Patents

Literature

163results about How to "Many gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

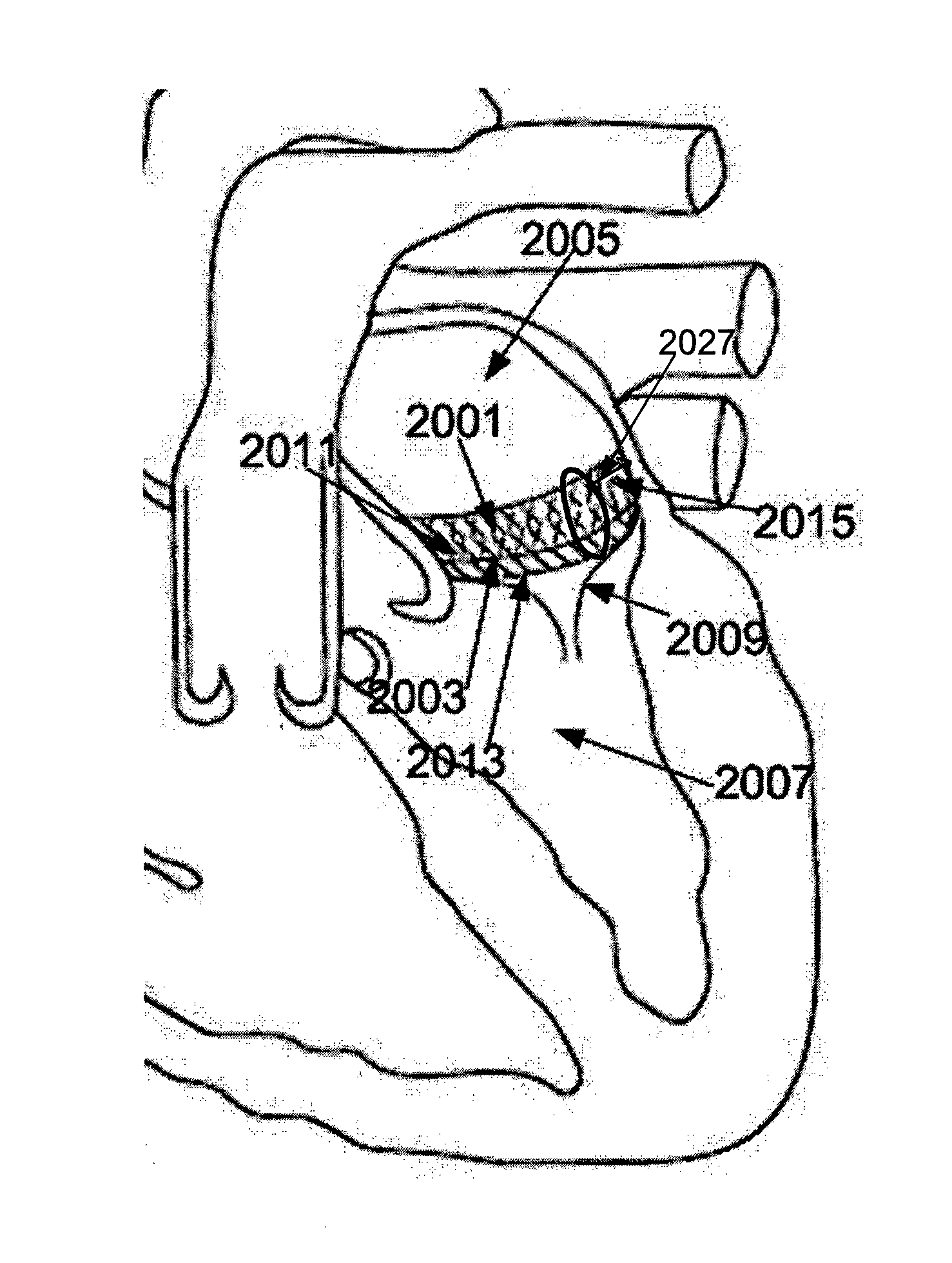

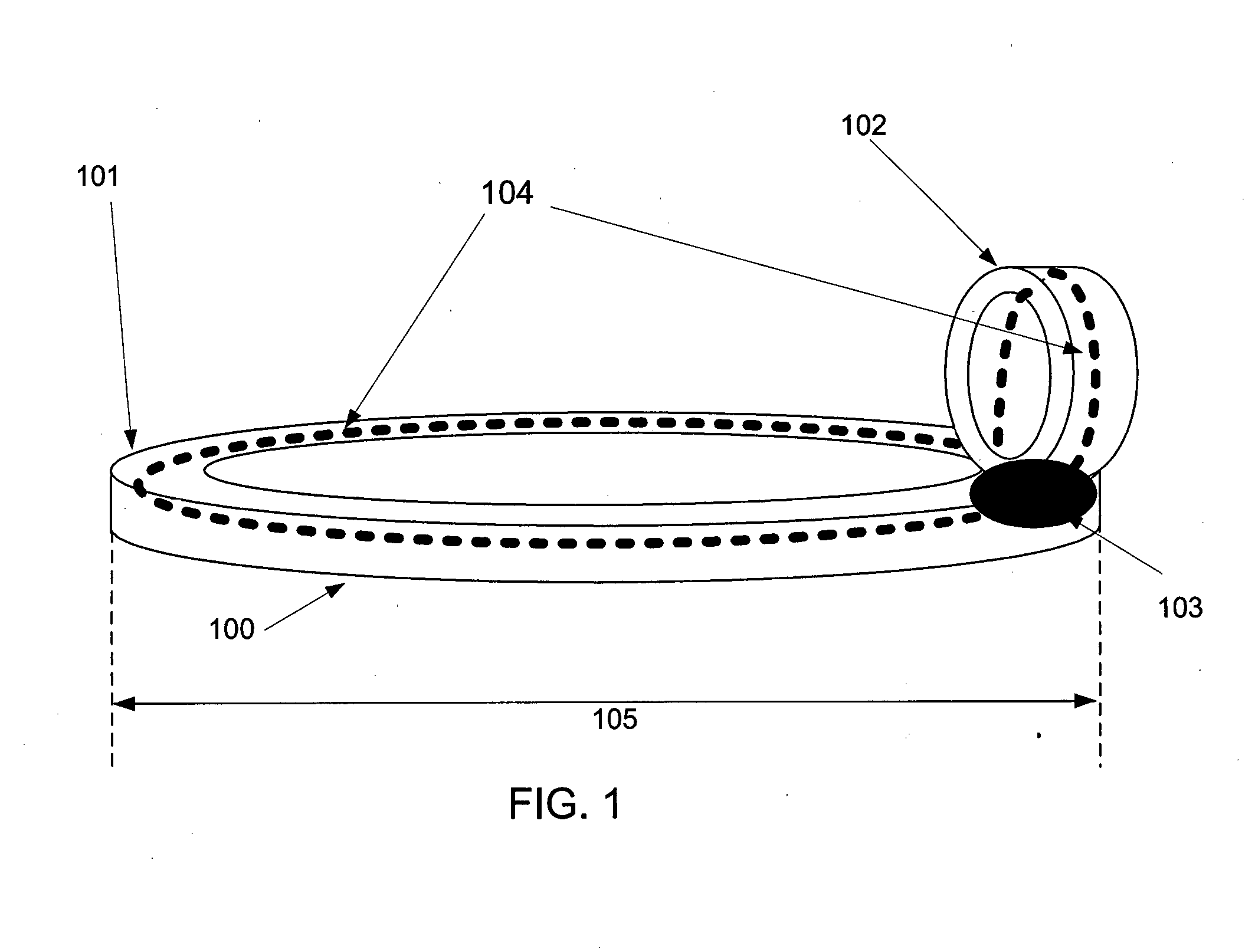

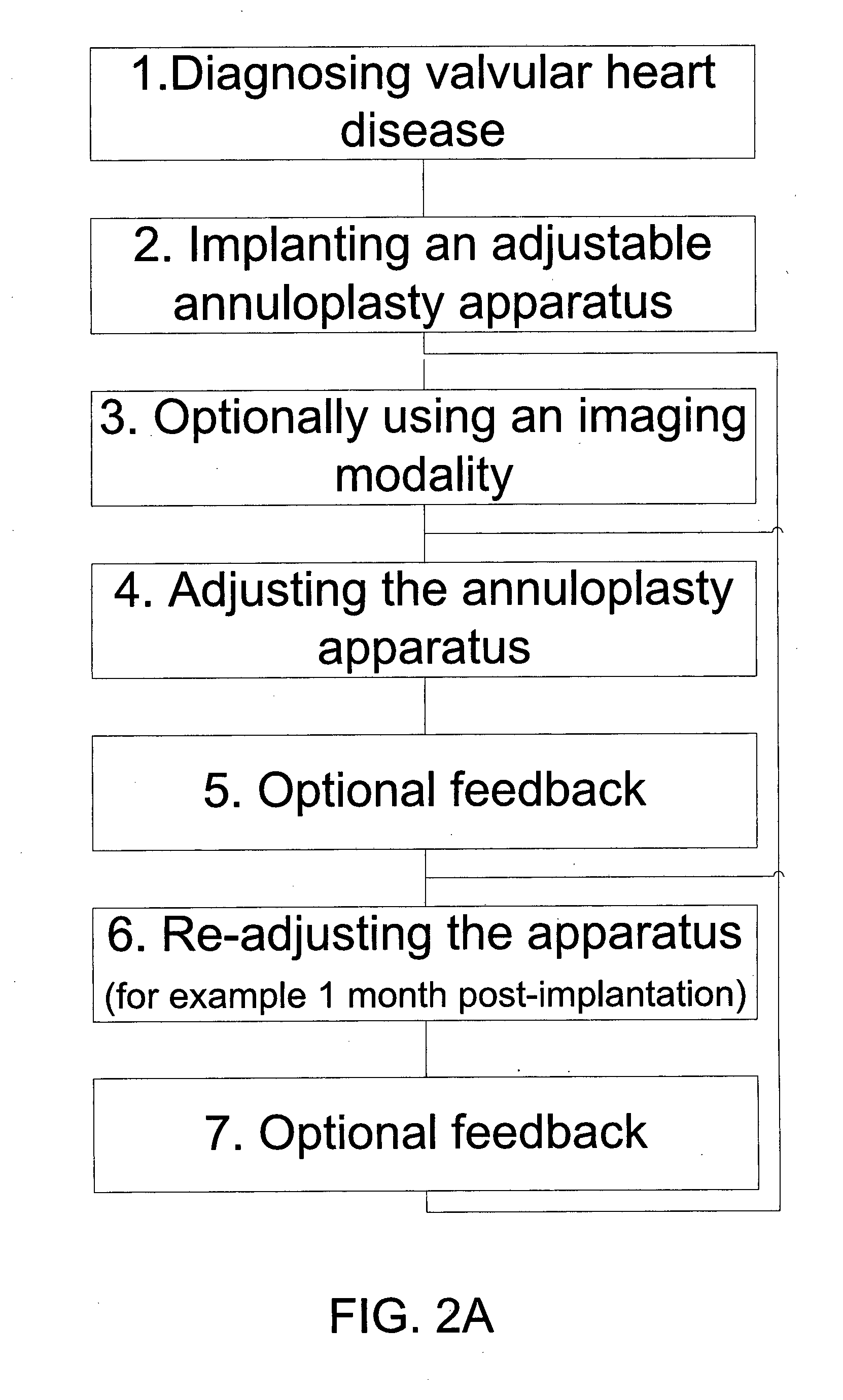

Adjustable annuloplasty apparatus

InactiveUS20160008130A1Reduce blood leakageReduce harmAnnuloplasty ringsMinimally invasive proceduresBalloon catheter

An adjustable implantable annuloplasty apparatus suited for post-implantation adjustments according to changing needs of the patient. The apparatus comprises a ring shaped main body, and a designated adjustment section extending from the main body. The main body and designated adjustment section of a deployed apparatus are fully contained within a 5 cm diameter. Optionally, the apparatus is mechanically adjusted in a minimally invasive procedure, for example by engaging the designated adjustment section using a balloon catheter. Optionally, the apparatus is adjusted at least one month post implantation.

