Supermolecular interlayer structured ultraviolet light absorbent, its preparation method and uses

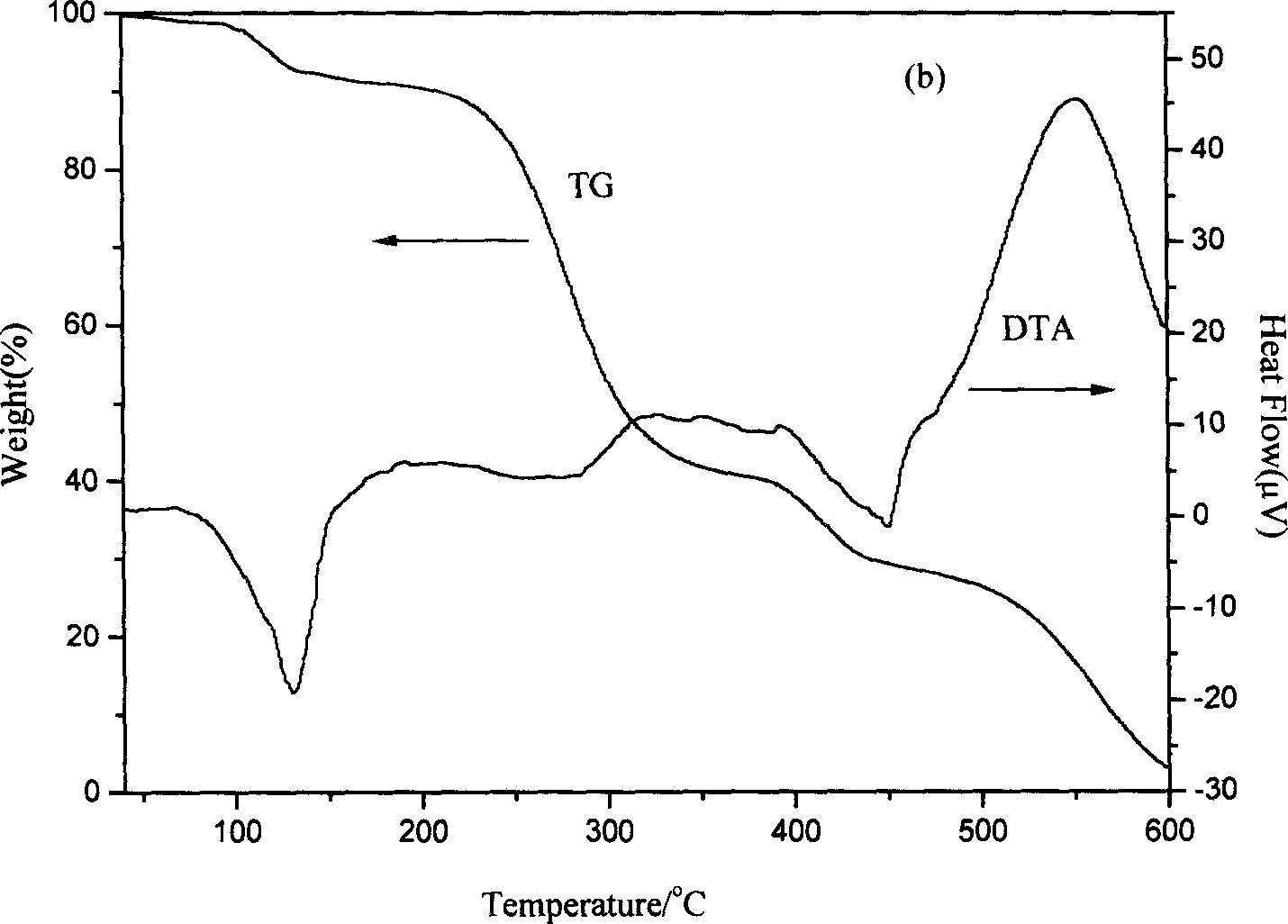

A technology of supramolecular intercalation and ultraviolet light, which is applied in the field of supramolecular intercalation structure ultraviolet absorbers and their preparation and application, can solve the problems of reduced elasticity, research on thermal stability of non-intercalated products, and material brittleness, etc. Achieve the effects of improved stability, excellent UV absorption capacity, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

