Process for preparing tert-butyl hydroperoxide

A technology of tert-butyl hydroperoxide and hydrogen peroxide, which is applied in the preparation of peroxy compounds, the preparation of organic compounds, chemical instruments and methods, etc., to achieve the effects of high stability, avoiding the difficulty of separation of the same phase, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

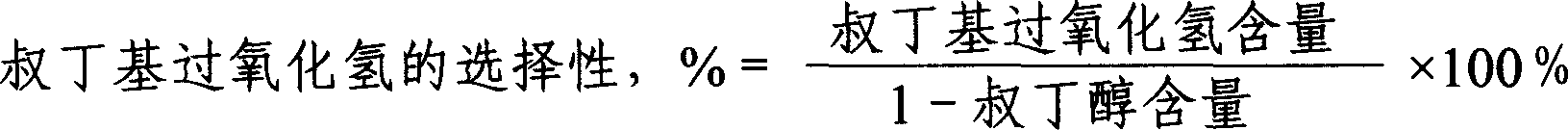

Embodiment 1

[0021] Weigh 3.5g of titanium-silicon molecular sieves and put them in a 100ml three-neck glass bottle, then add 50.6ml of tert-butanol and 10ml of 30% hydrogen peroxide to the bottle in turn. At this time, the molar ratio of tert-butanol to hydrogen peroxide is 5.57 . Put the three-necked glass bottle on a temperature-controlled magnetic stirrer, use a condenser tube to condense and reflux the upper part of the three-necked glass bottle, start the magnetic stirring and heating control, and start the reaction. The reaction temperature is controlled at about 65°C. After 6 hours of reaction, the selectivity of tert-butyl hydroperoxide is 100%, the utilization rate of hydrogen peroxide reaches 83.6%, and the conversion rate of tert-butanol is 15.01%.

Embodiment 2

[0023] Weigh 4g of titanium-silicon molecular sieve and put it in a 100ml three-necked glass bottle, and then add 27.6ml of tert-butanol and 30ml of 30% hydrogen peroxide to the bottle in turn. At this time, the molar ratio of tert-butanol to hydrogen peroxide is 1.00. Put the three-necked glass bottle on a temperature-controlled magnetic stirrer, use a condenser tube to condense and reflux the upper part of the three-necked glass bottle, start the magnetic stirring and heating control, and start the reaction. The reaction temperature is controlled at about 70°C. After 10 hours of reaction, the selectivity of tert-butyl hydroperoxide is 100%, the utilization rate of hydrogen peroxide reaches 66.83%, and the conversion rate of tert-butanol is 66.83%.

Embodiment 3

[0025] Weigh 4g of titanium-silicon molecular sieve and put it in a 100ml three-necked glass bottle, and then add 41.4ml of tert-butanol and 15ml of 30% hydrogen peroxide to the bottle in turn. At this time, the molar ratio of tert-butanol to hydrogen peroxide is 3.01. Put the three-necked glass bottle on a temperature-controlled magnetic stirrer, use a condenser tube to condense and reflux the upper part of the three-necked glass bottle, start the magnetic stirring and heating control, and start the reaction. The reaction temperature is controlled at about 80°C. After 3 hours of reaction, the selectivity of tert-butyl hydroperoxide is 100%, the utilization rate of hydrogen peroxide reaches 65.78%, and the conversion rate of tert-butanol is 21.85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com