Method for continuous and rapid preparation of nano nickel by microfluidics technology

A nano-nickel and microfluidic technology, applied in nanotechnology and other directions, can solve the problems of environmental pollution, product quality, lack of controllability of particle size distribution and morphology, and high investment, and achieve fast mass transfer rate, continuous Fast preparation, uniform reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

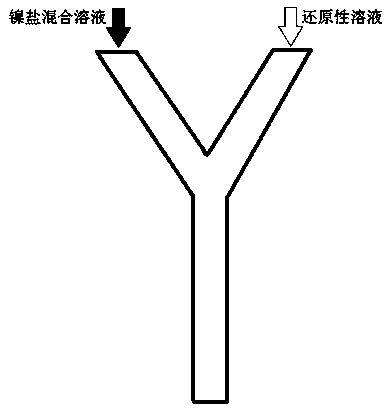

[0019] Such as figure 1 As shown, the microfluidic technology continuously and rapidly prepares the method for nano-nickel, and its specific steps are as follows:

[0020] (1) First, 6.5gNiSO 4 ·6H 2 Dissolve O in distilled water, adjust the pH of the solution to 12 by adding lye (NaOH solution), then add a surfactant under the condition of a stirring rate of 500r / min and mix evenly for 0.5h to obtain a nickel salt mixed solution, in which the surfactant For polyvinylpyrrolidone (PVP), NiSO 4 ·6H 2 The molar ratio of O to added surfactant is 1:1;

[0021] (2) Dissolve the reducing agent in distilled water to prepare a reducing solution, wherein the reducing agent is sodium borohydride, NiSO 4 ·6H 2 The molar ratio of O to sodium borohydride added is 1:4;

[0022] (3) Pump the nickel salt mixed solution obtained in step (1) and the reducing solution obtained in step (2) into the channel of the Y-shaped microreactor for micro-mixing reaction, and the mixed solution is cle...

Embodiment 2

[0024] Such as figure 1 As shown, the microfluidic technology continuously and rapidly prepares the method for nano-nickel, and its specific steps are as follows:

[0025] (1) First, 6.5gNiSO 4 ·6H 2 O was dissolved in distilled water, and the pH of the solution was adjusted to 12 by adding lye (NaOH solution), and then a surfactant was added and mixed evenly for 0.75 hours at a stirring rate of 600r / min to obtain a nickel salt mixed solution, in which the surfactant For polyvinylpyrrolidone (PVP), NiSO 4 ·6H 2 The molar ratio of O to added surfactant is 1:2;

[0026] (2) Dissolve the reducing agent in distilled water to prepare a reducing solution, wherein the reducing agent is sodium borohydride, NiSO 4 ·6H 2 The molar ratio of O to added sodium borohydride is 1:6;

[0027] (3) Pump the nickel salt mixed solution obtained in step (1) and the reducing solution obtained in step (2) into the channel of the Y-shaped microreactor for micro-mixing reaction, and the mixed so...

Embodiment 3

[0029] Such as figure 1 As shown, the microfluidic technology continuously and rapidly prepares the method for nano-nickel, and its specific steps are as follows:

[0030] (1) First, 6.5gNiSO 4 ·6H 2 Dissolve O in distilled water, adjust the pH of the solution to 9 by adding lye, then add a surfactant at a stirring rate of 300r / min and mix evenly for 1 hour to obtain a nickel salt mixed solution, wherein the surfactant is hexadecyl Trimethylammonium bromide (CTAB), NiSO 4 ·6H 2 The molar ratio of O to the added cetyltrimethylammonium bromide is 1:4;

[0031] (2) Dissolve the reducing agent in distilled water to prepare a reducing solution, wherein the reducing agent is potassium borohydride, NiSO 4 ·6H 2 The molar ratio of O to the added reducing agent is 1:4;

[0032] (3) Pump the nickel salt mixed solution obtained in step (1) and the reducing solution obtained in step (2) into the channel of the Y-shaped microreactor for micro-mixing reaction, and the mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com