A kind of preparation method of electrochromic smart fiber

An electrochromic and fiber technology, used in cable/conductor manufacturing, circuits, electrolytic coatings, etc., can solve the problems of unable to intelligently change color, limit fiber application, etc., achieve good electrochromic performance, fast conversion rate, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

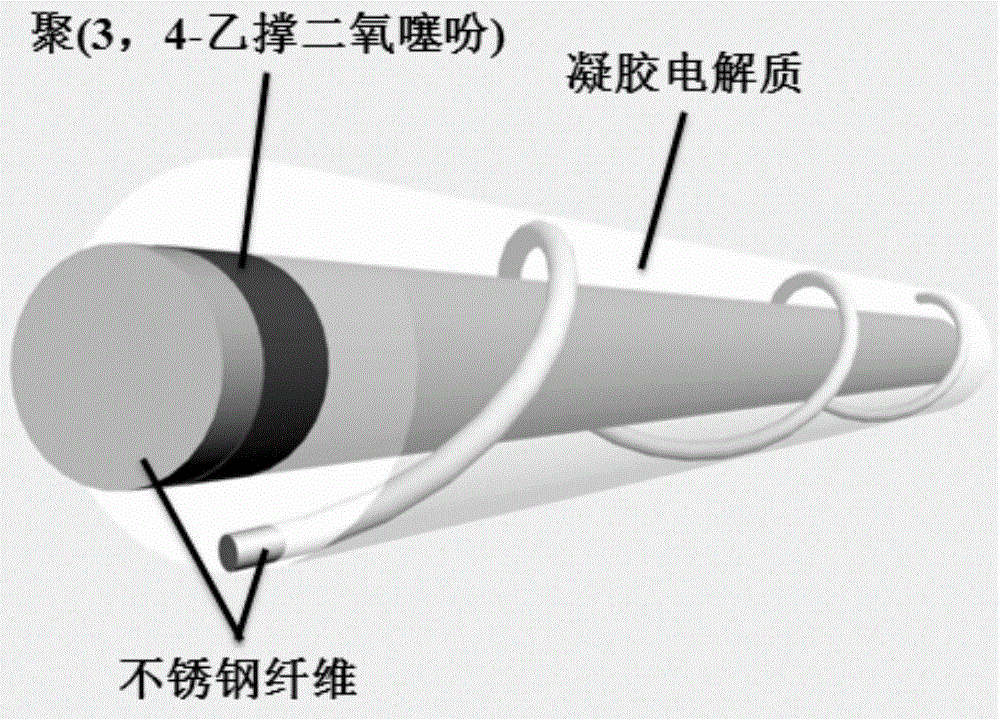

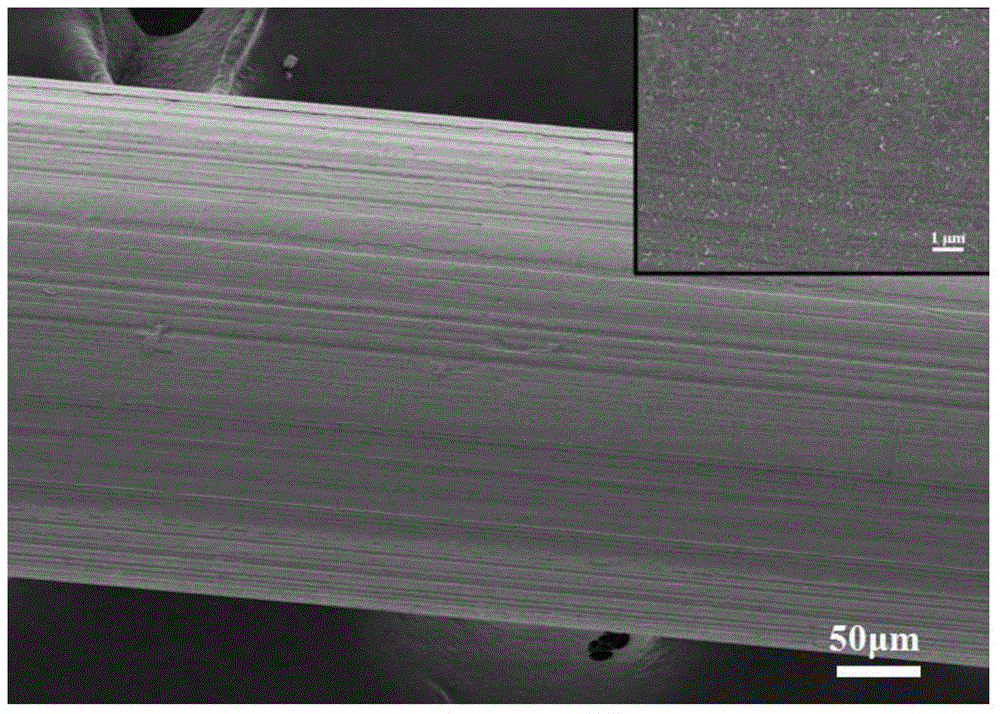

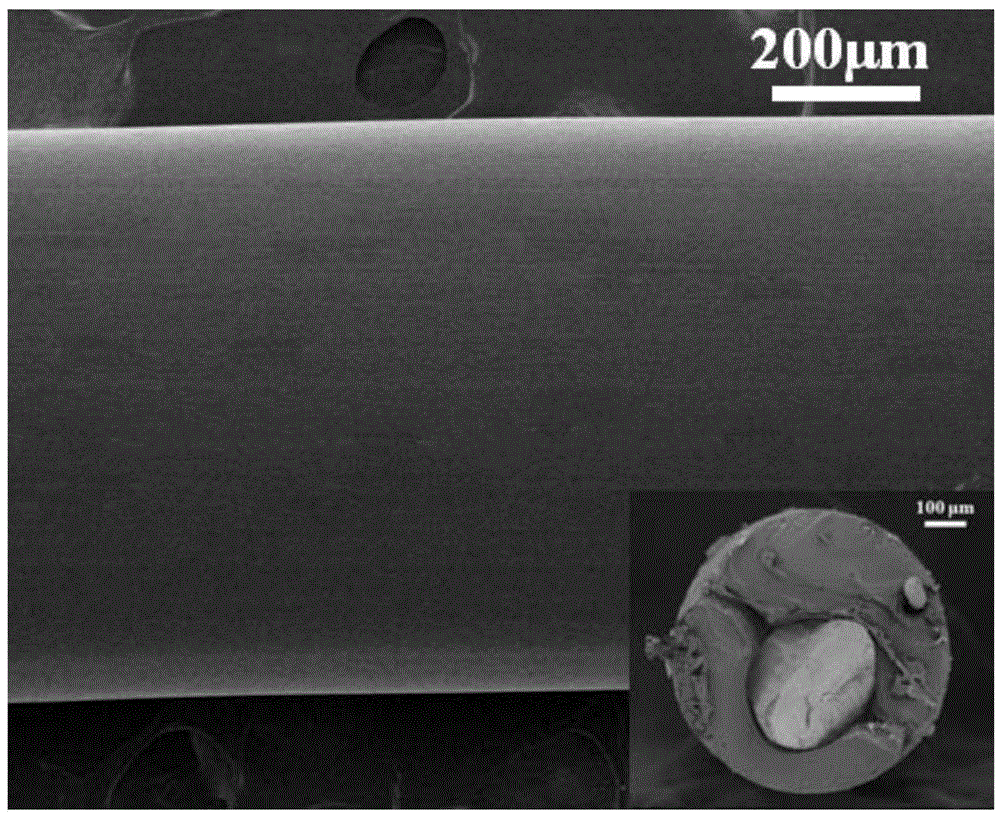

Embodiment 1

[0030] The stainless steel fibers were sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 30 minutes, and dried for later use. Dissolve 0.850mL of 3,4-ethylenedioxythiophene monomer in 200mL of 0.1mol / L lithium perchlorate propylene carbonate solution to obtain a deposition solution, and put 0.3mm stainless steel fiber vertically into the deposition solution as a working electrode , with the platinum sheet as the counter electrode and Ag / AgCl as the reference electrode, under the conditions of constant voltage 1.3V and deposition time 8s, the stainless steel fiber with poly(3,4-ethylenedioxythiophene) deposited on the surface was obtained, and the obtained The stainless steel fiber deposited with poly(3,4-ethylenedioxythiophene) was dried under vacuum at 50° C. for 3 h. Lithium perchlorate, PMMA, propylene carbonate, and acetone were mixed at mass fractions of 3.70%, 11.5%, 42.4%, and 42.4%, respectively, and stirred to form a gel electro...

Embodiment 2