Owner:HASIN TAL +1

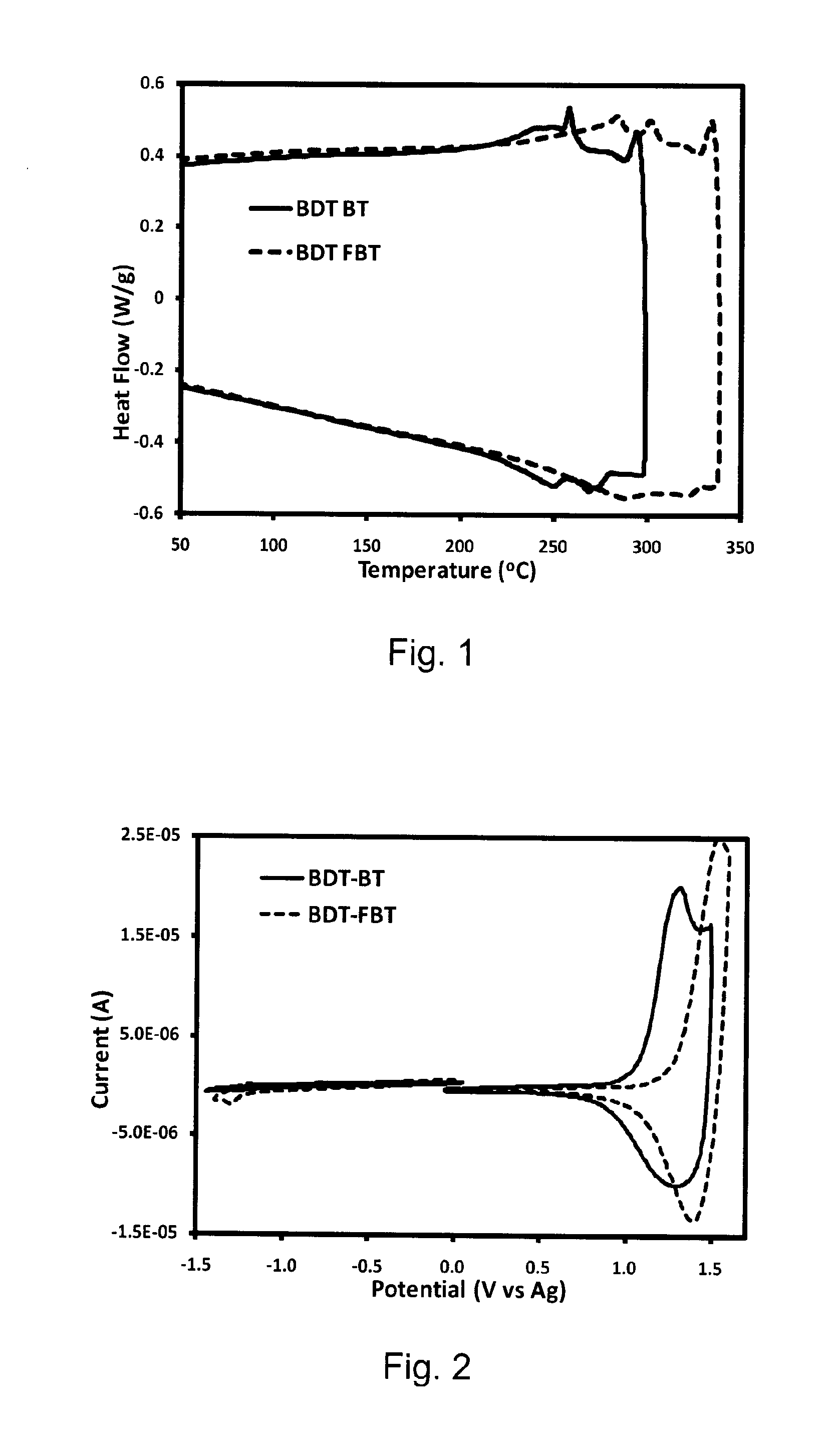

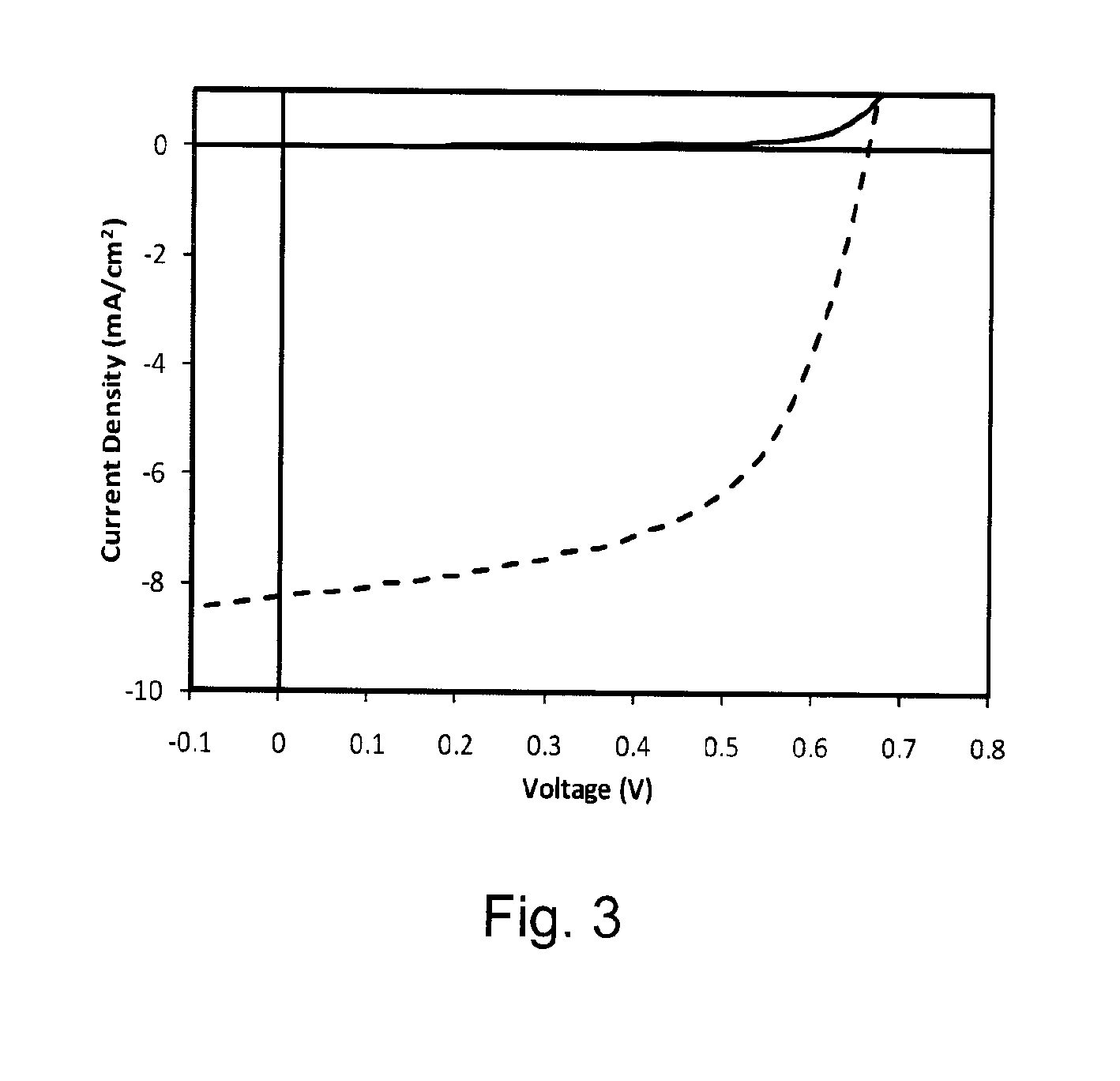

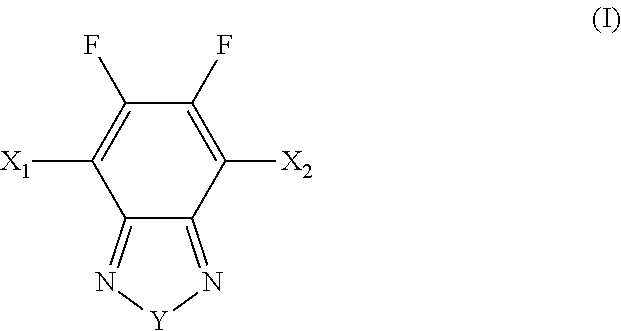

Fluorinated Monomers, Oligomers and Polymers for Use in Organic Electronic Devices

ActiveUS20120232237A1Maintain good propertiesEnhanced π-stackingOrganic chemistryNanoinformaticsArylOligomer

Compounds of Formula (I): (formula (I)) where: X1 and X2 are the same or different and each is independently Cl, Br, I, a substituted or unsubstituted aryl group or a substituted or unsubstituted heteroaryl group; and, Y is O, S, Se, NR1, R1C—CR2 or R1C═CR2, wherein R1 and R2 are the same or different and are each independently H or an organic group, are useful as monomers to produce oligomers or polymers that are useful in organic electronic devices.

