Preparation method of high-flexible light W18O49 electrochromic film

An electrochromic and thin-film technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the limitations of electrochromic high-flexible devices, not having good bendability, and unfavorable flexible substrates Problems such as film formation, to achieve good optical properties, fast transition rate, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

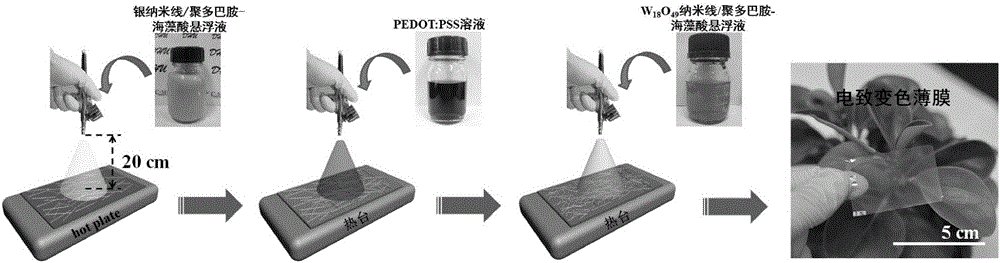

[0030] Add the polydopamine / alginic acid compound and the silver nanowire successively to a water-ethanol mixed solution with a volume fraction of 50% of water to prepare a spray solution A, wherein the concentration of the compound is 0.08 mg / ml, and the concentration of the silver nanowire is 0.65 mg / ml, mix commercially available PEDOT:PSS aqueous solution with absolute ethanol to obtain PEDOT:PSS dilution, wherein the volume fraction of commercially available PEDOT:PSS aqueous solution is 20%, polydopamine / alginic acid complex and W 18 o 49 The nanowires are successively added to a water-ethanol mixed solution with a volume fraction of 50% of water to configure a spray solution B, wherein the concentration of the compound is 0.025mg / ml, W 18 o 49 The nanowire concentration was 0.2 mg / ml. Place the PET film with a thickness of 0.15mm horizontally on a hot stage with a temperature of 50°C, then place the airbrush vertically at a height of 20cm from the PET film, and spray ...

Embodiment 2

[0032] Add the polydopamine / alginic acid compound and the silver nanowire successively to a water-ethanol mixed solution with a volume fraction of 70% of water to prepare a spray solution A, wherein the concentration of the compound is 0.08 mg / ml, and the concentration of the silver nanowire is 0.9 mg / ml, mix commercially available PEDOT:PSS aqueous solution with absolute ethanol to obtain PEDOT:PSS dilution, wherein the volume fraction of commercially available PEDOT:PSS aqueous solution is 10%, polydopamine / alginic acid complex and W 18 o 49 The nanowires are successively added to a water-ethanol mixed solution with a volume fraction of 50% of water to configure a spray solution B, wherein the concentration of the compound is 0.01mg / ml, W 18 o 49 The nanowire concentration was 0.3 mg / ml. Place the PET film with a thickness of 0.3mm horizontally on a hot stage with a temperature of 60°C, then place the airbrush vertically at a height of 30cm from the PET film, and spray the...

Embodiment 3

[0034] Add the polydopamine / alginic acid compound and the silver nanowire successively to a water-ethanol mixed solution with a volume fraction of 90% of water to prepare a spray solution A, wherein the concentration of the compound is 0.12 mg / ml, and the concentration of the silver nanowire is 0.65 mg / ml, mix commercially available PEDOT:PSS aqueous solution with absolute ethanol to obtain PEDOT:PSS dilution, wherein the volume fraction of commercially available PEDOT:PSS aqueous solution is 50%, polydopamine / alginic acid complex and W 18 o 49 The nanowires are successively added to a water-ethanol mixed solution with a volume fraction of 70% of water to configure a spray solution B, wherein the concentration of the compound is 0.05mg / ml, W 18 o 49 The nanowire concentration was 0.1 mg / ml. Place the PET film with a thickness of 0.5mm horizontally on a hot stage at a temperature of 70°C, then place the airbrush vertically at a height of 20cm from the PET film, and spray the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com