Colored transparent heat insulation glass coating and preparation method thereof

A heat-insulating glass and transparent pigment technology, which is applied in the direction of camouflage paint, multi-color effect paint, coating, etc., can solve the problem of the lack of information description, complicated preparation process and manufacturing problems of color transparent heat-insulating film and color transparent heat-insulating glass paint. Complex process and other issues, to achieve the effect of rich colors, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

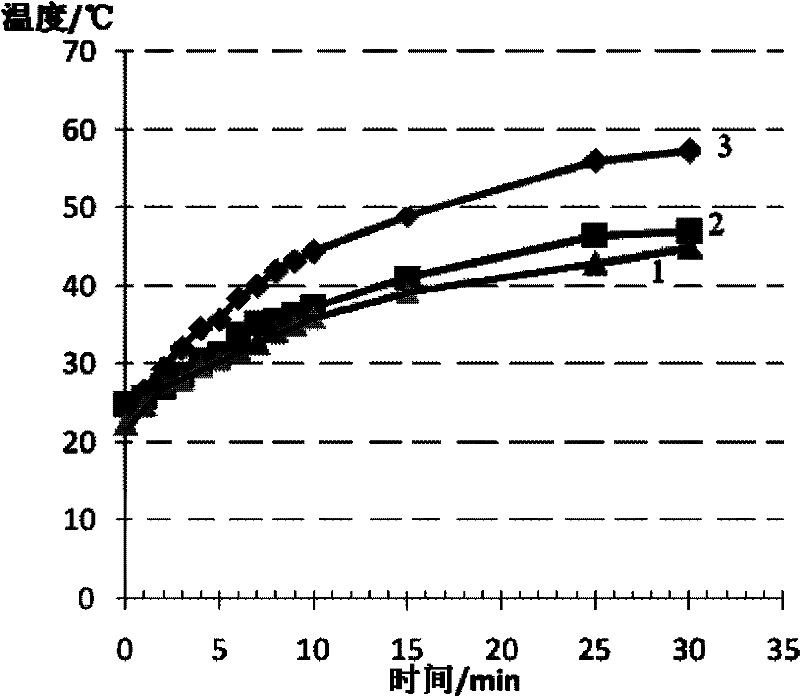

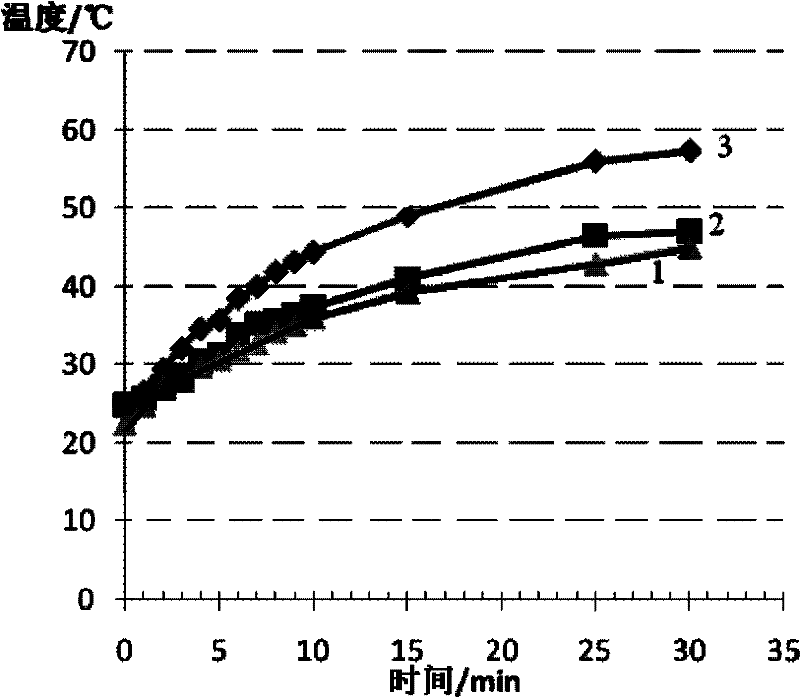

Embodiment 1

[0053]At room temperature, 85 grams of methyl silicone resin with a solid content of 30%, 13.9 grams of nano-ATO slurry with a solid content of 50%, 0.2 grams of red nano-scale transparent iron oxide pigment paste and 0.05 grams of polyacrylate leveling agent (BYK355) Mix evenly, then add 0.85 g of diethylenetriamine curing agent, stir slowly, mix evenly, and then use the flow coating method to apply the mixed product (ie, the heat-insulating coating including nano-ATO and red transparent pigment) on the glass.

Embodiment 2

[0055] At room temperature, 49.5 grams of epoxy-modified silicone resin with a solid content of 50%, 50 grams of nano-ATO slurry with a solid content of 30%, 0.15 grams of yellow nano-scale transparent iron oxide color paste and polydimethylsiloxane leveling Add 0.05 g of curing agent and mix evenly, then add 0.3 g of polyamide curing agent, stir slowly, mix evenly, and then use the scraping method to apply the product obtained by mixing (that is, the heat-insulating coating including nano-ATO and yellow transparent pigment) on the glass .

Embodiment 3

[0057] At room temperature, 57 grams of polyester-modified silicone resin with a solid content of 15%, 40 grams of nano-ATO slurry with a solid content of 35%, 0.8 grams of green nano-scale transparent iron oxide color paste and polydimethylsiloxane leveling Add 0.7 grams of triethylenetetramine curing agent and mix evenly, then add 1.5 grams of triethylenetetramine curing agent, stir slowly, mix evenly, and then use the scraping method to mix the product (that is, include nano-ATO and green transparent pigment The thermal insulation coating) is applied to on the glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com