Preparation method of hydraulic suspension main spring rubber

A hydraulic mount and rubber technology, applied in the direction of organic chemistry, etc., can solve problems such as easy cracking and poor aging resistance of main spring rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

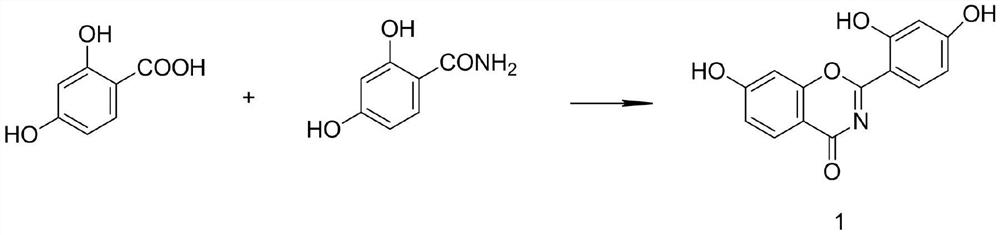

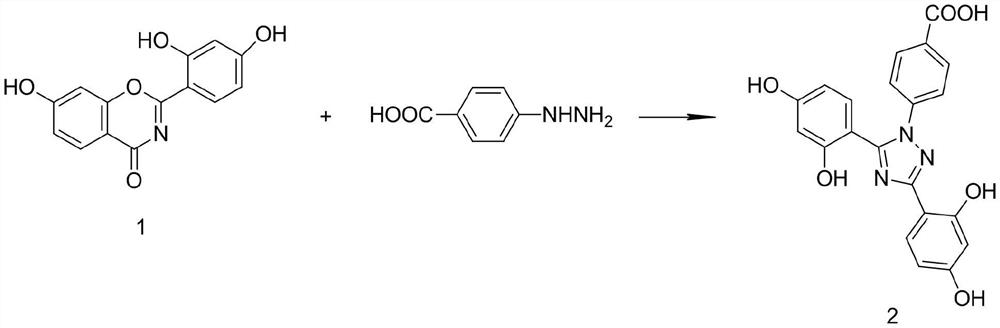

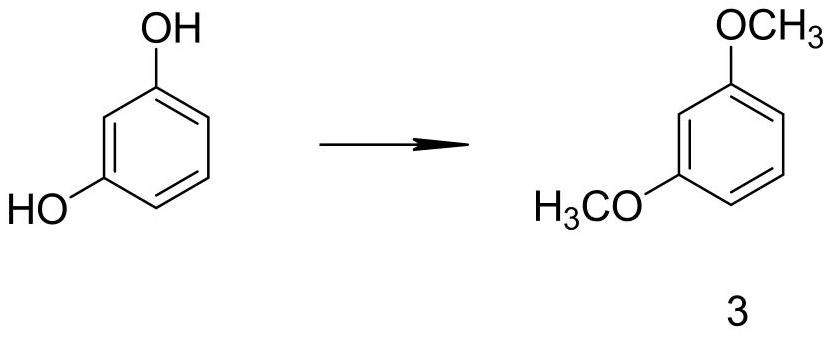

[0054] The UV absorber is prepared by the following steps:

[0055] Step S1, dissolve 22.3g of 2,4-dihydroxybenzoic acid and 19.8g of 2,4-dihydroxybenzamide in 30mL of o-xylene, add 1.2mL of pyridine, raise the temperature to 70°C, and slowly add 26.1mL of dichloro The sulfoxide should be dropped within 90 minutes. After the dropwise addition, the temperature was raised to 120°C for reflux reaction for 1.5 hours. After the reaction, the reaction liquid was cooled to room temperature, and excess thionyl chloride was removed by distillation under reduced pressure, then petroleum ether was added and stirred. After uniformity, filter, and dissolve the filter cake in a mixed solution of absolute ethanol and glacial acetic acid at a volume ratio of 3:1, reflux at 90°C for 30 minutes, filter with suction, and recrystallize with ethylene glycol monomethyl ether to obtain intermediate Body 1;

[0056] Step S2, dissolve 1.2g of 4-hydrazinobenzoic acid and 0.7g of triethylamine in 8.5g ...

Embodiment 2

[0065] The UV absorber is prepared by the following steps:

[0066] Step S1, dissolve 22.8g of 2,4-dihydroxybenzoic acid and 20.1g of 2,4-dihydroxybenzamide in 33mL of o-xylene, add 1.3mL of pyridine, raise the temperature to 72°C, and slowly add 26.2mL of dichloro The sulfoxide should be dropped within 90 minutes. After the dropwise addition, the temperature was raised to 120°C for reflux reaction for 1.5 hours. After the reaction, the reaction liquid was cooled to room temperature, and excess thionyl chloride was removed by distillation under reduced pressure, then petroleum ether was added and stirred. After uniformity, filter, and dissolve the filter cake in a mixed solution of absolute ethanol and glacial acetic acid at a volume ratio of 3:1, reflux at 90°C for 30 minutes, filter with suction, and recrystallize with ethylene glycol monomethyl ether to obtain intermediate Body 1;

[0067] Step S2, dissolve 1.3g of 4-hydrazinobenzoic acid and 0.75g of triethylamine in 8.8g...

Embodiment 3

[0076] The UV absorber is prepared by the following steps:

[0077]Step S1, dissolve 23.6g of 2,4-dihydroxybenzoic acid and 20.3g of 2,4-dihydroxybenzamide in 35mL of o-xylene, add 1.4mL of pyridine, raise the temperature to 75°C, and slowly add 26.4mL of dichloro The sulfoxide should be dropped within 90 minutes. After the dropwise addition, the temperature was raised to 120°C for reflux reaction for 1.5 hours. After the reaction, the reaction liquid was cooled to room temperature, and excess thionyl chloride was removed by distillation under reduced pressure, then petroleum ether was added and stirred. After uniformity, filter, and dissolve the filter cake in a mixed solution of absolute ethanol and glacial acetic acid at a volume ratio of 3:1, reflux at 90°C for 30 minutes, filter with suction, and recrystallize with ethylene glycol monomethyl ether to obtain intermediate Body 1;

[0078] Step S2, dissolving 1.4g of 4-hydrazinobenzoic acid and 0.8g of triethylamine in 9g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com