[0032] The stainless steel fibers were sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 20 minutes respectively, and dried for later use. Dissolve 0.425mL of 3,4-ethylenedioxythiophene monomer in 200mL of 0.2mol / L lithium perchlorate propylene carbonate solution to obtain a deposition solution, and place a 0.1mm stainless steel fiber vertically into the deposition solution as a working electrode , with the platinum sheet as the counter electrode and Ag / AgCl as the reference electrode, under the conditions of constant voltage 1.4V and deposition time 6s, the stainless steel fiber with poly(3,4-ethylenedioxythiophene) deposited on the surface was obtained, and the obtained The stainless steel fiber deposited with poly(3,4-ethylenedioxythiophene) was dried at 70° C. for 0.5 h under vacuum condition. Lithium perchlorate, PMMA, propylene carbonate, and acetone were mixed according to the mass fraction of 2%, 13%, 40%, and 45%, respectively, ...

Embodiment 3

[0034]The stainless steel fibers were sequentially immersed in deionized water, acetone and ethanol for ultrasonic cleaning for 30 minutes, and dried for later use. Dissolve 0.850mL of 3,4-ethylenedioxythiophene monomer in 200mL of 0.3mol / L lithium perchlorate propylene carbonate solution to obtain a deposition solution, and put 0.3mm stainless steel fiber vertically into the deposition solution as a working electrode , with the platinum sheet as the counter electrode and Ag / AgCl as the reference electrode, under the conditions of constant voltage 1.3V and deposition time 15s, the stainless steel fiber with poly(3,4-ethylenedioxythiophene) deposited on the surface was obtained, and the obtained The stainless steel fiber deposited with poly(3,4-ethylenedioxythiophene) was dried at 30° C. for 4 h under vacuum condition. Lithium perchlorate, PMMA, propylene carbonate, and acetone were mixed according to the mass fraction of 5%, 10%, 45%, and 40%, respectively, and stirred to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com