Patents

Literature

52results about How to "Stable electrode structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

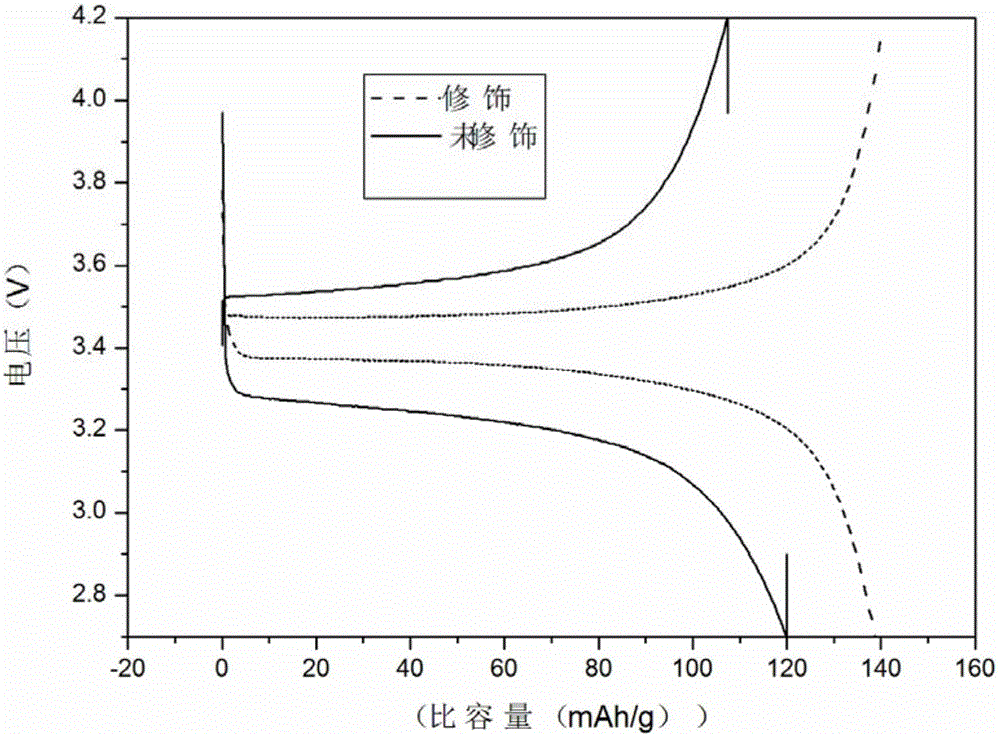

Lithium sulfide-porpous carbon compound positive material for lithium ion battery and preparation method thereof

InactiveCN102163720AImprove conductivityStop the spreadCell electrodesPorous carbonSodium-ion battery

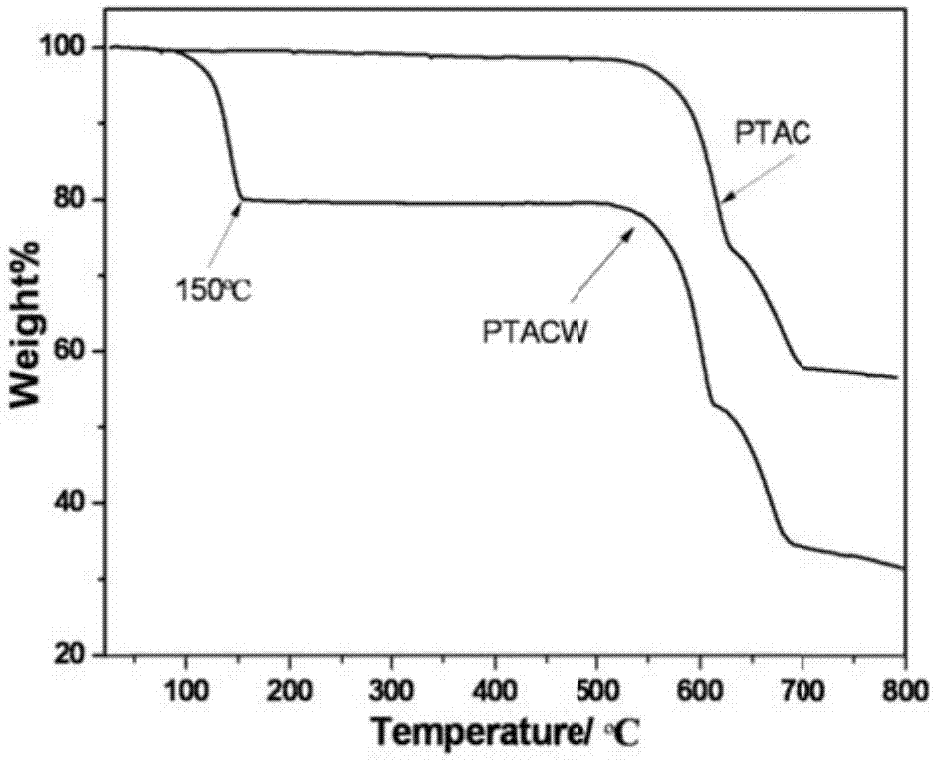

The invention provides a lithium sulfide-porpous carbon compound positive material for a lithium ion battery and a preparation method thereof. The positive material is formed by compounding lithium sulfide and ordered porous carbon, wherein the mass fraction of the lithium sulfide in the compound material is 20-80%; and the lithium sulfide exists in the pore spaces of the porous carbon. The preparation method comprises the following steps: firstly, carrying out ball milling on the ordered porous carbon and sulfur in the presence of inert gas; then carrying out thermal processing on the milled mixture at the temperature of 145-155 DEG C so that the sulfur fully is dispersed into the porous carbon; and finally, reacting lithium with the sulfur so as to generate the lithium sulfide by a chemical or electrochemical method, thereby obtaining the positive material provided by the invention. According to the invention, the preparation process is simple, and the raw material source is wide; the prepared positive material is used in a mode of pre-embedding lithium in a positive electrode, metal lithium is not required to serve as a negative electrode, and a carbon negative electrode, a silicon negative electrode and the like are used, thereby improving the safety performance and the assembling performance; the positive material has the advantages of good conductivity, high capacity and good circulation performance; and the positive material has a wide application prospect and the preparation method is suitable for industrial production.