Owner:NAT RES COUNCIL OF CANADA

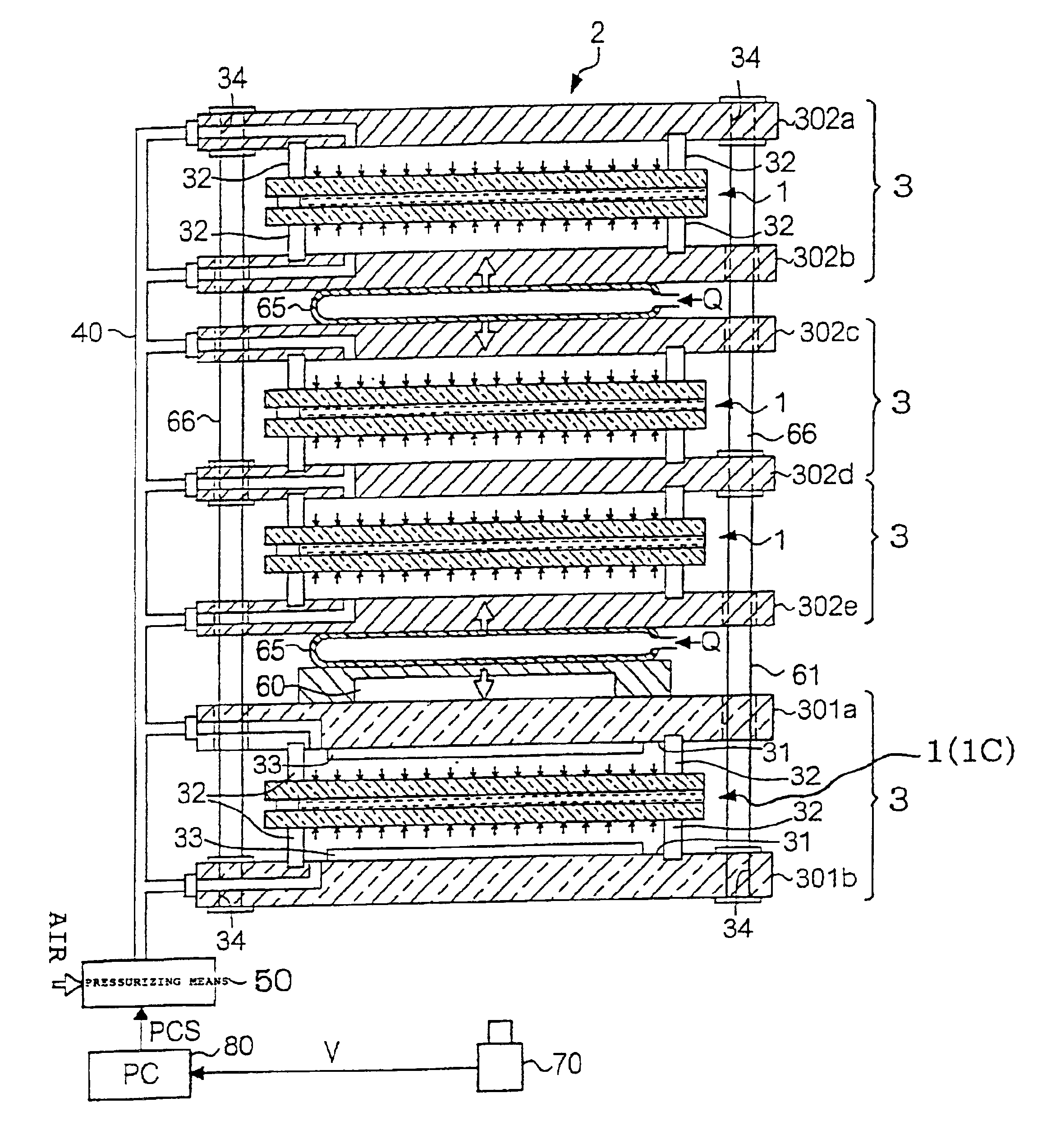

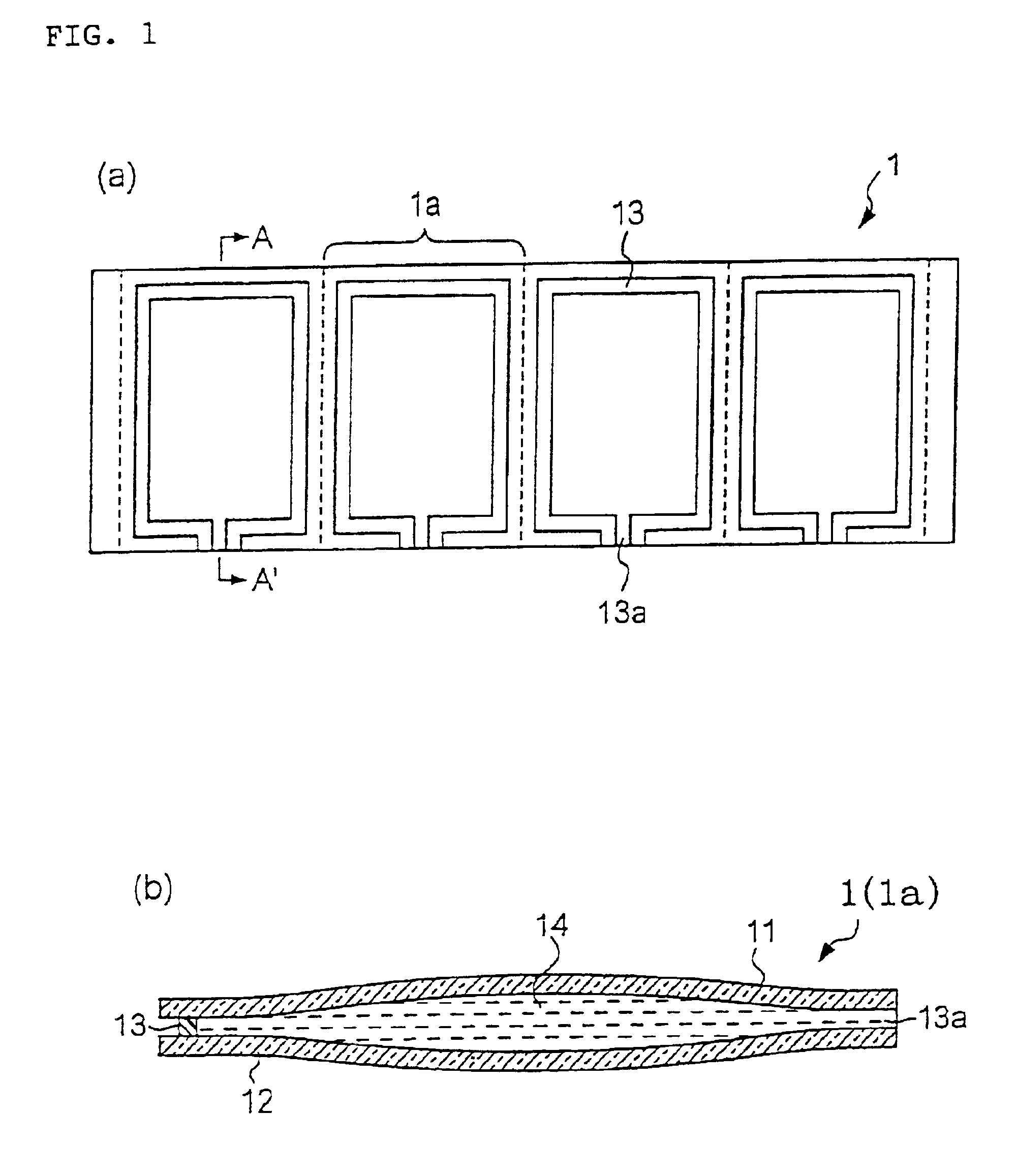

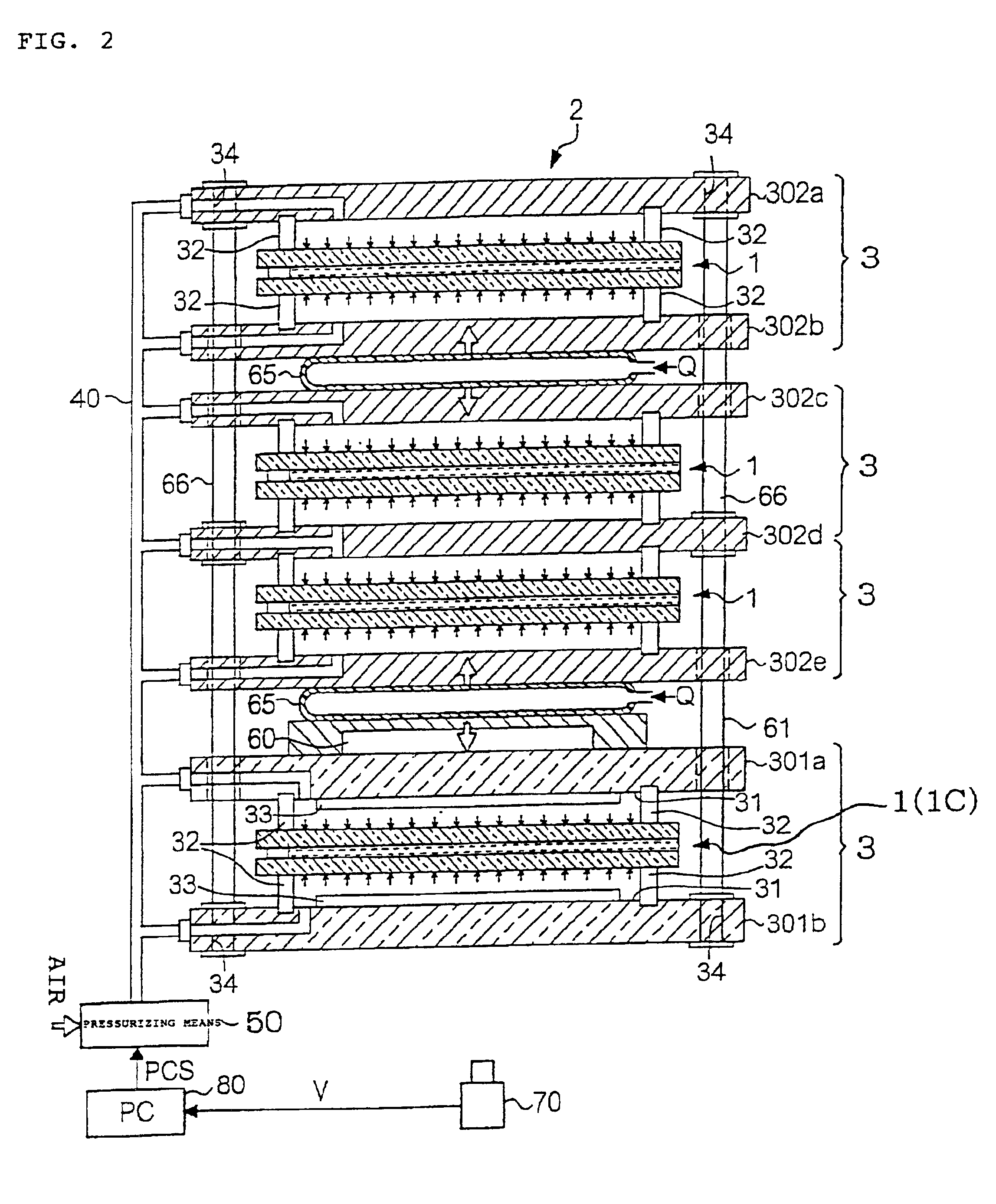

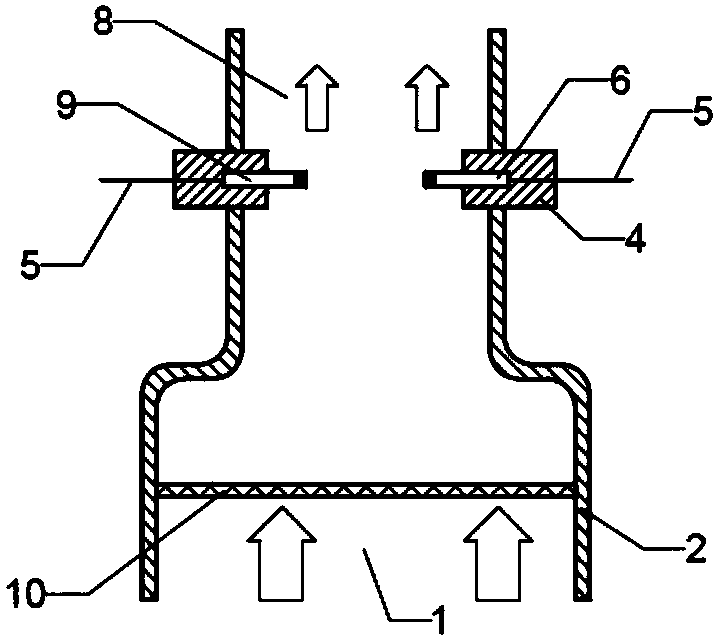

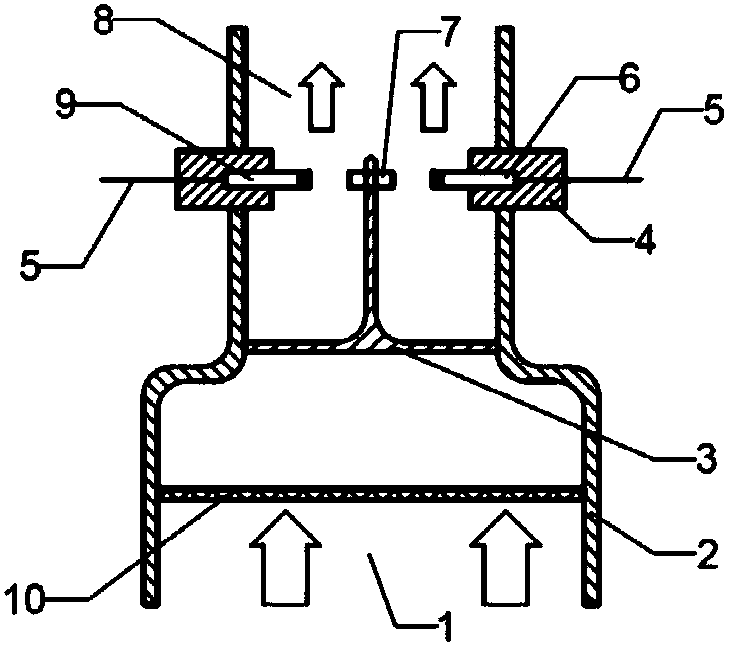

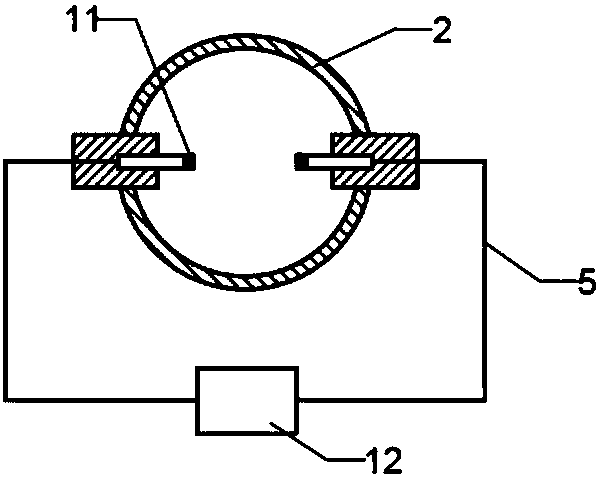

Cell gap adjusting device, pressurizing seal device and liquid crystal display device manufacturing method

A cell gap adjusting device 2 for adjusting a thickness between a pair of substrate plates (cell gap) in a liquid crystal cell 1 having a liquid crystal filled between the pair of substrate plates bonded together through a seal member having a frame form and an opening in a predetermined point of a frame wall thereof, the cell gap adjusting device characterized by comprising: a supporting part 3 having one or more pairs of supporting jigs 30 (301a, 301b, 302a-302e) for clamping to support one or more of the liquid crystal cells 1 and closing seals 32 in a frame form arranged between the liquid crystal cell 1 and the supporting jigs 30 (301a, 301b, 302a-302e) to form an enclosed space by both outer surfaces of the pair of substrate plates of the liquid crystal cell 1, opposed surfaces of the one pair of support jigs 30 (301a, 301b, 302a-302e) to the liquid crystal cell 1 and an inner surface thereof (of the closing seal); and a pressurizing part 50 for simultaneously pressurizing both outer surfaces of the one pair of substrate plates of the liquid crystal cell 1 by the pressure of a fluid introduced in the enclosed space.

