Graphene microchip electric conduction master batch and preparation method thereof

A technology of graphene microchips and graphene, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low yield, poor dispersion of graphene, and low conductivity of conductive masterbatch, and achieve low cost and easy uniformity Disperse and achieve the effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

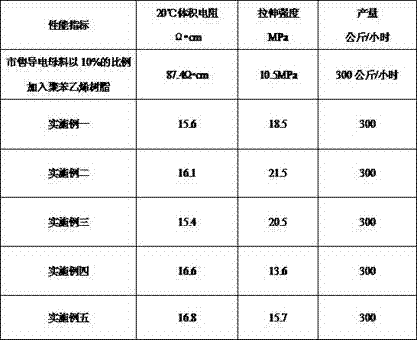

Examples

Embodiment 1

[0029] a. Mix 25 parts by weight of flake graphite with 50 parts by weight of metal tin, set the stirring speed to 100-500 rpm, perform mechanical vibration and stirring, heat to 230-350 ° C until the tin melts and becomes liquid, and continue to maintain mechanical stirring , the stirring time is 3 hours, the graphite powder is crushed and sheared to form graphene microflakes, and evenly dispersed in the metal tin liquid to obtain the graphene microflakes / metal tin composite liquid;

[0030] b. 30 parts by weight of glass beads with a particle size of 50 μm are mixed with the graphene microflake / metal tin composite liquid obtained in step a, and sprayed and quenched at a cooling rate of 60-100° C. / s to stabilize the graphene microflakes Uniformly exist in metal tin, and coated on glass beads;

[0031] c, put the glass microspheres coated with graphene microflakes / metal tin composite obtained in step b into the ball mill, set the ball mill speed to be 200-800 rpm, and mechanic...

Embodiment 2

[0034] a. Mix 30 parts by weight of pyrolytic graphite with 55 parts by weight of metallic tin, set the stirring speed to 100-500 rpm, carry out mechanical vibration and stirring, heat to 230-350 ° C until the tin melts and becomes liquid, and continue to maintain the mechanical Stir for 5 hours, crush and shear the graphite powder to form graphene microflakes, and disperse evenly in the metal tin liquid to obtain graphene microflakes / metal tin composite liquid;

[0035] b. 30 parts by weight of glass beads with a particle size of 80 μm are mixed with the graphene microflake / metal tin composite liquid obtained in step a, and sprayed and quenched at a cooling rate of 60-100° C. / s to stabilize the graphene microflakes Uniformly exist in metal tin, and coated on glass beads;

[0036] c, put the glass microspheres coated with graphene microflakes / metal tin composite obtained in step b into the ball mill, set the ball mill speed to be 200-800 rpm, and mechanically grind the graphene / ...

Embodiment 3

[0039] a. Mix 30 parts by weight of graphite oxide with 50 parts by weight of metal tin, set the stirring speed to 100-500 rpm, perform mechanical vibration and stirring, heat to 230-350 ° C until the tin melts and becomes liquid, and continue to maintain mechanical stirring , the stirring time is 4 hours, the graphite powder is crushed and sheared to form graphene microflakes, and evenly dispersed in the metal tin liquid to obtain the graphene microflakes / metal tin composite liquid;

[0040] b. 35 parts by weight of glass beads with a particle size of 90 μm are mixed with the graphene microflake / metal tin composite liquid obtained in step a, and sprayed and quenched at a cooling rate of 60-100° C. / s to stabilize the graphene microflakes Uniformly exist in metal tin, and coated on glass beads;

[0041] c, put the glass microspheres coated with graphene microflakes / metal tin composite obtained in step b into the ball mill, set the ball mill speed to be 200-800 rpm, and mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com