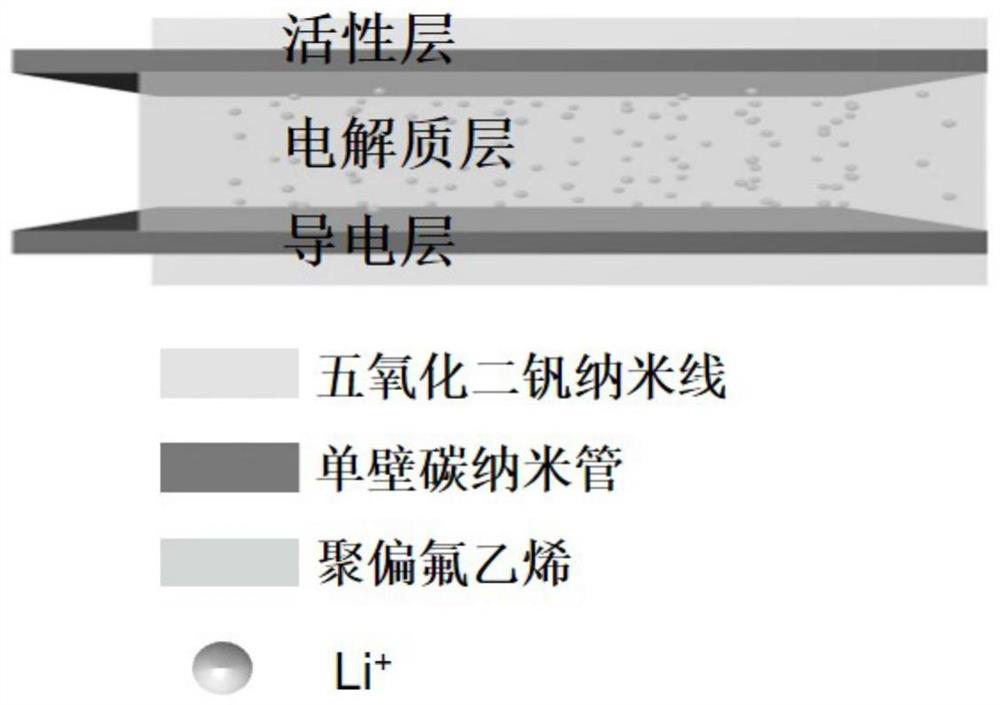

Electrochemical driving type color-changing deformation double-response actuator and preparation method thereof

A driven, double-response technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of limited actuator application, single deformation, etc., and achieve fast transition rate, good flexibility, and good optics performance and effect on actuation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

