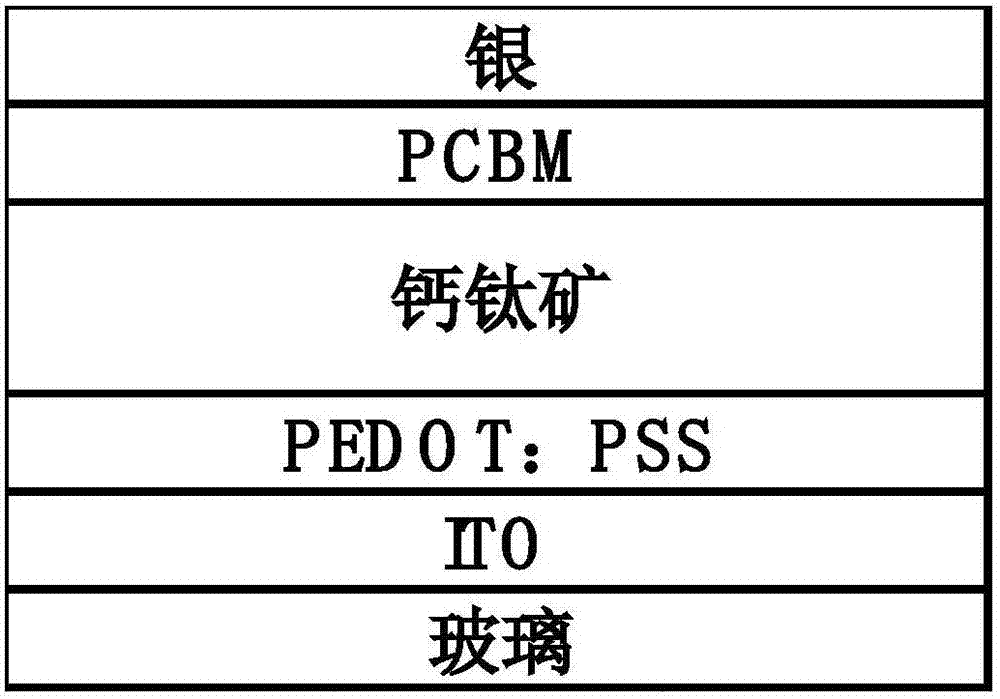

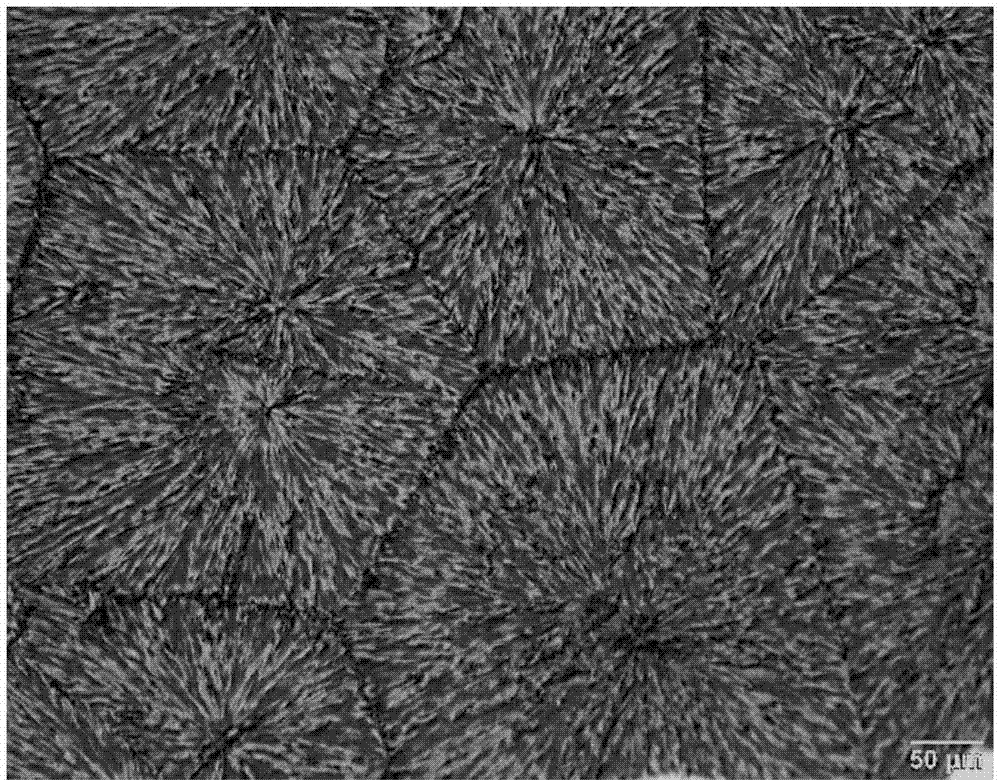

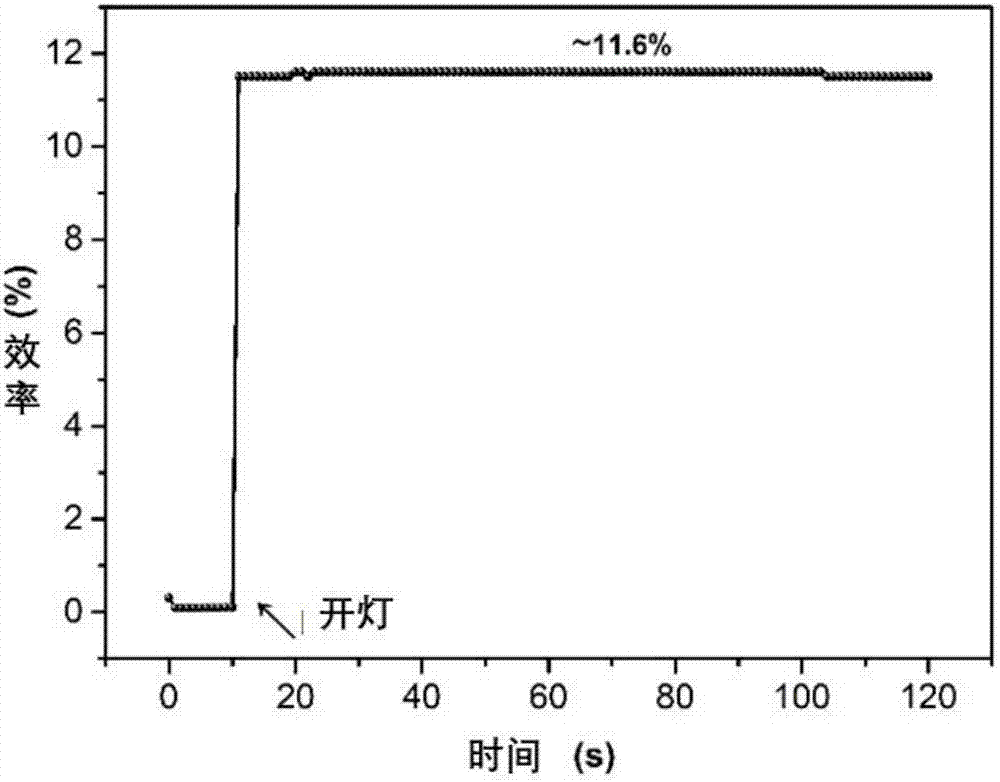

Method for preparing perovskite solar cell based on one-step spraying process

InactiveCN107359249ASimple processStrong maneuverabilityFinal product manufactureSolid-state devicesSolventPerovskite solar cell

The invention relates to the preparation technology of a perovskite solar cell, and specifically relates to a method for preparing the perovskite solar cell based on a one-step spraying process. The method comprises the steps of preparing a perovskite layer, wherein the preparation method of the perovskite layer comprises the steps of preparing a precursor solution; spraying a substrate with the obtained precursor solution to form a wet film; performing continuous heat treatment on the obtained wet film to obtain the perovskite layer, wherein the precursor solution comprises a precursor material and a perovskite solvent; and the perovskite solvent comprises a mixed solution of dimethyl sulfoxide and <gamma>-butyrolactone at volume ratio of 3:7 to 7:3, and isopropanol which accounts for 2.5-5% of the total volume of the solvent. The method is simple in process, high in operability and continuous and stable in preparation process; the area and thickness of the prepared battery device can be flexibly controlled, and the solar cell is high in conversion efficiency and stable; and therefore, the method provides an effective technological means for industrial production of the perovskite solar cell.

