Method for pollution-free production of molybdenum oxide

A clean production, molybdenum oxide technology, applied in the field of environmental pollution control, can solve the problems of waste of resources, high energy consumption, low output rate, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

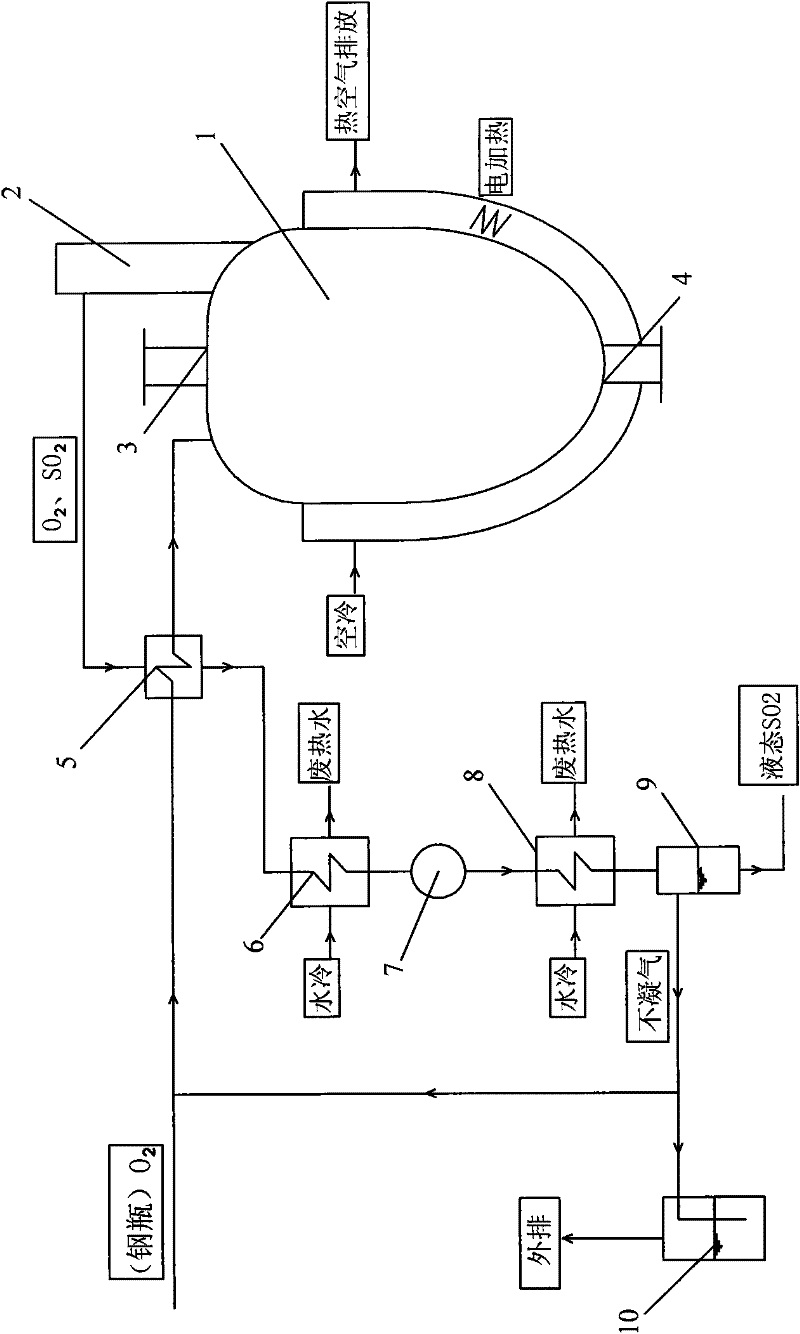

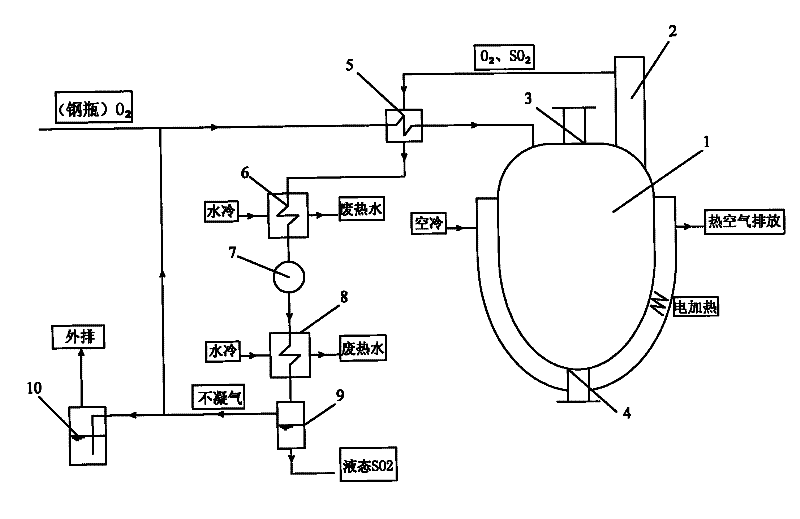

Method used

Image

Examples

Embodiment 1

[0045] Add molybdenum ore powder with an excess molybdenum mass percentage of 49.2% and a molybdenum sulfide mass percentage of 82% to the reactor, fill the reactor with oxygen until the absolute pressure is 0.4MPa, and heat until the oxygen temperature reaches 250 ~350°C, molybdenum sulfide reacts with oxygen to form molybdenum oxide and sulfur dioxide at the same time. The molybdenum oxide is collected by a high-temperature dust collector. The purity of the molybdenum oxide in the solid collected by the high-temperature dust collector is greater than 80%, the purity of the sulfur dioxide in the high-temperature gas is greater than 40%, and the liquid sulfur dioxide obtained after cooling, compression and separation has a purity of greater than 80%. %. After calculation, MoS 2 Convert to MoO 3 The conversion rate is greater than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com