Method for preparing carbon nanotube supported nanometer hydrated ruthenium oxide

A technology of carbon nanotubes and ruthenium dioxide, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., to avoid the influence of impurity ions, uniform size, and preparation conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

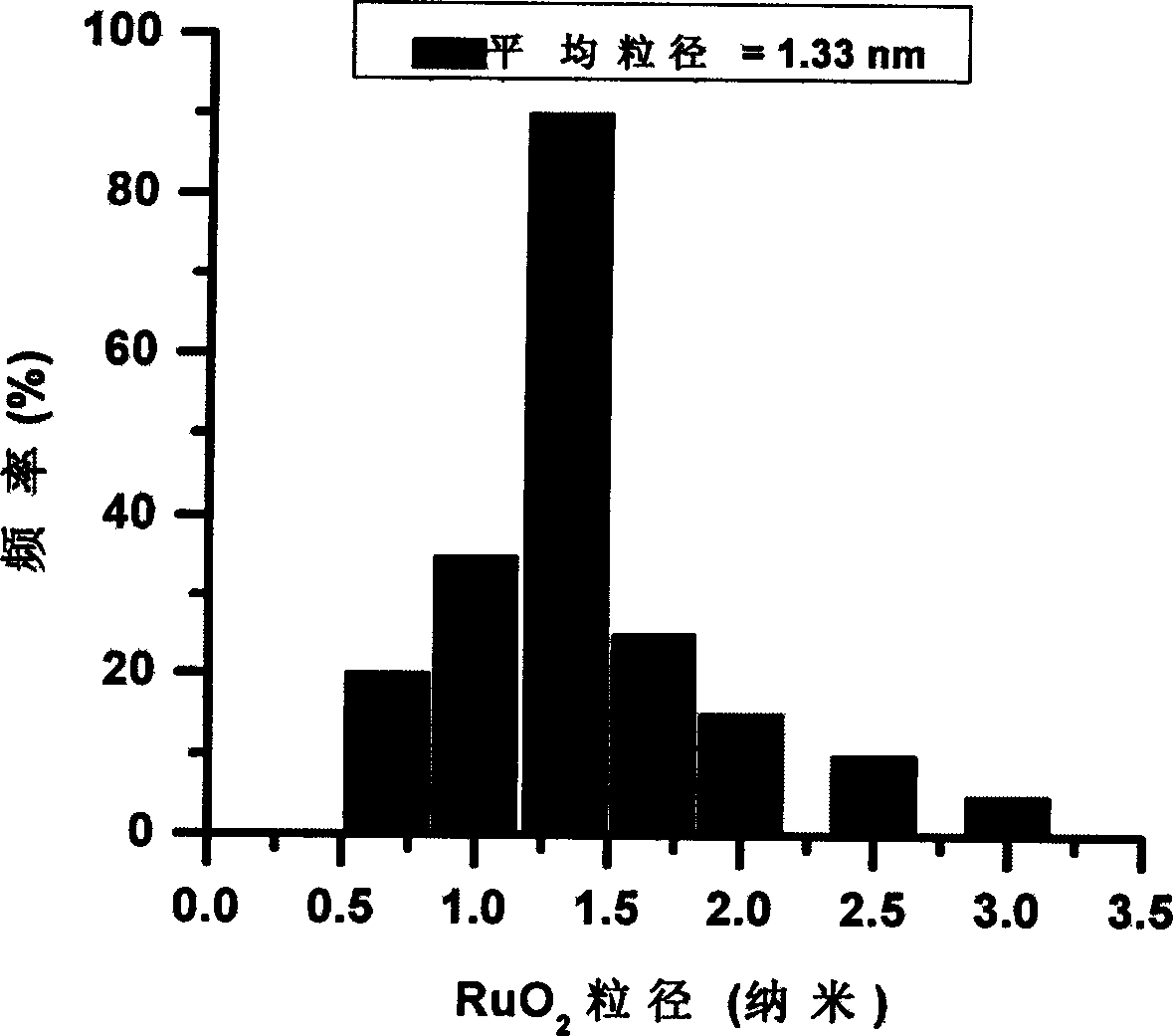

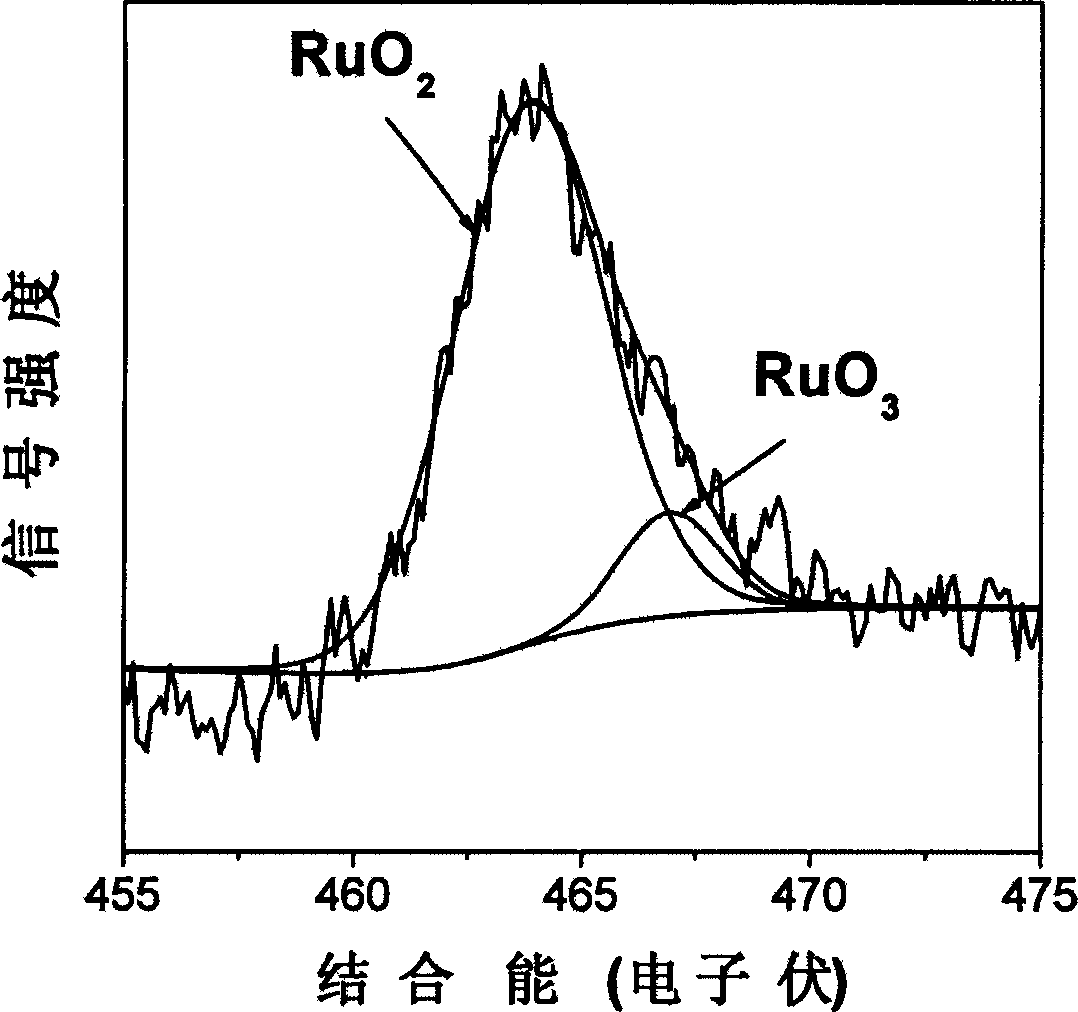

[0028] Add 500 mg of multi-walled carbon nanotubes to a 250 ml flask, add 10 ml of distilled water, and then add 25 mg of RuCl 3 ·nH 2 O, that is, the weight ratio of carbon nanotubes: ruthenium trichloride: water is 1:0.05:20, and ultrasonically oscillated for 0.5 h. At room temperature, hydrogen peroxide was slowly added dropwise, the weight ratio of hydrogen peroxide to ruthenium trichloride was 600:1, and the dropping time was 2 hours; after the hydrogen peroxide was completely added, the temperature was raised to 50° C., and refluxed for 6 hours. The suspension was filtered, the solid was washed with distilled water and acetone, and then dried in a drying oven at 100° C. for 24 hours to obtain a new composite material of nano-hydrated ruthenium dioxide supported by carbon tubes. According to the statistics of particle size distribution, the particle size of the hydrated ruthenium dioxide on the surface of the carbon nanotube is 1.15nm.

preparation Embodiment 2

[0030] Add 500mg of multi-walled carbon nanotubes to a 250ml flask, add 100ml of distilled water, and then add 500mg of RuCl 3 ·nH 2O, that is, the weight ratio of carbon nanotubes: ruthenium trichloride: water was 1:1:200 and ultrasonically oscillated for 4 hours. At room temperature, hydrogen