Method for fabricating different gate oxide thickness within the same chip

a technology of gate oxide and chip, which is applied in the direction of basic electric elements, electrical equipment, semiconductor devices, etc., can solve the problems of increasing the overall manufacturing cost, poor device performance, and significantly reducing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

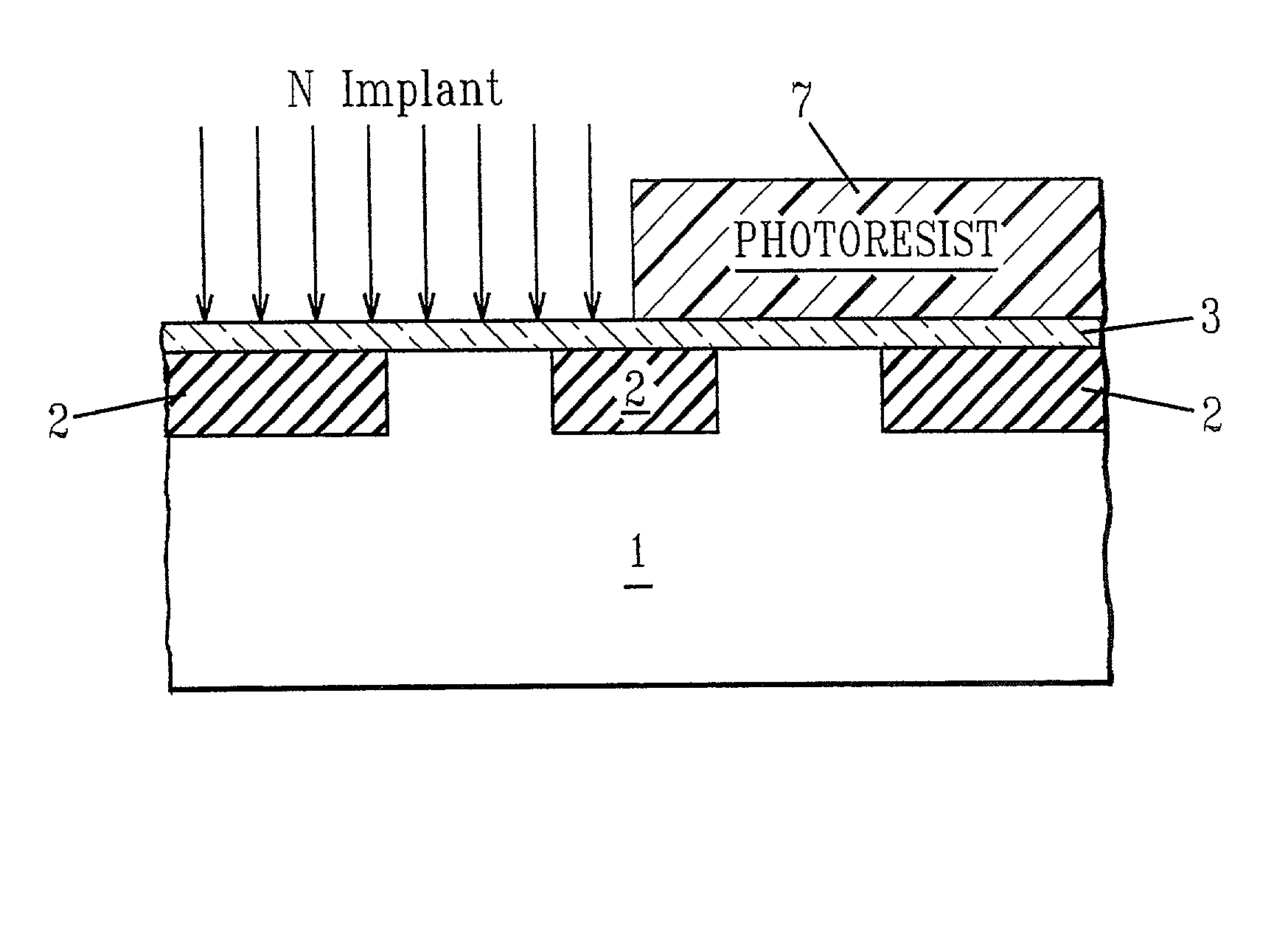

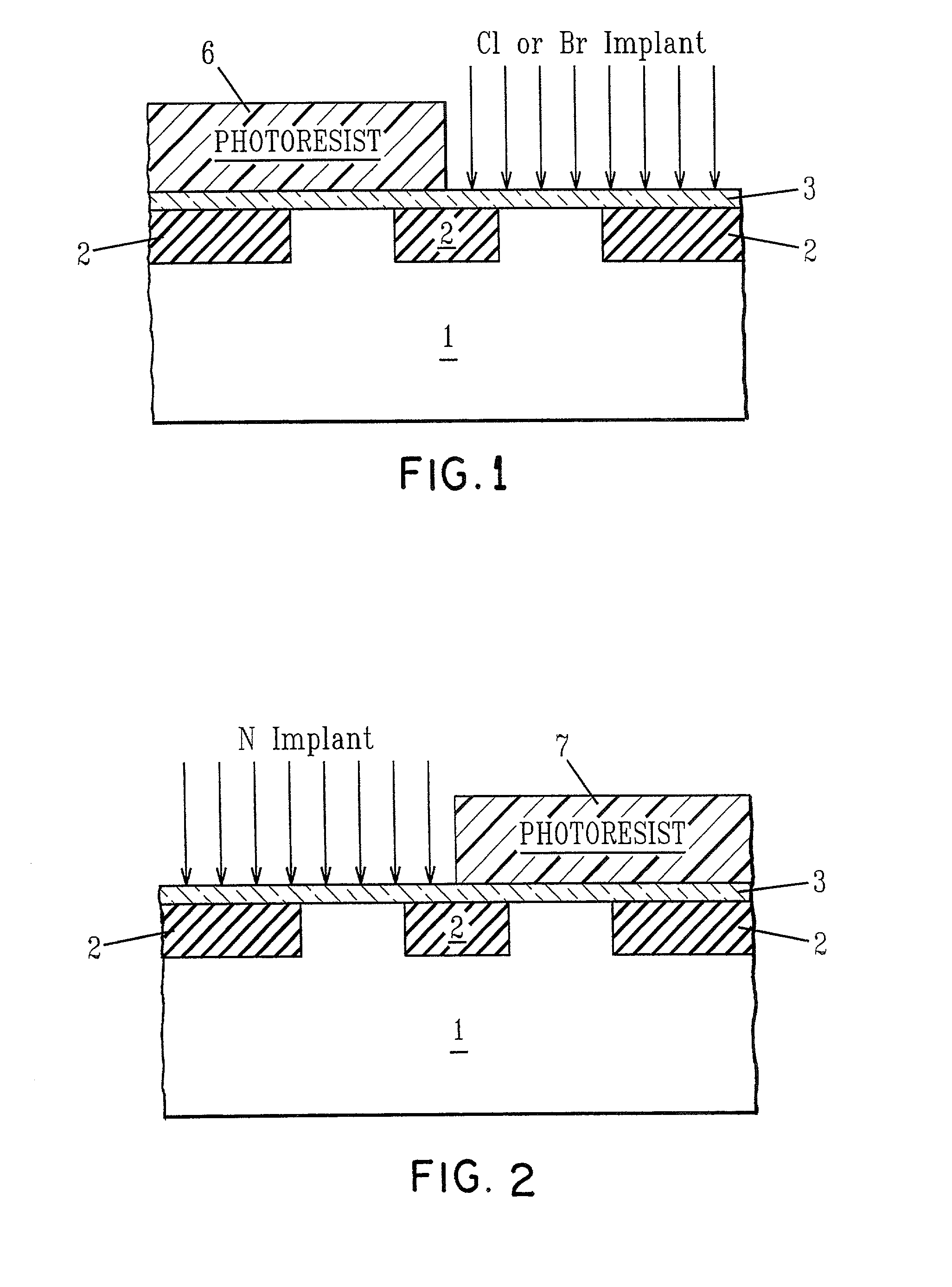

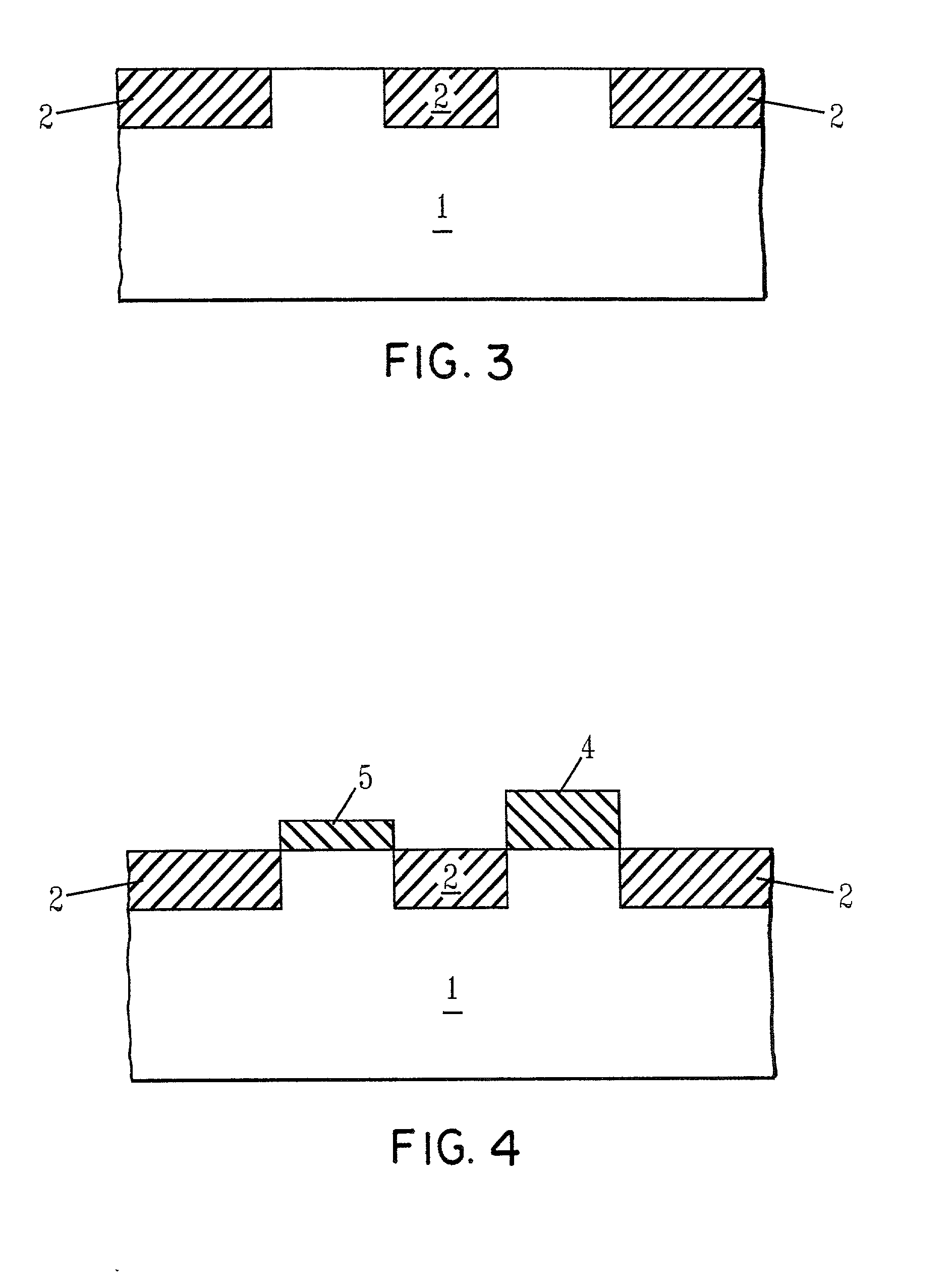

[0027] In order to facilitate an understanding of the present invention, reference is made to the figures which illustrate a portion of a partially fabricated integrated circuit. In particular, see FIG. 1 wherein is shown a semiconductor substrate 1, which is typically monocrystalline silicon or a SOI substrate (silicon on insulator). Shallow trench isolation regions 2 are formed as is conventional in the art. A layer of sacrificial silicon dioxide 3 is grown on the surface of the semiconductor substrate, typically to a thickness of about 25 to about 120 .ANG., with 60 .ANG. being an example. The sacrificial silicon dioxide layer is provided for cleaning the active silicon regions of residual nitride from the previous isolation process as well as for removing the near surface silicon which may have been damaged or contaminated in the previous processing.

[0028] By way of illustration only, the discussion that follows refers to a sequence whereby chlorine and / or bromine doping occurs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com