Owner:SEIKO EPSON CORP

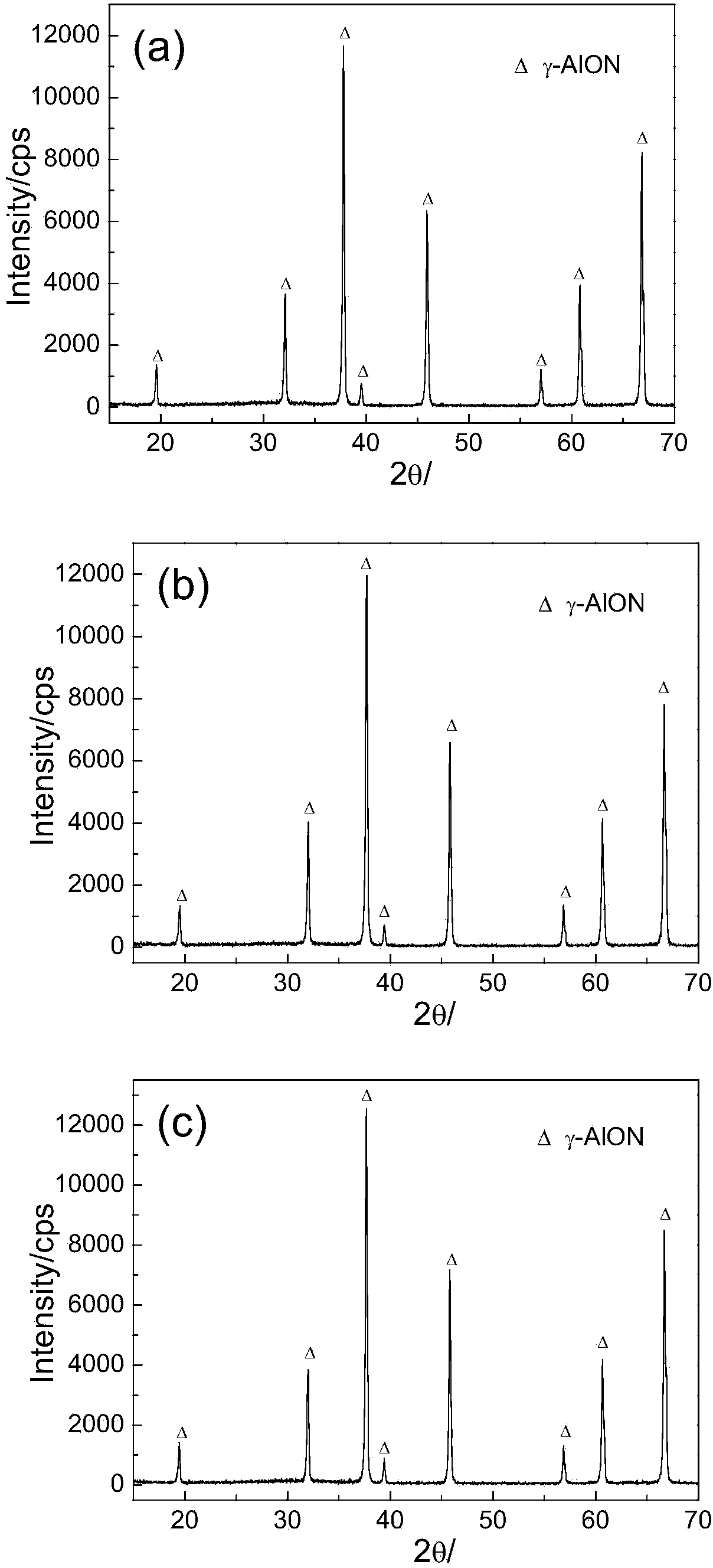

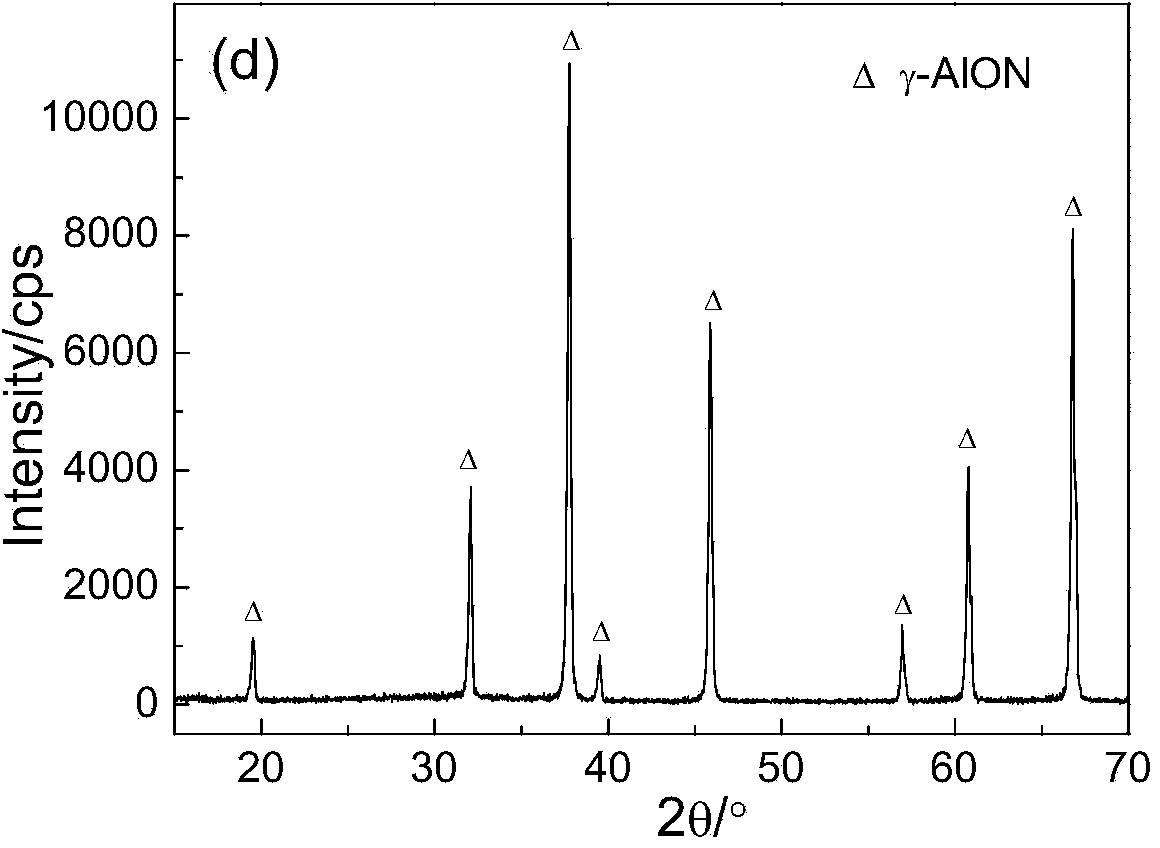

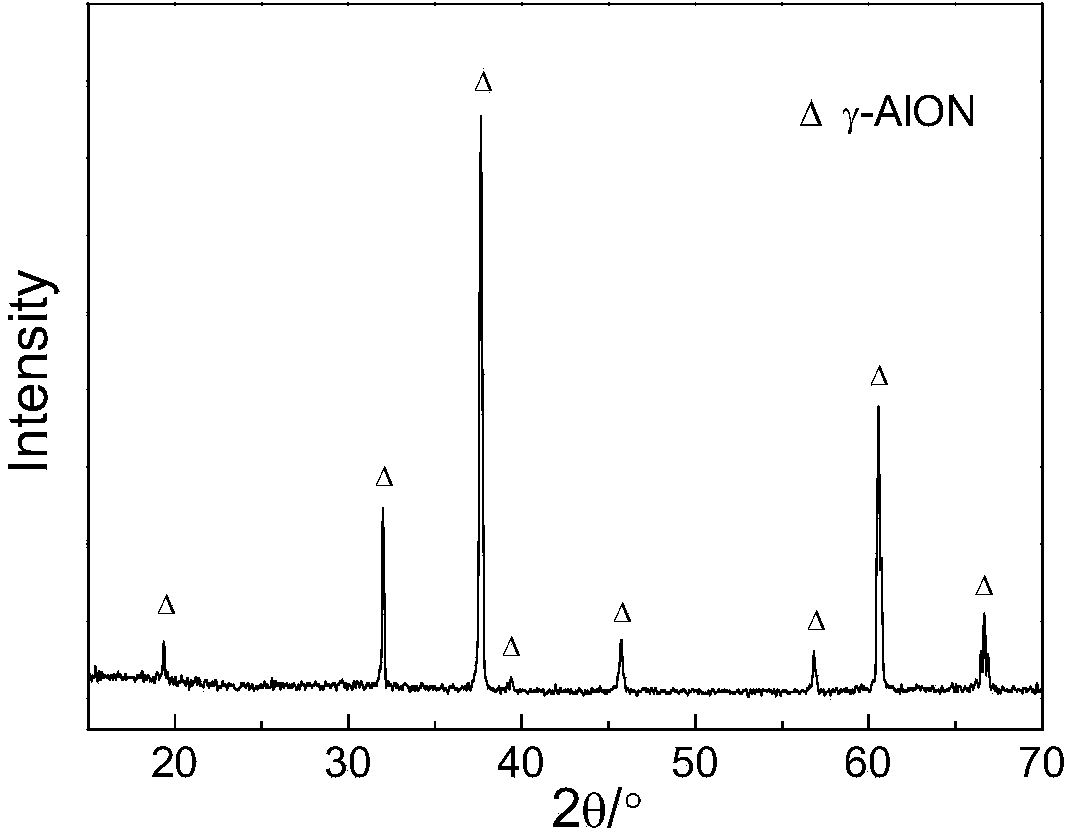

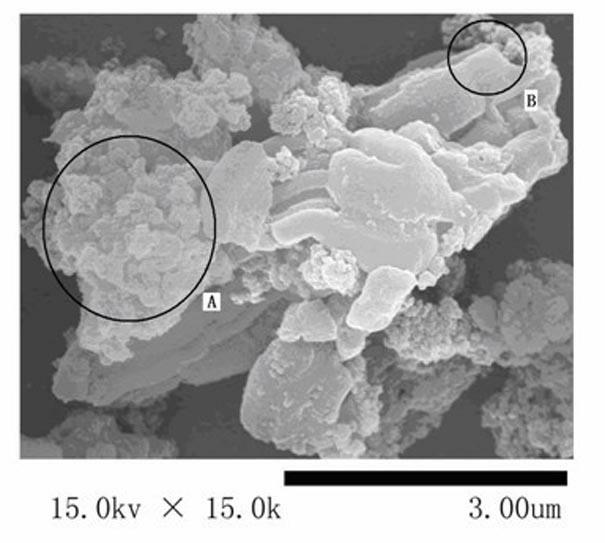

Preparation method for gamma-AlON transparent ceramic powder

The invention relates to a method for preparing pure-phase gamma-AlON transparent ceramic powder by carbothermal reduction of gamma-Al2O3, and belongs to the field of preparation of transparent ceramic materials. According to the preparation method, nano-alpha-Al2O3 and activated carbon are taken as raw materials; powder is filled in a graphite crucible loosely, wherein an aluminum oxide plate is paved at the bottom of the graphite crucible; an air hole which penetrates through the powder is preformed at the aluminum oxide plate; a graphite cover provided with fine and dense air holes is used for covering the hole; the pure-phase gamma-AlON transparent ceramic powder is prepared by adopting a two-step heating process in a flowing nitrogen environment with a micro positive pressure. By the adoption of the preparation method, the vacuumizing difficulty can be effectively reduced, powder is prevented from scattering in a vacuumizing stage, the time required for discharging adsorbed gas can be greatly shortened, the vacuumizing speed is high, and the preparation efficiency of the gamma-AlON powder is greatly improved; the obtained gamma-AlON powder phase has stable and reliable compositions and can be used for pressure-less sintering preparation of AlON transparent ceramics with high transmittance; the process is simple and is easy to operate, and is suitable for industrial production.

Owner:DALIAN MARITIME UNIVERSITY

Bulk blended yarn and production method thereof

The invention discloses a bulk blended yarn and a production method thereof. The bulk blended yarn is a staple fiber yarn having a skin core structure, wherein the staple fiber yarn is obtained by removing water-soluble polyvinyl alcohol fibers through dissolving, and the staple fiber yarn is formed by at least high shrinkage staple fibers and common staple fibers; meanwhile, the filling power of the bulk blended yarn is up to 90 % and more. The obtained bulk blended yarn is characterized in light weight and warm-keeping; the filling power is stable and durable; the bulk blended yarn is suitable for making sweaters, underwear, blankets, and the like.

Owner:东丽国际贸易(中国)有限公司

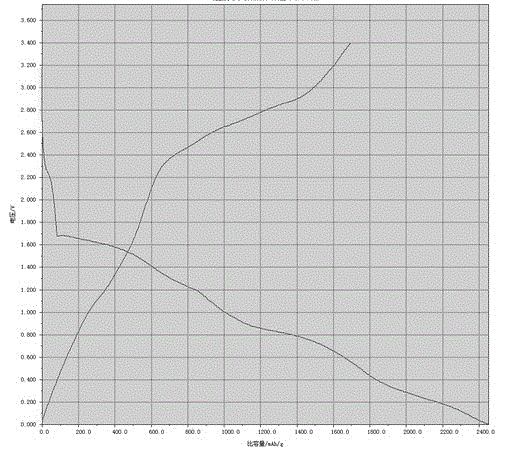

Electric core used for secondary lithium battery and preparation

InactiveCN101399368AIncrease costImprove efficiencyFinal product manufactureElectrode carriers/collectorsSolventCurrent collector

Owner:董兴国

Preparation method of porous graphene and applications of finished product thereof

InactiveCN103490050AEvenly distributedLarge specific surface areaCell electrodesSecondary cellsPorous grapheneTubing types

The invention relates to a preparation method of porous graphene and applications of finished product thereof. The preparation method comprises following steps: (1) ultrasonically dispersing graphene oxide in deionized water; (2) dissolving a certain amount of water-soluble transition metal salts in deionized water, dropwise adding the solution into the graphene oxide solution, and stirring at the same time; (3) subjecting the mixed solution to treatments of centrifugation and washing to extract products, drying the products for 1 to 20 hours; (4) putting the obtained materials into a tube-type furnace, heating, burning the materials at a constant temperature of 500 to 1050 DEG C for 1 to 20 hours, while controlling the flow speed of inert gas in the range of 10 to 300 mL / min, cooling, and collecting the solid products; (5) processing the solid products with dilute hydrochloric acid to remove the transition metal oxides in the solid products so as to obtain the porous graphene material. The porous graphene material prepared by the method has the advantages of few layers and controllable hole size, and solves the problems of non-conductivity of electrons in the vertical direction to the horizontal surface of the graphite material multi-layer graphene and obstructed route of Li. Furthermore, the construction of nano micro-hole structure is beneficial for storage, diffusion, and transportation of charges.

Owner:上海一广新能源科技有限公司

Cigarette filter tip composite material and preparation method thereof

InactiveCN101816456AReduce manufacturing costRich sourcesTobacco smoke filtersCellulose acetateNetwork structure

The invention discloses a cigarette filter tip composite material, which is characterized by consisting of the following components in percentage by mass: 30 to 90 percent of polylactic acid fibers and 10 to 70 percent of cellulose acetate fibers which form a network structure through splitting and physical entanglement and the adhesion of surface points. The invention also discloses a method for preparing the cigarette filter tip composite material. The polylactic acid fibers selected by the invention have the advantages of abundant sources, low cost and good processability, and the polylactic acid fibers are used to replace part of the cellulose acetate fibers and are used as the cigarette filter tip composite material, so that the production cost of cigarette filter tips can be reduced greatly, the production efficiency is improved, and the problems of environmental contamination, resource shortage, high cost and the like which are caused by the production of the cellulose acetate fibers are reduced. The preparation method provided by the invention has the advantages of simple and mature process and easy operation.