Owner:WUHAN UNIV OF TECH

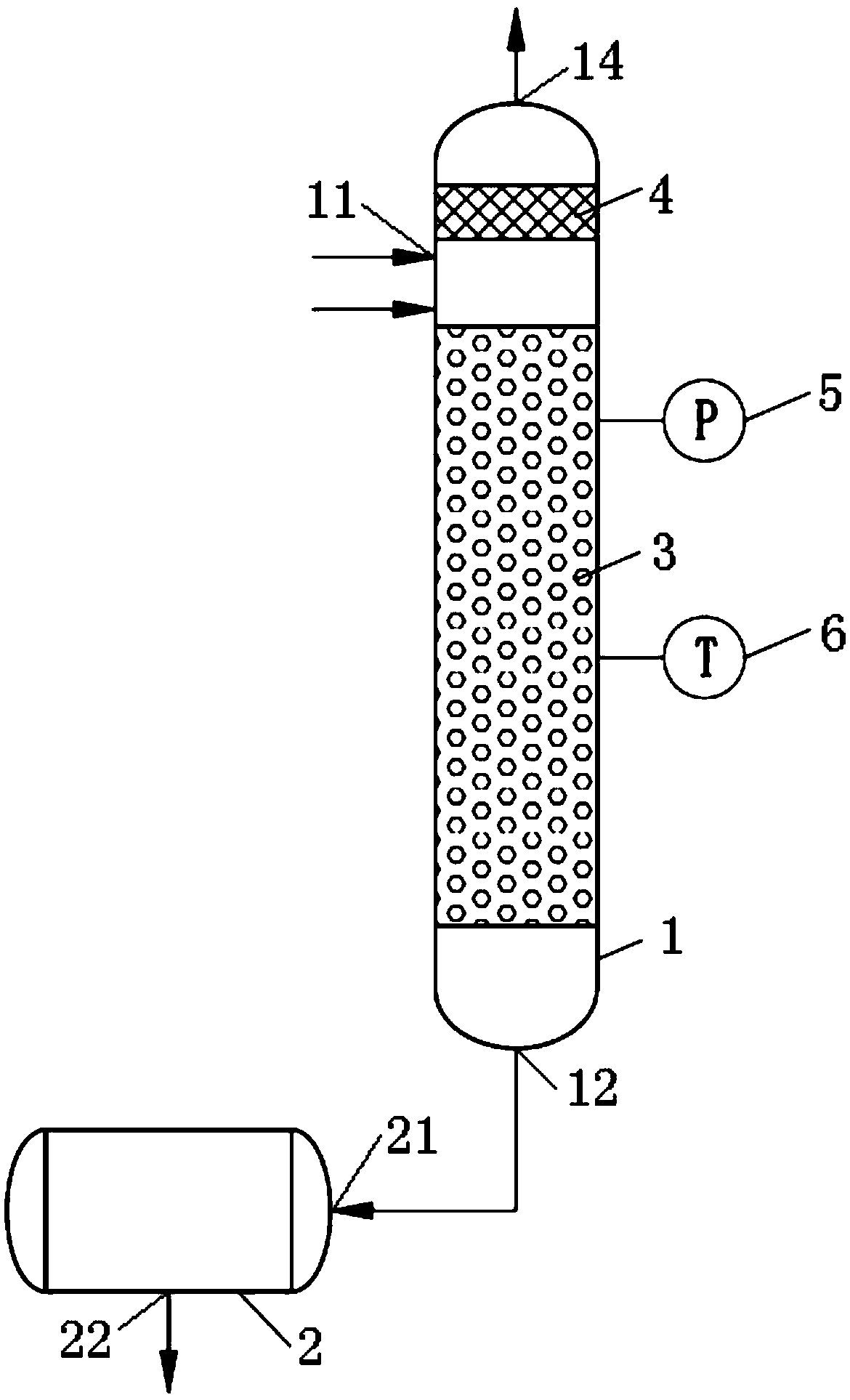

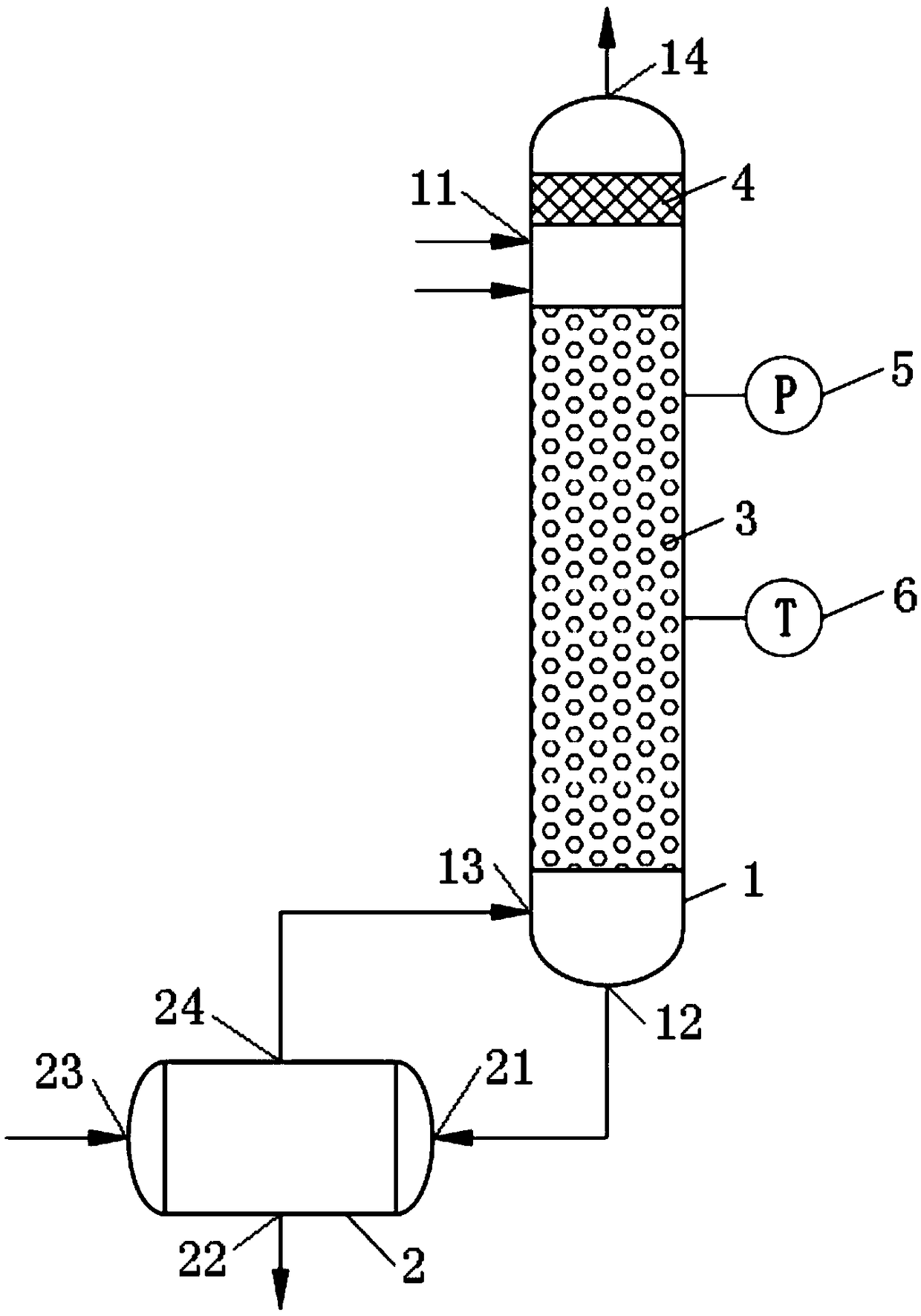

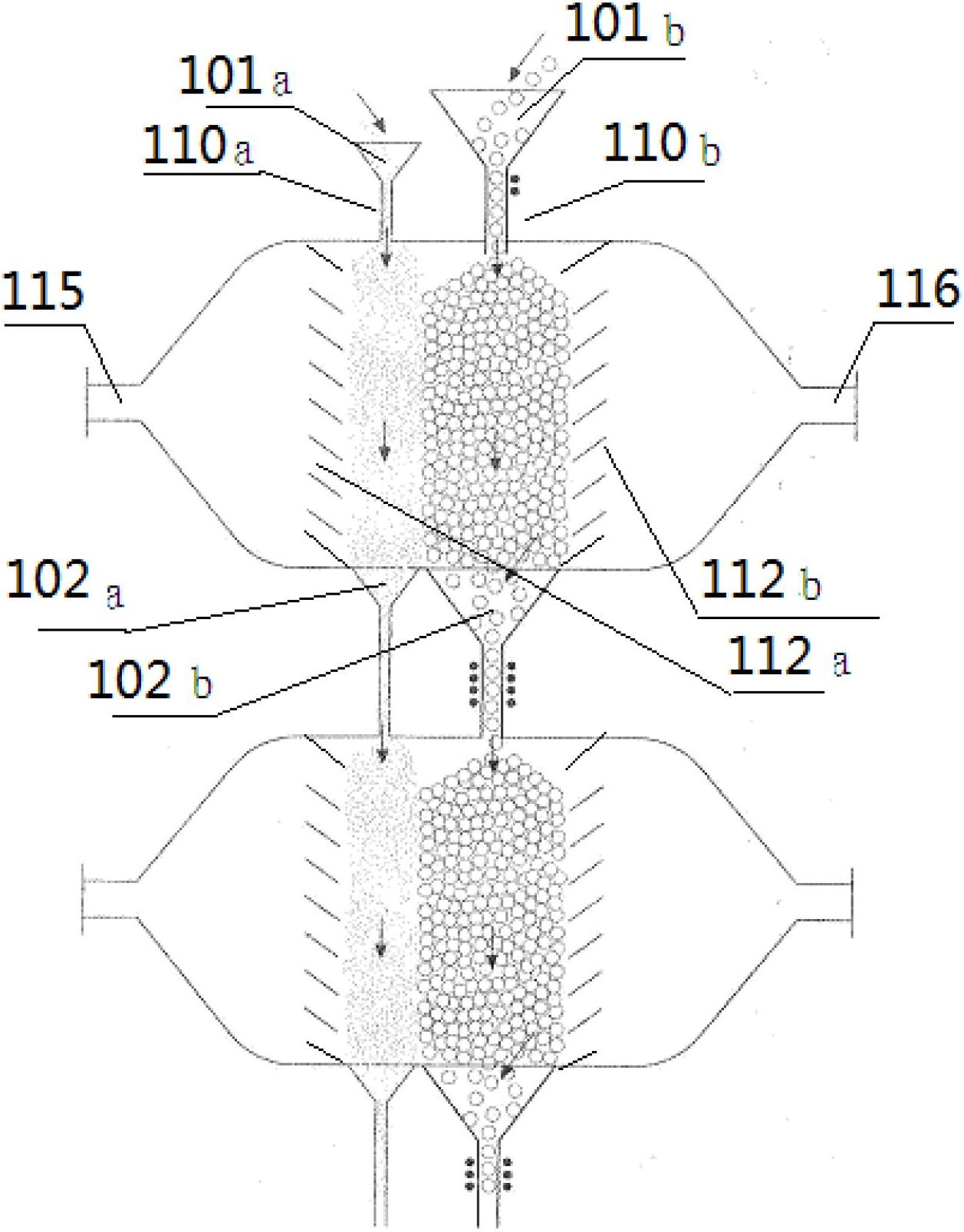

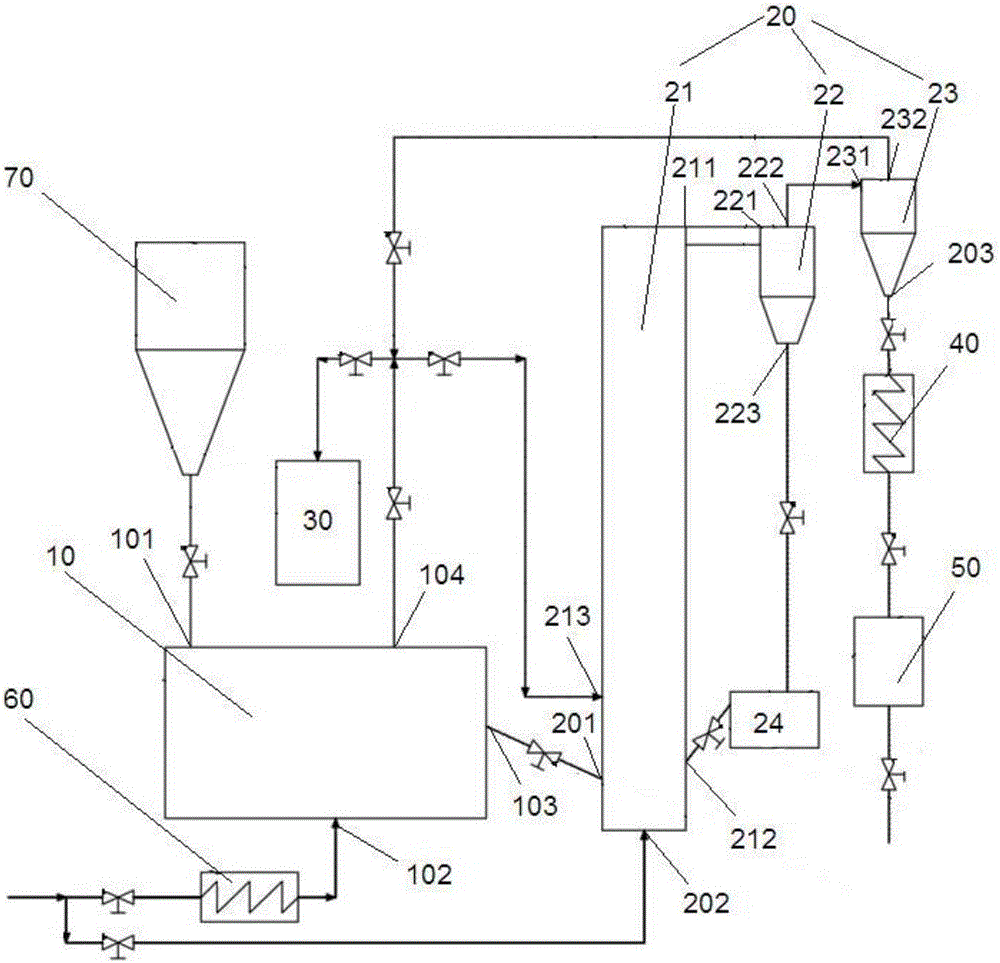

Reactor and method for preparing particle material

ActiveCN102671584AGuarantee continuous and stable operationPrevent or reduce depositionGas-gas reaction processesCarbon preparation/purificationProcess engineeringEngineering

