Method for extracting fracture toughness of materials

A fracture toughness and indenter technology, applied in the field of material mechanical properties characterization, can solve problems such as low efficiency, high critical test load, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

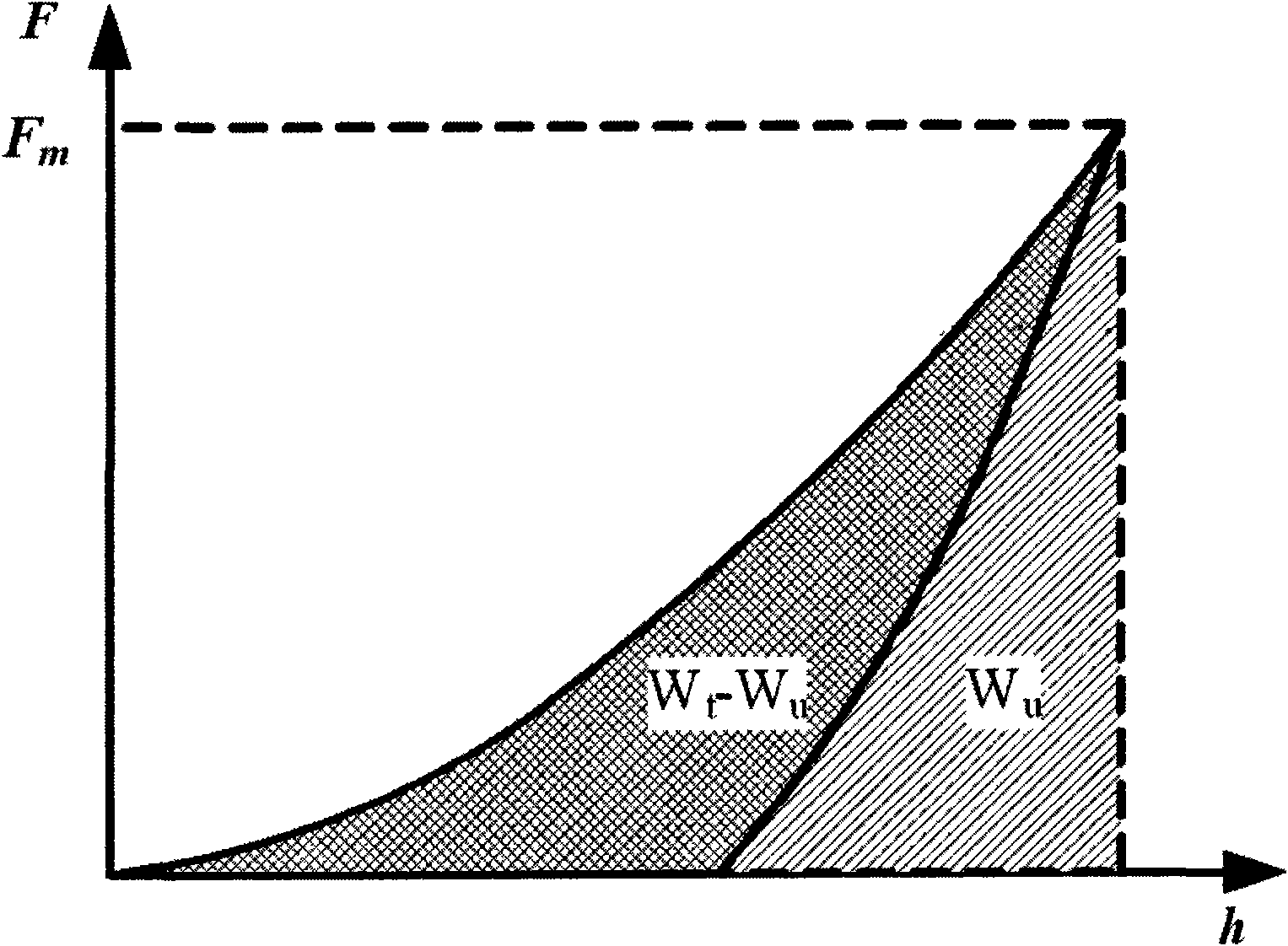

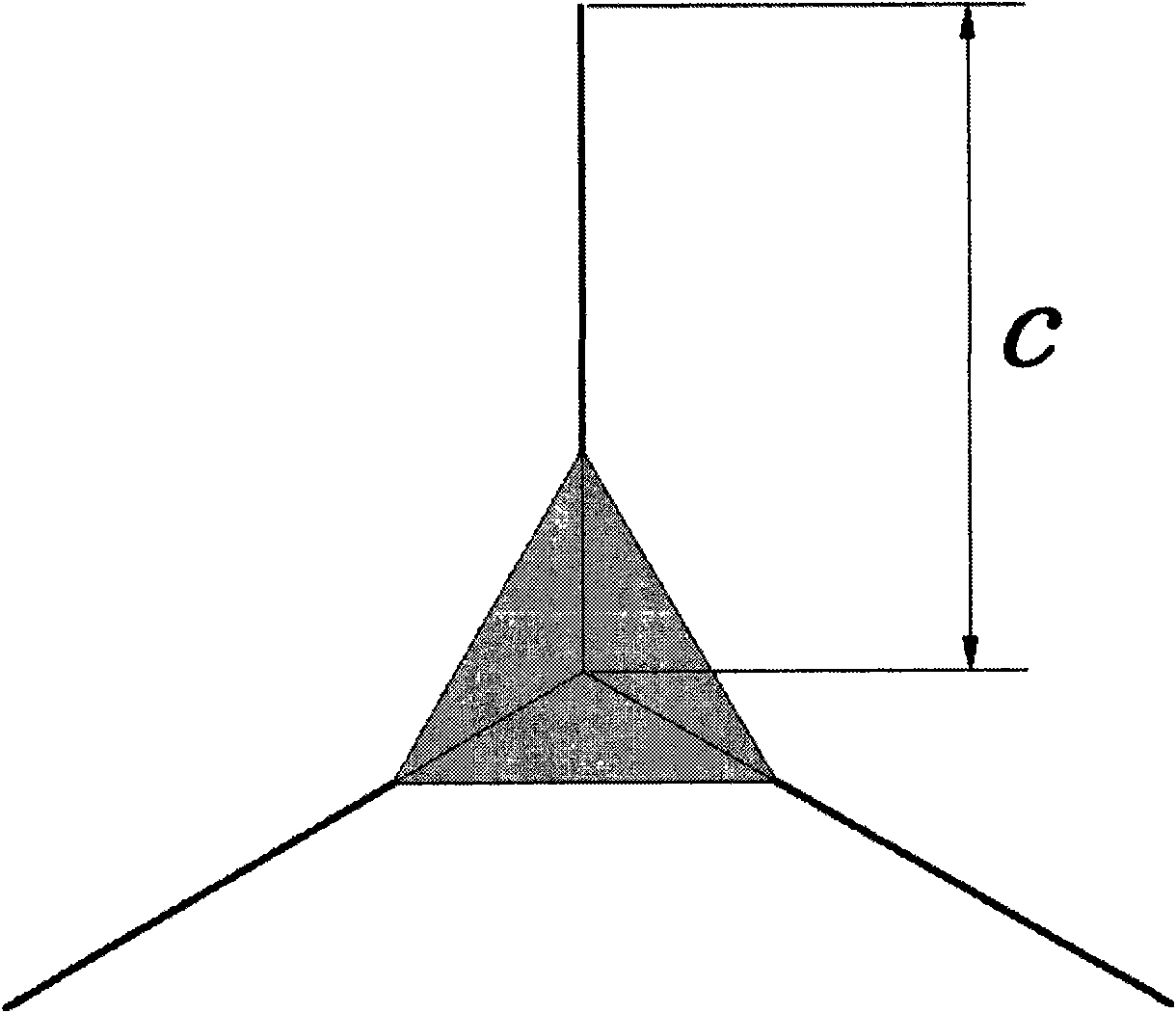

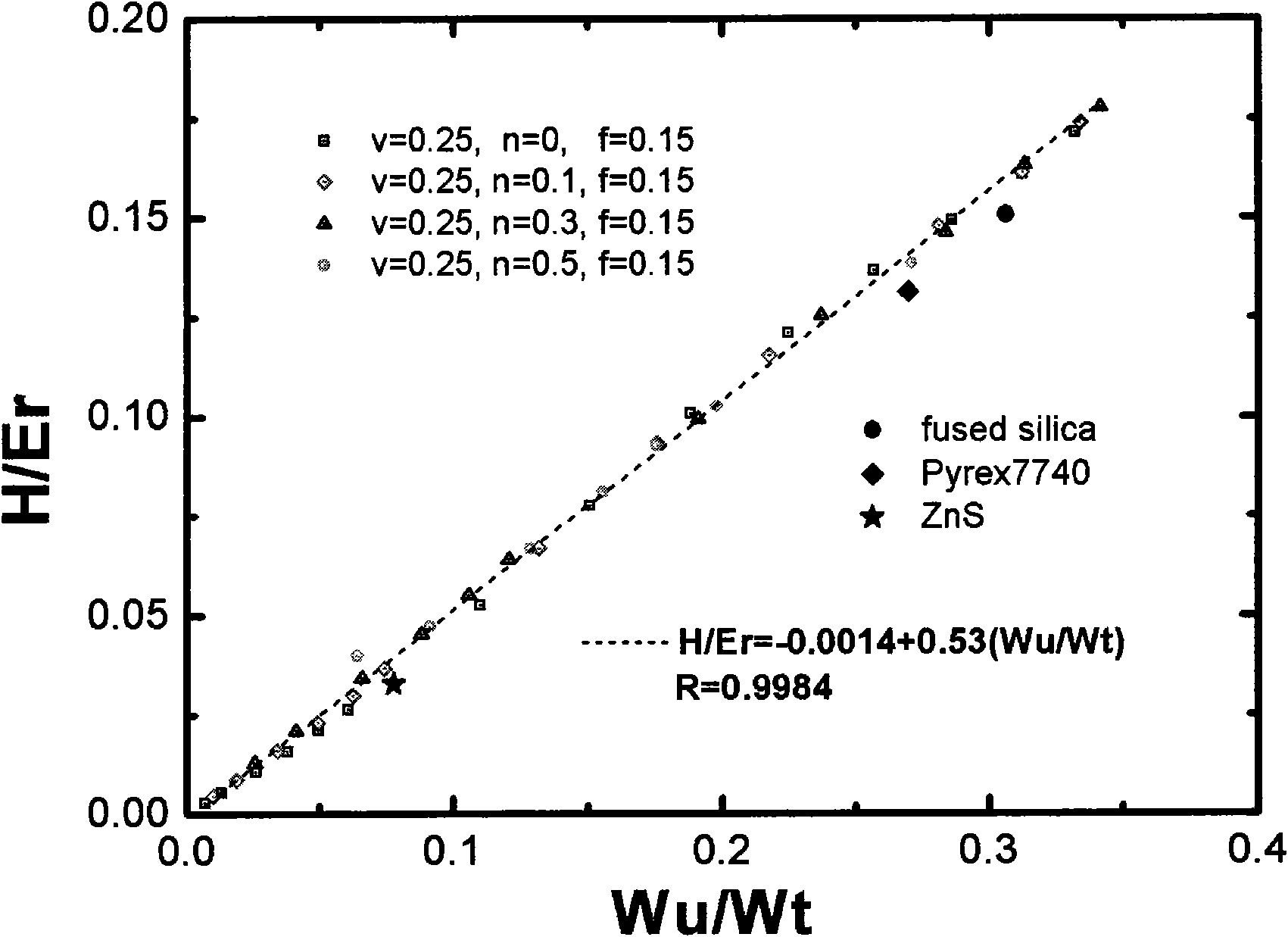

[0039] Such as figure 1 , 2 , shown in 3, 4: the pressure head that the test method that the present invention proposes adopts is cube-corner pressure head, and the analytical parameter that adopts is: unloading work W u , loading work W t , the maximum head load F m , Radial crack length c,. Due to the use of the cube-corner indenter, the low critical test load is realized; because only the cube-corner indenter is used, the simplicity of the test is realized; the analytical parameter W that is easier to measure accurately is adopted u , W t , which ensures the reliability of the method. First, an instrumented indentation device equipped with a cube-corner indenter is used to perform an indentation test on the material to be tested. For the operation of the indentation test and the problems that should be paid attention to, please refer to the relevant instrumented indentation test standards [7] .

[0040] It should be emphasized that, for the present invention, only w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com