Low-density building foaming glass and preparation method thereof

A foam glass, low-density technology, applied in the field of material processing, can solve the problems of low SiO2 content, influence on the overall performance of the finished product, and high ordinary glass, and achieve the effects of easy large-scale industrial production, high product quality, and uniform cell distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

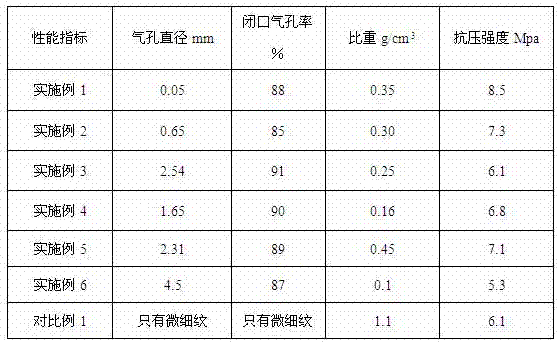

Examples

Embodiment 1

[0033] (1) Weigh 10 parts by weight of soda-lime glass powder with a particle size of 10.0 μm, made of quartz glass, borosilicate glass, tempered glass, amorphous alumina glass hollow glass microspheres 89 parts; hollow glass microspheres The outer diameter is 1.5mm, the pore size is 30μm, 1 part of silicone rubber binder, 0.5 parts of titanium nickel yellow and copper chrome black mixed colorant, after the raw materials are prepared, first mix glass powder and silicone rubber binder, and then add The coloring agent and glass microspheres ensure that the surface of the interface between the glass powder and the glass microspheres is evenly covered with the coloring agent and are mixed and stirred evenly to obtain a mixed powder.

[0034] (2) Put the mixed powder into a mold, put it into a high-temperature furnace at 700°C, heat it, and keep it warm for 0.8 hours. After the glass powder is melted, the microspheres are bonded together to form a glass skeleton, and continue to hea...

Embodiment 2

[0037] (1) Weigh 30 parts by weight of high-white glass powder with a particle size of 1.0 μm, made of quartz glass, borosilicate glass, tempered glass, amorphous alumina glass and 70 parts of hollow glass microspheres; hollow glass microspheres The outer diameter of the glass is 0.5 mm, the pore size is 100 μm, and 1 part of silicone rubber binder. After the raw materials are prepared, glass microspheres are added to the glass powder, and the mixed powder is obtained after mixing and stirring evenly.

[0038] (2) Put the mixed powder into a mold, put it into a high-temperature furnace at 850°C for heating, and keep it warm for 1 hour. After the glass powder is melted, the microspheres are bonded together to form a glass skeleton, and continue to heat the glass skeleton microspheres The bonding part forms a porous structure, and the cooling rate is controlled at 2°C / min to ensure that the gas in the glass forms enough holes to avoid the collapse of the holes during the cooling ...

Embodiment 3

[0041](1) Weigh 15 parts of a mixture of high-white glass powder and soda-lime glass powder with a particle size of 5.0 μm in parts by weight, made of quartz glass, borosilicate glass, tempered glass, and amorphous alumina glass hollow glass microspheres 83 parts; the outer diameter of hollow glass microspheres is 1.0 mm, the pore size is 400 μm, 2 parts of silicone rubber binder, 0.2 parts of cobalt green colorant, after preparing the raw materials, first mix glass powder and silicone rubber binder, and then add The coloring agent and glass microspheres ensure that the surface of the interface between the glass powder and the glass microspheres is evenly covered with the coloring agent and are mixed and stirred evenly to obtain a mixed powder.

[0042] (2) Put the mixed powder into a mold, put it into a high-temperature furnace at 750°C, heat it, and keep it warm for 0.6 hours. After the glass powder melts, the microspheres are bonded together to form a glass skeleton, and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com