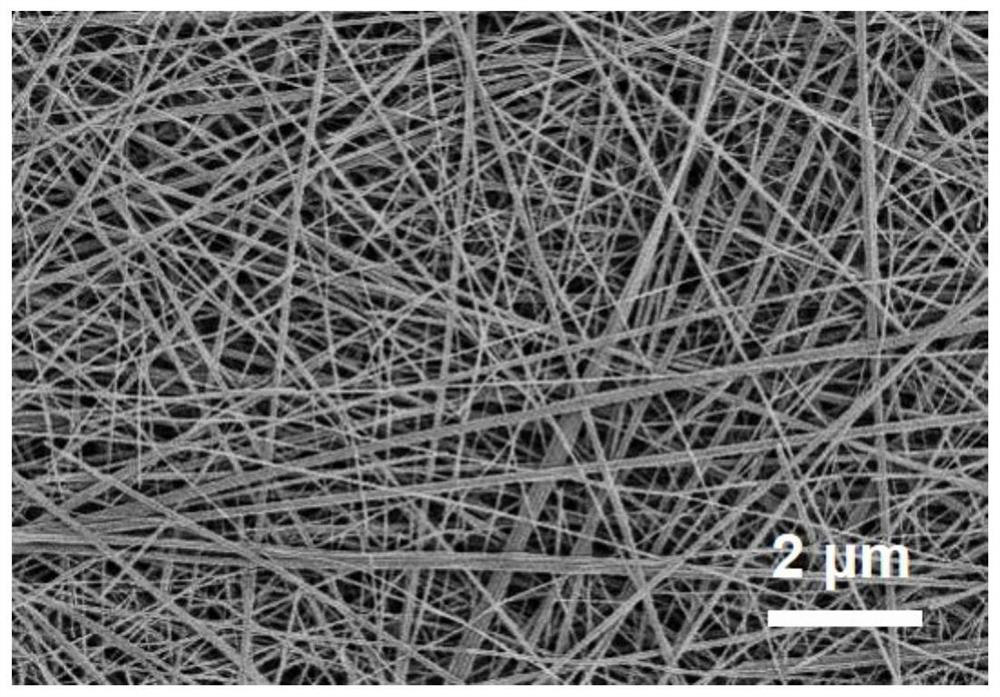

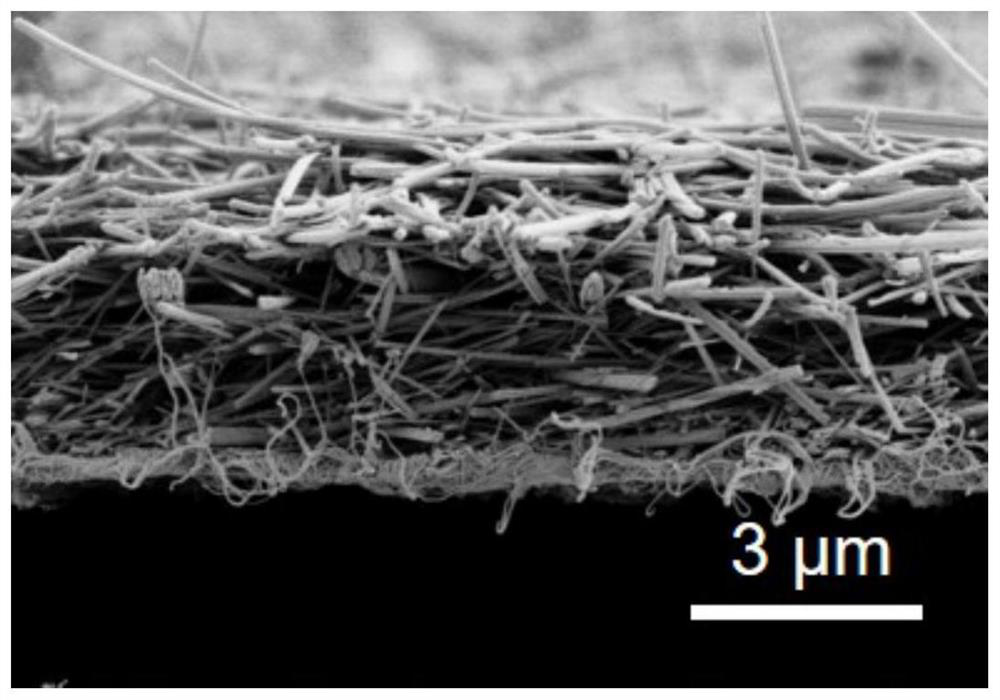

[0033] Add single-walled carbon nanotubes into water, ultrasonically disperse for 2 hours, and configure a single-walled carbon nanotube dispersion. The concentration of the single-walled carbon nanotube dispersion is 0.15mg / ml. Ultrasonic disperse for 2 minutes, configure a vanadium pentoxide nanowire dispersion with a length of about 3 μm, and a concentration of 1 mg / ml; use 2 ml of a single-walled carbon nanotube dispersion with a concentration of 0.15 mg / ml, and filter it to the area 10cm 2 On the polyvinylidene fluoride film, then peeled off to obtain a conductive layer, then the vanadium pentoxide nanowire dispersion liquid with a concentration of 1mg / ml, the dosage is 3ml, suction-filtered onto the conductive layer, and the film obtained by suction filtration was in Heated on a hot stage at 30°C to obtain a deformed and color-changing double-layer network structure film; finally, the deformed and color-changing double-layer network structure film was bonded by a polyvin...

Embodiment 2

[0036] Add single-walled carbon nanotubes into water, ultrasonically disperse for 2 hours, and configure a single-walled carbon nanotube dispersion. The concentration of single-walled carbon nanotubes is 0.15mg / ml. 2min, prepare the vanadium pentoxide nanowire dispersion with a length of about 3μm, the concentration is 1.5mg / ml; the single-walled carbon nanotube dispersion with a concentration of 0.15mg / ml, the dosage is 2ml, and the area is 10cm 2 on the polyvinylidene fluoride film, then peeled off to obtain the conductive layer, then the vanadium pentoxide nanowire dispersion with a concentration of 1.5mg / ml, the dosage is 3ml, suction filtered onto the conductive layer, and the film obtained by the suction filtration was Heated on a hot stage at 30°C to obtain a double-response film; finally, the double-response film was bonded by a polyvinylidene fluoride gel electrolyte containing 1mol / L lithium salt. The thickness of the gel electrolyte was 2 μm, and the obtained thickne...

Embodiment 3

[0038] Add single-walled carbon nanotubes into water, ultrasonically disperse for 2 hours, and configure a single-walled carbon nanotube dispersion. The concentration of single-walled carbon nanotubes is 0.5mg / ml. 2min, prepare a dispersion of vanadium pentoxide nanowires with a length of about 3μm, and a concentration of 1mg / ml; use 5ml of a single-walled carbon nanotube dispersion with a concentration of 0.5mg / ml, and filter it to an area of 30cm 2 on the polyvinylidene fluoride film, then peeled off to obtain the conductive layer, then the vanadium pentoxide nanowire dispersion liquid with a concentration of 1mg / ml, the consumption is 3ml, suction filtered onto the conductive layer, and the film obtained by the suction filtration was obtained at 30 Heating on a hot stage at ℃ to obtain a deformed and color-changing double-layer network structure film; finally, the deformed and color-changing double-layer network structure film is bonded by a polyvinylidene fluoride gel ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com