A method for realizing fully automatic continuous preparation of microspheres

A fully automatic, microsphere technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of inability to realize continuous automatic batch production, long-term continuous and stable work, and influence, and achieve continuous microsphere The effect of stable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

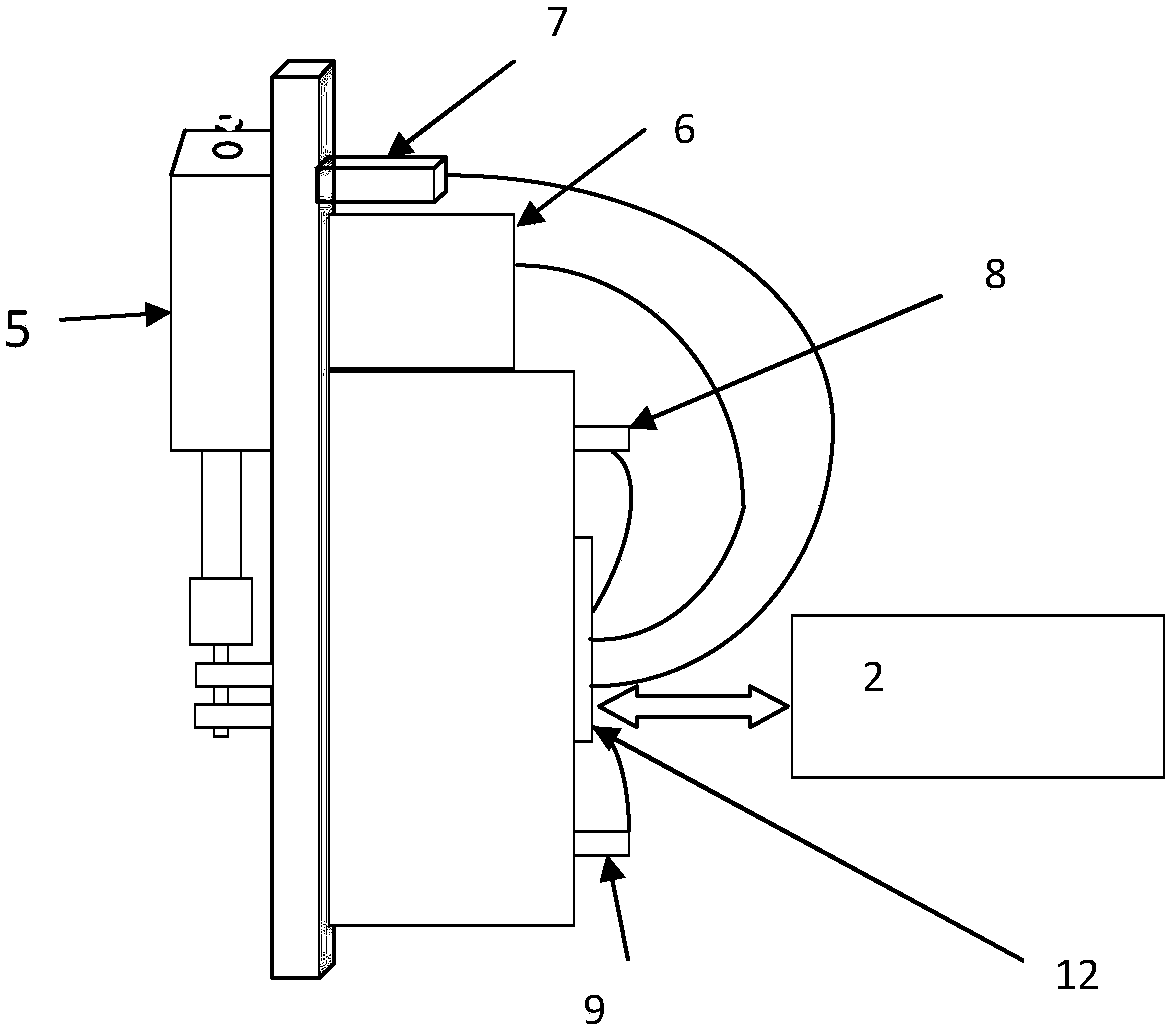

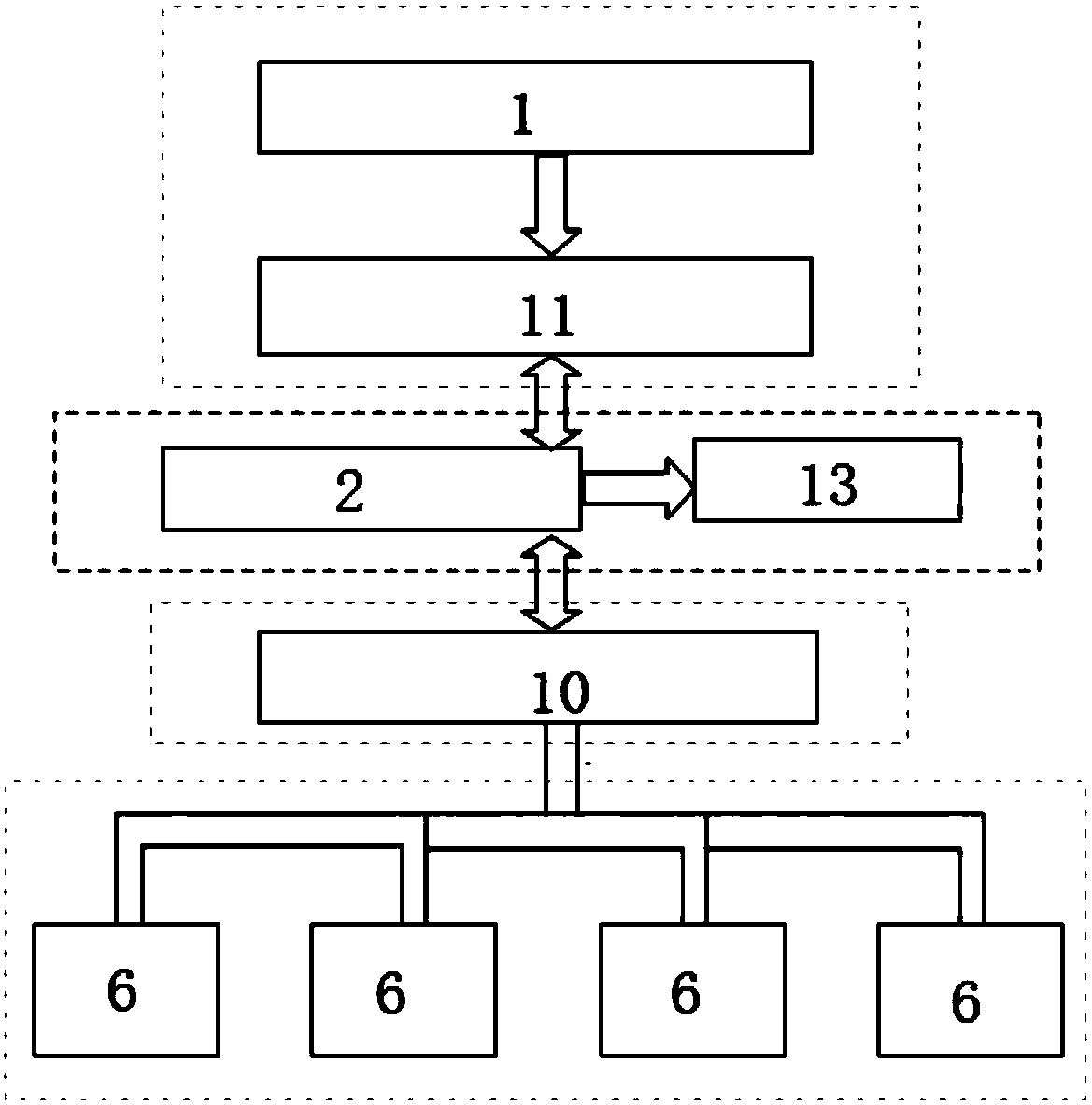

[0042] A method for realizing fully automatic continuous preparation of microspheres, the specific steps comprising:

