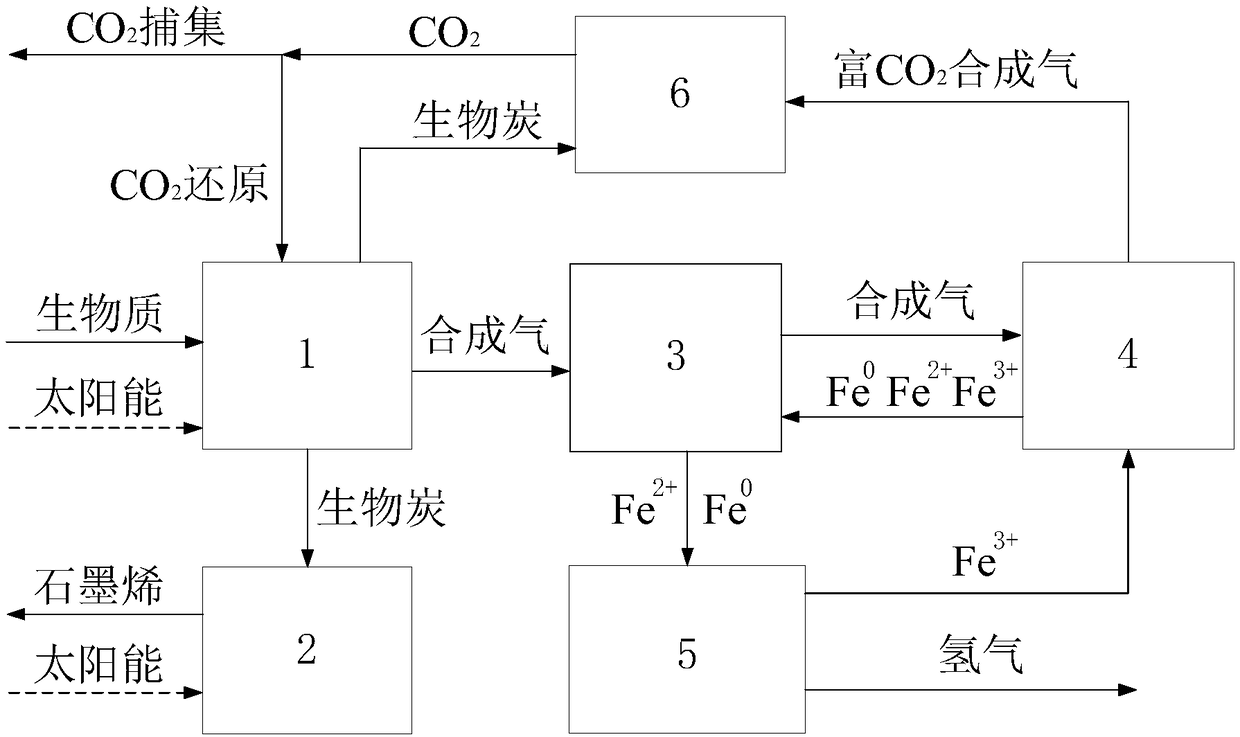

CO2 emission reduction system and method synergized with hydrogen production by step-by-step conversion of biomass energy

A technology of biomass energy and biomass, which is applied in the field of biomass energy step-by-step hydrogen production and CO2 emission reduction system, which can solve the problems of small processing capacity, retention, and large energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

