Reactor and method for preparing particle material

A granular material and granular material bed technology, applied in the field of granular material preparation, can solve problems such as difficult to meet continuous production, clogging, and easy bonding of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

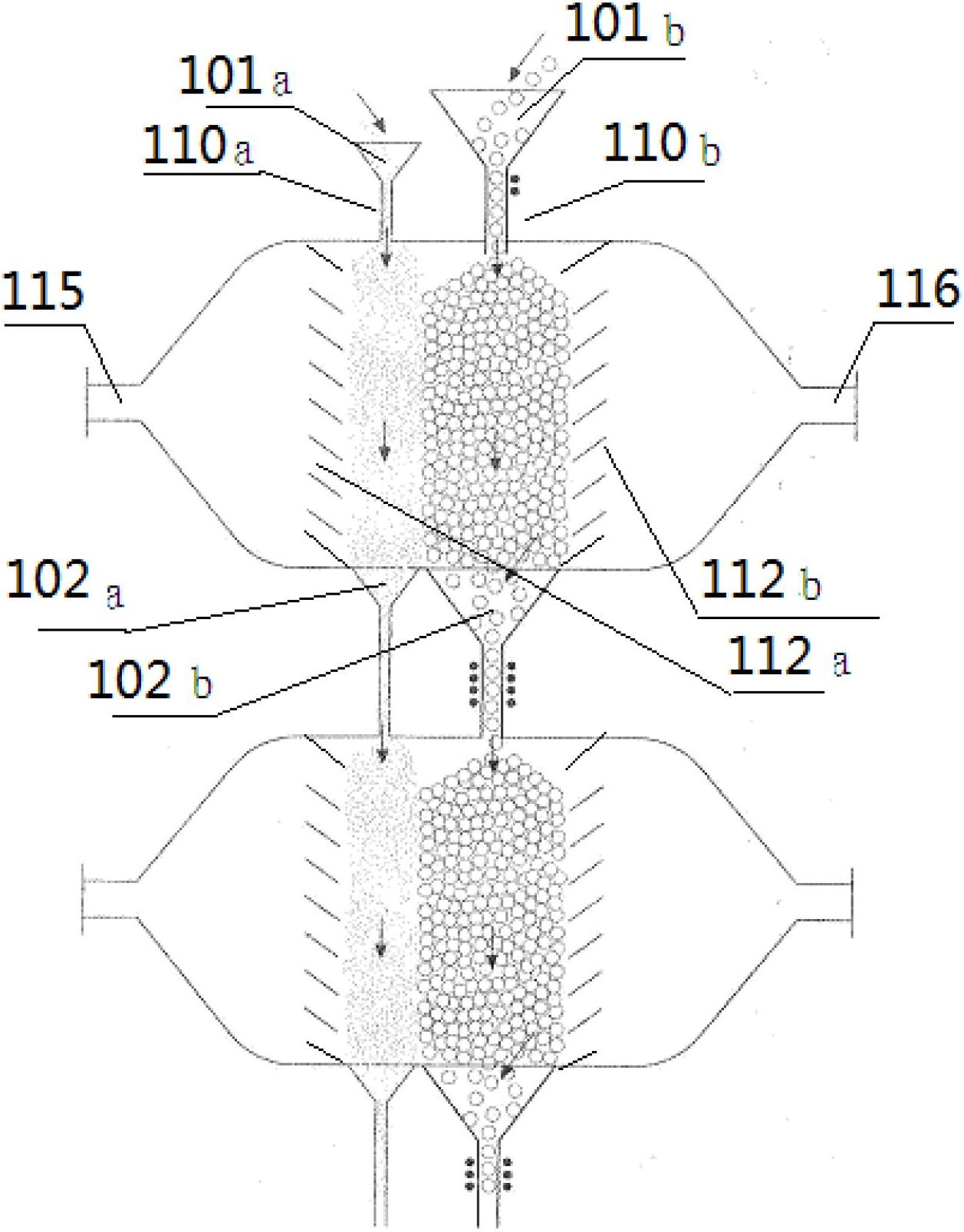

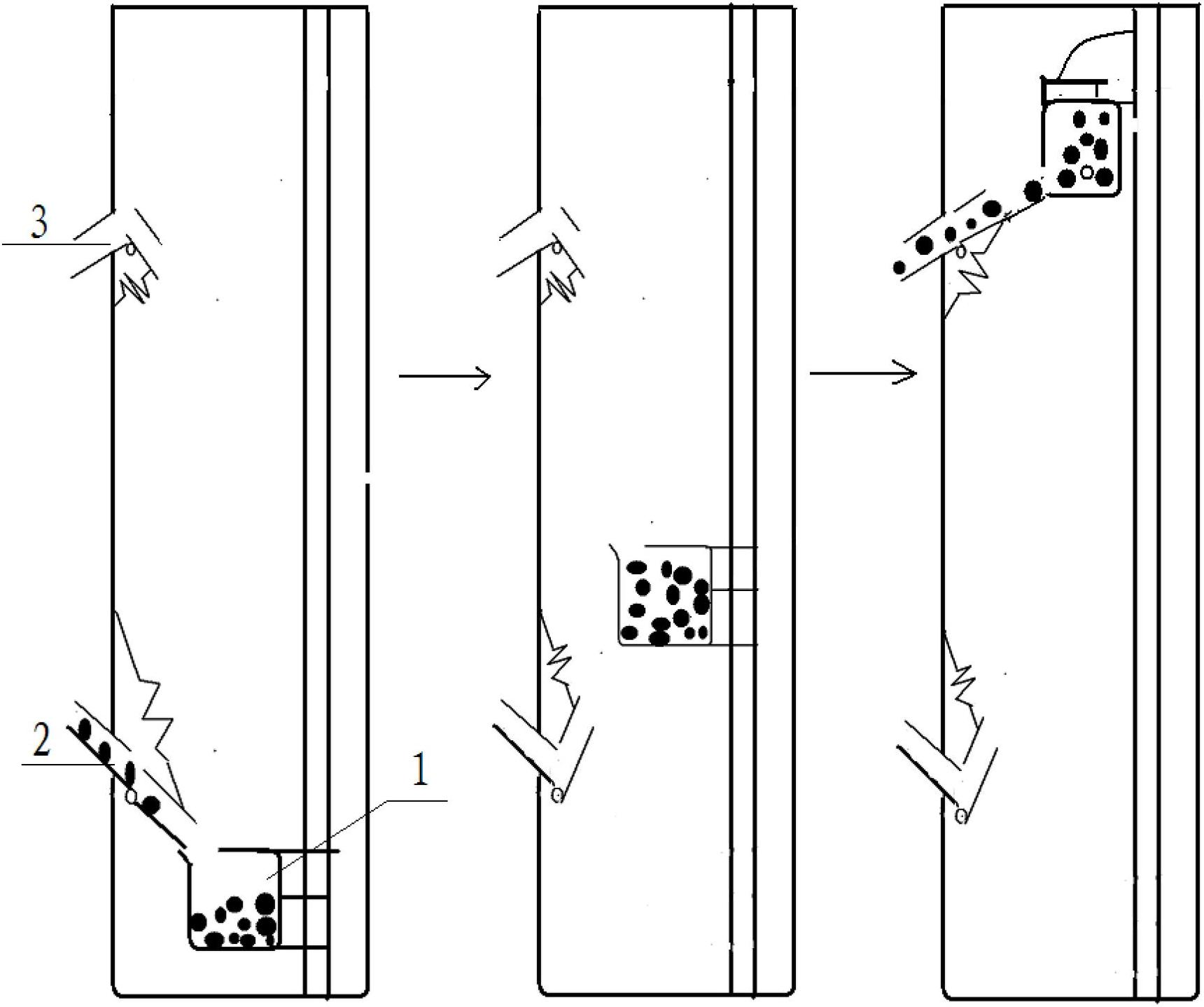

[0103] figure 1 Schematic diagram of the reactor structure for the preparation of granular materials provided in Example 1; figure 2 It is a schematic diagram of the structure of the particle conveying mechanism; Figure 3a , Figure 3b is a schematic diagram of the structure of the reactor cavity gas curtain; Figure 3c , Figure 3d It is a schematic diagram of the structure of the raw material gas pipeline air curtain;