The invention discloses a reactor and method for preparing a particle material. The reactor for preparing the particle material comprises more than one reactor cavity body, wherein each reactor cavity body is used for forming and stacking a particle bed layer; the upper end of each reactor cavity body is respectively provided with a first feeding port and a second feeding port; the lower end thereof is correspondingly provided with a first discharging port and a second discharging port; a raw material gas inlet is arranged on the sidewall of the reactor cavity body at one side close to the first feeding port and the first discharging port; a tail gas outlet is arranged on the sidewall of the reactor cavity body at to one side close to the second feeding port and the second discharging port; a first distributor and a second distributor are respectively arranged inside the reactor cavity body to be close to the raw material gas inlet and the tail gas outlet; and each reactor cavity body is externally or internally provided with a dynamic generating mechanism. The invention also discloses a method for preparing the particle material. According to the reactor and method for preparing the particle material, disclosed by the invention, a plurality of disadvantages in the prior art are overcome, and efficient and energy-saving, long-term and steady, safe and reliable preparation of the particle material is realized.

Owner:储晞

Preparation method of non-shedding elastic-aerogel-coated long fiber composite material

InactiveCN106699216AContinuous and stable preparationGuaranteed to fall offCeramicwareHydrolysateFibrous composites

The invention relates to a preparation method of a non-shedding elastic-aerogel-coated long fiber composite material. The preparation method comprises the following steps: S1. mixing an ethyl orthosilicate hydrolysate and an acidic silica sol to obtain a first mixture; S2. mixing a modified silica sol hydrolysate and ammonia water to obtain a second mixture; S3. mixing the first mixture and the second mixture to obtain a mixed gel material; S4. immersing long fibers in the mixed gel material to obtain an elastic gel composite; and S5. drying the elastic gel composite to obtain the composite material. By adopting the quick gel technique of mixing the two prepared mixtures, the volume ratio can be adjusted to adjust the density and composition of the aerogel, thereby preparing the gel material continuously and stably, and ensuring no shedding of the composite material in case of no violence. An inorganic silicon source is properly introduced into the organic silicon source in the first mixture, thereby effectively lowering the production cost.

Owner:汉信天诚(江苏)科技有限公司

Method for synthesizing methionine hydroxy analogue by continuous and rapid hydrolysis of 2-hydroxy-4-methylthio butyronitrile

ActiveCN109912471AContinuous and stable preparationReduce usageSulfide preparationMethionine hydroxy analogReaction temperature

The invention provides a method for synthesizing methionine hydroxy analogue by continuous and rapid hydrolysis of 2-hydroxy-4-methylthio butyronitrile. The method comprises the following steps: feeding acid and 2-hydroxy-4-methylthio butyronitrile into a microchannel reactor loading a solid catalyst for reaction, controlling the reaction temperature to be 80 to 130 DEG C and the pressure to be 0.1 to 0.5MPa, ensuring that the residence time of a reactant in a micro channel is 1 to 10min, adding water into the mixed liquid flowing out from the microchannel reactor, continuously hydrolyzing for20 to 60min, and ensuring that the reaction temperature to be 100 to 140DEG C and the reaction pressure to be 0.1 to 0.6MPa to obtain the methionine hydroxy analogue and a small amount of a byproduct, namely ammonium sulfate. By adopting the method, continuous and rapid preparation of the methionine hydroxy analogue is reazlied, the traditional intermittent tower device is avoided, the use of inorganic acid of 50 percent is reduced, no ammonium hydroxide is needed for neutralization, no organic solvent is used, and cleaness, environmental protection and sustainability are achieved; the acidolysis time of 2-hydroxy-4-methylthio butyronitrile is greatly reduced, pyrolysis polymerization of raw materials and production of by-products are reduced, and the product quality and yield are improved.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

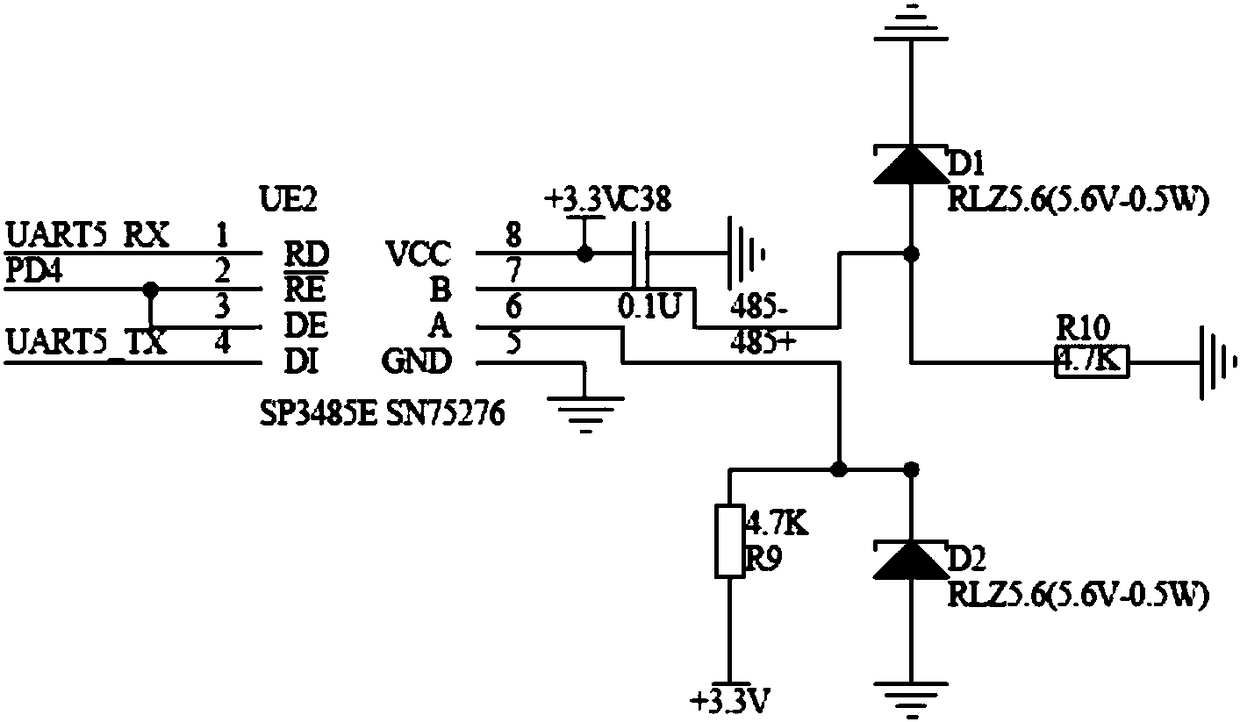

Fuzzy neural network-based oxygenator pressure control method

InactiveCN109188916AContinuous and stable preparationFluid pressure control using electric meansAdaptive controlHigh concentrationFuzzy rule

The invention relates to a fuzzy neural network-based oxygenator pressure control method. The method comprises the following steps of: 1, constructing a fuzzy neural network controller, wherein the fuzzy neural network controller comprises an antecedent network and a seccedent network, the antecedent network comprises four layers such as an antecedent network input layer, a fuzzification layer, afuzzy rule matching layer and a normalization layer, and the seccedent network comprises three layers such as a seccedent network input layer, a rule seccedent calculation layer and a controller output layer. The fuzzy neural network-based oxygenator pressure control method combines the advantages of fuzzy control and neural network control, is used for dynamically controlling system pressure of oxygenators in real time, is capable of solving deficiencies of oxygenators working in a manner of controlling switching via time or fixing pressure limit values, and is beneficial for stably and continuously preparing high-concentration oxygen.

Owner:苏州日尚医疗科技有限公司

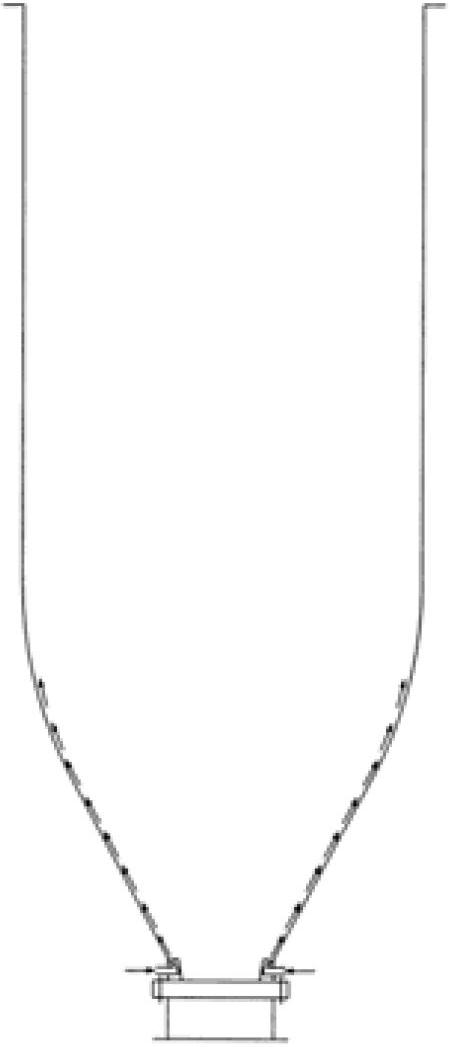

Method for continuous and stable preparation of lithium battery high nickel ternary precursor material

InactiveCN108493407AAchieving a porous structureGreenCell electrodesLi-accumulatorsContinuous measurementDischarge rate