Owner:CENT SOUTH UNIV

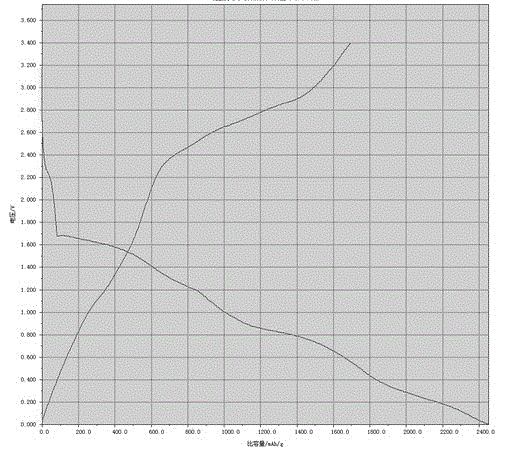

Modified composite material containing silicon-based material, preparation method thereof and use thereof in lithium ion battery

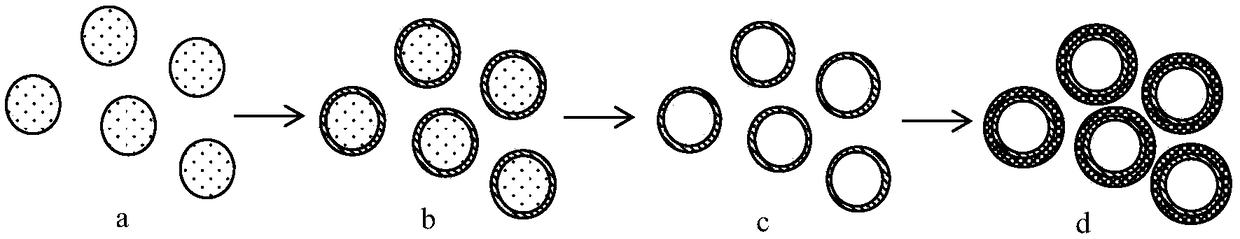

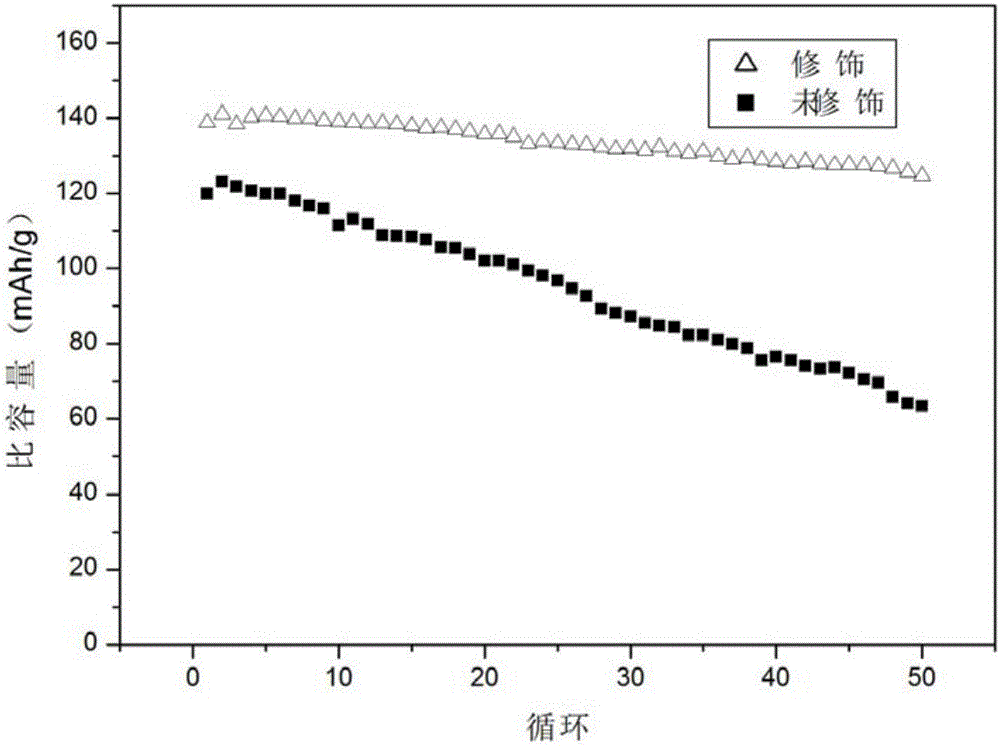

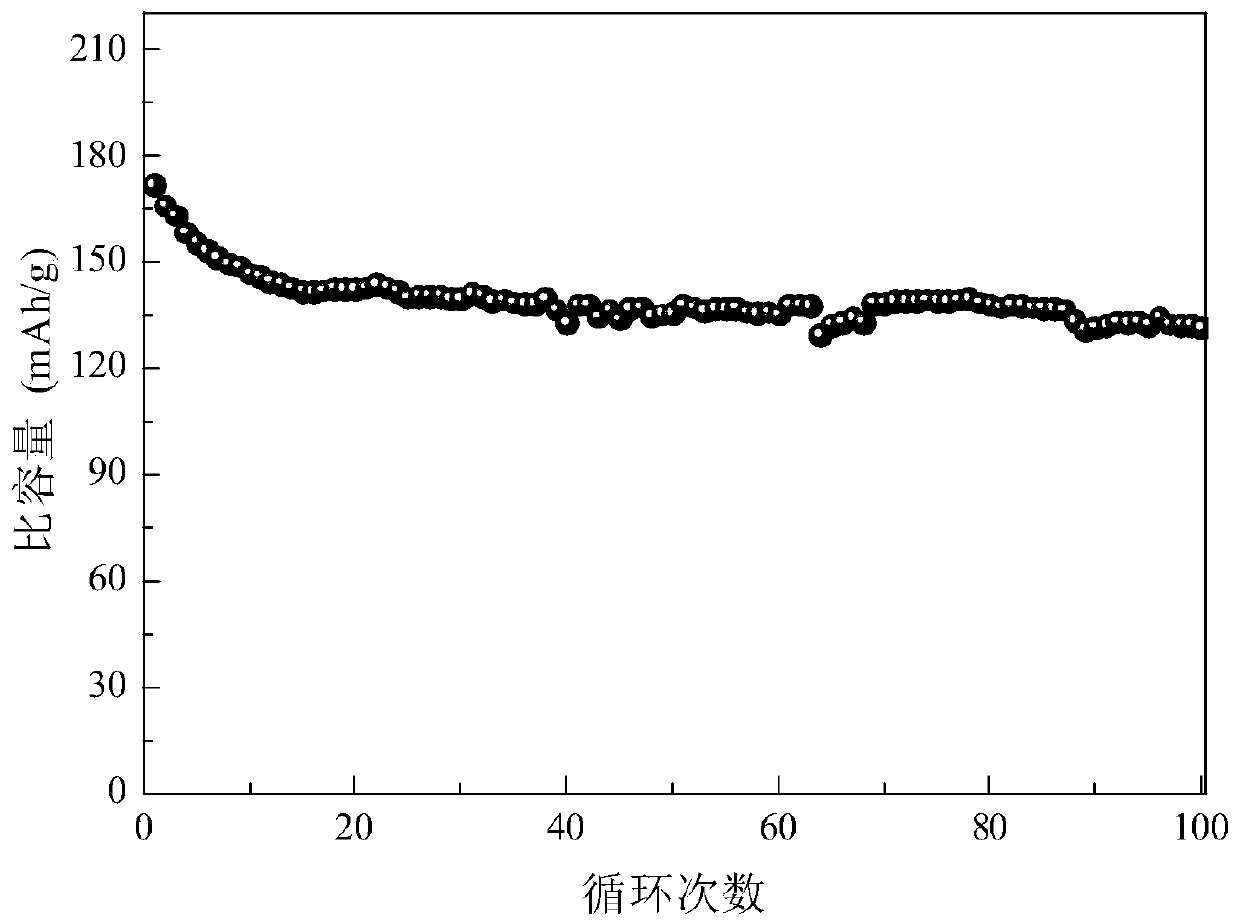

InactiveCN109103441AImprove overall performanceStable electrode structureNegative electrodesSecondary cellsSolventCharge and discharge

The invention discloses a modified composite material containing a silicon base material, which comprises a silicon base core and a polymer cladding layer covering the surface of the core, and a preparation method and use thereof in a lithium ion battery. The method comprises the steps of : 1) adding a polymer into a liquid solvent and dispersing to obtain a slurry; 2) adding a silicon-based material or a mixture of that silicon-based material and the carbon material into the slurry and mixing the solid and liquid; 3) removing the solvent to obtain a modified composite material containing a silicon-based material. As the polymer coat layer is introduced on the surface of the silicon base core, so that the electrolyte can be isolated and the side reaction of the electrolyte on the surface of the silicon base core can be prevented; the method can also improve the crushing, electrode pulverization and peeling of the silicon-based negative electrode material in the process of processing and using, and reduce the electrode crushing and peeling caused by the huge volume expansion of the silicon-based material in the process of charging and discharging, so as to achieve the purpose of stabilizing the electrode structure and improving the cell cycle performance.