Owner:云南西部星空卫星科技有限公司

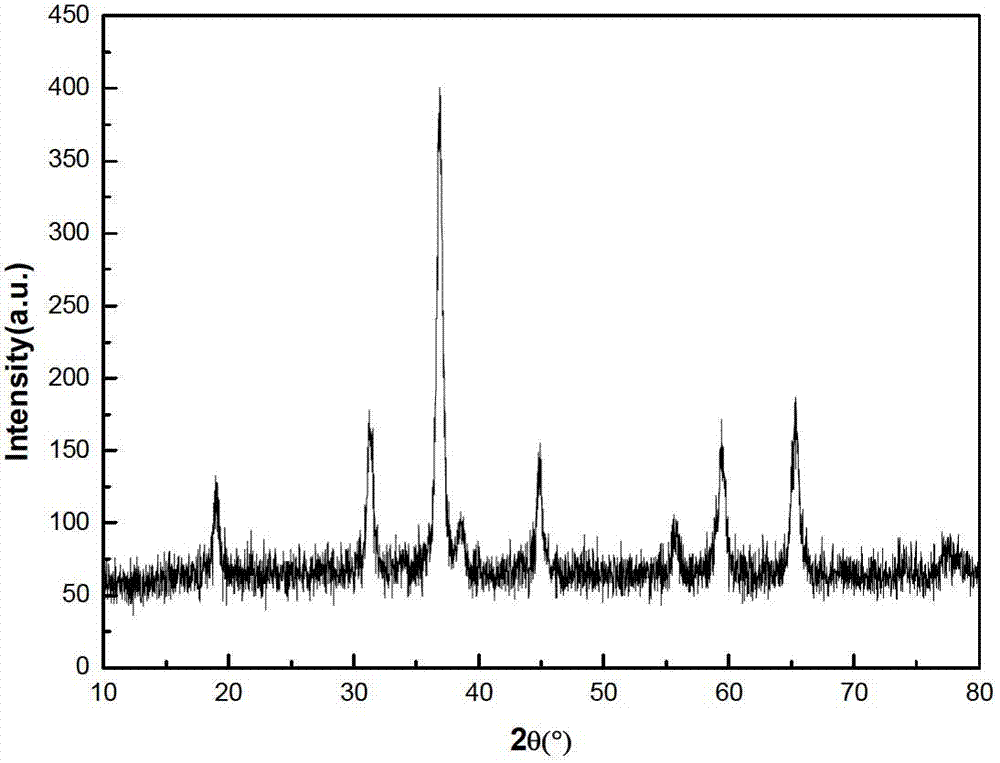

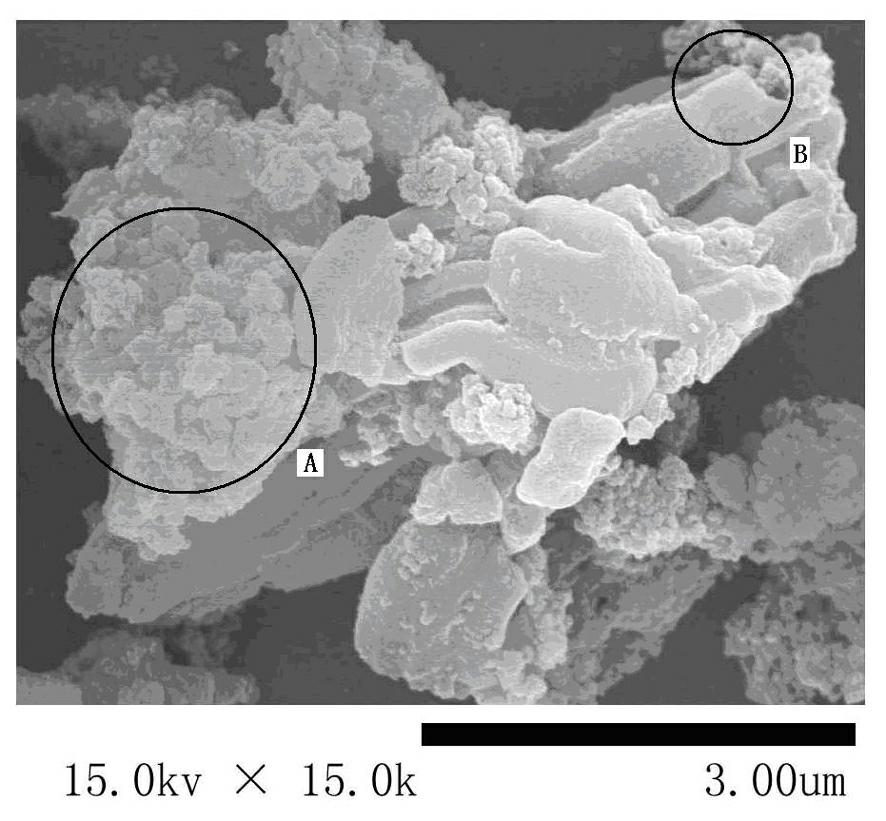

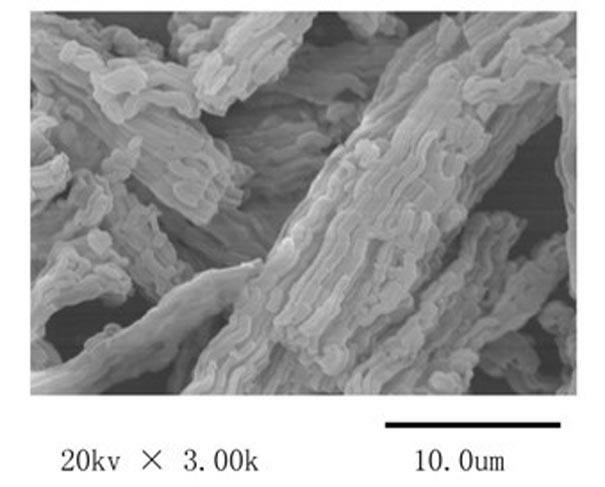

Sea-urchin-shaped hiberarchy cobaltosic oxide nanosphere and preparing method thereof

ActiveCN102887548ASimple processReduce manufacturing costMaterial nanotechnologyCobalt oxides/hydroxidesCobalt dichlorideUrea

The invention provides a sea-urchin-shaped hiberarchy cobaltosic oxide nanosphere and a preparing method thereof. The preparing method comprises the following steps of: mixing cobalt dichloride water solution with glycerol, adding urea into the mixture, reacting, removing impurities, burning, and obtaining the sea-urchin-shaped hiberarchy cobaltosic oxide nanosphere. According to the sea-urchin-shaped hiberarchy cobaltosic oxide nanosphere prepared by the method, the horsehide-shaped hiberarchy has abundant gaps, a large amount of pore ways of which the inner parts are communicated and a larger specific surface area, thus a lot of novel physicochemical characteristics which are generated in a coupling way can be owned, and the sea-urchin-shaped hiberarchy cobaltosic oxide nanosphere can be widely applied to the fields of electrochemistry, catalysis, biosensing, air-sensitive and magnetic materials.

Owner:中科(马鞍山)新材料科创园有限公司

Method for controlling fruit cracking of jujube trees in fields

InactiveCN107853060AReduce and control field cracking rateHigh densityFertilising methodsCultivating equipmentsZiziphus jujubaNutrient

The invention discloses a method for controlling fruit cracking of jujube trees in fields, and relates to the field of technologies for planting jujube trees. The method includes (1), carrying out cultivation management; (2), regulating and controlling nutrient elements; (3), regulating and controlling bioactive substances. The method has the advantages that varieties are selected, the field management is carried out, the nutrient elements and the bioactive substances are regulated and controlled, and accordingly the fruit cracking rate of the jujube trees in the fields can be lowered and controlled by the aid of the method.

Owner:明光现代农业科技合作推广服务中心 +1

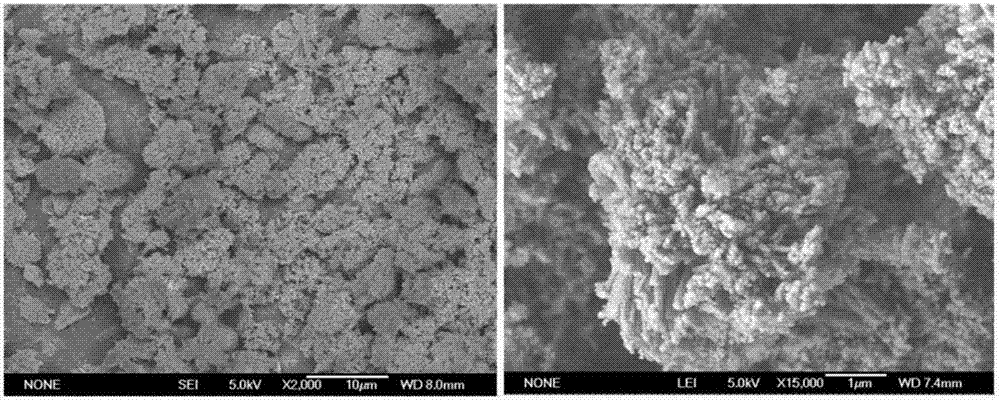

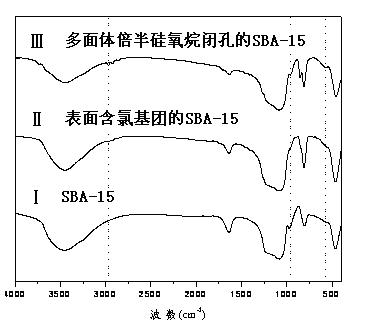

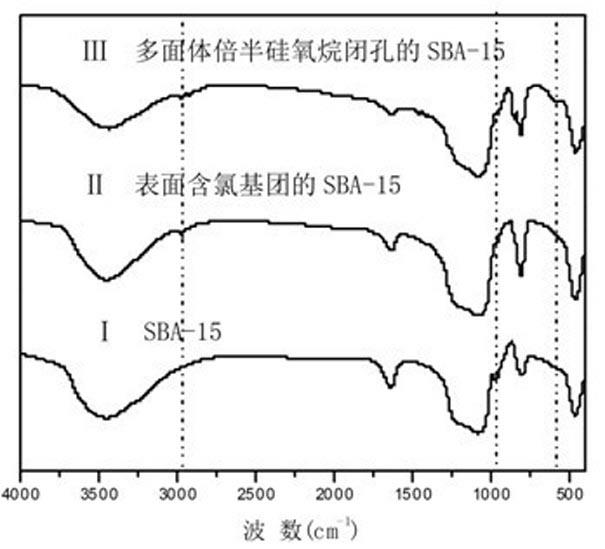

Closed mesoporous silicon oxide and preparation method of same

InactiveCN102631884AExcellent overall performanceHigh specific surface areaOther chemical processesSilicon compoundsChemistryLow-k dielectric

The invention discloses closed mesoporous silicon oxide and a preparation method of same. The preparation method comprises the steps of treating dry mesoporous silicon oxide with polychlorinated silane to prepare mesoporous silicon oxide containing chlorine groups on the surface; reacting the mesoporous silicon oxide containing the chlorine groups on the surface with polyhedral silsesquioxanes and polychlorinated silane to obtain a crude product; and after washing and drying, conducting calcination at the temperature of 230-300 DEG C, thereby obtaining the closed mesoporous silicon oxide. A coating layer is formed at the outer surface and the mesopores of the mesoporous silicon oxide by polyhedron silsesquioxane and mutual connection is realized through a Si-O bond or Si-N bond. The inner pores of the mesoporous silicon oxide are kept; besides, the mesopores of the mesoporous silicon oxide are closed by polyhedron silsesquioxane, and a larger specific surface area and more pores are obtained, so that the dielectric constant of the materials is lowered and the adsorptive property of the mesoporous silicon oxide is improved and the method provided by the invention ensures that the advantages of the mesoporous silicon oxide in preparing materials with low dielectric constant are brought into full play.

Owner:SUZHOU UNIV

Graphene nano steam generation device and cosmetic instrument

PendingCN108479658AStrong dischargeNot easy to accumulate waterChiropractic devicesMedical devicesManufacturing technologyEngineering

Owner:HANGZHOU QINGKE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

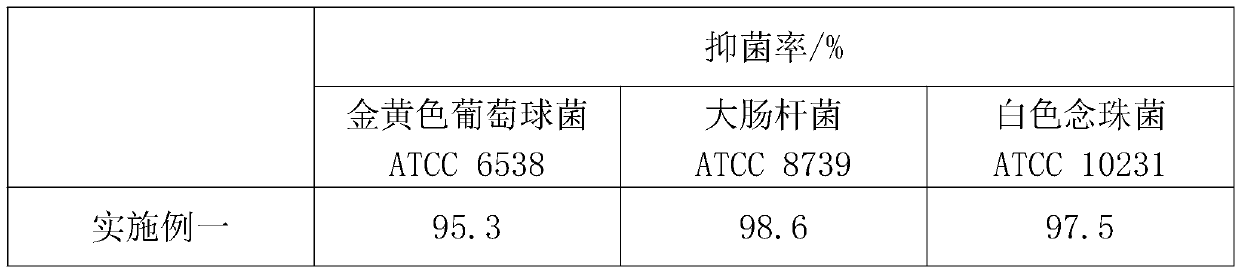

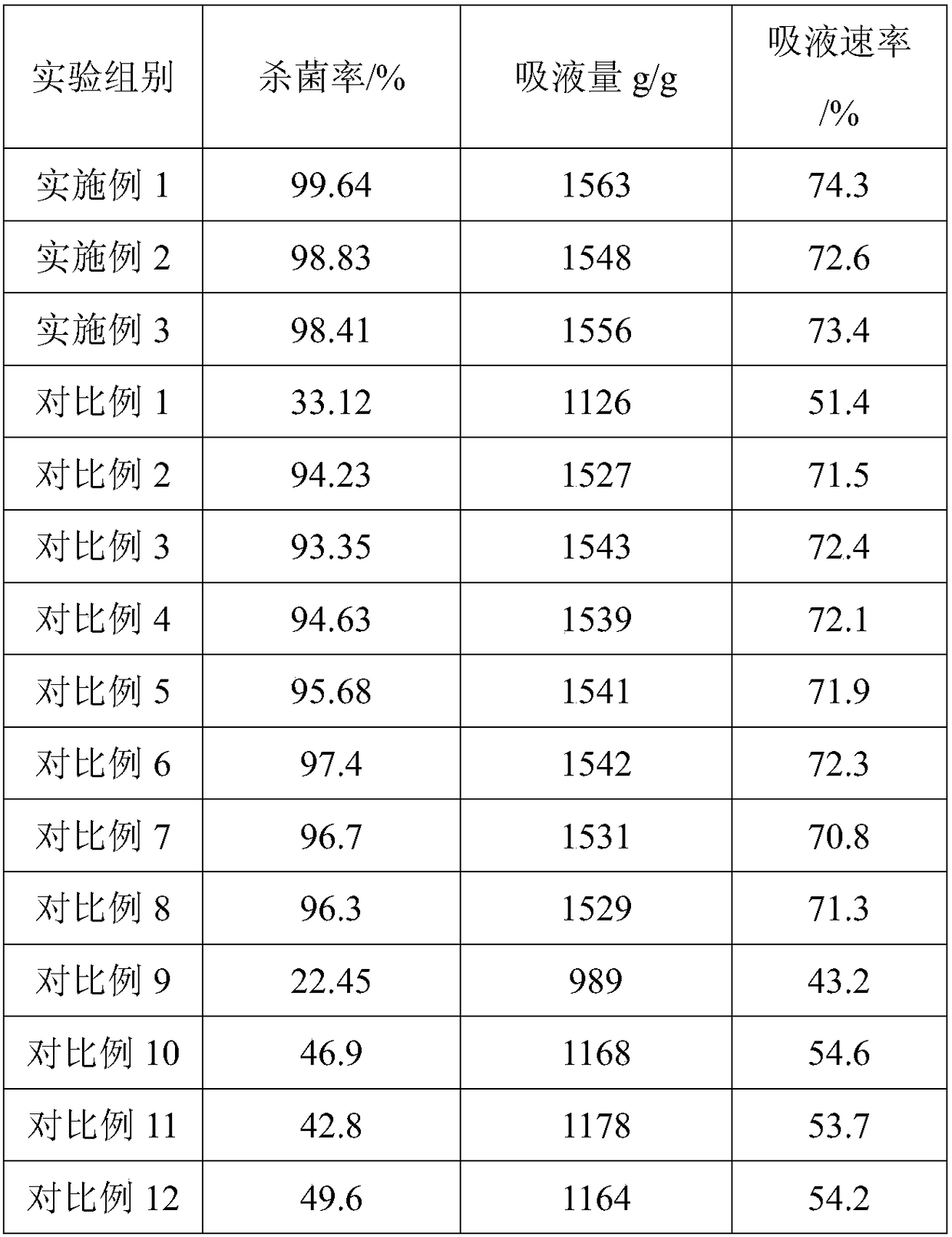

Preparation method for antibacterial melt-blown non-woven fabric

ActiveCN111424428AMany gapsFluffy structurePhysical treatmentBiochemical fibre treatmentPolymer scienceMethacrylate methyl

The invention relates to the technical field of non-woven fabrics, and provides a preparation method for an antibacterial melt-blown non-woven fabric. The preparation method comprises the following steps of (1) carrying out oxygen plasma treatment on a polypropylene non-woven fabric, and carrying out graft modification on the polypropylene non-woven fabric to prepare a modified polypropylene non-woven fabric; (2) polymerizing an amino-terminated hyperbranched polymer with propylene diamine and methyl methacrylate as raw materials, and preparing a modified hyperbranched polymer through polycondensation of carboxymethyl chitosan and the amino-terminated hyperbranched polymer; and (3) adding a copper chloride solution into a modified hyperbranched polymer aqueous solution, dropwise adding a sodium borohydride solution under nitrogen protection and ice bath conditions, carrying out impregnation treatment on the modified polypropylene non-woven fabric in the modified hyperbranched polymer aqueous solution after the reaction is finished, and drying to obtain the antibacterial melt-blown non-woven fabric. The preparation method solves a problem that the melt-blown non-woven fabric in theprior art only has an efficient filtering effect and does not have antibacterial property.