Belonging to the technical field of ternary battery preparation, the invention in particular relates to a method for continuous and stable preparation of a lithium battery high nickel ternary precursor. The method for continuous and stable preparation of a lithium battery high nickel ternary precursor provided by the invention carries out stepwise sinking in a high-speed rotating settling chamber,controls the composition of a synthetic precursor by continuous measurement, and sets different rotation rates in each layer of settling chamber so as to ensure the uniformity of settling particle size at each layer, utilizes high-speed rotation to realize spheroidization and controllable particle size of the high nickel ternary material, further realizes coating of low nickel with high nickel continuously, solves the defect of difficult control of the coating process at present, realizes continuous, stable and controllable preparation of high nickel precursor. The finally obtained ternary precursor has the characteristics of uniform particle size distribution, compact particles and high tap density, finally can be sintered and then applied to lithium ion batteries, and under the condition of 0.1C discharge rate, the discharge capacity is up to 296 mAh / g, and the capacity still remains at about 256 mAh / g after 200 cycles.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

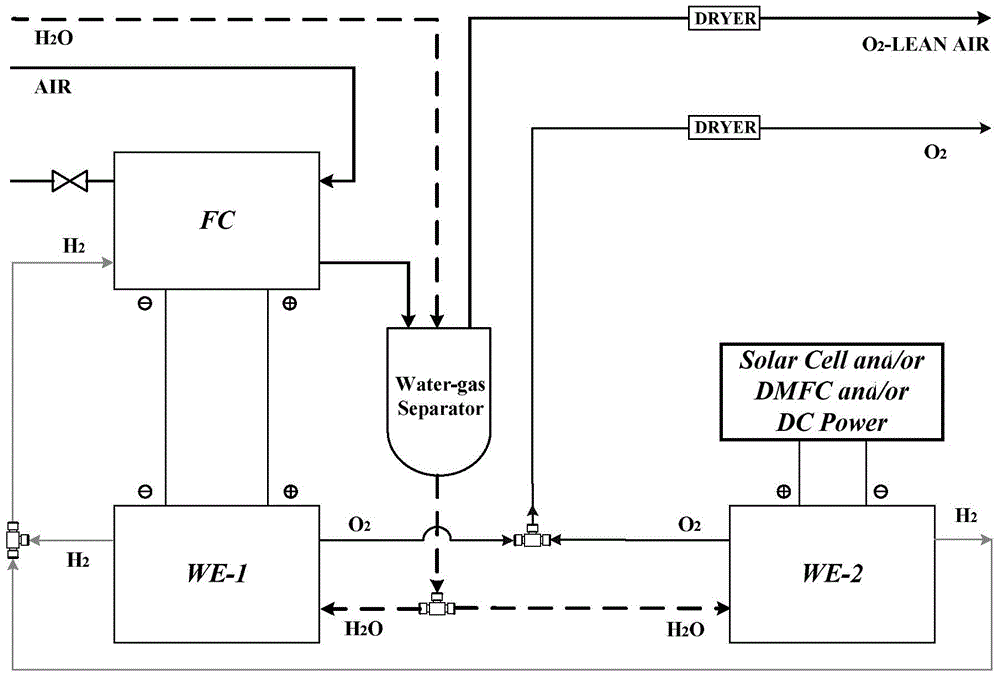

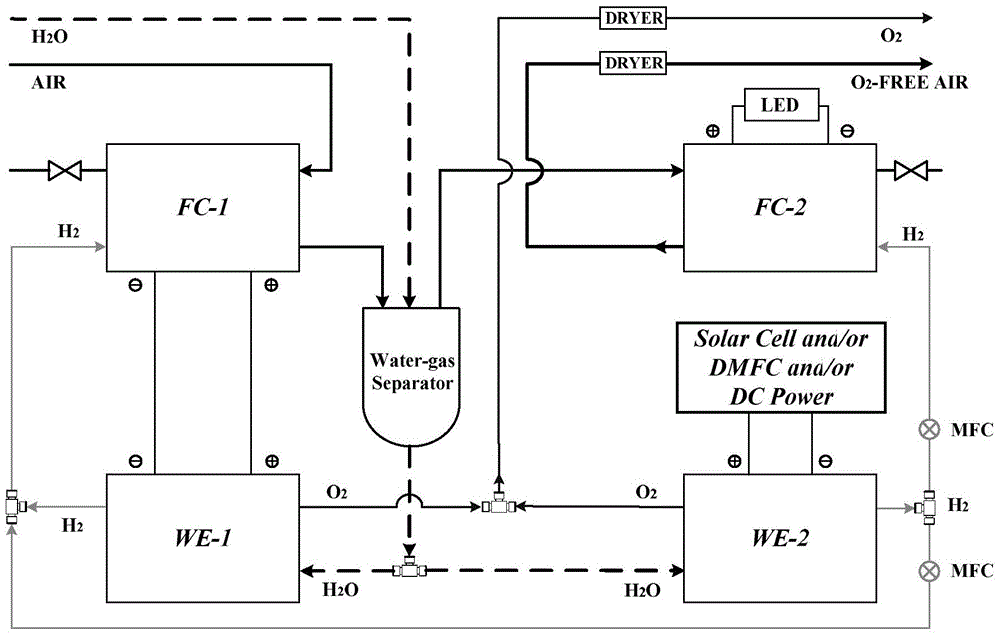

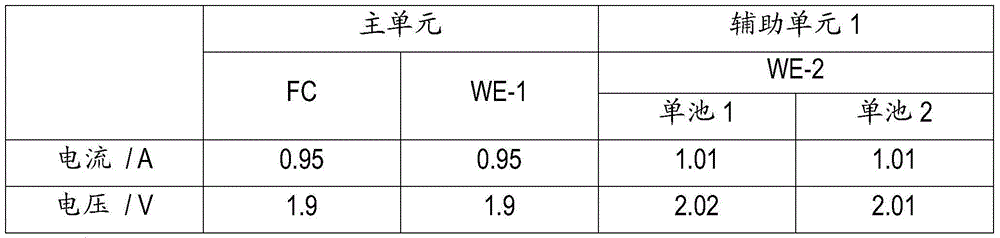

Electrochemistry method for preparing pure oxygen and poor-oxygen gas by oxygen-containing gas mixture

ActiveCN104611717AIncrease power consumptionImprove energy efficiencyCellsEnergy inputElectrolysisHydrogen fuel cell

The present invention relates to an electrochemical method for preparing a pure-oxygen gas and an oxygen-poor gas by using an oxygen-containing gas mixture. The method comprises at least two electrolyzed-water units and power supply units corresponding to the electrolyzed-water units. Each of the power supply units comprises at least one hydrogen energy recycling power supply unit and an externally-connected power supply unit. Each of the hydrogen energy recycling power supply unit uses a hydrogen fuel battery. Each of the externally-connected power supply unit uses at least one of the following items: a solar cell, a direct methanol fuel cell, and a power supply of an external alternating-current grid. Each of the power supply units is in circuit connection with the corresponding electrolyzed-water unit separately. Hydrogen generated by all the electrolyzed-water units is output to the hydrogen fuel batteries as a fuel. Oxygen generated by the electrolyzed-water units is the required pure oxygen. A negative electrode and a positive electrode of each of the hydrogen fuel battery of each of the hydrogen energy recycling power supply units input hydrogen and an oxygen-containing gas mixture. The input hydrogen is connected to a negative positive hydrogen chamber of the electrolyzed-water unit through a pipe. Gas-liquid separation is performed on exhaust of a positive electrode side is output as oxygen-poor gas. In the present invention, high-purity oxygen can be stably and continuously prepared in low cost on an indoor site and an outdoor site.

Owner:DALIAN UNIV OF TECH

Flexible lithium battery piece of composite solid electrolyte and preparation method of flexible lithium battery piece

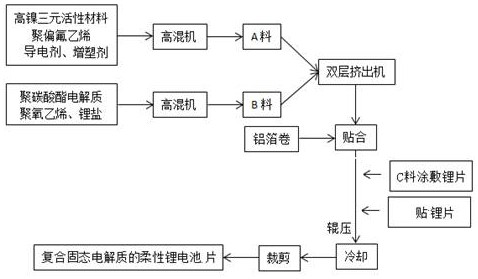

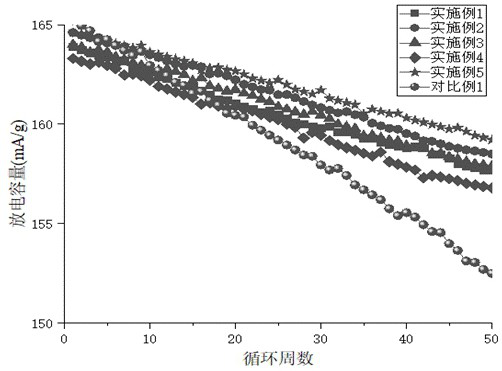

InactiveCN113078365AImprove interface compatibilityPromote environmental protectionFinal product manufactureSecondary cellsMethacrylateSolid state electrolyte

The invention relates to the field of solid electrolyte of a lithium battery, and discloses a flexible lithium battery piece of a composite solid electrolyte and a preparation method of the flexible lithium battery piece. The method comprises the following steps: (1) preparing a high-nickel ternary active material, polyvinylidene fluoride, a conductive agent and a plasticizer into a material A; (2) preparing a material B from polycarbonate electrolyte, polyoxyethylene and lithium salt; (3) preparing a material C from the polyethylene glycol-polyglycerol methacrylate segmented copolymer gel and a lithium salt; and (4) melting, extruding and compounding the material A and the material B into an AB sheet by using a double-layer co-extrusion extruder, thermally laminating the layer A with an aluminum foil roll surface, coating the material C on the material B layer, laminating a lithium sheet, rolling, continuously drawing, cooling and cutting to obtain the flexible lithium battery sheet of the composite solid electrolyte. The method provided by the invention is clean in environment, simple in process and easy for large-scale production, improves good interface compatibility of the electrode material and the solid electrolyte, effectively reduces solid / solid contact impedance, and has an excellent application prospect.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

