Eu3+/Eu2 doped aluminate multicolor fluorescent material and preparing method thereof

A fluorescent material and aluminate technology, applied in the field of solid luminescent materials, can solve the problems of uneven atmosphere contact, expensive preparation facilities, safety problems of reducing gas, etc., and achieve stable physical and chemical properties of products, good ultraviolet absorption, and emission peak intensity. and position-adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

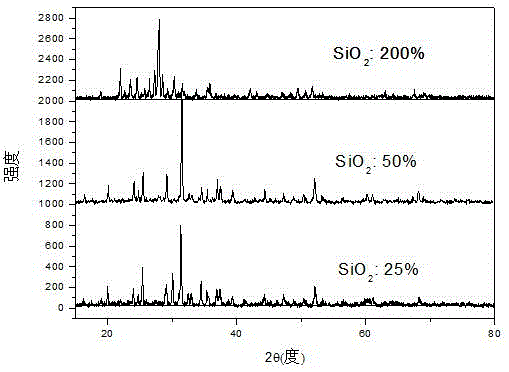

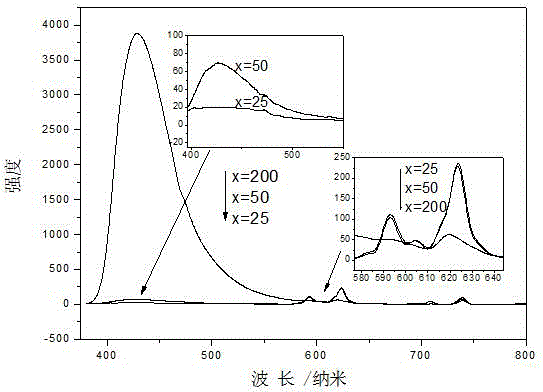

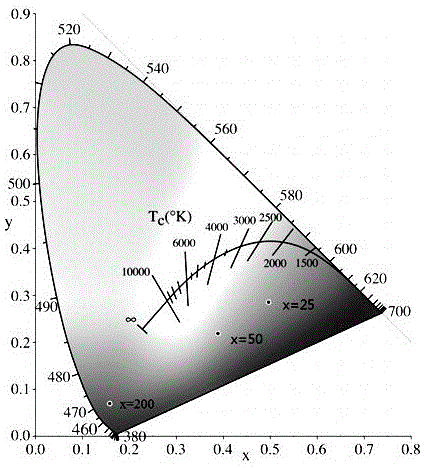

[0021] Weigh CaCO 3 : 0.4954g, Al 2 o 3 : 0.5046g, Eu 2 o 3 : 0.0174g, SiO 2 : 0.0744g, a total of 1.0918g. In this embodiment, the heat treatment temperature is 1000° C., and the reaction time is 20 h. X-ray diffraction results (such as figure 1 shown) indicates that the sample is a calcium aluminate phase with a spinel structure. After grinding, measure its emission spectrum at room temperature with F-4600 fluorescence spectrophotometer (e.g. figure 2 shown). Under the excitation of 365nm near-ultraviolet light, Eu was detected 2+ :5 d →4 f weak broadband emission, while Eu 3+ : 5 D. 0 ? 7 f J (J=0,1,2,3,4) The emission intensity is relatively high, indicating that the incorporated Eu 3+ Partially self-reduced to Eu 2+ , and Eu 2+ transfer most of the energy to Eu 3+ , and its emission spectrum color coordinate position is: x=0.4976y=0.286 (such as image 3 ), the position is close to the red light area, and the fluorescent material emits bright red lig...

Embodiment 2

[0023] Weigh CaCO 3 : 0.4954g, Al 2 o 3 : 0.5046g, Eu 2 o 3 : 0.0174g, SiO 2 : 0.1487g Total 1.1661g. In this embodiment, the heat treatment temperature is 1200° C., and the reaction time is 10 h. X-ray diffraction results (such as figure 1 shown) indicates that a new phase appeared in the sample besides the calcium aluminate phase with spinel structure. After grinding, measure its emission spectrum at room temperature with F-4600 fluorescence spectrophotometer (e.g. figure 2 shown). Under the excitation of 365nm near-ultraviolet light, Eu was detected 2+ :5 d →4 f broadband emission, and Eu 3+ : 5 D. 0 ? 7 f J (J=0,1,2,3,4) emission, the intensity difference is not big, indicating that the incorporated Eu 3+ Partially self-reduced to Eu 2+ , Eu 2+ / Eu 3+ There is energy transfer between them, and the emission spectrum color coordinate position is: x=0.389y=0.2181 (such as image 3 ), located close to the white light area, the fluorescent material emits b...

Embodiment 3

[0025] Weigh CaCO 3 : 0.4954g, Al 2 o 3 : 0.5046g, Eu 2 o 3 : 0.0174g, SiO 2 : 0.5948g, a total of 1.6122g. In this embodiment, the heat treatment temperature is 1300° C., and the reaction time is 8 hours. X-ray diffraction results (such as figure 1 shown) shows that the calcium aluminate phase of the sample is close to disappearing, while CaAl appears 2 Si 2 o 8 Mutually. After grinding, measure its emission spectrum at room temperature with F-4600 fluorescence spectrophotometer (e.g. figure 2 shown). Under the excitation of 365 nm near ultraviolet light, Eu was detected 2+ :5 d →4 f Strong broadband emission, and Eu 3+ : 5 D. 0 ? 7 f J (J=0,1,2,3,4) weaker emission, indicating incorporated Eu 3+ Partially self-reducing to Eu 2+ , and its emission spectrum color coordinate position is: x=0.1588y=0.0699 (such as image 3 ), the position is close to the blue-purple area, and the fluorescent material emits bright blue-purple light visible to the naked eye....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com