Owner:FUJIAN HENGAN HLDG CO LTD +2

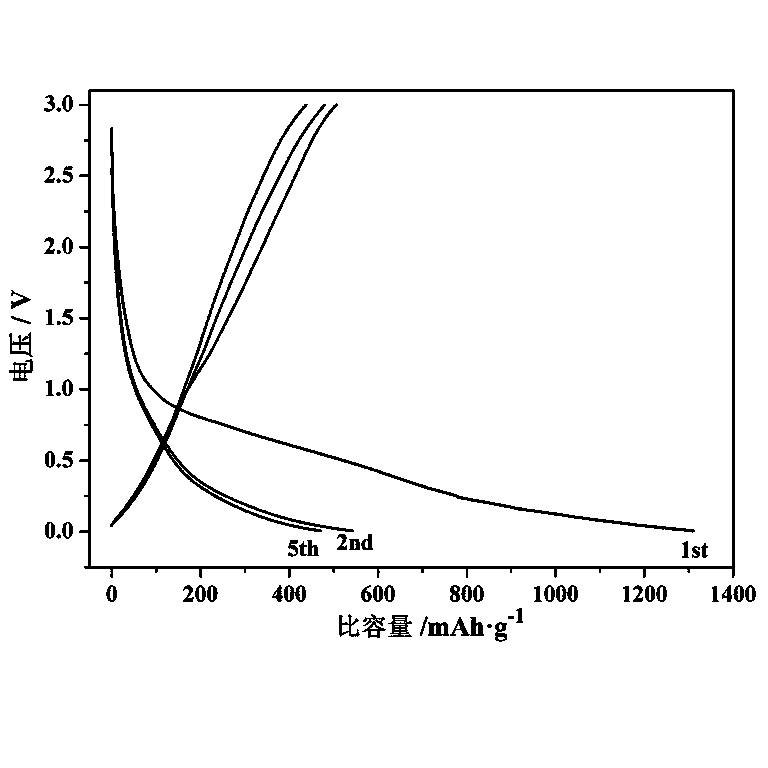

Method for preparing multilevel structure copper nitrate anode material

ActiveCN104993147AUniform particle sizeAct as a skeleton supportCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a method for preparing a multilevel structure copper nitrate anode material. The method comprises the steps of dissolving 100-200 g copper nitrate powder in 500 ml distilled water, adding 1-5 g carbon fiber after complete dissolution, stirring for 30 min at a high speed, then heating to 60-80 DEG C, adding 50-100 ml ethyl alcohol and 5 ml 1 mol / L glacial acetic acid, stirring for 3 min, then adding 1-2 g carbon black, and continuing to stir till complete volatilization; then, placing the obtained head product in an oven to be baked for 24 h at 60 DEG C, taking out the product, and grinding the product into powder, so that the multilevel structure copper nitrate anode material is obtained. The method has the advantage that the obtained copper nitrate anode material is of a stable multilevel composite structure, and the multilevel composite structure enables the copper nitrate anode material to have high capacity and long service life.

Owner:NINGBO UNIV

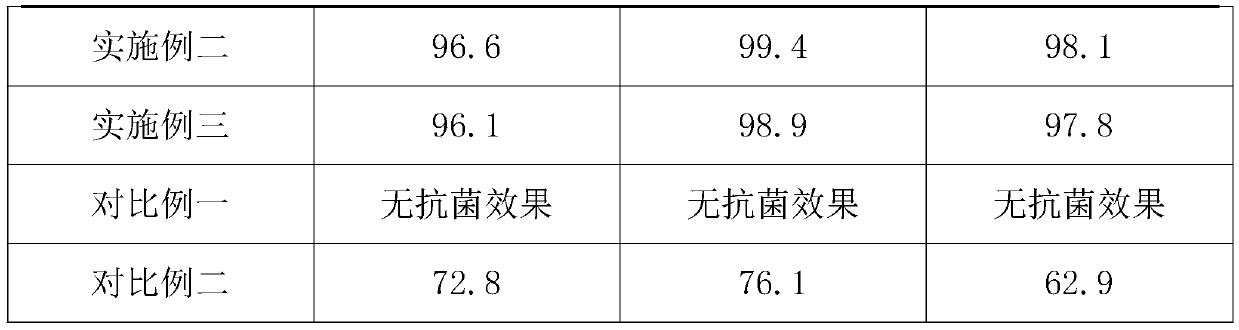

Antibacterial high-water-absorption linen and preparation method thereof

InactiveCN108729214AImprove water absorptionEnsure safetyBiochemical fibre treatmentLiquid repellent fibresPolyesterPotassium persulfate

The invention discloses antibacterial high-water-absorption linen. The antibacterial high-water-absorption linen comprises an antibacterial outer layer, a jute fiber layer and an inner base layer, wherein the antibacterial outer layer is made of polyester fiber material soaked by an antibacterial agent, the jute fiber layer is arranged in the antibacterial outer layer, the jute fiber layer is formed by interweaving warp yarns and weft yarns of jute fibers, the inner base layer is arranged inside the jute fiber layer, and the inner base layer is made of spandex fibers; and the antibacterial agent is prepared from the following raw materials: hydrogel, polylactic acid, sodium alginate, acrylamide, potassium persulfate, N,N'-methylene bisacrylamide, cortex cinnamomi extract liquid, carbon nanotube, chitosan, antibacterial reinforcing additive, water absorption reinforcing additive, and silane coupling agent KH-570. By preparing the antibacterial agent, the antibacterial agent is used forsoaking the polyester fiber material, so that the prepared antibacterial high-water-absorption linen has excellent antibacterial and water absorption performances.

Owner:长沙浩然医疗科技有限公司

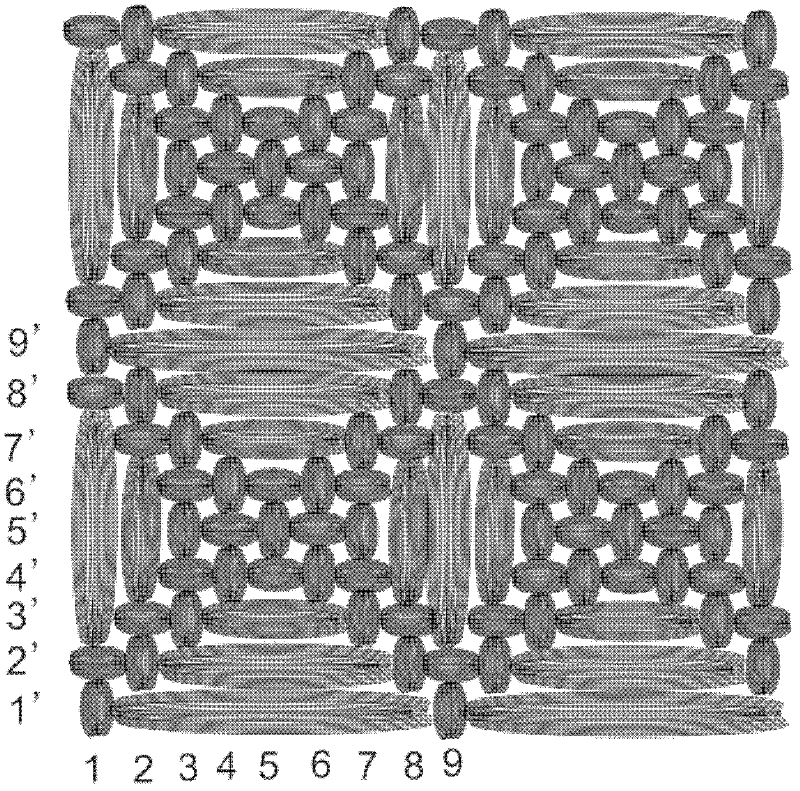

Super absorbent dust-free wiping cloth and manufacturing method thereof

InactiveCN102505253ALoose arrangementLarge specific surface areaCarpet cleanersFloor cleanersSuper absorbentLaser cutting

The invention discloses a super absorbent dust-free wiping cloth and a manufacturing method thereof. The wiping cloth is formed by interweaving warps and wefts and is characterized in that the dust-free wiping cloth is formed by circularly arranging square concave weave repeat units formed by interweaving the warps and the wefts along the warp direction and the weft direction respectively; at least one of the warp and the weft is formed by superfine fiber filaments; and in one weave repeat unit, the warps and the wefts are respectively arranged stepwise and upward in sequence from the central lowest point, and the floating length of the adjacent warps and the adjacent wefts on the steps increases in sequence to form concavo-convex patterns which are piled up alternately from low to high and have four high sides and low middle. The manufacturing method comprises the steps of beaming, drafting and reeding, weaving, weight reducing, tenter setting, laser cutting and packaging, thereby obtaining the super absorbent dust-free wiping cloth. The super absorbent dust-free wiping cloth has soft handfeel, good wiping effect and super absorbency and can be used in a dust-free room with a higher cleanliness requirement. The manufacturing method is simple and can be used for manufacturing the high-quality dust-free wiping cloth.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

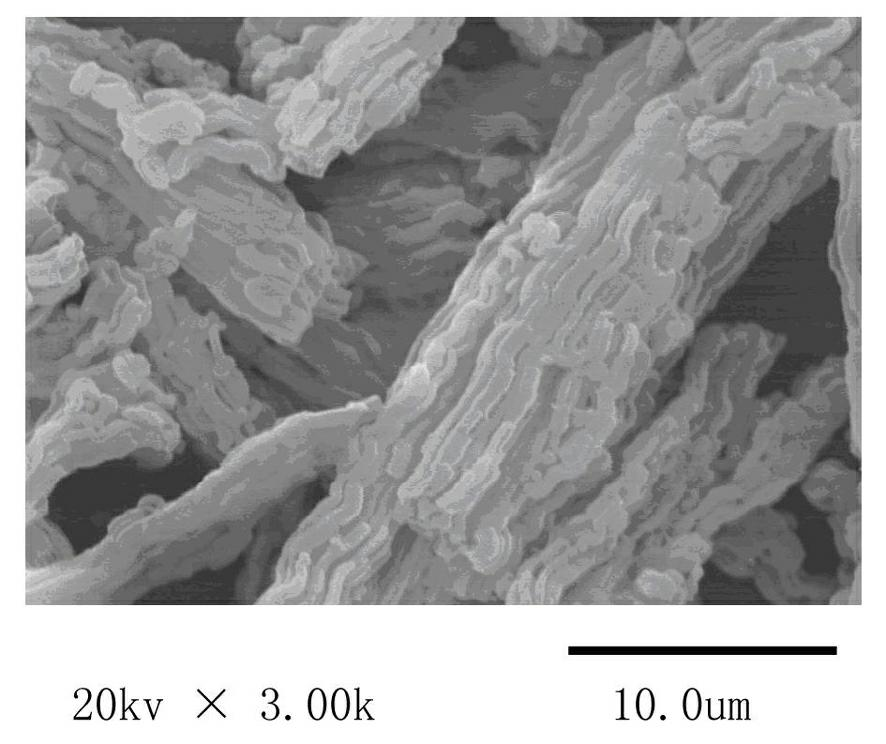

High-silicon porzite in gramineous plant structure biomorph and preparation method of high-silicon porzite in gramineous plant structure biomorph

The invention relates to a high-silicon porzite in gramineous plant structure biomorph and a preparation method of the high-silicon porzite in gramineous plant structure biomorph. According to the technical scheme, the preparation method comprises the following steps of impregnating for 3-24 hours under the condition of normal pressure or the pressure of 10<3>-10<4> Pa by taking 10%-70% by weight of a gramineous plant as a template and 30%-90wt% of aluminum sol as an impregnant, and uniformly stirring; baking the gramineous plant impregnated with the aluminum sol under the condition of 60-200 DEG C for 24-48 hours, and then preserving heat under the condition of 1100-1400 DEG C for 2-12 hours to obtain the high-silicon porzite in the gramineous plant structure biomorph. The preparation method disclosed by the invention is not only capable of integrally retaining the intrinsic structures of natural plants, but also capable of forming porzite nanoparticles on the surfaces of the hole walls of the natural plants, thereby thinning the hole structure and enhancing the frame strength, the high-temperature volume stability and the acid-proof and alkali-proof corrosivity; the porous morphological intrinsic structure has large specific area and has high potential in the fields of high-temperature insulation, catalyst carriers and the like.

Owner:WUHAN UNIV OF SCI & TECH

Composite and efficient oil-water-separation filter paper for hydraulic filter

InactiveCN105986512AWell dispersedGood dispersionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperAlkali freeSisal fiber

The invention discloses composite and efficient oil-water-separation filter paper for a hydraulic filter. The composite and efficient oil-water-separation filter paper is prepared by, by weight, 50-55 parts of 3-5mm alkali-free superfine glass fiber, 55-60 parts of bleached softwood pulp, an appropriate amount of distilled water, 0.8-1 part of anionic polyacrylamide, an appropriate amount of concentrated sulfuric acid with the concentration being 98wt%, 10-12 parts of nano titanium dioxide, 20-25 parts of ferroferric oxide colloidal solution with the solid content being 30%, an appropriate amount of anhydrous ethanol, 60-65 parts of fluoro-silicon emulsion with the solid content being 40wt%, 1-1.2 parts of alkenyl succinic anhydride, 7-8 parts of sisal fiber, 3-4 parts of waste rubber powder, 0.9-1.1 parts of silane coupling agent kh550, 1.5-2 parts of organic silicon emulsion and 2-3 parts of urea. By the scientific and reasonable component proportion, the composite and efficient oil-water-separation filter paper is good in absorbability, good in hydrophobic and oleophylic performance and capable of efficiently separating oil and water. When the filter paper is applied to the hydraulic filter, hydraulic equipment can be well protected.