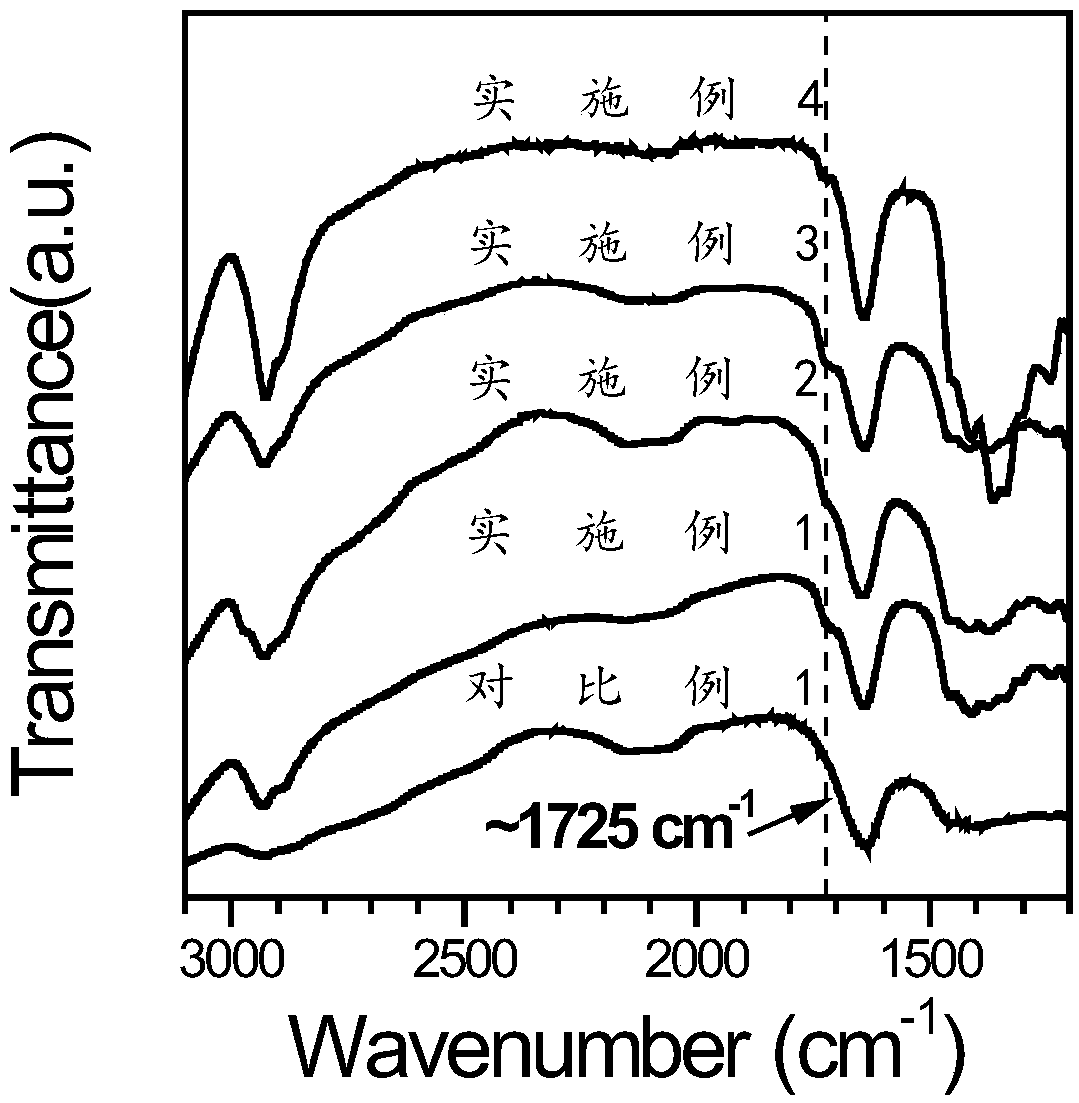

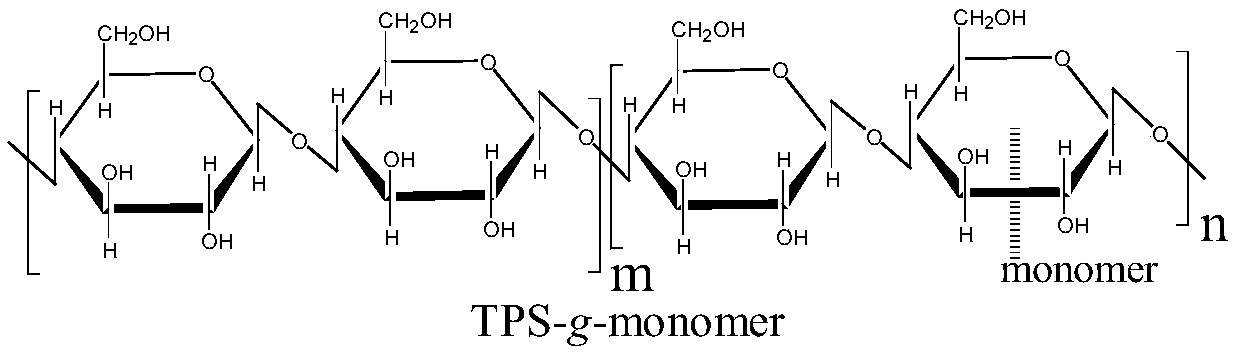

Modified thermoplastic starch and preparation method and application thereof

InactiveCN111100245AContinuous and stable preparationEconomical and practicalPolymer sciencePlasticizer

The invention relates to modified thermoplastic starch as well as a preparation method and application thereof, and mainly solves the technical problems of poor continuity of a thermoplastic starch preparation process, easiness in adhesion and caking of prepared granules due to precipitation of a plasticizer, influence on subsequent use and poor performance stability in the prior art. The modifiedthermoplastic starch comprises the following components in parts by mass: (1) 55-85 parts of raw material starch; (2) 15 to 45 parts of a plasticizer; (3) 1-20 parts of a reactive monomer; and (4) 0.05 to 1 part of an initiator, and is prepared through reaction of the above components. According to the technical scheme, the problems are well solved, and the method can be used for industrial production of thermoplastic starch modified materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Active coke preparation device and method

ActiveCN106635105AContinuous and stable preparationLow running costDirect heating destructive distillationSpecial form destructive distillationFluidized bedTar

The invention provides an active coke preparation device and method. The active code preparation device comprises a low-temperature pyrolysis furnace and a circulating fluidized bed device, wherein a coal material feeding opening, a first smoke gas inlet and a hot semi-coke outlet are formed in the low-temperature pyrolysis furnace; a hot semi-coke inlet, a second hot smoke gas inlet and an active coke outlet are formed in the circulating fluidized bed device; the hot semi-coke inlet communicates with the hot semi-coke outlet. By using the active coke preparation device, the active coke can be prepared by a two-step method. In the first step, the coke preparing coal is subjected to low-temperature pyrolysis and abrasion in the low-temperature pyrolysis furnace to form hot semi-coke with smaller particle diameters; in the second step, the hot semi-coke is subjected to deep pyrolysis and abrasion in the circulating fluidized bed device to form an active coke product. On one hand, the tar-containing pyrolysis gas and the active code can be prepared in a separated way, so that the problem of easy blockage due to tar separation can be favorably solved; on the other hand, the active code can be continuously and stably prepared; the operation cost is lower; the device and the method are very suitable for industrial large-scale application.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

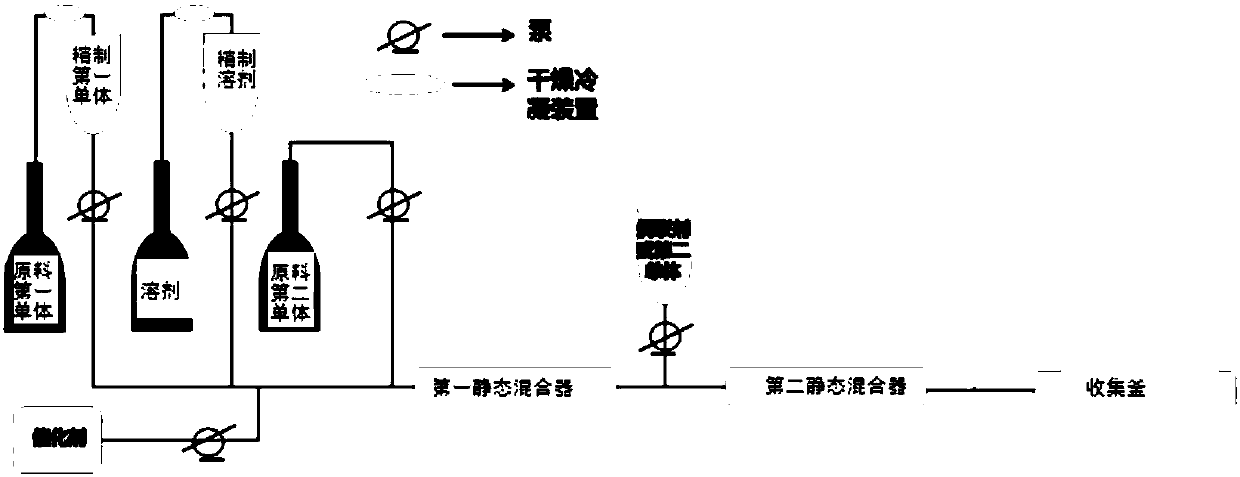

Method for continuously preparing block/star-shaped polymer on basis of tubular reaction device

The invention provides a method for continuously preparing a block / star-shaped polymer on the basis of a tubular reaction device and belongs to the field of a polymer compounding method. According tothe method, a first static reactor and a second static reactor in the tubular reaction device are utilized to react; the sectional variable angle crossing blades in the first static reactor and the second static reactor and the size and connecting mode of the reactors are designed according to the characteristics of anionic polymerization reaction; a micro-channel reactor is combined with the reactors, so that the reaction speed and yield in the reaction process can be promoted; compared with intermittent kettle reaction, the reaction has the advantage that the reaction rate is increased by about 30 times; the device is capable of achieving 200 tons / year output and finally realizing the preparation for narrow distributed block / star-shaped polymer; the method is capable of realizing continuous stable production on the basis of the characteristics of the tubular reaction and promoting the product batch stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

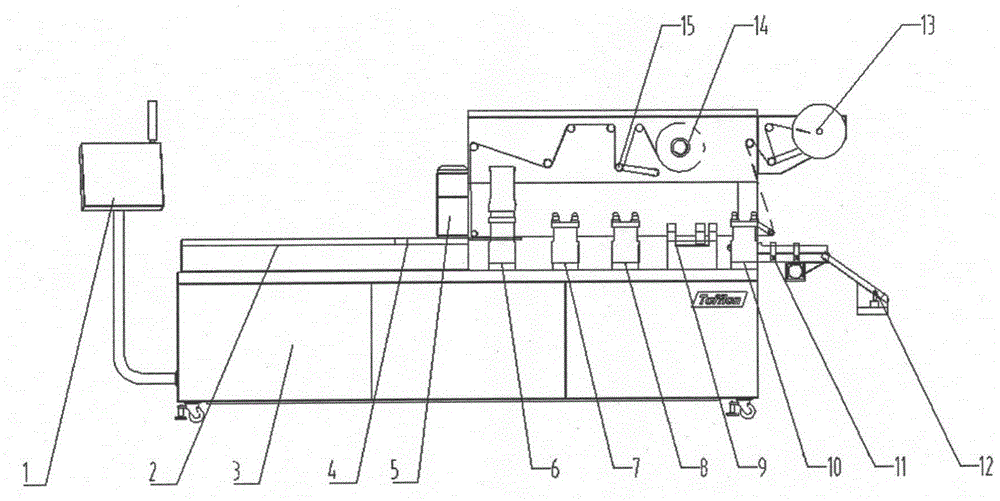

Hot sealing machine for freeze drying tablet production equipment

InactiveCN105691751AAvoid cropping errorsContinuous and stable preparationWrapper twisting/gatheringFreeze-dryingControl system