Owner:JIANGSU TAFEL NEW ENERGY TECH CO LTD +2

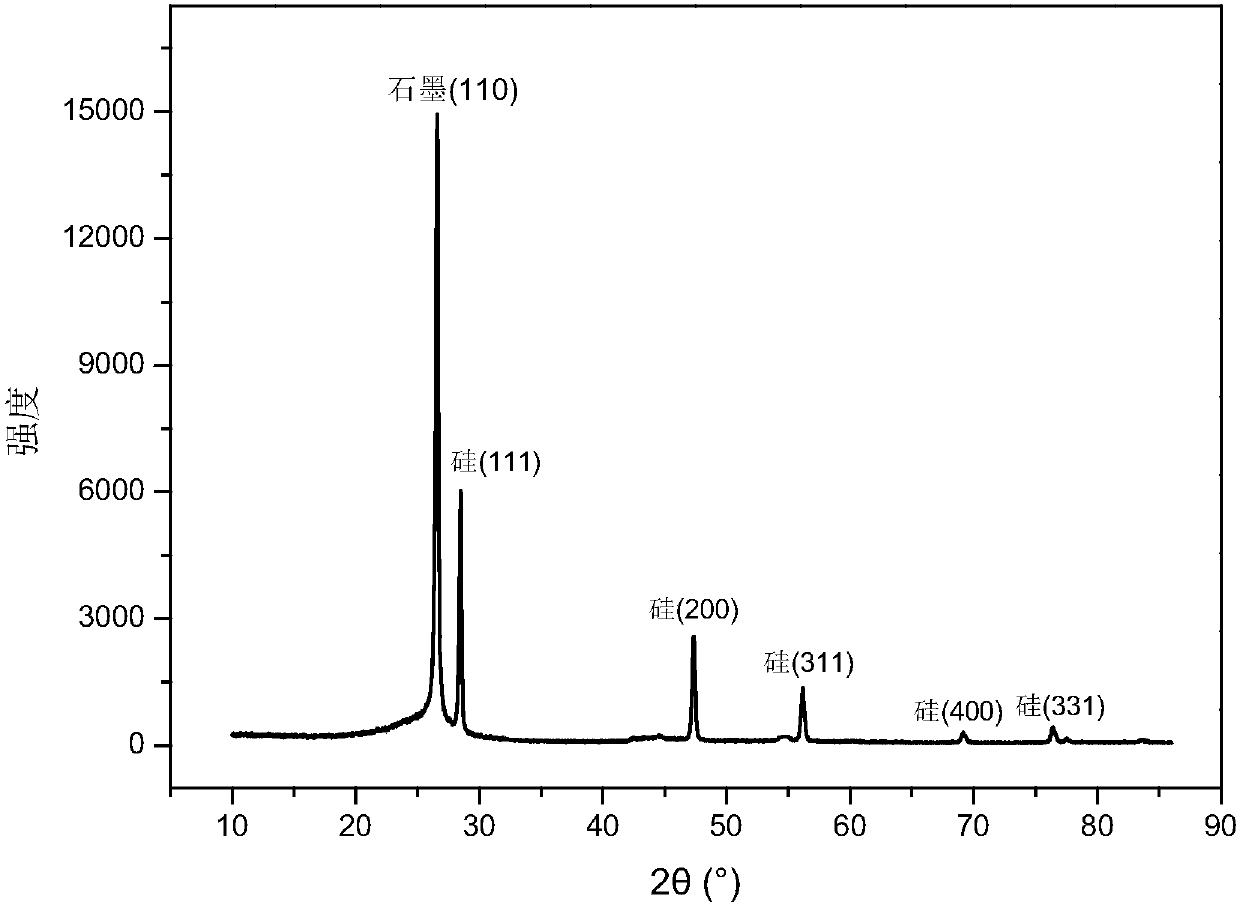

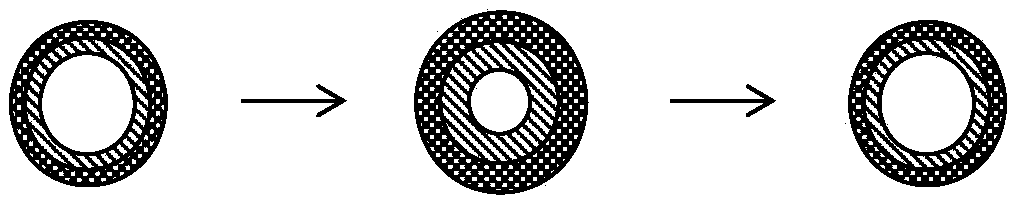

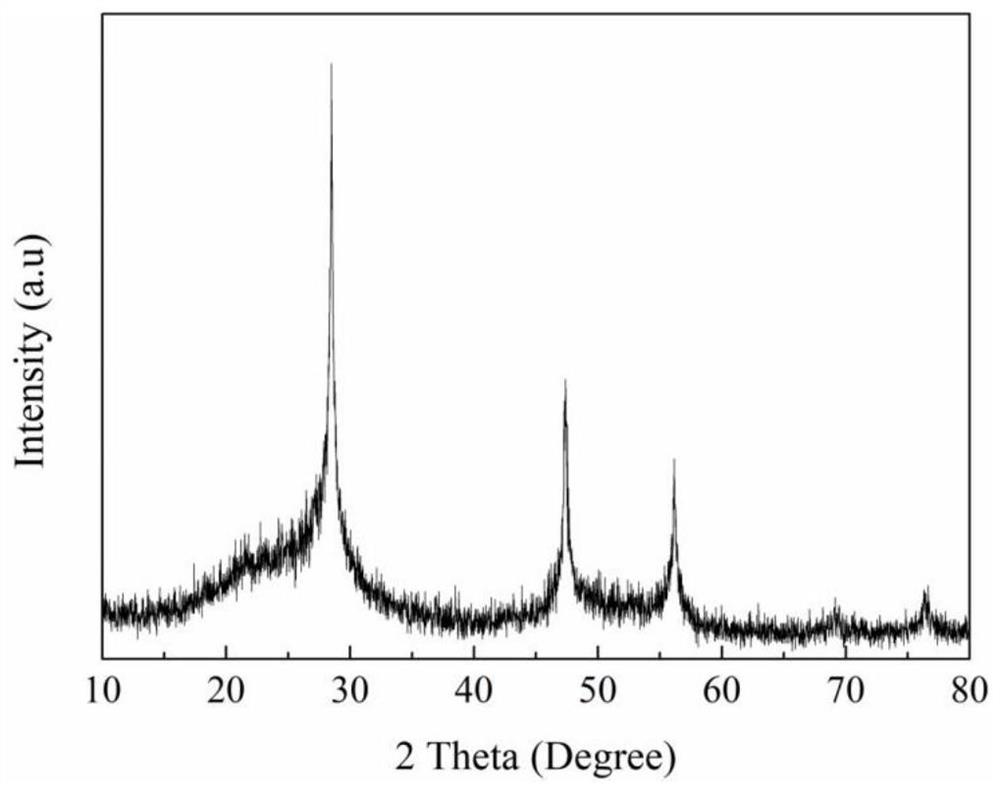

Porous silicon monoxide composite material and preparation and application thereof

ActiveCN110854377AControl contentThe pre-processing process is simpleMagnesium silicatesSilicaCarbon coatingComposite material

The invention belongs to the field of lithium ion battery materials, and particularly discloses a porous silicon monoxide composite material. The composite material comprises an inner core, a middle layer compounded on the surface of the inner core and an outer layer compounded on the surface of the middle layer, wherein the inner core is silicon, the middle layer is silicon monoxide and silicateof metal M dispersed in the silicon monoxide, the outer layer is a carbon coating layer, and the metal M is a metal element capable of reducing silicon oxide. The invention also provides a preparationmethod of the composite material and an application of the composite material as a negative electrode active material of a lithium ion secondary battery. Research finds that the composite material has the characteristics of long cycle life, high initial efficiency and the like.