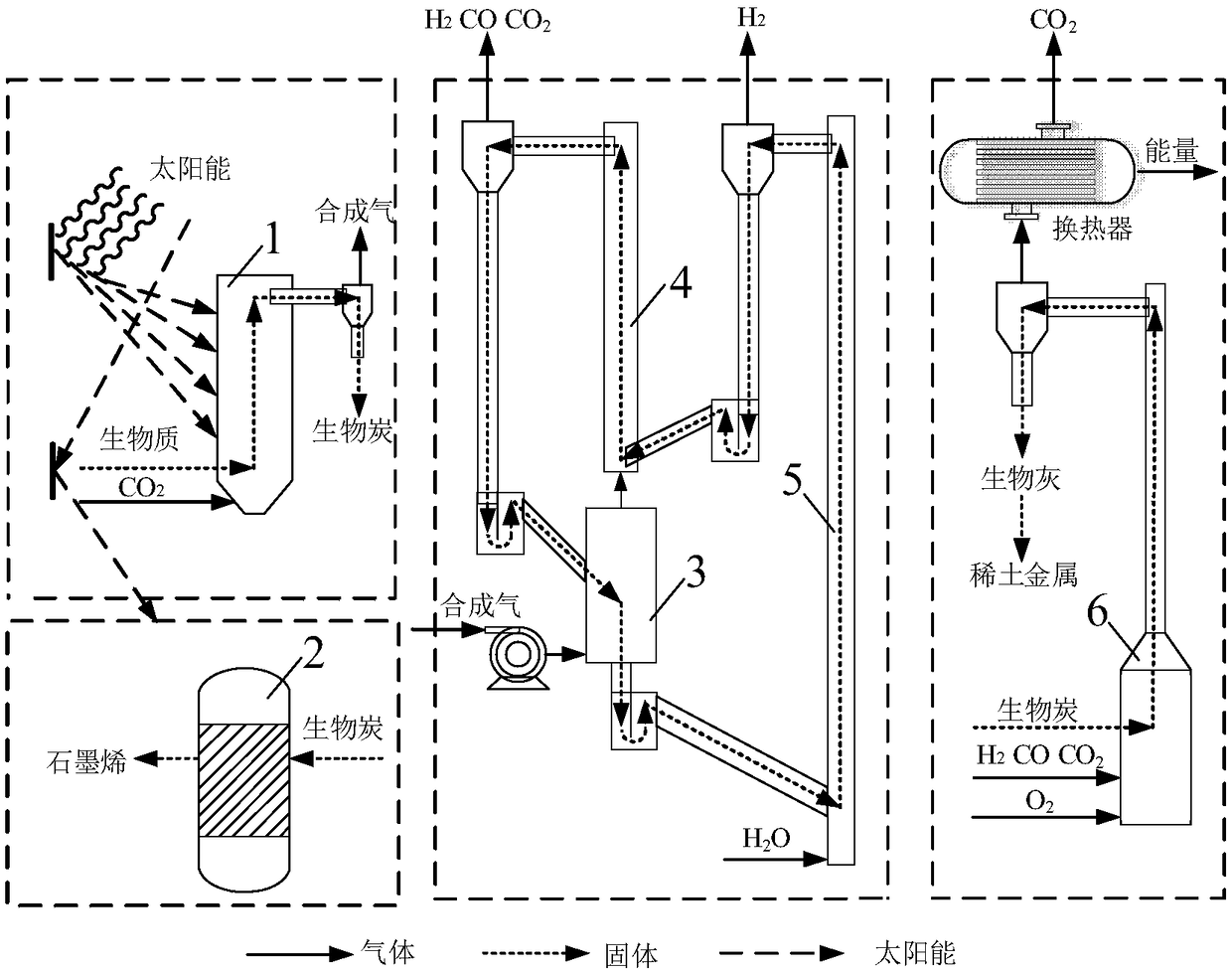

[0049] Include the following steps:

