Full-automatic tester for slump degree of cement concrete

A technology of cement concrete and slump, applied in the direction of instruments, flow characteristics, measuring devices, etc., can solve the problems of poor continuity of experiments, inability to guarantee verticality, difficulty in ground cleaning, etc., achieve good accuracy and authenticity, and test The process is simple and easy to achieve the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

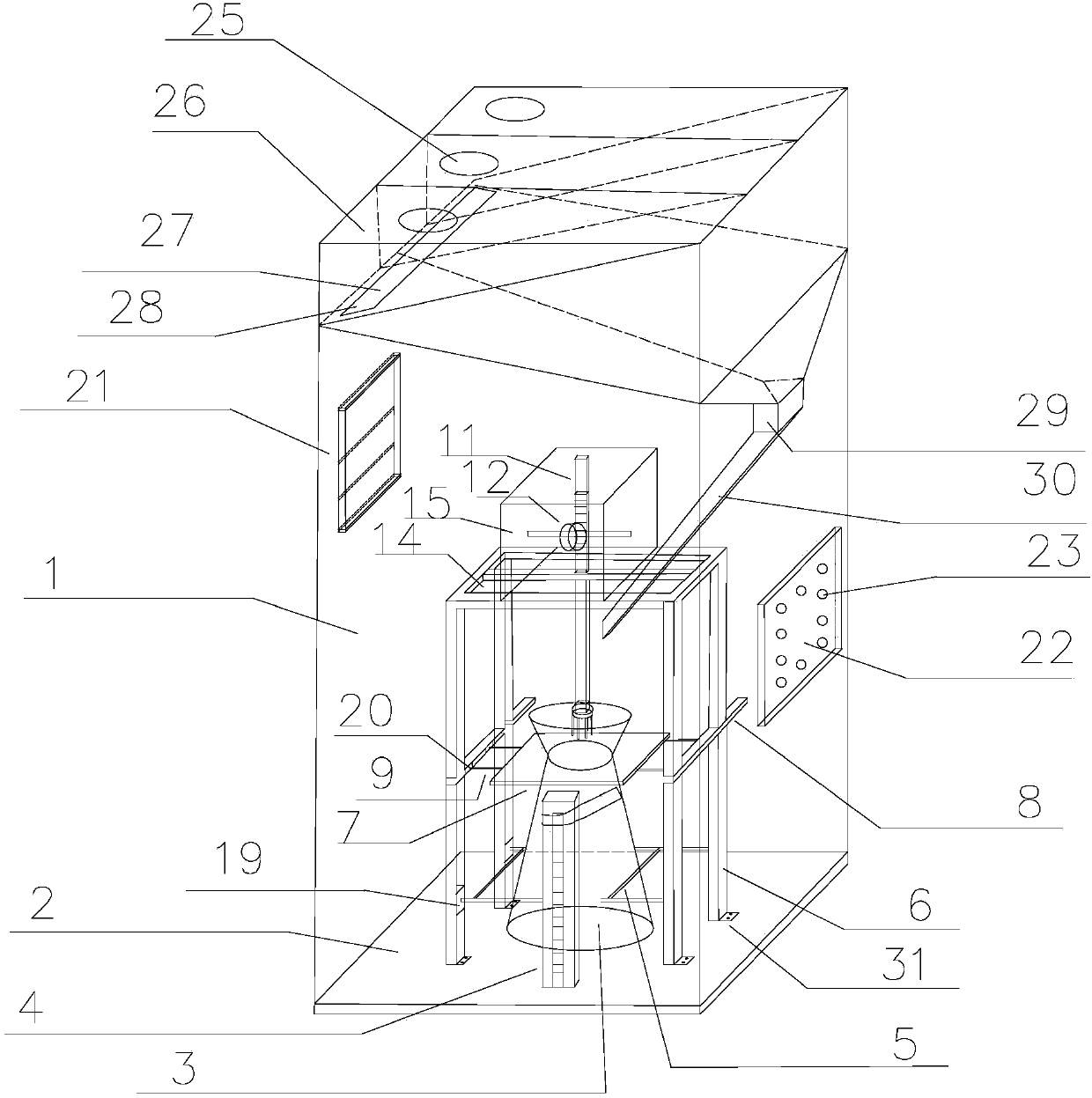

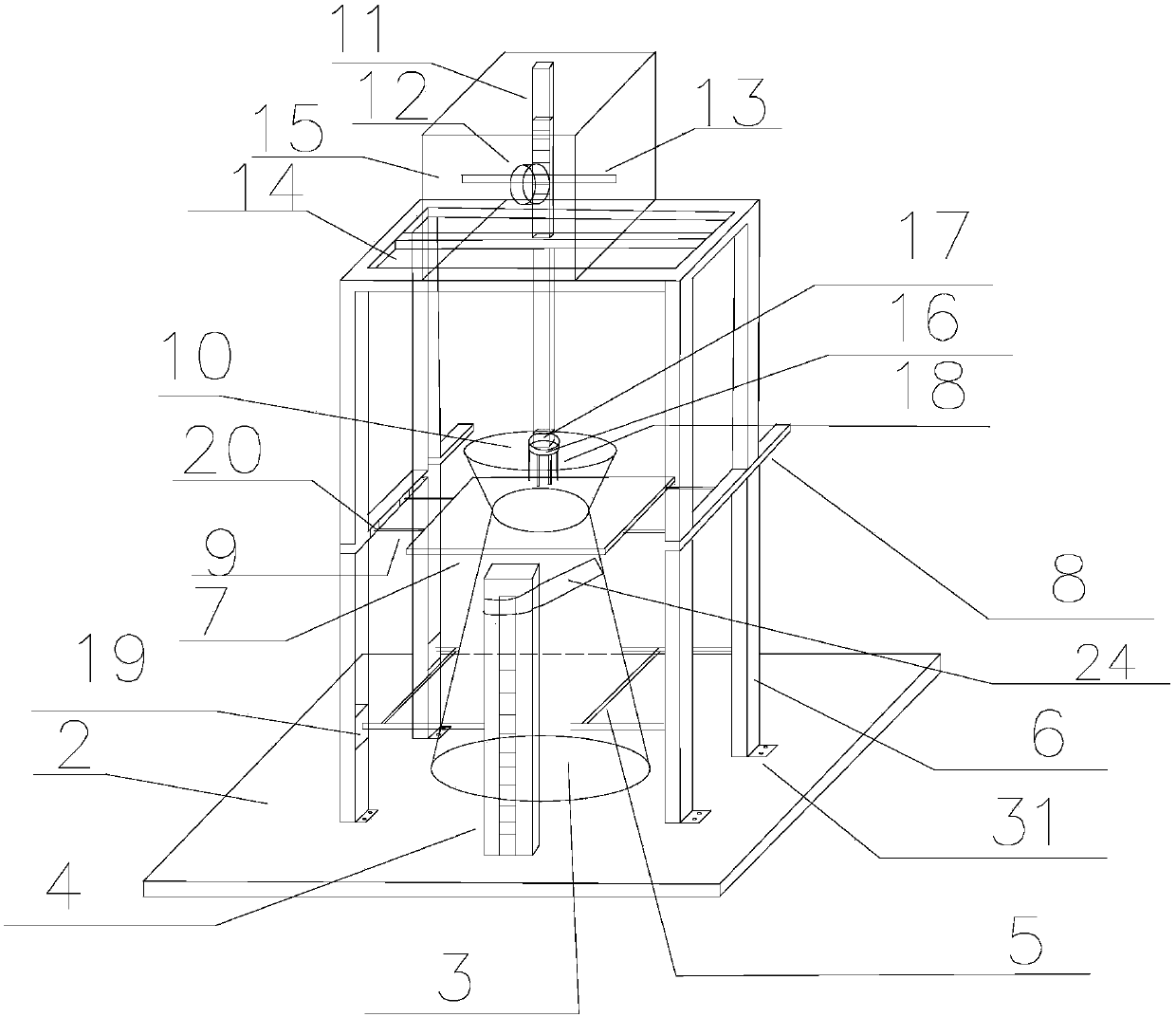

[0032] see figure 1 and figure 2 , the present invention includes an environmental chamber 1, a test device and a control panel 22. The test device includes a platform base 2, a slump cylinder 3, a material storage device (feeding device), an inserting and pounding device, a scraping device, a measuring device and a power device. The platform base 2 is fixedly connected with the bottom of the environmental box 1 .

[0033] The environmental box 1 is a temperature, humidity and wind speed curing box, which can set the temperature, humidity and wind speed at the same time. The working principle of the environmental box is to adjust the temperature and humidity inside the environmental box through the installed temperature and humidity controller to simulate different constructions. The temperature and humidity of the concrete on site. Specifically, a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com