Degreasing agent for cleaning oil stains on surface of steel and preparation method thereof

A surface oil stain and degreasing agent technology, which is applied in the field of degreasing agent for oil stain cleaning on the steel surface and its preparation, can solve the problems of poor non-saponifiable oil treatment effect, inability to store for a long time, unfavorable on-site operating environment, etc., and achieve good and efficient decontamination effect , prevent impurities from re-deposition, and facilitate the effect of removing oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

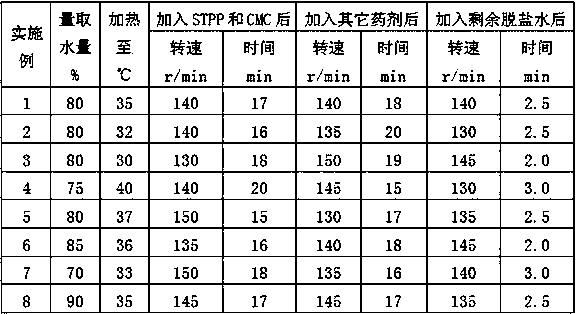

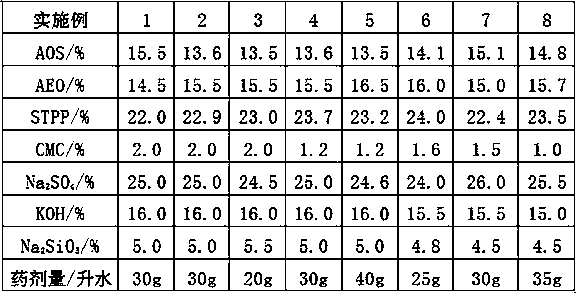

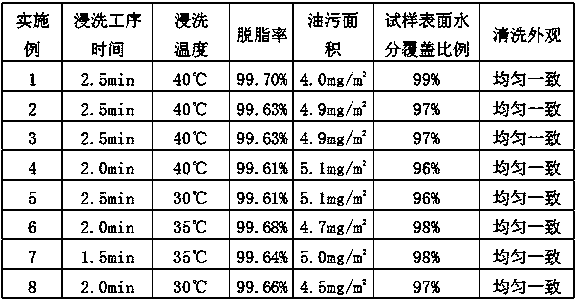

[0017] Embodiments 1-8: The degreasing agent used for cleaning oil stains on steel surfaces adopts the following proportions and preparation methods.

[0018] (1) Composition distribution ratio: The total amount of medicine added to each liter of desalted water is 20-40g; the weight percentage distribution ratio of medicines is: AOS 13.5%-15.5%, AEO 14.5%-16.5%, STPP 22%-24% , CMC 1%~2%, Na 2 SO 4 24%~26%, KOH (potassium hydroxide) 15%~16%, Na 2 SiO 3 (Sodium silicate) 4.5%~5.5%; Among them, the carbon number distribution of AOS is C14~C16; the degree of substitution of CMC is 0.4~0.8. The content of components in each embodiment is shown in Table 1.

[0019] Table 1: The component content of each embodiment

[0020]

[0021] (2) Preparation method: prepare according to the ratio described in step (1). First, weigh (measure) 70%-90% of the total volume of desalted water, heat it to 30-40°C, and keep it warm; then pre-mix STPP and CMC, add it to the above-mentioned de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com