Owner:CENT SOUTH UNIV +1

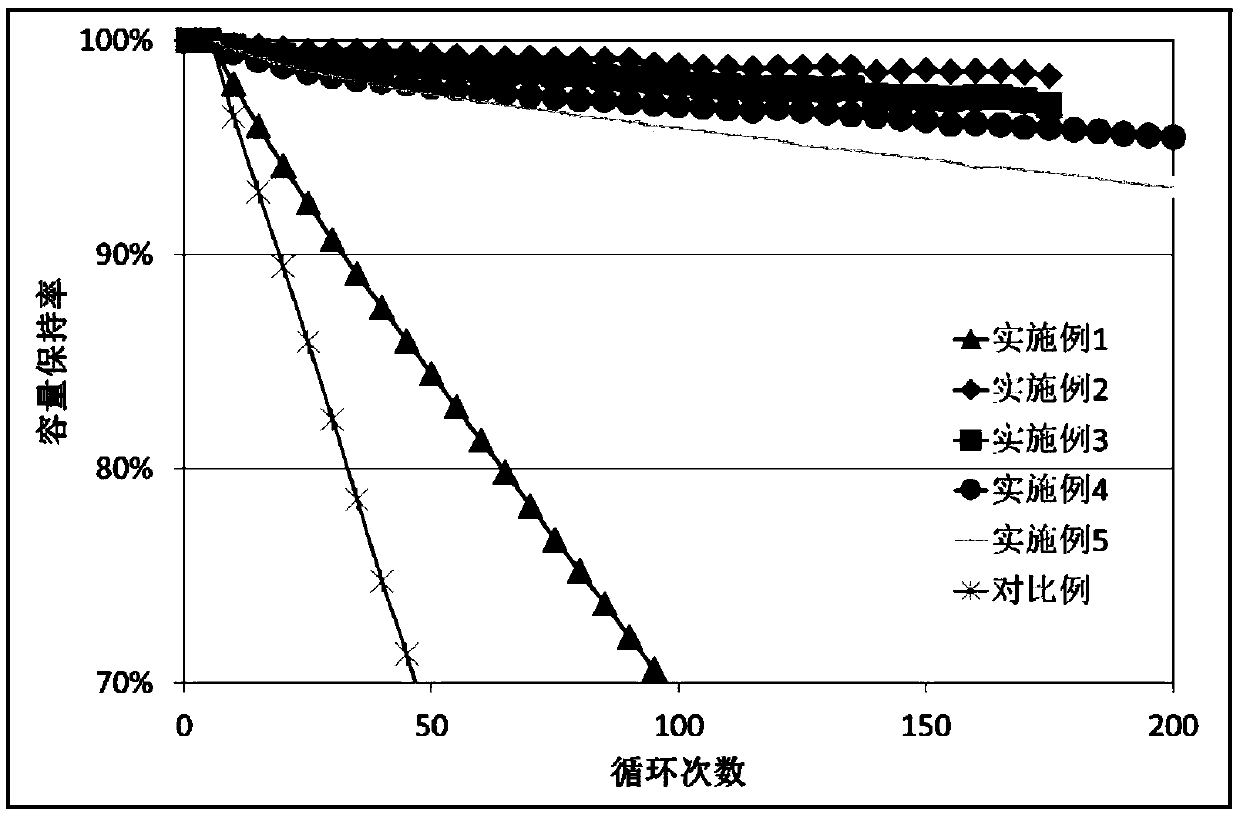

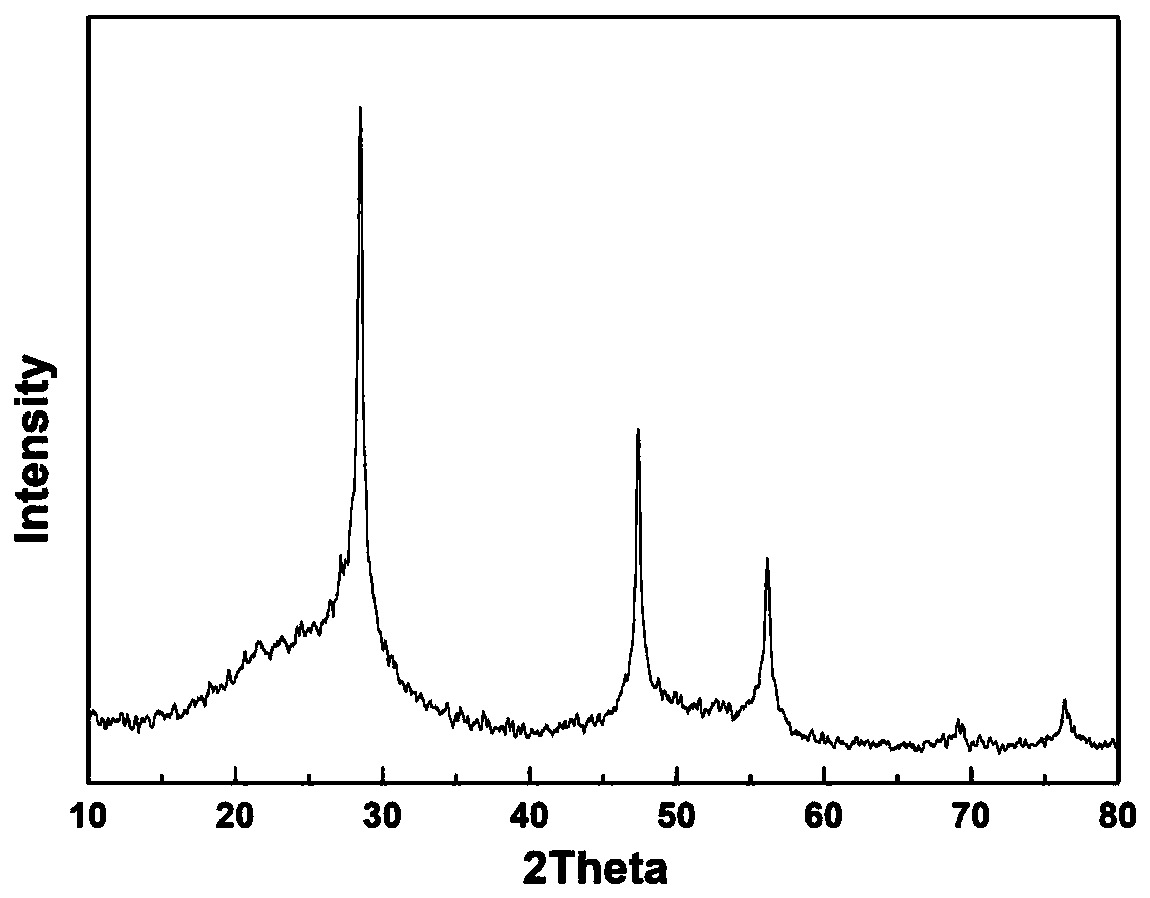