[0043] (1) perfusing the sample so that the sample is continuous: the sample includes a dispersed phase and a continuous phase;

[0044] a. Real-time detection of whether the sample reaches the upper limit, if reached, stop perfusing the sample, and enter step b, otherwise, continue perfusing the sample, and perform step a;

[0045] b. Real-time detection of whether the sample reaches the lower limit, if reached, start to perfuse the sample, and return to step a, otherwise, continue to step b;

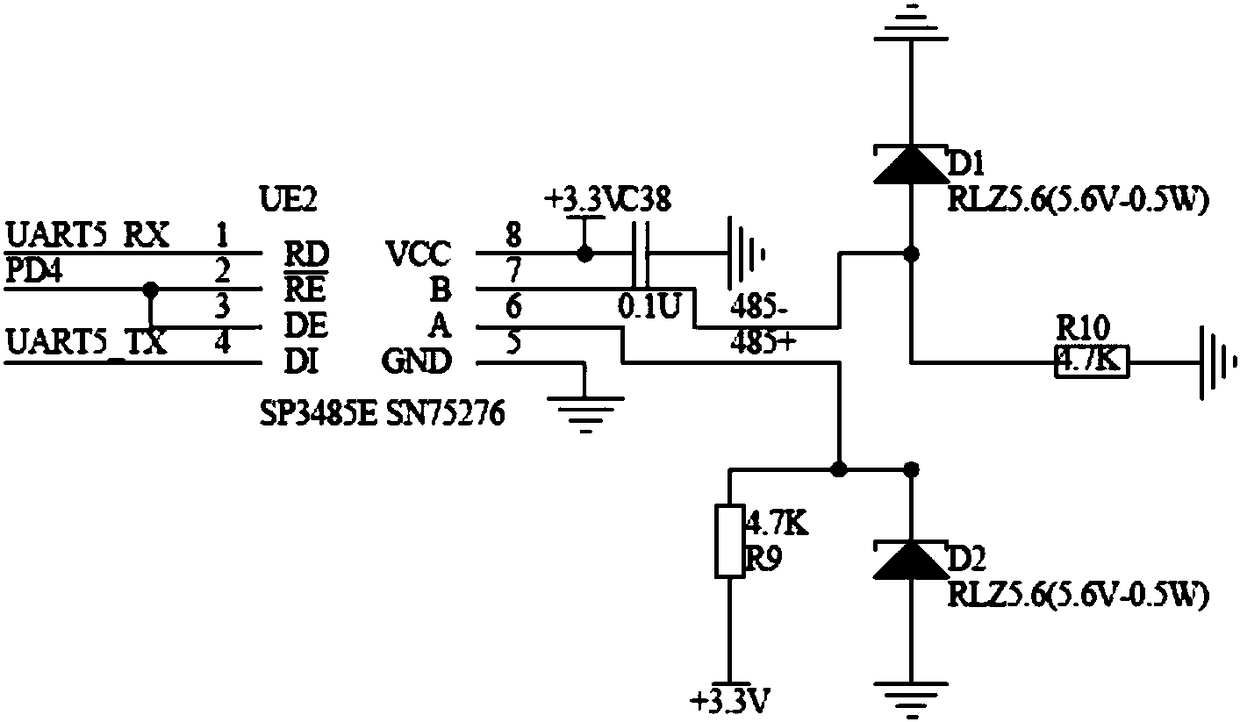

[0046] (2) The sample is passed into the microfluidic chip, and the sample entering the microchannel is precisely controlled to realize the generation, transportation, and merging of droplets. After the droplets are generated, they are solidified in situ to form microspheres. Such as Figure 5 shown.

[0047]The above-mentioned fully automatic and continuous microsp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com