Method of preparing olefins from synthetic gas

A technology for synthesis gas and olefins, which is applied in the production of hydrocarbons from carbon oxides, ethylene production, and bulk chemical production. It can solve the problems of large investment, long olefin route, and large consumption of manpower and material resources, so as to increase economic benefits and optimize production efficiency. Technical effect, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

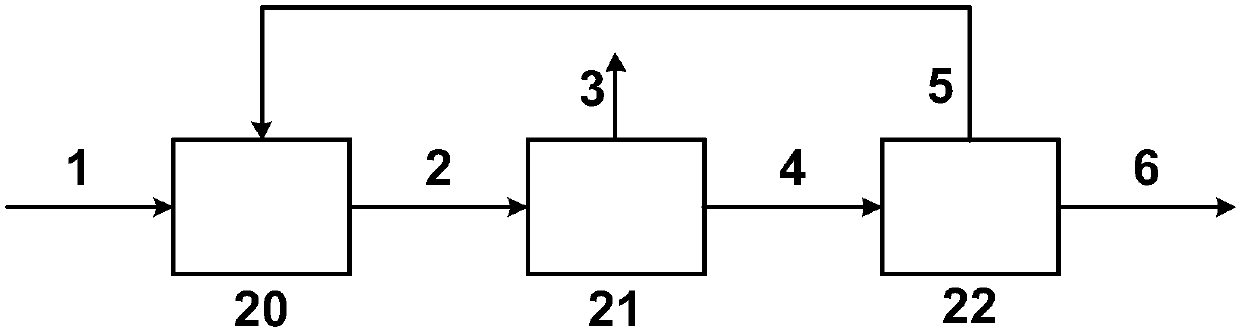

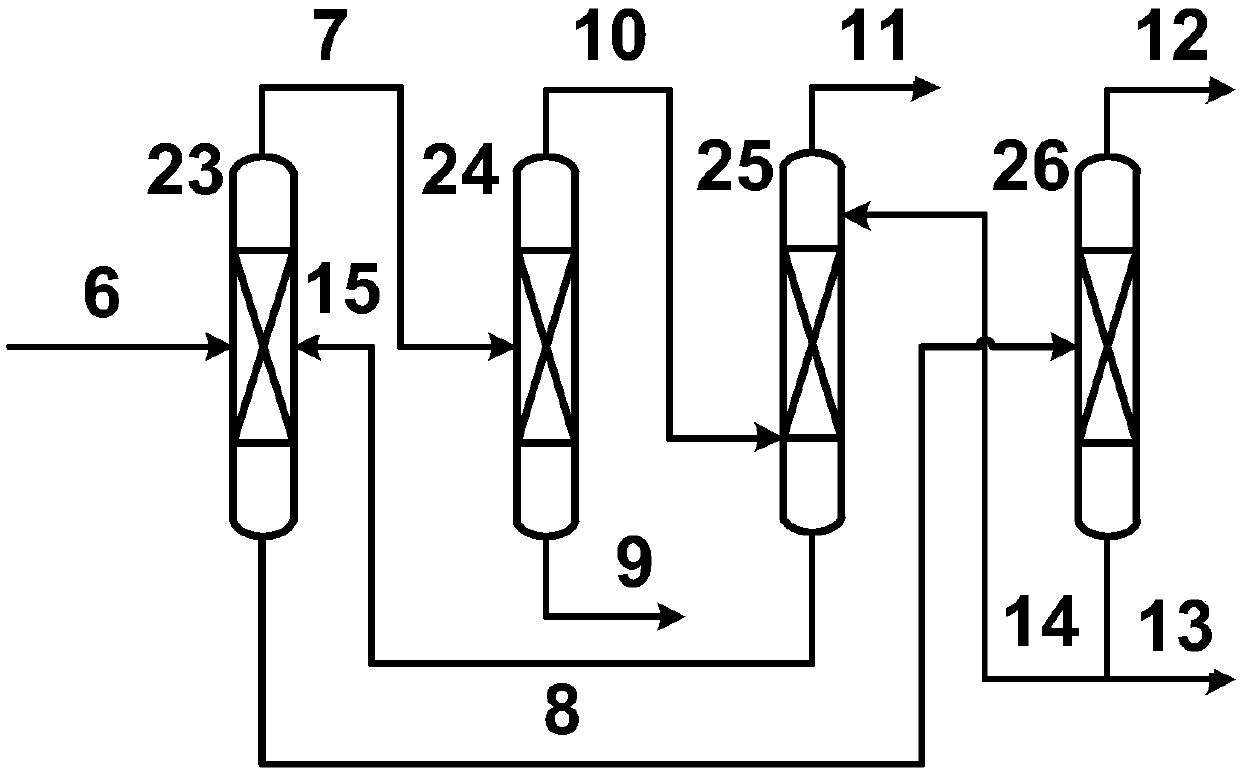

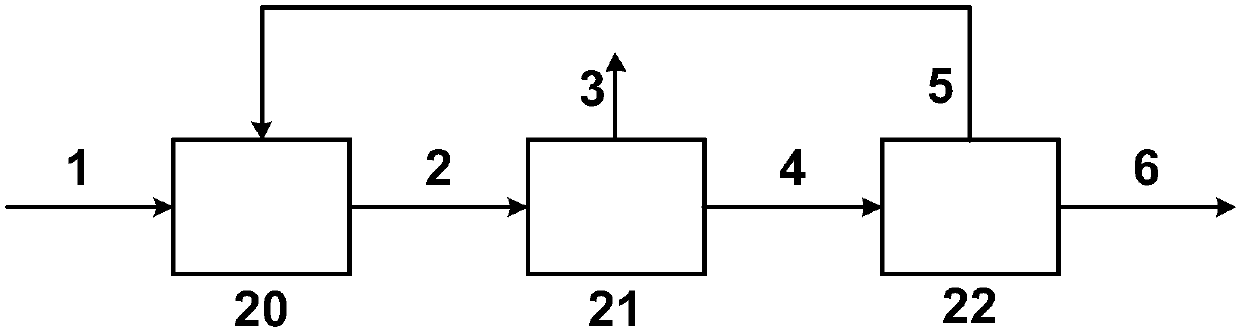

Method used

Image

Examples

Embodiment 1

[0057] The molecular sieve in the catalyst system used in the reaction zone is SAPO molecular sieve; the product stream obtained in the reaction zone contains: 25.00% carbon dioxide, 3.40% hydrogen, 46.40% carbon monoxide, 15.70% mixed hydrocarbons, which are sent to the decarburization zone, which uses methyl Diethanolamine is used as an absorbent, the dehydrogenation zone adopts the PSA separation method, and the recycle stream is all recycled back to the reaction zone. The diene (ethylene and propylene) in the product logistics of this technical solution increases by 5.50‰ compared with the existing coal chemical technology, the material consumption decreases by 2.90% compared with the existing coal chemical technology, the energy consumption decreases by 21.26% compared with the existing coal chemical technology, and the waste water output is lower than the existing coal chemical technology. The existing coal chemical technology will reduce 1.004 million tons / year, and the ...

Embodiment 2