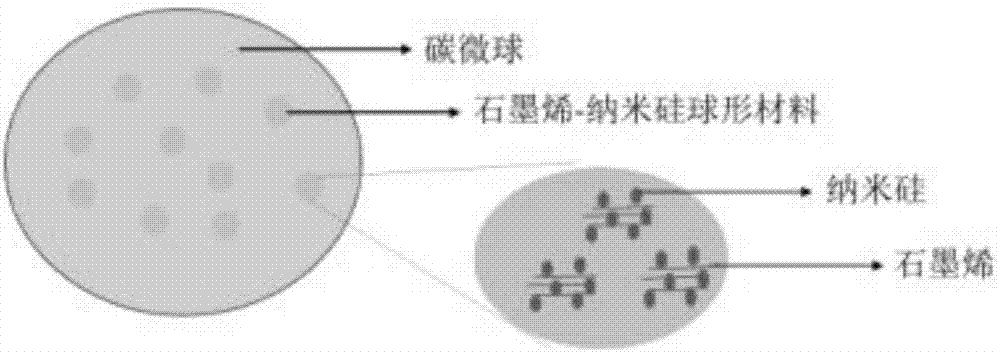

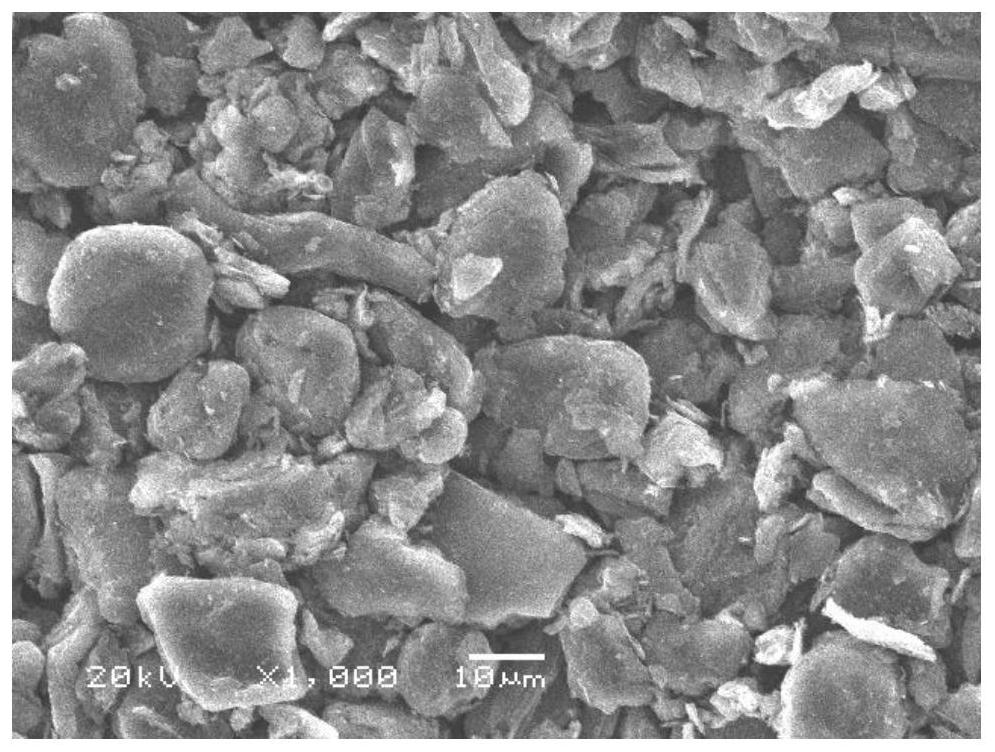

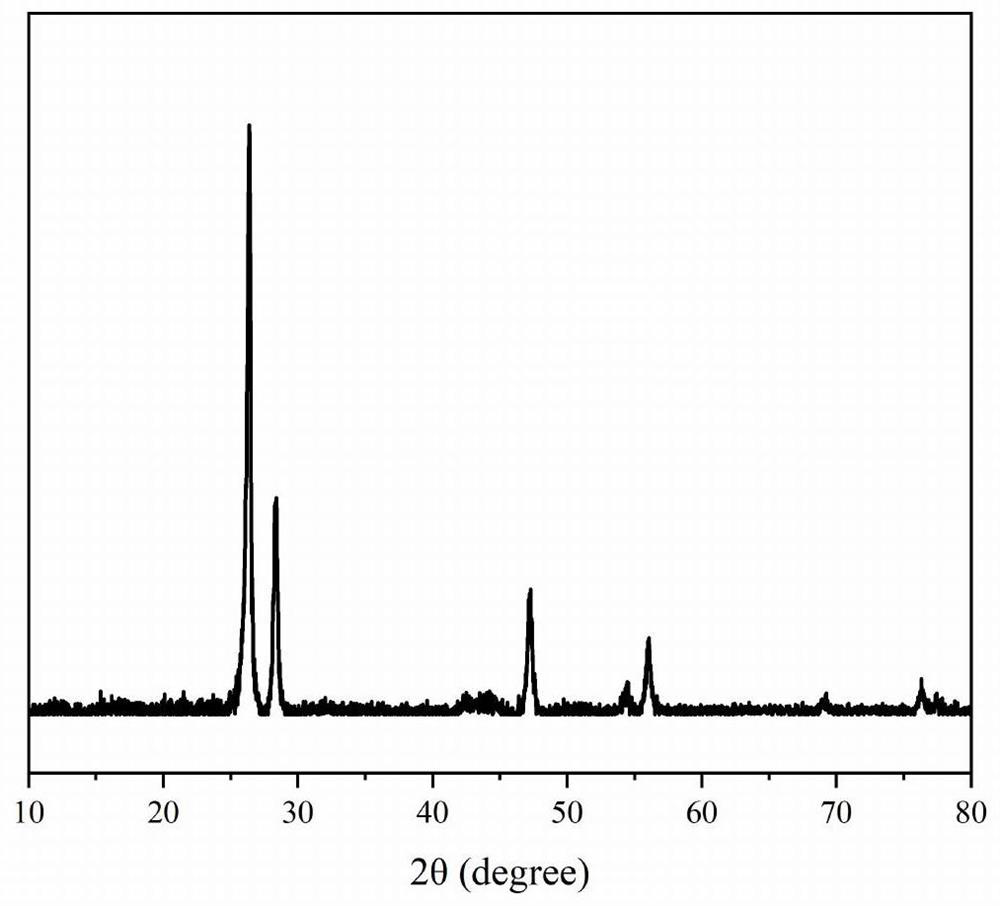

