A method for producing sialic acid through fermentation

A technology of sialic acid and fermentation broth, applied in the field of bioengineering, can solve the problems of no further hydrolysis, no report of sialic acid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The optimization of the carbon and nitrogen source of embodiment 1 fermentation medium

[0049] 1. Determination of carbon source content in fermentation medium

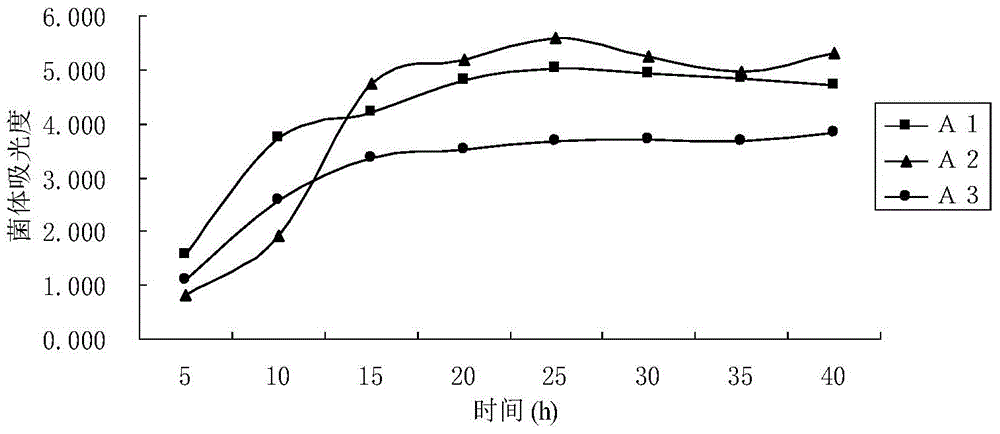

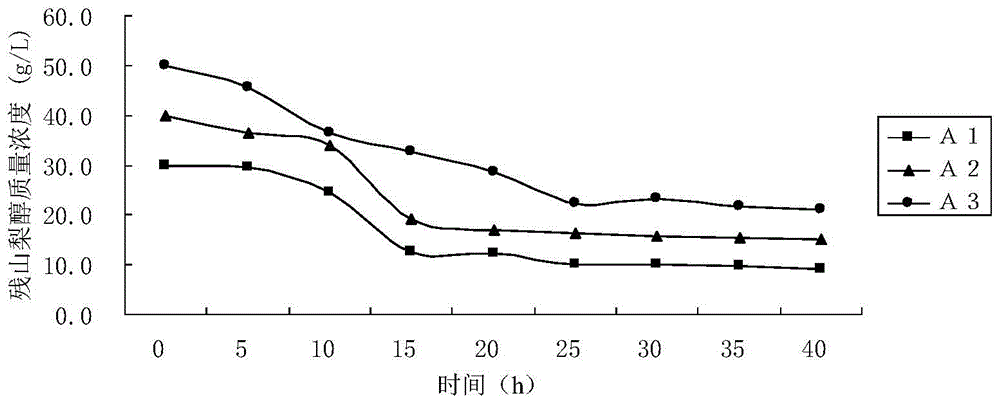

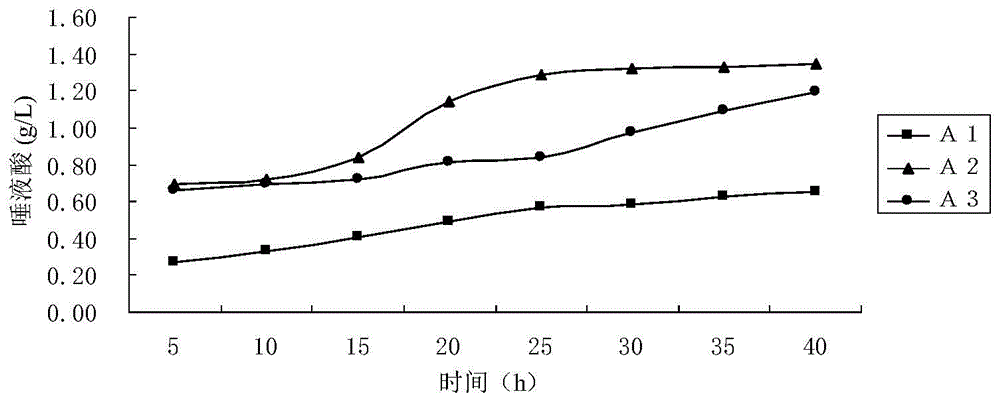

[0050] Experiment with three kinds of content (30, 40, 50g / L) of carbon source sorbitol with single factor experiment, determine suitable carbon source content, name it as A1, A2, A3 respectively, other components and content in the fermentation medium are : Dipotassium hydrogen phosphate 2.5g / L, ammonium sulfate 5g / L, yeast extract 1.2g / L, magnesium sulfate 0.9g / L, copper sulfate 0.002g / L, pH8.0 (sterilized at 121°C for 15min).

[0051] 500mL three-neck flask culture: the cultured seed solution was inserted into a 500mL three-neck flask with 300mL fermentation medium according to the inoculum amount of 4% (v / v) for cultivation, the shaker speed was 250r / min, the temperature was 37°C, and cultured for 40h. Sampling at regular intervals, measuring the mass concentration of sorbitol and the bacterium absorbance...

Embodiment 2

[0062] The influence of embodiment 2 hydrogen peroxide stress on thalline fermentation ability

[0063] 1. The effect of the addition time and amount of hydrogen peroxide on the yield of sialic acid in the final product

[0064] Carry out the following single factor experiment respectively, when fermenting to 5h, add the H of 1, 2, 4, 8mmoL / L respectively 2 o 2 , respectively named as C1, C2, C3, and C4; when the fermentation reached 10h, 2, 4, 8, and 16mmoL / L of H 2 o 2 , respectively named D1, D2, D3, D4; when fermented to 15h, add 4, 8, 16, 32mmoL / L of H 2 o 2 , respectively named E1, E2, E3, E4.

[0065] 500mL three-necked flask culture: put the cultured seed solution into a 500mL three-necked flask with 300mL fermentation medium according to the inoculum amount of 4% (v / v) for cultivation, the shaker speed is 250r / min, the temperature is 37°C, and the pH is 7.6 ~8.0, cultivated for 40 hours, measured the content of sialic acid at the end of fermentation, and made a ...

Embodiment 3

[0077] The influence of embodiment 3 rotating speed on thalline fermentation ability

[0078] During the fermentation process, different rotational speeds were set to 300, 400, 500, and 600 r / min, respectively, and single-factor experiments were carried out.

[0079] 500mL three-necked flask culture: put the cultivated seed solution into 300mL fermentation medium according to the inoculum size 4% (v / v), rotate at 250r / min, temperature 37°C, pH7.6~8.0, cultivate for 40h, Sampling, measuring the content of sialic acid in the fermentation broth and the dry weight of bacteria, by analyzing the influence of different stirring speeds on the specific growth rate of bacteria cells and the specific synthesis rate of sialic acid, determine the optimal rotating speed of segmental stirring and the effect of segmental stirring. point in time.

[0080]Scale-up culture: 3.7L fermenter with 2L liquid volume, 4% inoculum, 37°C fermentation temperature, 250r / min stirring speed, 8.0 pH, 1 (V / V·...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com