Method for preparing perovskite solar cell based on one-step spraying process

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as inability to large-scale continuous production, and achieve the effects of efficient and stable conversion efficiency, simple process, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

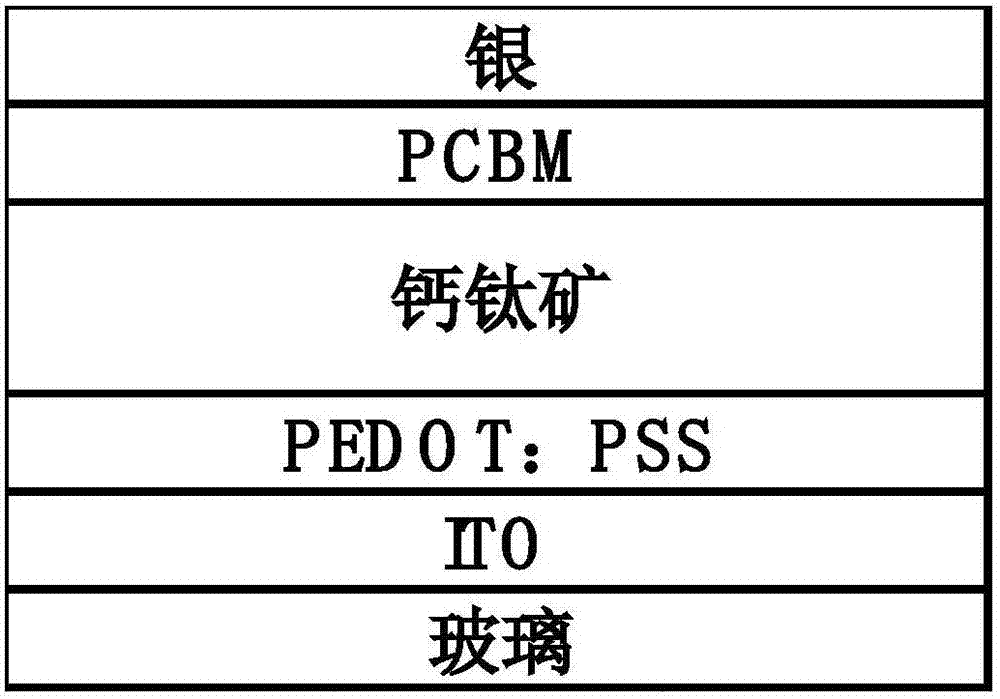

[0026] The patterned ITO conductive glass substrate with a square resistance of 15Ω was ultrasonically cleaned with deionized water, absolute ethanol, acetone, and isopropanol in sequence, and heated and dried to remove residual solvent. UV ozone treatment for 10 minutes to remove small organic molecules remaining on the surface of the conductive glass.

[0027] The PEDOT:PSS solution with a concentration of 13 g / L was filtered with a water-based PVDF filter membrane, and 40 μl of the solution was coated on a treated transparent ITO conductive glass substrate of 20 mm×15 mm at a speed of 5000 rpm. The coated substrate was heat-treated at 135° C. for 20 minutes, and the excess part was wiped off with a cotton swab to obtain a PEDOT:PSS film as a hole transport layer.