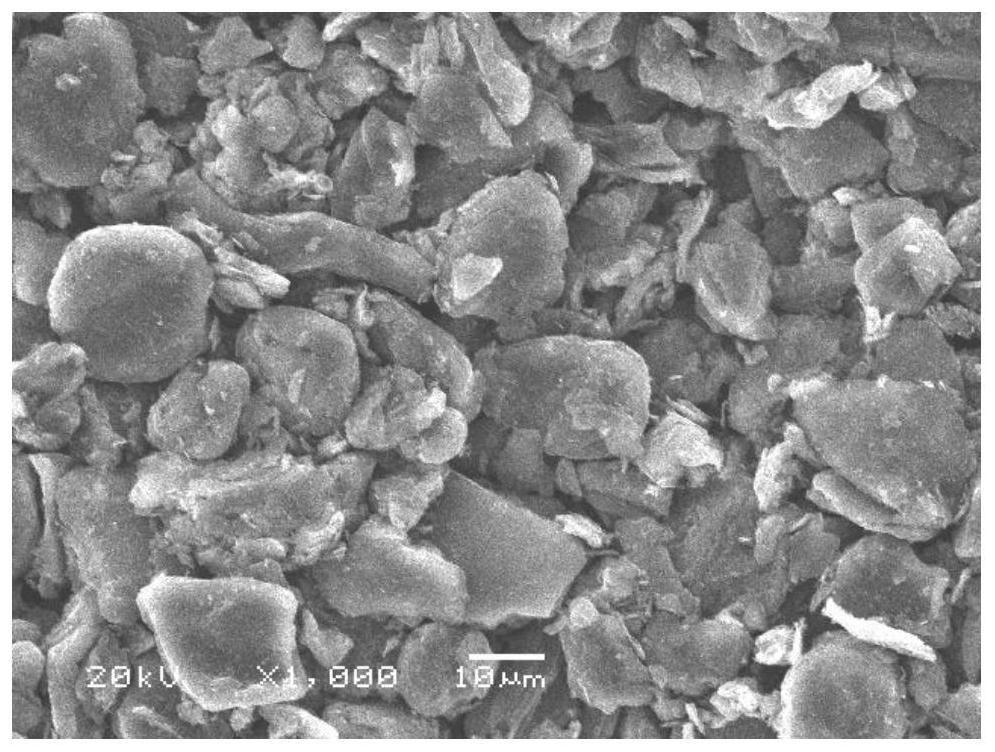

Preparation method of graphene-silicon carbon lithium ion battery negative electrode material