[0059] The molecular sieve in the catalyst system used in the reaction zone is 80% SAPO molecular sieve and 20% AlPO 4 Molecular sieve; the product stream obtained in the reaction zone contains: 25.00% carbon dioxide, 3.39% hydrogen, 46.39% carbon monoxide, 15.72% mixed hydrocarbons, sent to the decarburization zone, the decarburization zone uses methyldiethanolamine as the absorbent, and the dehydrogenation zone uses In the PSA separation method, all the recycle streams are recycled back to the reaction zone. The diene (ethylene and propylene) in the product logistics of this technical solution increases by 9.63‰ compared with the existing coal chemical technology, the material consumption is reduced by 2.92% compared with the existing coal chemical technology, the energy consumption is reduced by 21.27% compared with the existing coal chemical technology, and the waste water output is lower than the existing coal chemical technology. The existing coal chemical technology wil...

Embodiment 3

[0061] The molecular sieve in the catalyst system used in the reaction zone is 50% SAPO molecular sieve and 50% AlPO 4 Molecular sieve; the product stream obtained in the reaction zone contains: 25.00% carbon dioxide, 3.38% hydrogen, 46.38% carbon monoxide, and 15.74% mixed hydrocarbons, which are sent to the decarburization zone. The decarburization zone uses methyldiethanolamine as an absorbent, and the dehydrogenation zone uses In the PSA separation method, all the recycle streams are recycled back to the reaction zone. The dienes (ethylene and propylene) in the product logistics of this technical solution increase by 9.63‰ compared with the existing coal chemical technology, the material consumption is 2.94% lower than the existing coal chemical technology, the energy consumption is 21.28% lower than the existing coal chemical technology, and the waste water output is lower than the existing coal chemical technology. The existing coal chemical technology will reduce 1.004 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com