The invention discloses a hot sealing machine for freeze drying tablet production equipment. The hot sealing machine is characterized by comprising a control system and a stand; the stand is provided with a feed guide rail, a feed traction mechanism and an output belt with a servo traction mechanism; a coating material loading shaft for fixing a freeze drying tablet film coating material, an uncoiling mechanism and a waste coiling mechanism are arranged above the stand; and the stand is provided with a hot sealing film coating mechanism, a tear line pressing mechanism, a steel seal printing mechanism and a cutting mechanism in a product conveying direction in sequence. A transmission action of the coating material is actuated through the feed traction mechanism and the servo traction mechanism; an action of the hot sealing film coating mechanism is synchronized with a traction action; a main traction mechanism performs an interval traction motion; an auxiliary traction mechanism performs a continuous motion, and the traction speed is slightly quicker than the maximum instant speed of the main traction mechanism, but the traction force is slightly lower than the locking clamping force of the main traction mechanism; and the main traction and the auxiliary traction are used for effectively preventing the deviation of the coating material and the cutting error caused by thermal expansion and cold shrinkage of the coating material.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

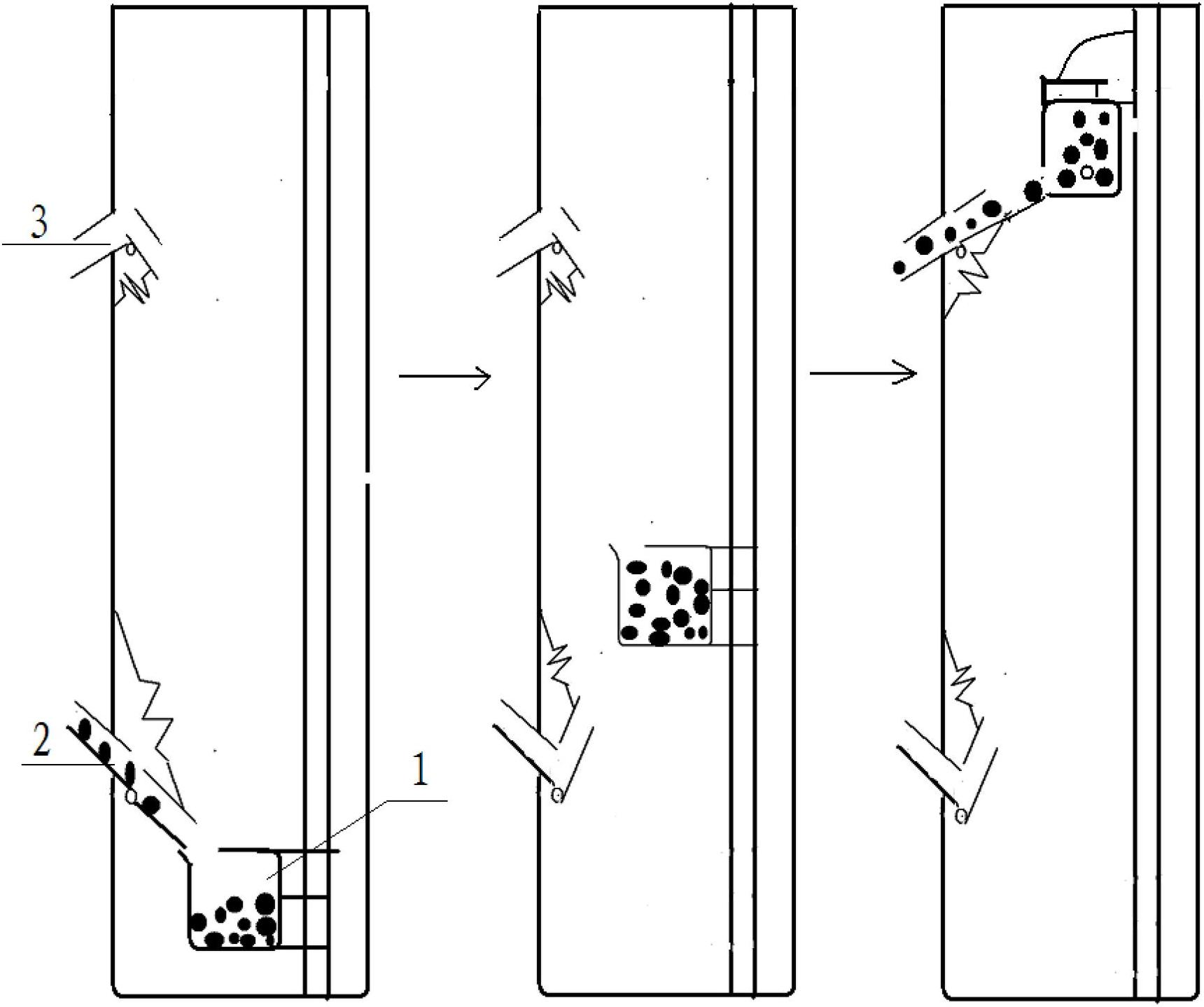

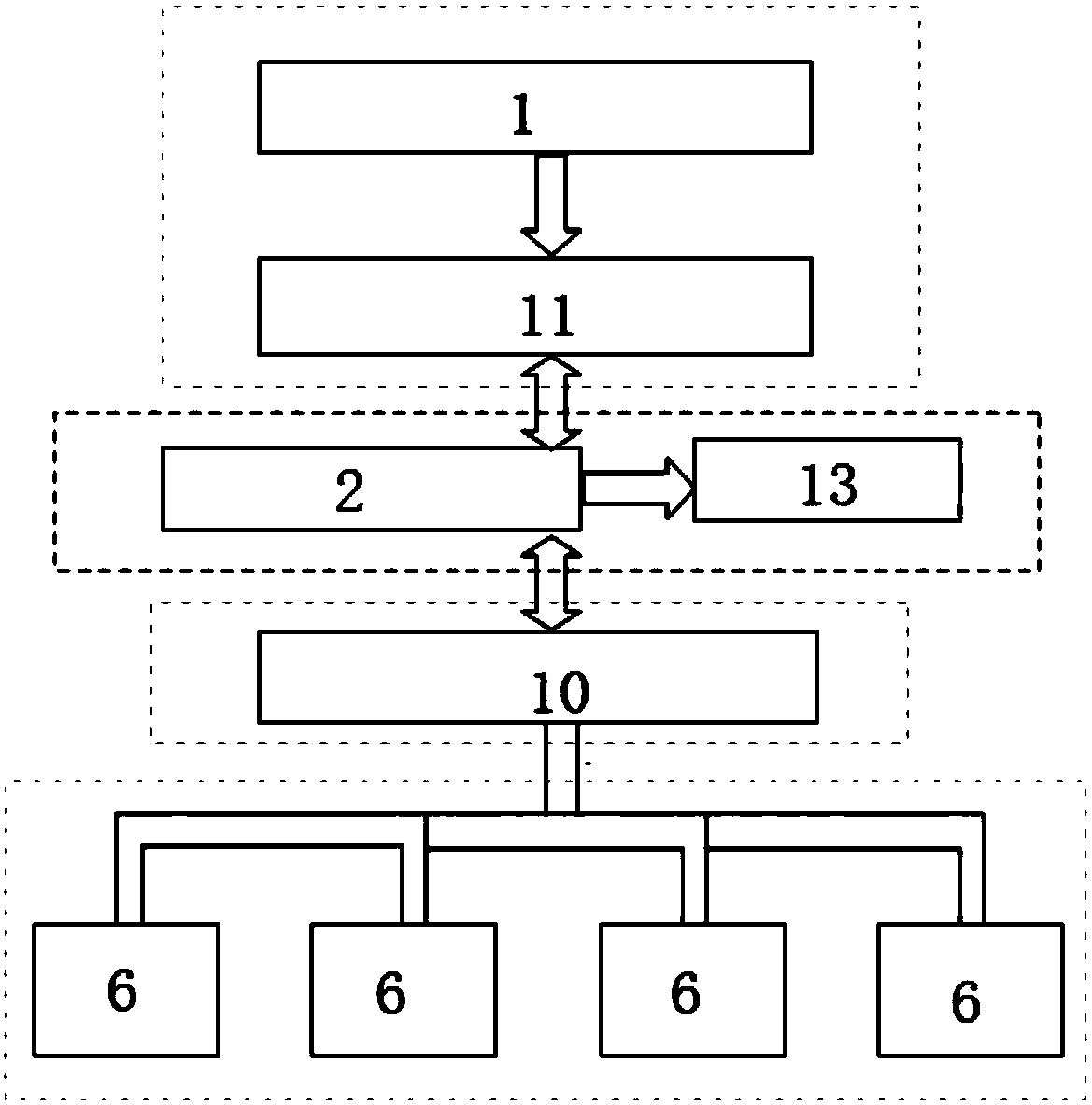

A method for realizing fully automatic continuous preparation of microspheres

ActiveCN106249663BContinuous and stable preparationWithout human interventionProgramme controlComputer controlLower limitMicrosphere

The invention relates to a method for achieving fully-automatic and continuous preparation of a micro-balloon. The method comprises steps of: (1) pouring into samples to allow the sample to be uninterruptedly poured, wherein the samples comprise dispersion phases and continuous phases: a, detecting whether the samples reach an upper limit position in real time, if yes, stopping pouring into the samples and then entering step b, and if not, continuing to pour into the samples and executing the step a; and b, detecting whether the samples reach a lower limit position, in real time, if yes, starting to pour into the samples and returning to the step a, and if not, continuing to execute the step b; and (2) injecting the samples into a micro-flow control chip, carrying out precise control on the samples injected into a micro-channel, thereby achieving generation, transportation and combination of liquid drops, and after the liquid drops are generated, carrying out in-situ solidification to form a micro-balloon. According to the invention, through a CPU controlling injector and a switching valve, automatic extraction and pouring of liquid are achieved; it is ensured that there is liquid in the injector, thereby achieving continuous and stable preparation of the micro-balloon; and the whole process is free of manual interference, and operation parameters in an operation process can be recorded.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

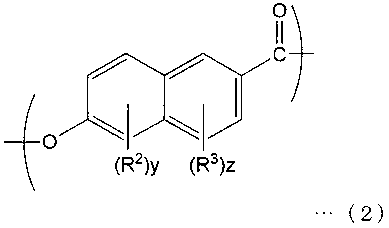

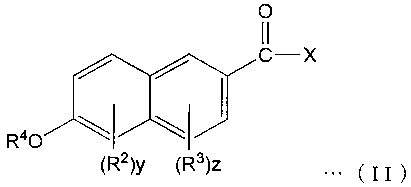

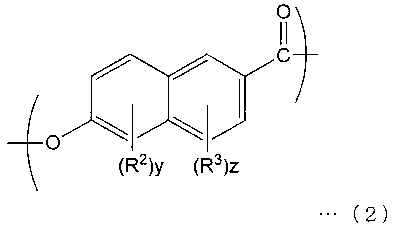

Method of producing liquid crystal polyester

InactiveCN103224613AContinuous and stable preparationPrevent sinteringLiquid crystal compositionsPolyesterPolymer science

A method is provided of producing a liquid crystal polyester, including: preparing a liquid crystal polyester prepolymer containing a repeating unit represented by general formula (1) and a repeating unit represented by general formula (2) by melt polymerization, cooling and solidifying the prepolymer to obtain a solidified prepolymer, pulverizing the solidified prepolymer to obtain a prepolymer powder, and heating the prepolymer powder to conduct solid-phase polymerization. A liquid crystal polyester is thereby prepared having a polymerization degree higher than the prepolymer. Preparing a liquid crystal polyester is performed with a rate of temperature rise within a temperature range of from a temperature 10 DEG C. lower than a final end-point temperature of the solid-phase polymerization to the final end-point temperature of from 0.01 DEG C. / min to 0.03 DEG C. / min.