[0104] like figure 1 As shown, the reactor for preparing granular materials provided in this embodiment includes: a two-stage reactor cavity, which constitutes a two-stage reaction, the height of the reactor cavity is 0.5 meters, and the height of the reactor is 1.5 meters.

[0105] The reactor cavity is used to form a packed particle bed, and the filling rate of the granular material seeds is more than 50%. The upper end of the first reactor cavity is respectively provided with a first feeding port 101a and a second feeding port 101b, and the lower e...

Embodiment 2

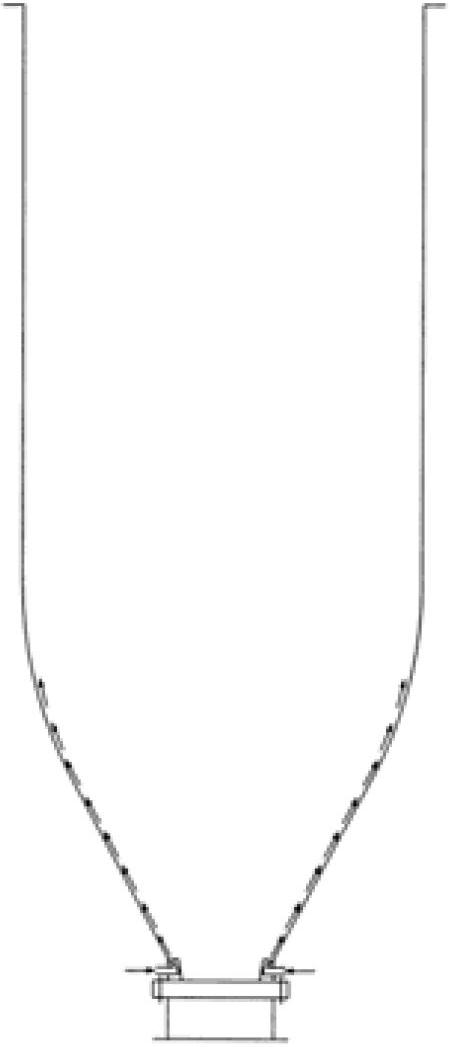

[0140] Figure 4 Schematic diagram of the reactor structure for the preparation of granular materials provided in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com