Test system and method

A technology of testing system and testing method, which is applied in the direction of automatic testing system, electronic circuit testing, measuring electricity, etc., can solve the problems of inaccurate test results, waste of time, waste of manpower and material resources, etc., to improve test efficiency and reduce costs, The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

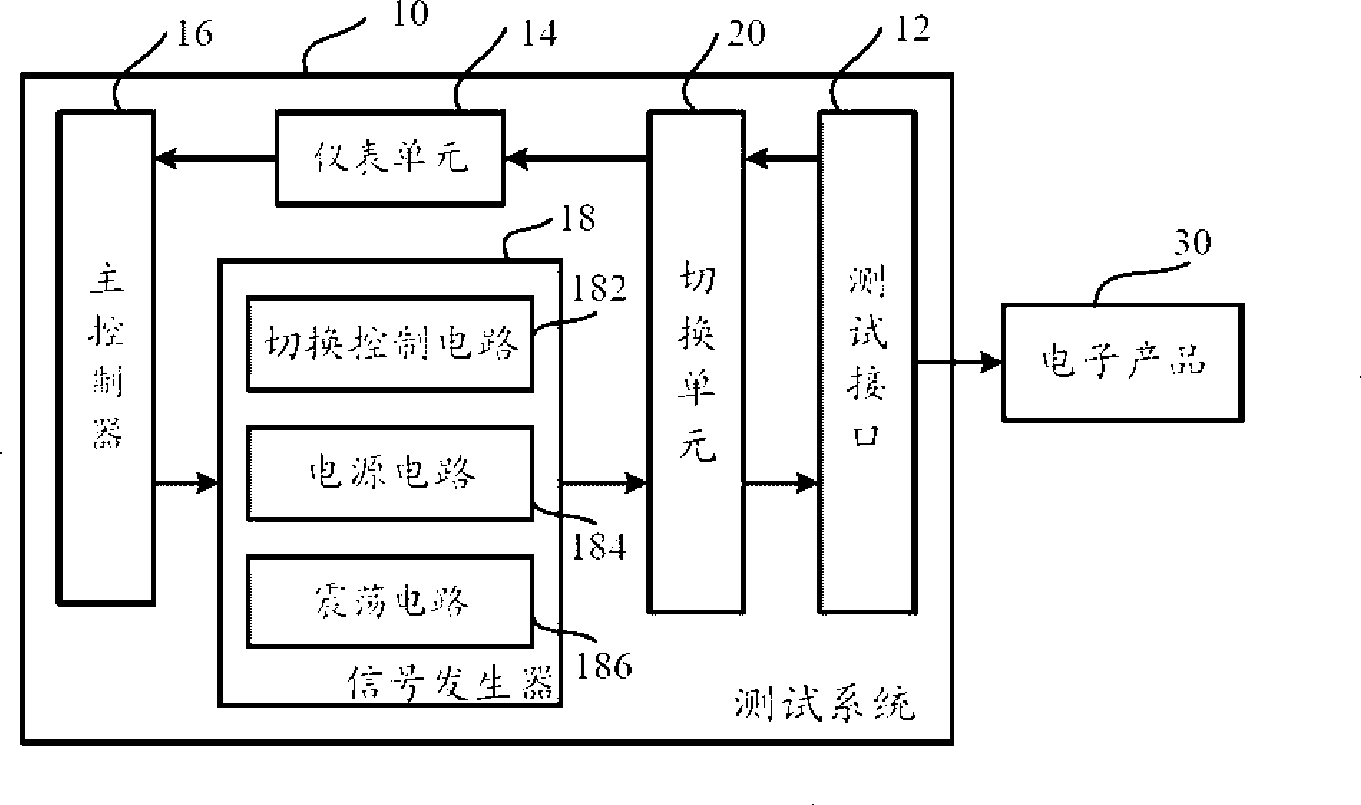

[0011] Such as figure 1 As shown, a test system 10 for testing an electronic product 30 includes a test interface 12 , an instrument unit 14 , a main controller 16 , a signal generator 18 and a switching unit 20 .

[0012] Test interface 12 is the input / output (Input / Output, I / O) interface of test system 10, and it comprises a plurality of test pins, is connected with the corresponding test point of electronic product 30 respectively, for example with the signal input port of electronic product 30 , the signal output port, the power port, and the ports of the components to be tested in the circuit board of the electronic product 30 are connected. Correspondingly, the above-mentioned multiple test pins can be divided into output test pins and input test pins. Wherein, one end of the output test pin is connected to the signal input port or the power supply end of the electronic product 30 , and the other end is connected to the signal generator 18 through the switching unit 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com