Owner:ANHUI PHOENIX INT CO LTD

Toothpaste for eliminating bad breath

InactiveCN104606102AProportionally largeMany gapsCosmetic preparationsToilet preparationsToothpasteHumectant

The invention discloses toothpaste for eliminating bad breath, and relates to the technical field of toothpaste. The toothpaste comprises the following ingredients: 13-50% of a friction agent, 20-65% of a humectant, 2.0-2.2% of a foaming agent, 1.2-1.5% of a thickening agent, 3-8% of modified bamboo charcoal, 1-5% of bamboo vinegar, 0.3% of sodium saccharin, 0.15% of enhanceparaben, 0.15-0.3% of sodium pyrophosphate, 1.0-1.2% of edible essence and the balance of deionized water. Compared with conventional toothpaste, the toothpaste has the functions of improving the degree of fresh breath and prolonging the time for fresh breath.

Owner:LIUZHOU TEACHERS COLLEGE

Method for cultivating organic-selenium-rich pleurotus nebrodensis with traditional Chinese medicine dregs

InactiveCN105766364AHigh biological efficiencyNeat fruitingHorticultureFertilizer mixturesSlurryPleurotus nebrodensis

The invention discloses a method for cultivating organic-selenium-rich pleurotus nebrodensis with traditional Chinese medicine dregs, and relates to the field of edible fungus cultivation. According to the invention, wastes such as traditional Chinese medicine dregs, selenium-rich mushroom residue and biogas slurry are reasonably formulated and utilized, and are blended to form a pleurotus nebrodensis special-purposed medium with the components of cotton seed hull, wheat bran, sawdust, corn flour, gypsum powder, urea, calcium superphosphate, calcium oxide, an organic-selenium-rich additive and the like. With the combination of the two measures of organic-selenium-rich medium cultivation and mixed liquid spraying, the pleurotus nebrodensis cultivation biological efficiency is substantially improved. Fruiting is even, and the obtained pleurotus nebrodensis has good quality and high organic selenium content. Intertidal selenium contents are uniform, and the change is not sharp. The adopted additive has high stability and biological activity, and assists in sterilizing and preventing pests. The additive has a good sustained-release effect.

Owner:王贵孝

Novel aluminum alloy anodic oxidation process

The invention discloses a novel aluminum alloy anodic oxidation process. The novel aluminum alloy anodic oxidation process comprises the following steps: (S01) mechanical polishing is performed; (S02)pretreatment: a polished aluminum alloy is put in circular flowing degreasing liquid for degreasing; (S03) cleaning: after degreasing is finished, water of 50-55 DEG C is used for spraying the surface of the aluminum alloy until no residue is on the surface; (S04) anodic oxidation: the cleaned aluminum alloy is immediately put in anodic oxidation liquid for anodic oxidation; (S05) coloring: the aluminum alloy treated in the step (S04) is cleaned until no residue is on the surface, and is dried; and screen printing of color paste is performed on an anodic oxidation film of the aluminum alloy;and (S06) the hole sealing treatment is performed by 10-12 min. The anodic oxidation process adopts a sulfuric acid anodic oxidation method; and through assistance by mated methods, the prepared anodic oxidation film of the aluminum alloy has natural fragrance to improve additional value. Further, the anodic oxidation film prepared by the anodic oxidation process is high in hardness, more in air gaps and high in absorption force, facilitates dyeing, and achieves higher corrosion resistance after closing treatment.

Owner:FOSHAN CITY GAOMING GAOSHENG ALUMINUM CO LTD

Preparation process of novel aluminum alloy anodic oxidation film

The invention discloses a preparation process of a novel aluminum alloy anodic oxidation film. The preparation process comprises the steps that S01, degreasing treatment is conducted; S02, chemical polishing treatment is conducted; S03, corrosive wash is conducted, specifically, an aluminum profile after being subjected to degreasing is placed in circularly flowing corrosive wash liquid for corrosive wash; S04, washing is conducted; S05, anodic oxidation treatment is conducted; S06, coloring is conducted, specifically, an aluminum alloy treated through the S04 step is washed until the surfacehas no residue, drying is conducted, and color paste is screen-printed on the anodic oxidation film of the aluminum alloy; and S07, hole sealing is conducted, specifically, the surface of the aluminumalloy is rinsed by using 50-55 DEG C of water, and hole sealing treatment is conducted in 100-102 DEG C of water steam. The preparation process of the novel aluminum alloy anodic oxidation film adopts a sulfuric acid anode oxidation method, supplemented with matched components and methods, the prepared aluminum alloy anodic oxidation film has natural fragrance, and added value of the aluminum alloy anodic oxidation film is promoted. Further, the anodic oxidation film prepared through the anodic oxidation process has high hardness, many gaps and high adsorption capability, is beneficial for dyeing, and has high corrosion resistance after being subjected to sealing treatment.

Owner:FOSHAN CITY GAOMING GAOSHENG ALUMINUM CO LTD

Modified activated carbon adsorption desulfurization agent and its preparation method

InactiveCN103495403AHigh activityImprove adsorption capacityOther chemical processesGlycerolCopper oxide

A modified activated carbon adsorption desulfurization agent is prepared from the following raw materials: by weight, 100-120 parts of coconut shell activated carbon, 1-2 parts of ammonium persulfate, 1-2 parts of copper oxide, 1-2 parts of lanthanum oxide, 1-2 parts of chromium oxide, 12-14 parts of corn cob, 1-2 parts of agar, 4-5 parts of glycerin, 8-10 parts of modified attapulgite and a proper amount of water. The modified activated carbon adsorption desulfurization agent containing lanthanum, chromium, copper and multiple metal oxides can more thoroughly and rapidly oxidize sulfides; the modified activated carbon adsorption desulfurization agent processed by spray drying has higher activity and stronger adsorption ability; and due to the addition of the corn cob, the modified activated carbon adsorption desulfurization agent has more spaces and can absorb more sulfides.

Owner:BENGBU PIONEER FILTER

Preparation method of acellular dermal matrix material

InactiveCN109364298AClean up thoroughlyLow toxicityTissue regenerationProsthesisAntigenSplit skin graft

The invention discloses a preparation method of an acellular dermal matrix material. The preparation method of the acellular dermal matrix material is characterized in that removing flesh and hair from an animal skin, then taking a split-skin graft, and carrying out defatting, unhairing, inactivation of virus, cell extraction, crosslinking modification, cleaning and moisturizing, packing and irradiation sterilization processes to obtain the acellular dermal matrix material. The preparation method of the acellular dermal matrix material has the characteristics that the process time is short, aneffect of removing antigen substances is good, and the material has quite good adhering property, moisture retention property, breathability and the like.

Owner:JIANGYIN BENXIANG BIOTECHOLOGY

Nano-manganese dioxide for removing underground water heavy metal pollution and preparation method of nano-manganese dioxide for removing underground water heavy metal pollution

ActiveCN106319019AGood for oxidation adsorptionIrregular spatial structureBacteriaMicroorganism based processesPseudomonas putidaCell culture media

Disclosed are nano-manganese dioxide for removing underground water heavy metal pollution and a preparation method of the nano-manganese dioxide for removing underground water heavy metal pollution. The preparation method includes the steps of 1), inoculating one or more of Leptothrix discophora SS-1, Pseudomonas putida MnB1 and Bacillus sp SG-1 to a microbial growth medium and culturing at 25-30 DEG C; 2), centrifuging a mixture obtained in the step 1 to obtain a bacterial body and cleaning and precipitating the bacterial body; 3), inoculating the bacterial body obtained in the step 2 to a manganite culture medium and culturing at 25-30 DEG C; 4), adding MnCl2 and Na3VO4 into a product obtained in the step 3 and culturing at 28-30 DEG C so as to obtain black precipitate, namely the nano-manganese dioxide.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Dense low-resistance super capacitor diaphragm material and preparation method thereof

InactiveCN107527749ALower resistanceImprove uniformityHybrid capacitor separatorsCarvacryl acetateNonwoven fabric

The invention discloses a dense low-resistance super capacitor diaphragm material which comprises the following raw materials, by weight, 100 parts of matrix fibers, 15 to 20 parts of polyvinylidene fluoride fibers, 25 to 30 parts of acetone, 100 to 110 parts of dimethylacetamide, 10 to 20 parts of ceramic fiber, 10 to 20 parts of SAF superabsorbent fiber, 1 to 2 parts of zinc oxide, 2 to 4 parts of cationic starch and 5 to 15 parts of vinyl acetate emulsion. The invention also discloses a preparation method of the dense low-resistance super capacitor diaphragm material. In the invention, the polyvinylidene fluoride fiber is firstly subjected to spinning to obtain a spinning diaphragm with a thickness of 6-8 [mu]m, and then the matrix fiber is made into a non-woven fabric by a wet nonwoven fabric process, and the two are combined via a heat-pressing manner to be produced into the dense low-resistance super capacitor diaphragm material.

