Method for preparing multilevel structure copper nitrate anode material

A negative electrode material, copper nitrate technology, applied in the field of preparation of copper nitrate negative electrode material, can solve the problems of unobtainable cost, rising cost, high energy consumption, etc., and achieve the effect of stable structure, low cost and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

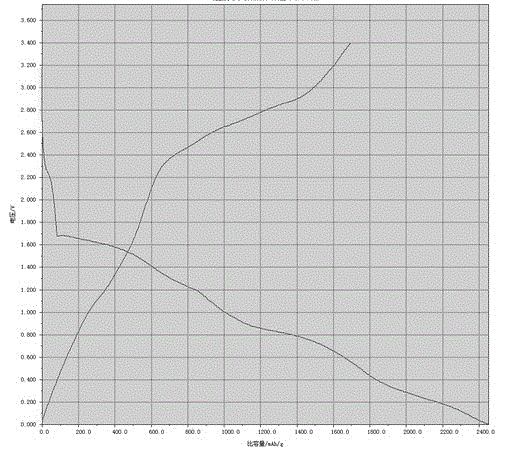

Embodiment 1

[0014] Take 100g of copper nitrate powder and dissolve it in 500ml of distilled water. After it is completely dissolved, add 1g of carbon fiber, stir at high speed for 30 minutes, then heat up to 60°C, then add 50ml of ethanol and 5ml of 1mol / L glacial acetic acid, and stir for 3 minutes. Add 1g of carbon black and continue to stir until the solution is completely volatilized; next, put the obtained primary product in an oven at 60°C for 24 hours, take out the product and grind it into powder. The obtained product is the copper nitrate negative electrode material with a multi-level structure. The obtained product is used as the research electrode, and the metal lithium sheet is used as the counter electrode, and a button-type lithium-ion battery is assembled in a glove box filled with argon, and the charge-discharge cycle is carried out in the potential range of 0.0-3.4V at a rate of 0.1C. The initial discharge capacity was 2452mAh / g, the charge capacity was 1698mAh / g, and the ...

Embodiment 2

[0016] Take 200g of copper nitrate powder and dissolve it in 500ml of distilled water. After it is completely dissolved, add 5g of carbon fiber, stir at high speed for 30 minutes, then heat up to 80°C, then add 100ml of ethanol and 5ml of 1mol / L glacial acetic acid, and stir for 3 minutes. Add 2g of carbon black and continue to stir until the solution is completely volatilized; Next, put the obtained primary product in an oven at 60°C for 24 hours, take out the product and grind it into powder. The obtained product is the copper nitrate negative electrode material with a multi-level structure. The obtained product is used as the research electrode, and the metal lithium sheet is used as the counter electrode, and a button-type lithium-ion battery is assembled in a glove box filled with argon, and the charge-discharge cycle is carried out in the potential range of 0.0-3.4V at a rate of 0.1C. The initial discharge capacity was 2389mAh / g, the charge capacity was 1780mAh / g, and the...

Embodiment 3

[0018] Take 150g of copper nitrate powder and dissolve it in 500ml of distilled water. After it is completely dissolved, add 3g of carbon fiber, stir at high speed for 30 minutes, then heat up to 70°C, then add 80ml of ethanol and 5ml of 1mol / L glacial acetic acid, and stir for 3 minutes. Add 1g of carbon black and continue to stir until the solution is completely volatilized; next, put the obtained primary product in an oven at 60°C for 24 hours, take out the product and grind it into powder. The obtained product is the copper nitrate negative electrode material with a multi-level structure. The obtained product was used as the research electrode, and the metal lithium sheet was used as the counter electrode, and a button lithium-ion battery was assembled in a glove box filled with argon, and the charge-discharge cycle was carried out in the potential range of 0.0-3.4 V at a rate of 0.1C. The initial discharge capacity was 2783mAh / g, the charge capacity was 2109mAh / g, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com