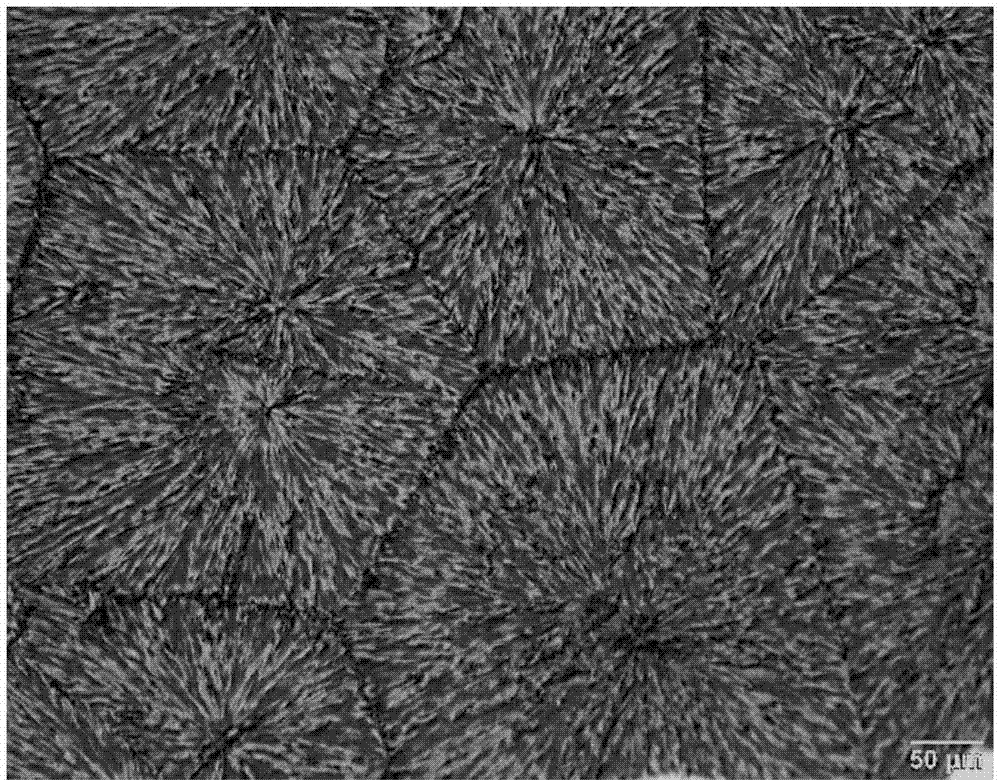

[0028] Lead iodide and potassium iodide ammonium are formulated into a perovskite precursor solution with a concentration of 400mg / ml according to a molar ratio of 1:1, and the solvent is dimethyl sulfoxide and g...

Embodiment 2-5

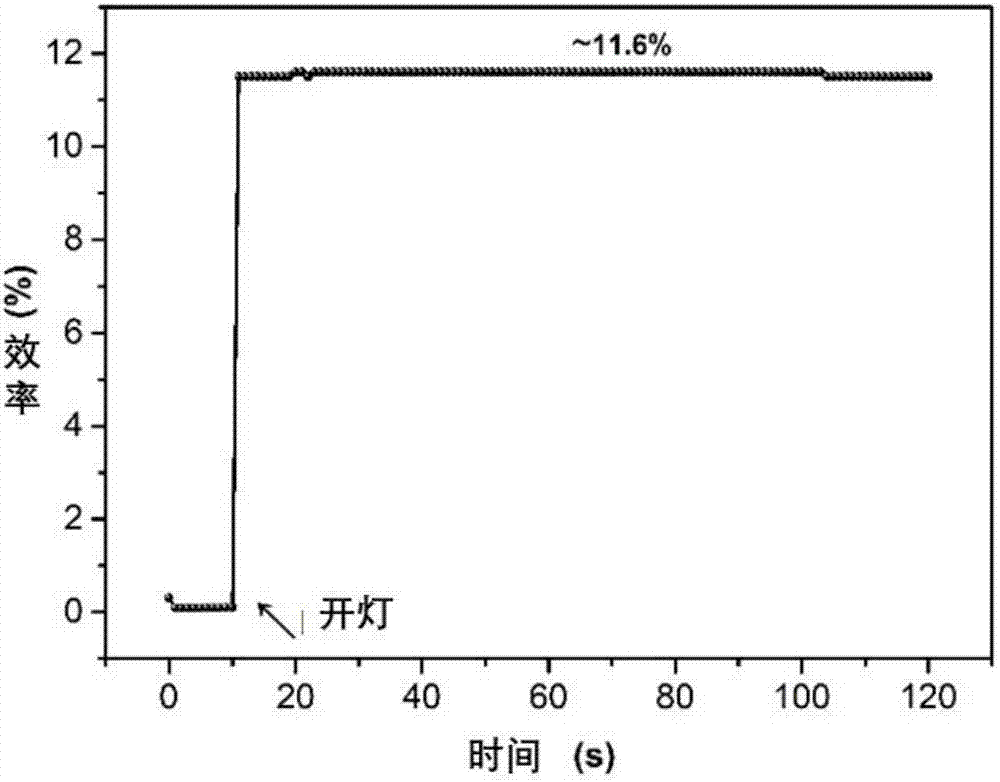

[0037] The cleaning of the ITO substrate and the hole transport layer, the electron transport layer, the preparation method of the silver electrode, the spraying parameters and the heat treatment method, the addition content of the anti-solvent isopropanol is consistent with that in Example 1, and the content ratio of GBL and DMSO is changed, The device effect of obtaining the solar cell is as follows:

[0038] Table 3 Embodiment 2-5 solar cell device performance

[0039]

Embodiment 6-7

[0041] The cleaning of the ITO substrate and the hole transport layer, the electron transport layer, the preparation method of the silver electrode, the spraying parameters and the heat treatment method, the content ratio of GBL and DMSO are consistent with those in Example 1, and the addition of isopropanol is changed to obtain solar energy. The device effect of the battery is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com