Owner:SUZHOU HAILINGDA EIECTRONIC TECH CO LTD

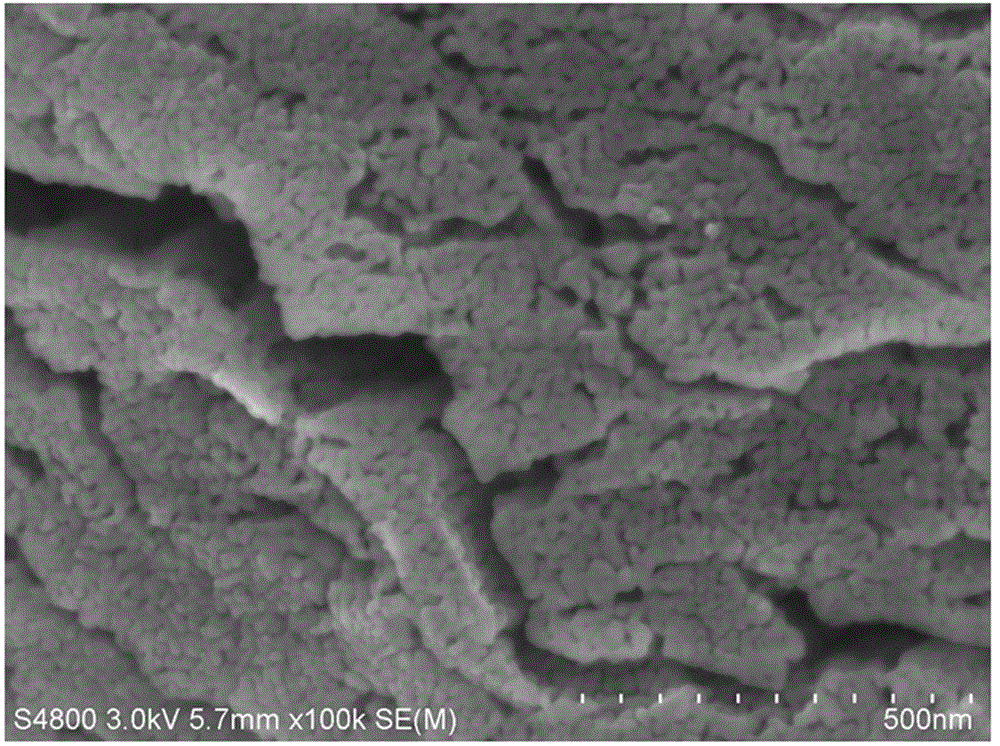

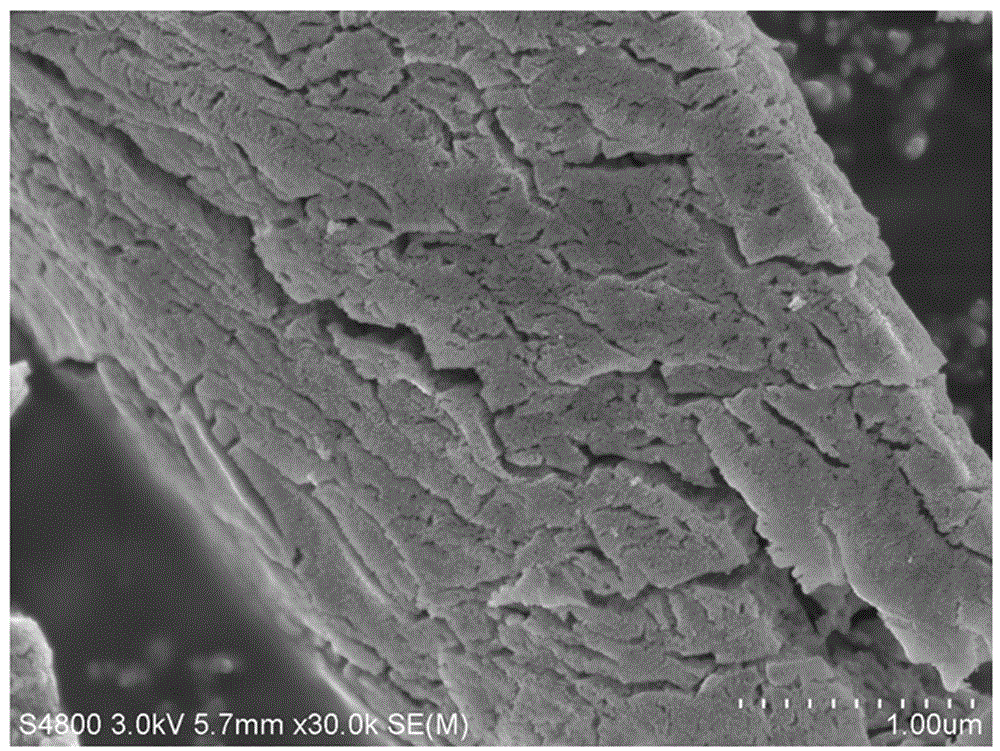

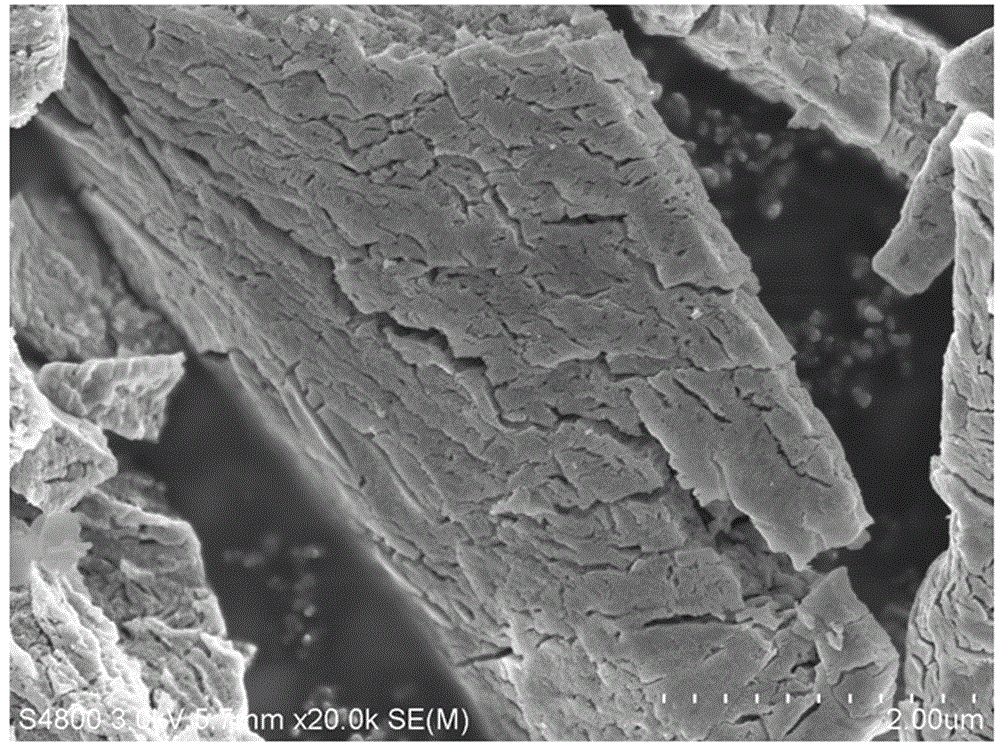

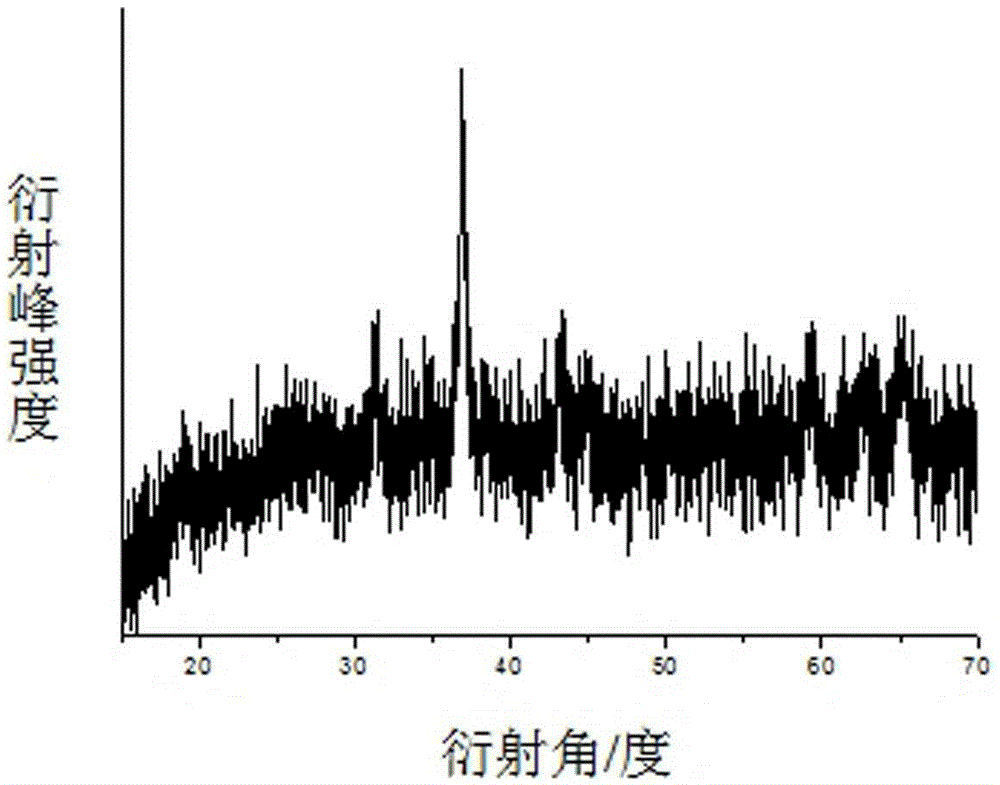

Preparation method of manganese sesquioxide hierarchical-structure material

InactiveCN105883924ALarge specific surface areaMany gapsMaterial nanotechnologyHybrid capacitor electrodesCapacitanceSesquioxide

The invention belongs to the technical field of functional material preparation and relates to a preparation method of a manganese sesquioxide hierarchical-structure material. The method comprises the following steps: dropwise adding a soluble manganese salt aqueous solution into an oxalic acid aqueous solution; reacting at constant temperature under a stirring condition until precursor precipitate is generated; and after the reaction is over, filtering, washing, drying and calcining to obtain the manganese sesquioxide hierarchical-structure material. The product is a flaky hierarchical-structure material formed by assembling a large quantity of manganese oxide nano particles. The flake size is 10-20mu m, and the size of the manganese oxide nano particles is 20-30nm. With low preparation cost and easiness in operation control, the technology has relatively high production efficiency and can realize industrial mass production. The manganese sesquioxide hierarchical-structure material prepared by the preparation method is used as an electrode material and has relatively high specific capacitance and good cycle performance.

Owner:BOHAI UNIV

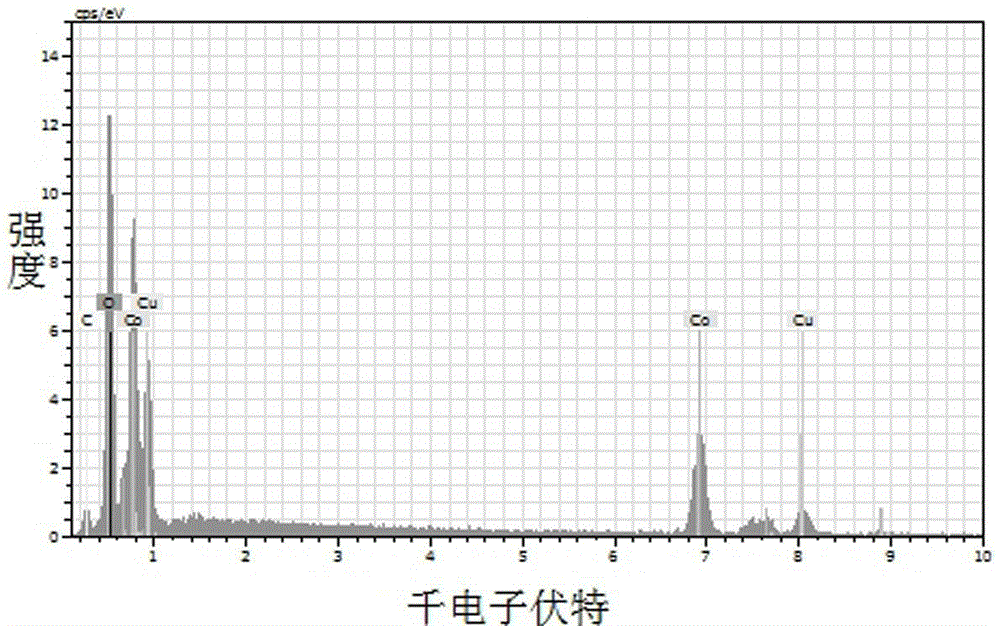

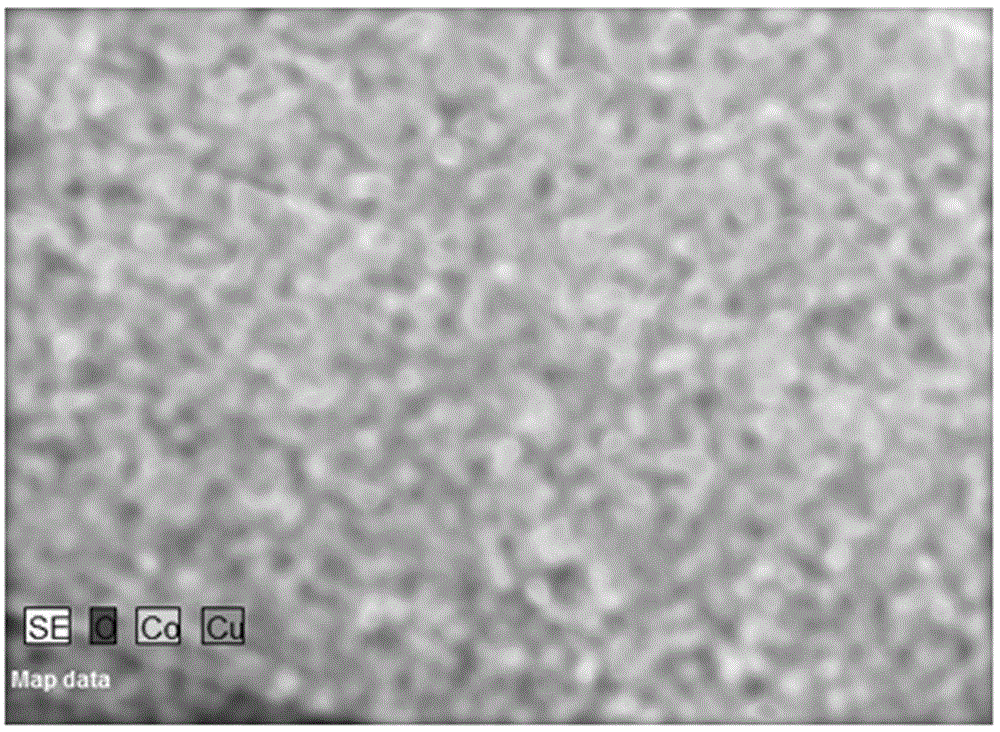

Preparation method of copper cobaltate porous microrod and nickel foam composite electrode material

InactiveCN105336503AImprove diffusion and mass transfer performanceLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureDispersityMetallic materials

The invention belongs to the field of preparation of inorganic nonmetallic materials, and particularly relates to a preparation method of a copper cobaltate porous microrod and nickel foam composite electrode material. The preparation method comprises the steps that clean nickel foam is soaked in an oxalic acid aqueous solution, and a mixed aqueous solution of soluble copper salt and soluble cobalt salt is dropwise added into the oxalic acid aqueous solution under the condition of stirring at room temperature; stirring reaction is conducted till micron-structure precursors grow out on the surface of the nickel foam, the nickel foam is taken out, cleaning, drying and calcining are sequentially conducted, and the copper cobaltate porous microrod and nickel foam composite electrode material is obtained. According to the preparation method of the copper cobaltate porous microrod and nickel foam composite electrode material, the technology is simple and easy to carry out, the product purity is high, the preparation cost is low, the diameter of a copper cobaltate microrod ranges from 0.5 micrometer to 2 micrometers, the length of the copper cobaltate microrod is about 5-10 micrometers, the size of a nano pore channel ranges from 10 nm to 50 nm, the uniformity and the dispersity of the product are both good, the copper cobaltate porous microrod and nickel foam composite electrode material can be directly applied to electrode materials of supercapacitors, the production technology is simple, and the preparation method is prone to be applied to practical large-scale production.

Owner:BOHAI UNIV

Modified thermosetting resin and preparation method thereof

The invention discloses a modified thermosetting resin and a preparation method thereof. 100 parts of heat curable resin and 0.1-100 parts of closed pore meso pore silicon oxide are uniformly mixed at the temperature of 30-180DEG C, and a modification thermosetting resin is obtained. The closed-pore mesoporous is prepared through the steps that: polyhedral silsesquioxane forms a coating on an external surface and apertures of meso pore silicon oxide, the closed-pore mesoporous silicon oxide is connected by Si-O key or Si-N key. The closed pore meso pore silicon oxide has a higher specific surface area comparing to the original closed-pore mesoporous silicon oxide, and simultaneously possesses more interfaces, which can avoid that the resin enters interfaces of inorganic materials, guaranteeing the modification thermosetting resin possesses a low dielectric property, and a stable performance. The preparation method for modified thermosetting resin disclosed in the invention has the characteristics of extensive applicability and simple operation.

Owner:SUZHOU UNIV +1

A kind of vegetation concrete and its preparation method and application

ActiveCN110317008BReduce manufacturing costPromote resource utilizationSuperphosphatesHops/wine cultivationCelluloseVegetation

The invention discloses a vegetation concrete, which comprises the following components by weight: 5-8 parts of low-alkalinity cementitious material, 3-5 parts of plant fiber, 0.02-0.05 part of cellulose ether, 40-60 parts of soil, organic fertilizer 20-40 parts of soil, 0.5-1 part of chemical fertilizer, 0.5-3 parts of grass seed, 10-20 parts of pottery sand, 20-30 parts of water. The invention also discloses the preparation method and application of the above-mentioned vegetation concrete. The vegetation concrete of the present invention is weak in alkalinity in the process of hydration, and can provide a suitable growth environment for plants; it can also reduce the phenomenon of cracking and falling off, and increase stability; and it has excellent fertilizer and water retention performance, providing plants with Excellent growing environment. The preparation method of the vegetation concrete of the invention is simple and easy to operate, and it can be applied to projects of ecological slope protection, side slope greening, isolation zone greening or mine greening.

Owner:HUAXIN CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com