peroxide was slowly added dropwise, the weight ratio of hydrogen peroxide to ruthenium trichloride was 100:1, and the dropping time was 10 h; after the hydrogen peroxide was completely added, the temperature was raised to 80° C., and refluxed for 3 h. The suspension was filtered, the solid was washed with distilled water and acetone, and then put into a drying oven at 120° C. for 8 hours to obtain a new nano-hydrated ruthenium dioxide composite material supported by carbon tubes. According to the statistics of the particle size distribution, the particle size of the hydrated ruthenium dioxide on the surface of the carbon nanotube is 1.85nm.

preparation Embodiment 3

[0032] Add 250mg of single-walled carbon nanotubes to a 250ml flask, add 25ml of distilled water, and then add 25mg of RuCl 3 ·nH 2 O, that is, the weight ratio of carbon nanotubes: ruthenium trichloride: water is 1:0.1:100 and ultrasonically oscillated for 3 hours. At room temperature, hydrogen peroxide was slowly added dropwise, the weight ratio of hydrogen peroxide to ruthenium trichloride was 300:1, and the dropping time was 4 hours; after the hydrogen peroxide was completely added, the temperature was raised to 100° C., and refluxed for 2 hours. The suspension was filtered, the solid was washed with distilled water and acetone, and then dried in a drying oven at 110° C. for 12 hours to obtain a new nano-hydrated ruthenium dioxide composite material supported by carbon tubes. According to the particle size distribution statistics, the particle size of the hydrated ruthenium dioxide on the surface of the carbon nanotube is 1.25nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com