Heat converter of plate-type gas water heater

A technology for gas water heaters and heat exchangers, applied in heat exchange equipment, water heaters, fluid heaters, etc., can solve the problem of reduced corrosion resistance and oxidation resistance, affecting the service life of gas water heaters, low melting point of tin-lead alloys, etc. problems, to achieve the effect of reducing the extrusion process, increasing the effective heat transfer area, and strong anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings, and the invention is not limited thereto.

[0019] figure 1 It is a schematic diagram of a single plate in the heat exchanger of a gas water heater, represented by figure 1 It can be seen that several grooves 2 are evenly distributed on the wall surface of the plate, and the inclination between the bottom surface of each groove and the horizontal position is 30-60°. depends.

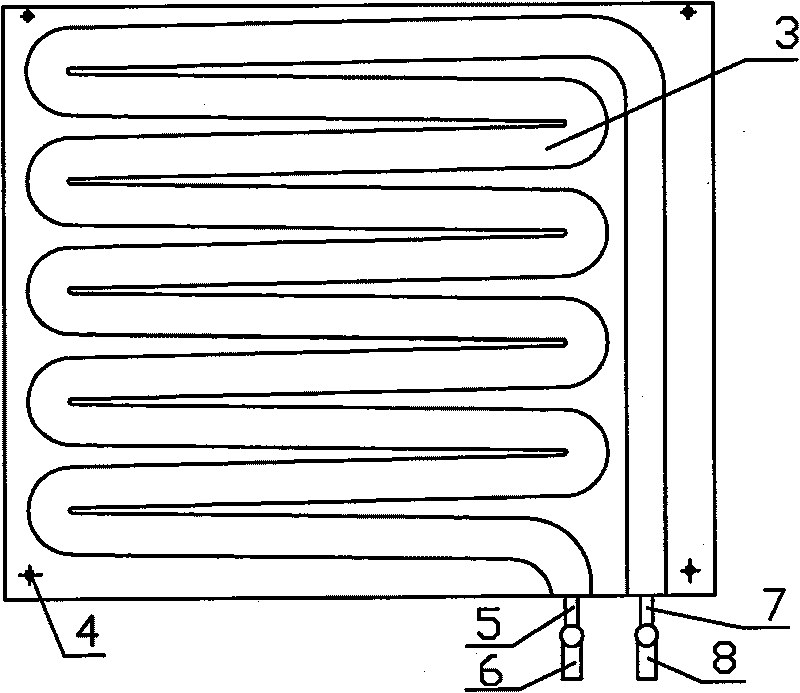

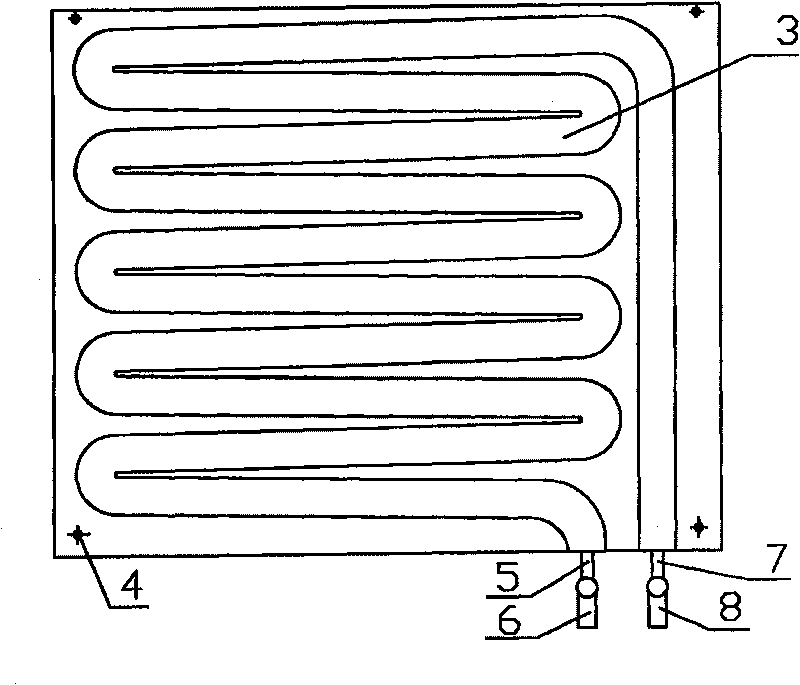

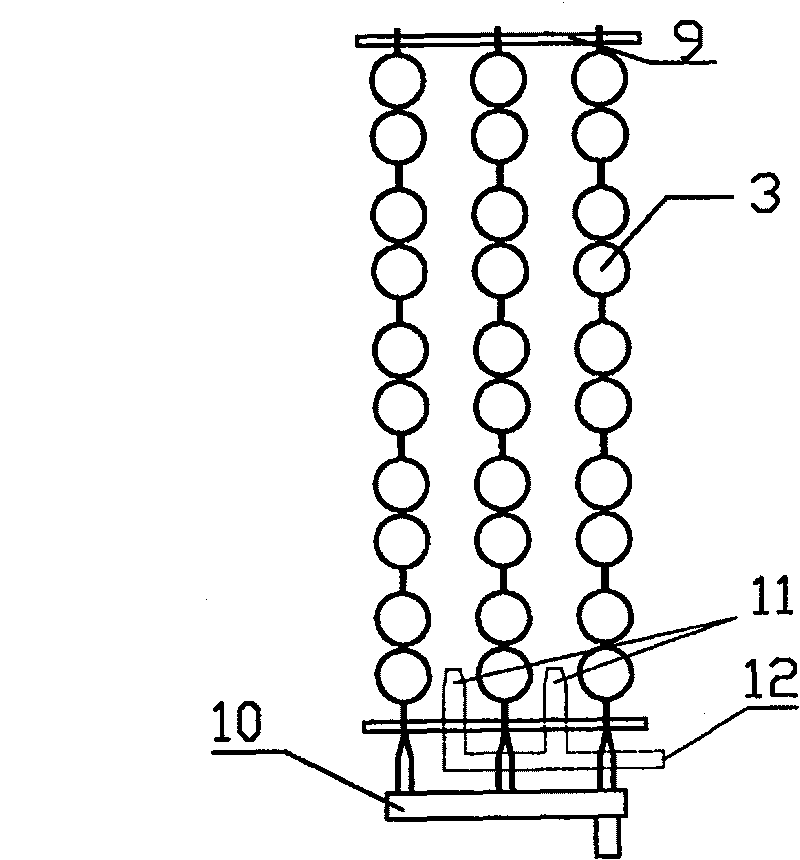

[0020] figure 2 It is a schematic diagram of the structure of a single plate of a heat exchanger for a gas water heater, which is represented by figure 2 It can be seen that a single plate body is composed of two plates, and a flow channel 3 is arranged between the two plates. The cross-sectional shape of the flow channel 3 is circular, and the flow channel is in the figure 1 On the basis of another stamping, it is formed on the surface of the plate (because the area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com