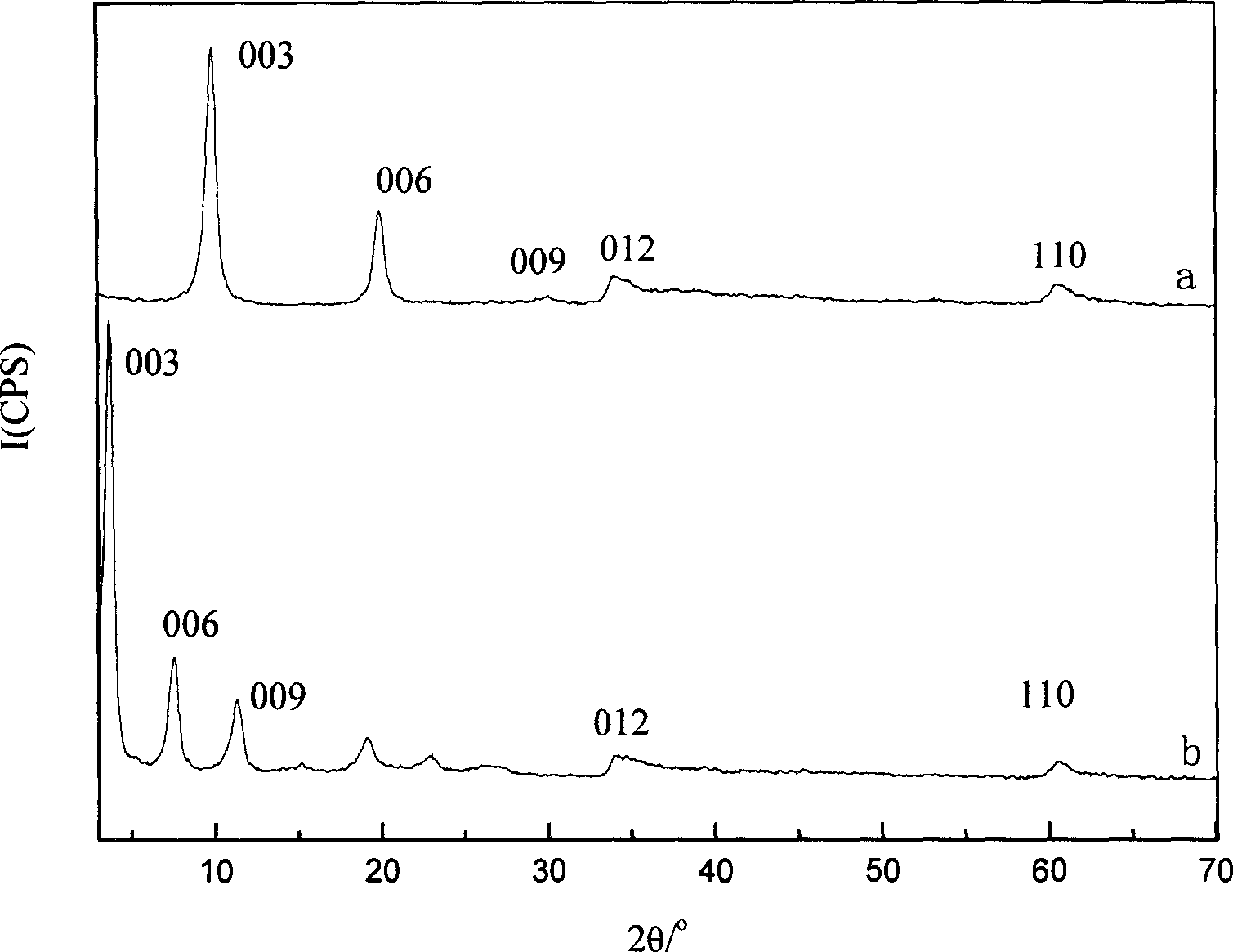

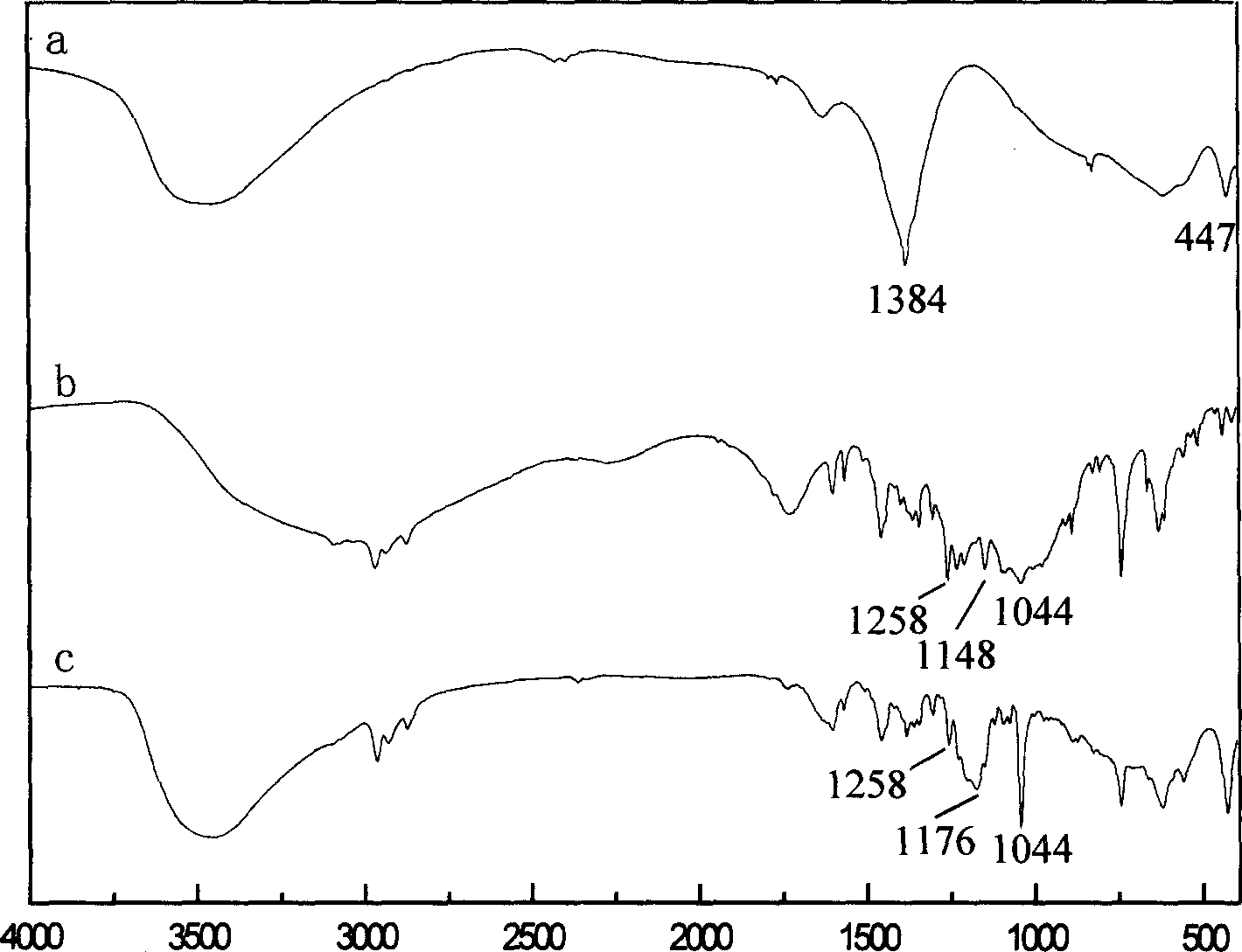

[0032] Step A: 35.7g (0.12mol) of solid Zn(NO 3 ) 2 ·6H 2 O and 22.5g (0.06mol) solid Al(NO 3 ) 3 9H 2 O dissolves in removing CO 2 150ml of mixed salt solution was prepared in deionized water; another 14.4g (0.36mol) of solid NaOH was dissolved in 2 150ml of alkaline solution was prepared in deionized water. The alkali solution and the salt solution were quickly nucleated in a fully back-mixed rotating liquid film reactor at room temperature, and the resulting slurry was crystallized at 100°C for 6h. After centrifugation, the precipitate was washed and the pH value of the washing water was close to 7, and finally dried at 70°C for 24 hours to obtain ZnAl-NO 3 -LDHs, whose Zn 2+ / Al 3+ =2:1.

[0033] ZnAl-NO 3 -LDHs precursors are fully dispersed in CO removal 2 Prepare a 0.10M suspension in deionized water.

[0034] Step B: Dissolve BZO in deCO2 at room temperature 2 Prepare 0.15M aqueous solution in deionized water, add NaOH to adjust pH=7.

[0035] Step C: Ad...

Embodiment 2

[0038] Step A: Prepare hydrotalcite suspension according to Example 1.

[0039] Step B: Dissolving BZO in deCO 2 In deionized water, prepare a 0.10M aqueous solution with a pH of 3.5.

[0040] Step C: Stir rapidly under the protection of nitrogen while adding the BZO solution prepared in step B at a volume ratio of 1:1

[0041] In the suspension prepared in step A, react at room temperature for 10 h, filter, wash until the pH is about 7, and dry at 70° C. for 24 hours to obtain a BZO anion intercalation ultraviolet absorber. The test found that the maximum absorption peak appeared at 357nm, and the absorption rate was 90%.

Embodiment 3

[0043] Prepare hydrotalcite suspension according to Example 1, BZO is dissolved in 2 In deionized water, prepare a 0.15M aqueous solution, and add NaOH to adjust the pH=8. According to the method of Example 1, the precursor suspension and the BZO solution were mixed in a volume ratio of 1:2, reacted at 100°C for 6 hours, filtered, washed until the pH was about 7, and dried at 70°C for 24 hours to obtain BZO anion intercalation ultraviolet absorbent. The test found that the maximum absorption peak appeared at 335nm, and the absorption rate was 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com