Owner:SUMITOMO CHEM CO LTD

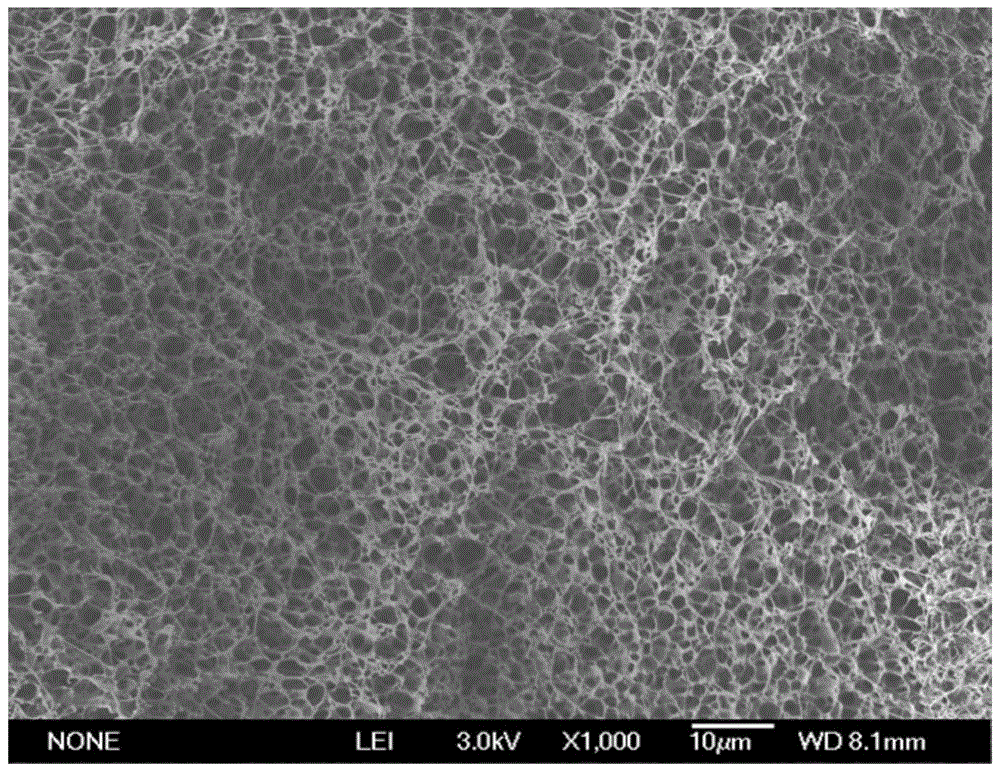

Method of fast preparing graphene through microwave assisted stirring

The invention provides a method of fast preparing graphene through microwave assisted stirring. Graphite powder is adopted as a raw material, graphite powder and a foamer are mixed, graphite is infiltrated by the foamer and then put into a high mixing machine, high speed stirring is utilized to make graphite in a complete suspension state and a high speed motion state, meanwhile, microwave stripping is adopted to aid so that the foamer among graphite layers can fast react to generate support force, and continuous, fast, environment-friendly and clean preparation of a graphene material can be achieved. According to the method of fast preparing graphene through microwave assisted stirring, the technical effect of continuous, clean and environment-friendly production of graphene is achieved, and industrialized production of graphene dry powder is promoted; further, cutting and stripping are completed through one step in the high mixing machine, graphene is scattered evenly, not only is the layer structure of graphene maintained to the greatest extent, but also the graphene material can be prepared continuously and stably, surface integrity and topological symmetry of graphene are not destroyed, and the quality of graphene finished products is ensured further.

Owner:山东聊城莱鑫粉末材料科技有限公司

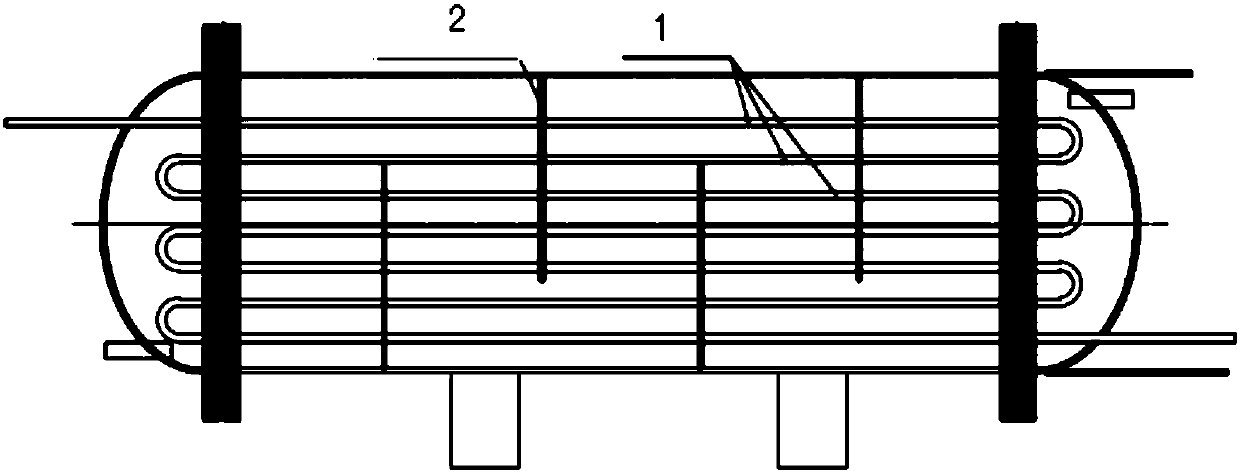

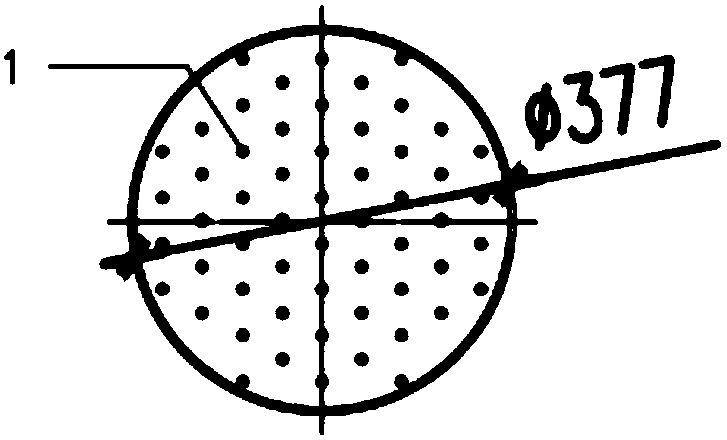

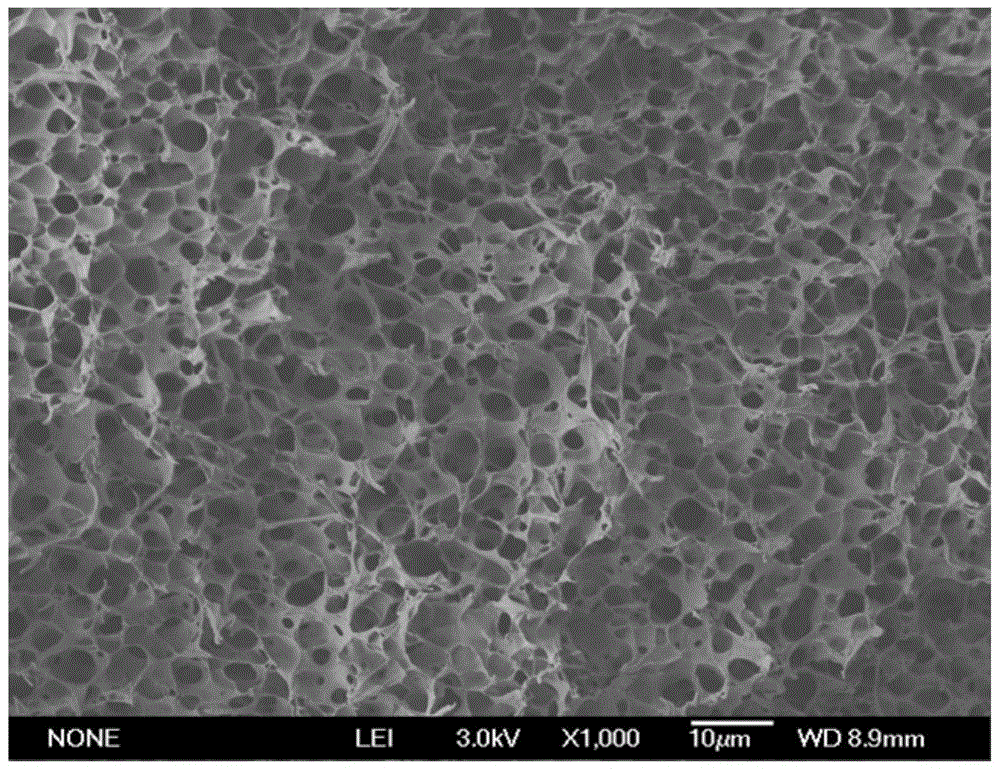

A method for large-scale clean preparation of graphene

Provided is a large-scale clean preparation method for graphene, comprising: (i) preparing graphite raw material, water, foaming agent and surfactant into a suspension and stirring the suspension at a rotating speed of 300-500rpm to disperse the graphite raw material uniformly to obtain a dispersed suspension; (ii) feeding the dispersed suspension into a feed inlet (1) of a spraying device, the feed inlet communicating with a conveying chamber (2), the conveying chamber being internally provided with at least one ultrasonic probe (5); the dispersed suspension being subjected to ultrasonic treatment so that the foaming agent enters layers of graphite; the conveying chamber being internally provided with at least one air compressor (4) for pressurizing the dispersed suspension to accelerate the dispersed suspension to flow forward; the conveying chamber communicating with a drying chamber (3), and the dispersed suspension after treatment flowing into the drying chamber; and (iii) arranging a gas heating nozzle and at least one nozzle (7) at the top of the drying chamber; the dispersed suspension flowing through the nozzle and entering the drying chamber to be atomized by heated gas; the foaming agent being decomposed by heat so that interlayer spacing of graphite is increased; and after atomization and foaming, obtaining the graphene stripped off under a high-speed air flow. Preferably, at least one ultrasonic probe (6) is arranged at the nozzle. According to the method, two processes, i.e., mechanical stripping and drying, are integrated into a spray dryer and an ultrasonic device is arranged at the nozzle, thus providing graphite with a higher energy, increase the intercalating probability and improving the intercalating effect of the foaming agent. Hence, product quality is ensured and, environmental protection and no-pollution are achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

A kind of preparation method of high molecular weight polybutylene succinate

The invention provides a preparation method of high-molecular-weight poly(butylene succinate).Butanedioic acid and butanediol are adopted as raw materials, the product poly(butylene succinate) is formed through an oligomer forming stage, a polymer forming stage and an extrusion chain extension reaction stage in sequence, the oligomer forming stage is completed under the condition of negative pressure being 3 Kpa, the number-average molecular weight of poly(butylene succinate) finally generated after the reaction is larger than or equal to 1.0*105, and the distribution range of the molecular weight is 1.2-1.6.The preparation method is high in esterification rate, the molecular weight of the generated product is high, the distribution range of the molecular weight is narrow, no gel is generated in the reaction process, and the preparation process is easy to control.