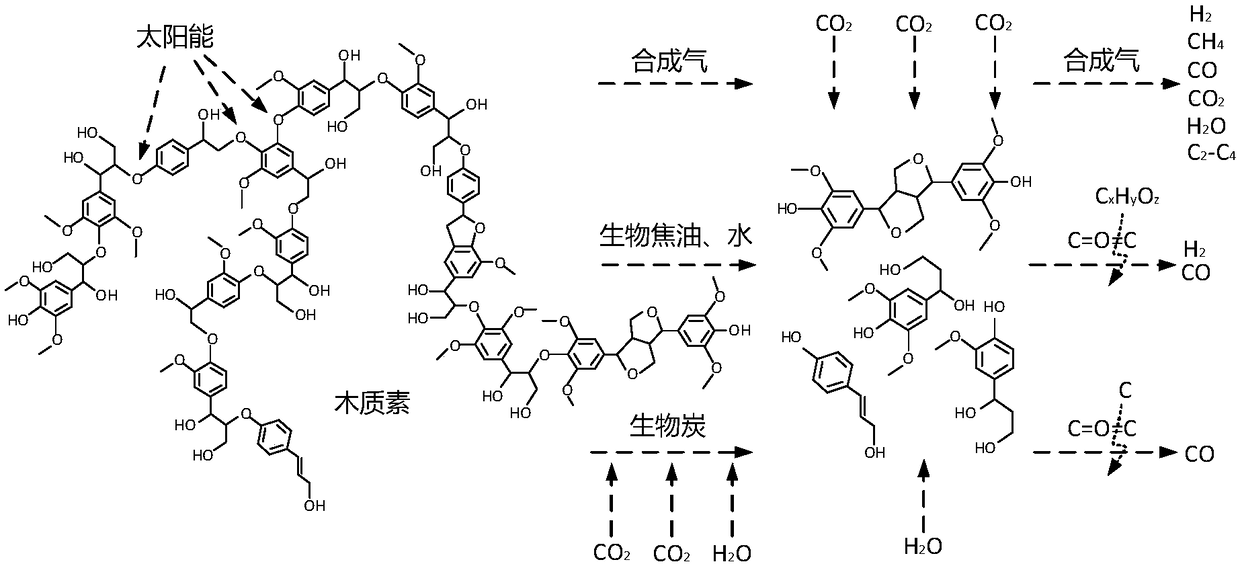

[0050] 1) CO 2 In the photothermal reduction device, in CO 2 Biomass gasification as a gasification medium at 800°C to obtain syngas and biochar;

[0051] 2) The synthesis gas is passed into the primary fuel reactor and the secondary fuel reactor and is gradually oxidized by the oxygen carrier, and the temperature is controlled at 950°C;

[0052] 3) The oxygen carrier reduced by the synthesis gas is sent to the steam reactor through the U valve, and is oxidized by water vapor at 800°C to produce hydrogen;

[0053] 4) 10% biochar with a high degree of graphitization is used for graphene preparation, and graphene oxide is reduced at 650° C. under hydrogen conditions to obtain reduced graphene oxide;

[0054] 5) The remaining 90% of the biochar is sent to the combustion furnace to assist the heating device for combustion, while capturing CO 2gas, and will capture 4% CO in the gas 2 It is passed into a photothermal reduction device as a g...

Embodiment 2

[0056] 1) CO 2 In the photothermal reduction device, in CO 2 Biomass gasification as a gasification medium at 880°C to obtain syngas and biochar;

[0057] 2) The synthesis gas is passed into the primary fuel reactor and the secondary fuel reactor and is gradually oxidized by the oxygen carrier, and the temperature is controlled at 920°C;

[0058] 3) The oxygen carrier reduced by the synthesis gas is sent to the steam reactor through the U valve, and is oxidized by water vapor at 850°C to produce hydrogen;

[0059] 4) 25% biochar with a high degree of graphitization is used for graphene preparation, and graphene oxide is reduced at 750°C and hydrogen to obtain reduced graphene oxide;

[0060] 5) The remaining 75% of the biochar is sent to the combustion furnace to assist the heating device to burn, and at the same time capture CO 2 gas, and will capture 5% CO in the gas 2 It is passed into a photothermal reduction device as a gasification medium for biomass conversion.

Embodiment 3

[0062] 1) CO 2 In the photothermal reduction device, in CO 2 As a gasification medium, biomass gasification is carried out at 900°C to obtain syngas and biochar;

[0063] 2) Pass the synthesis gas into the primary fuel reactor and the secondary fuel reactor and be oxidized by the oxygen carrier step by step, and the temperature is controlled at 900°C;

[0064] 3) The oxygen carrier reduced by the synthesis gas is sent to the steam reactor through the U valve, and is oxidized by water vapor at 900°C to produce hydrogen;

[0065] 4) 15% biochar with a high degree of graphitization is used for graphene preparation, and graphene oxide is reduced at 720°C and hydrogen to obtain reduced graphene oxide;

[0066] 5) The remaining 85% of the biochar is sent to the combustion furnace to assist the heating device to burn, and at the same time capture CO 2 gas, and will capture 8% CO in the gas 2 It is passed into a photothermal reduction device as a gasification medium for biomass co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com