Owner:陕西延长泾渭新材料科技产业园有限公司

A kind of method for preparing polypropylene hollow fiber porous membrane

ActiveCN103464003BShort manufacturing cycleReduce manufacturing costSemi-permeable membranesPolymer scienceDiluent

A method for preparing a polypropylene hollow fiber porous membrane relates to a method for preparing a polypropylene hollow fiber porous membrane by using a heat-induced phase separation method. The present invention adopts tributyl phosphate and other diluents to prepare porous polypropylene membranes with a spongy structure at high polymer concentrations; at the same time, adopts a co-rotating twin-screw extruder and a specific feeding process to continuously and stably prepare polypropylene hollow fibers membrane. The method effectively improves the strength of the polypropylene porous membrane, shortens the membrane-making period and reduces the membrane-making cost.

Owner:TSINGHUA UNIV

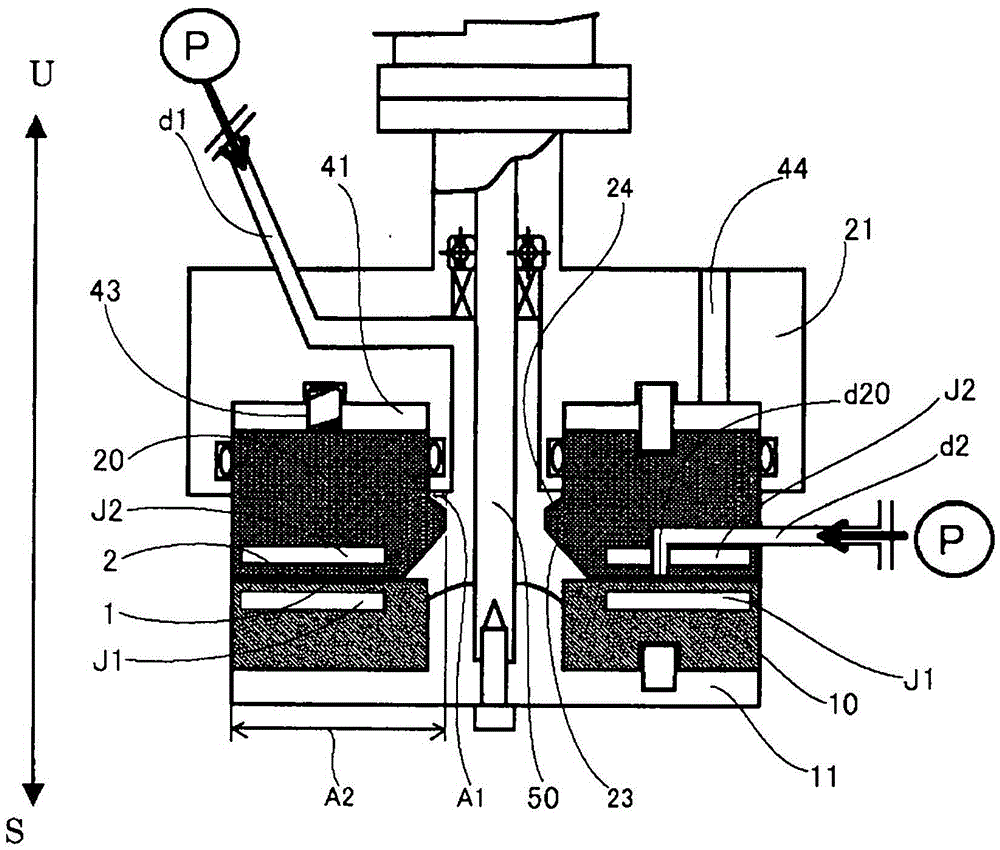

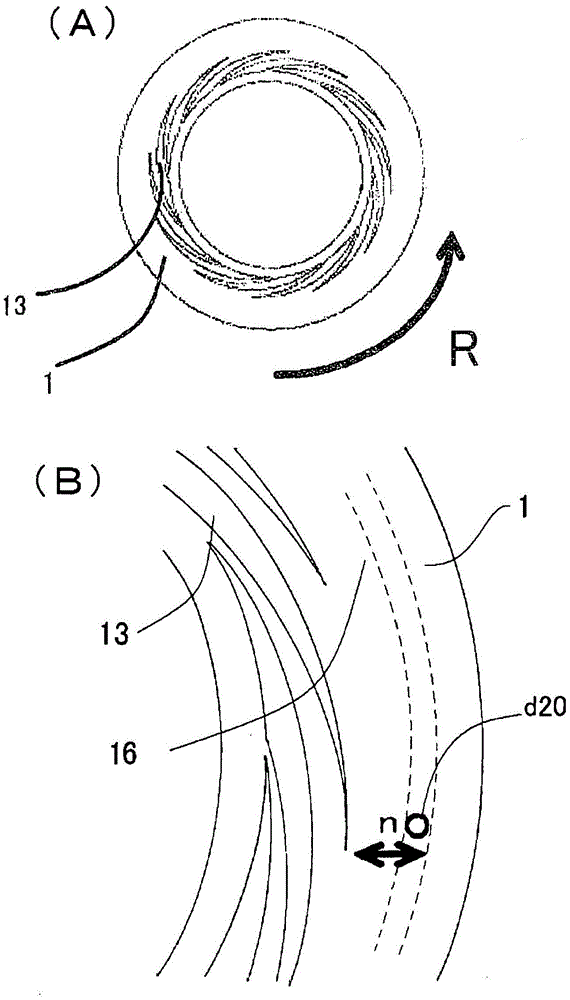

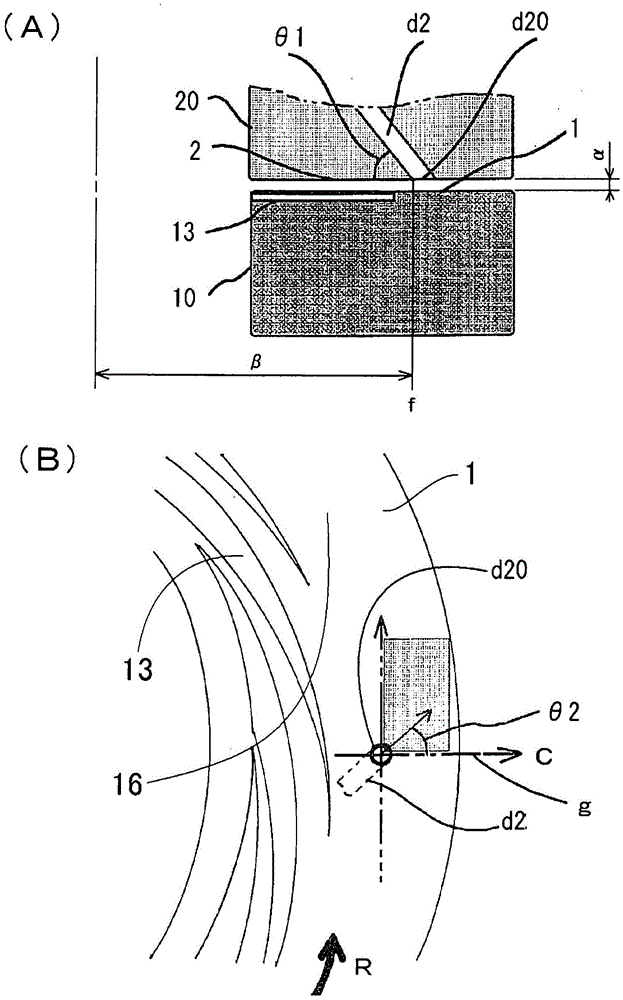

Method for Preventing Adhesion of Adhesion Using Forced Film Type Fluid Treatment Device

ActiveCN103561856BPrevent adhesionContinuous and stable preparationOrganic chemistryRotary stirring mixersEngineeringRaw material

The present invention provides a method for preventing the adhesion of deposits, which is a fluid treatment method, a thin film produced between at least two processing surfaces that are arranged opposite, can be approached and separated, and at least one of them rotates relative to the other. The fluid to be treated is mixed with the fluid to obtain a treated material, and the treated material is prevented from adhering to the above-mentioned processing surface constituting the flow path of the treated fluid. Using at least two types of fluids to be treated, including a raw material fluid containing at least one raw material and a fluid used to process the above-mentioned raw material, are arranged in opposite directions, can be approached and separated, and at least one of them is relatively opposite to the other. The fluid to be treated is mixed with the thin film fluid generated between the rotating at least two processing surfaces (1, 2) to obtain a processed raw material. At this time, by introducing the raw material fluid from the center of the processing surfaces (1, 2), the raw materials processed between the processing surfaces (1, 2) are prevented from adhering to the processing surfaces (1, 2).

Owner:M TECH CO LTD

A comprehensive utilization method of vanadium-containing leaching solution for removing silicon waste slag

ActiveCN108359815BHigh recovery rateSolve the pollution of the environmentVanadium oxidesCeramic materials productionAluminum ammonium sulfateAmmonium metavanadate

The invention provides a preparation method of a vanadium containing solution. The preparation method comprises the following steps that vanadium containing lixivium is subjected to silicon removal and dealumination to obtain the vanadium containing solution and silicon removal waste residues; the silicon removal waste residues are leached through concentrated sulfuric acid to obtain an acid leaching solution; after the acid leaching solution is precisely filtered, silicon residues and an aluminum sulfate solution are obtained; and the aluminum sulfate solution and an ammonium sulfate solutionare mixed, recooling crystallization is carried out after reacting, aluminum ammonium sulfate crystals and crystallization mother liquor are obtained through second solid-liquid separation, and the crystallization mother liquor is used for replacing part or all of aluminum salt to be mixed with a silicon-chrome-silicon containing solution for silicon removal. According to the method, the siliconremoval waste residues can be subjected to resource utilization, and an aluminum ammonium sulfate product high in additional value can be obtained; meanwhile, the consumption of the aluminum salt canbe reduced, high-purity ammonium metavanadate can be prepared continuously and stably, and therefore a high-purity vanadium pentoxide product with the purity not smaller than 99.9% is prepared, and the vanadium recovery rate is increased; and the process is simple, the cost is low, and energy consumption is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com