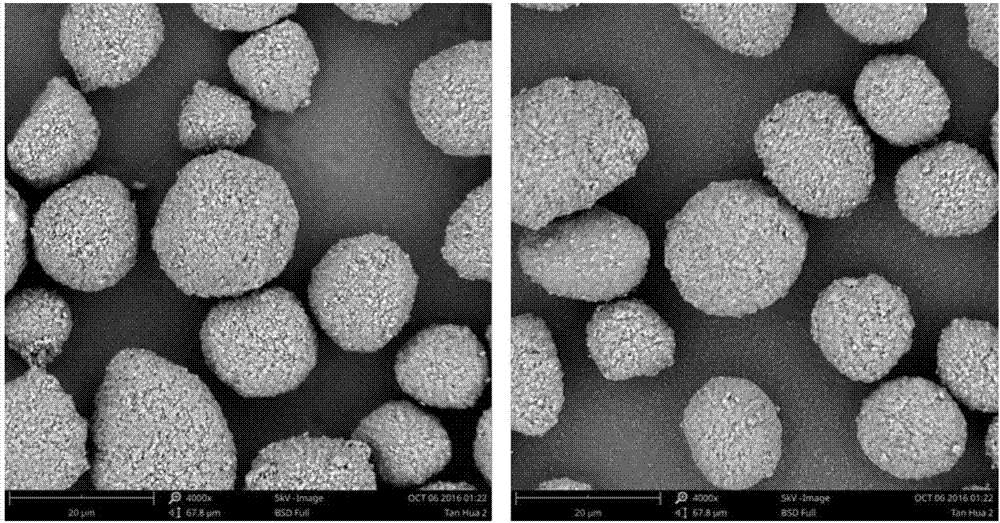

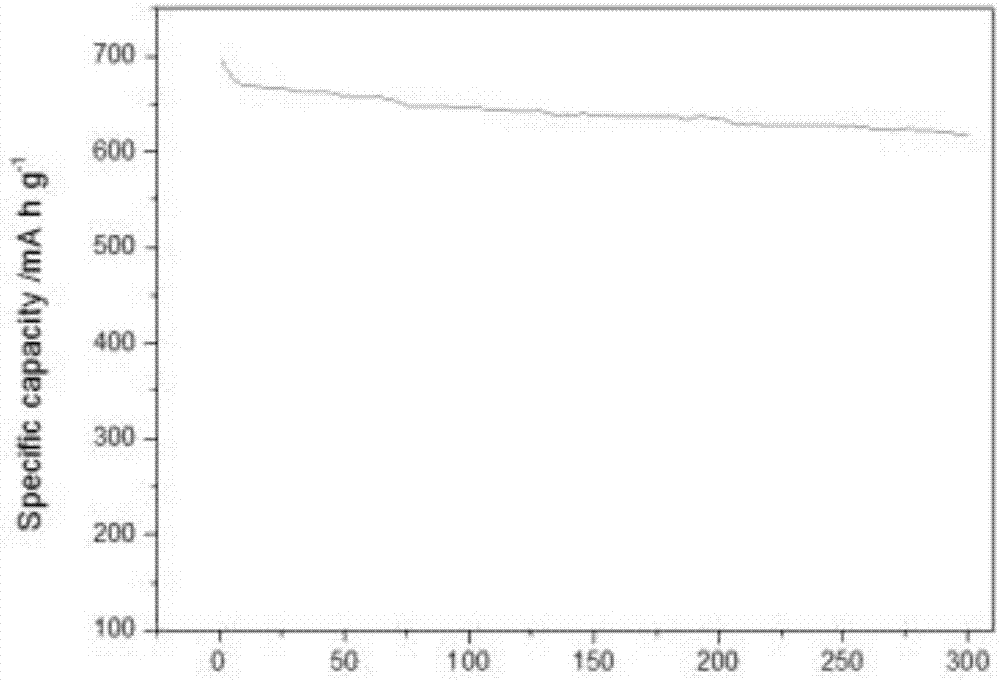

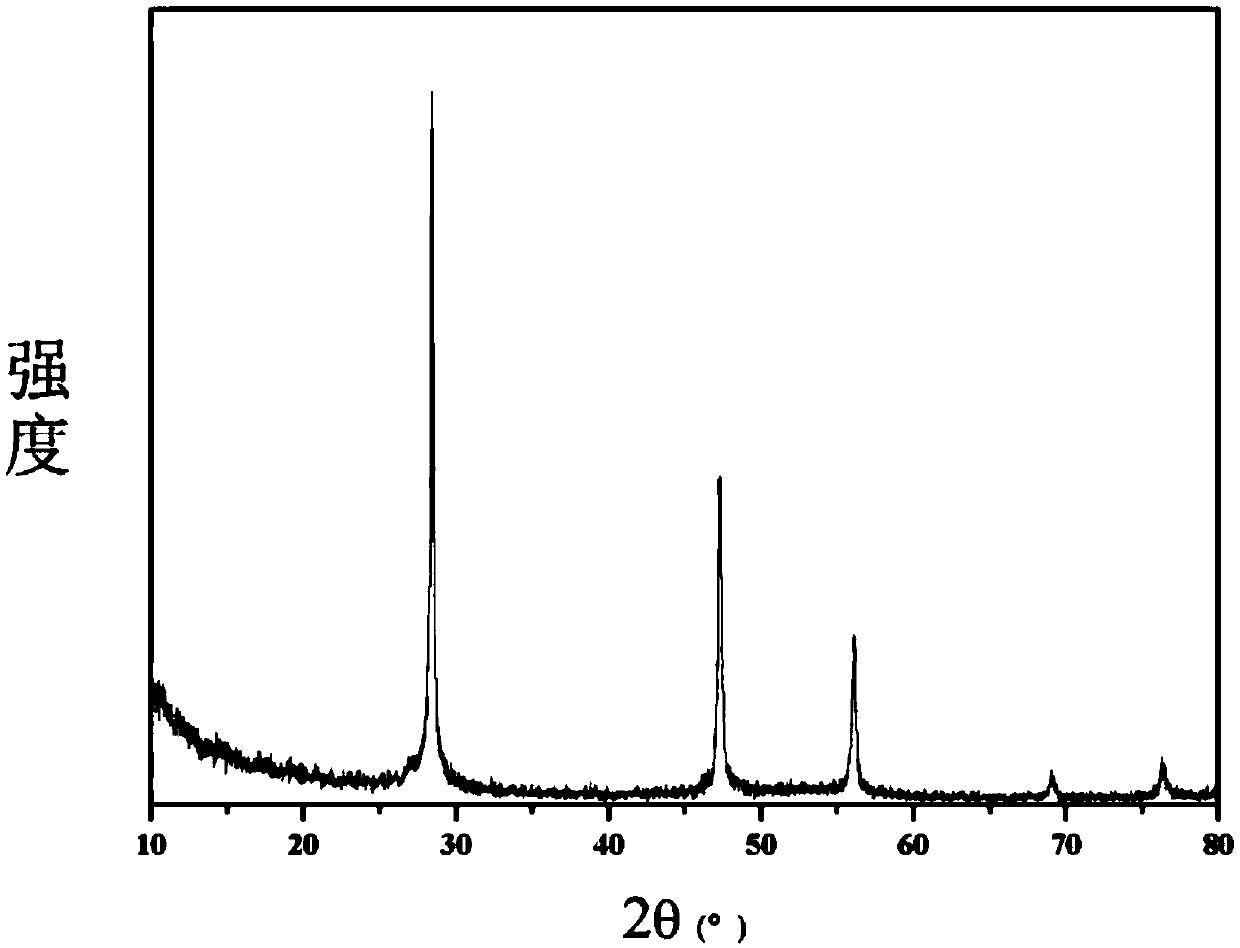

ActiveCN107342411ARelieve deformation stressImprove mechanical propertiesMaterial nanotechnologyCell electrodesMicrosphereHeat conducting

The invention relates to the technical field of preparation of an electrode material, and specifically relates to a preparation method of a graphene-silicon carbon lithium ion battery negative electrode material. The preparation method comprises the following steps of performing graphene coating on nanometer silicon particles, preparing a carbon coated primary composite material, and performing carbonization and mixing. Nanometer silicon is dispersed into interlayer or surfaces of the graphene sheets to form a spherical-like graphene / nanometer silicon composite material; by virtue of high mechanical performance and flexibility of graphene, deformation stress of silicon can be relieved, and by virtue of excellent conductivity and heat conducting performance, quick electron conduction and heat evacuation can be provided; after heat treatment, the carbon-coated primary composite material can be prepared through growth of carbon microspheres; by virtue of the formed carbon coating layer, direct contact between silicon and an electrolyte caused by the island effect of the silicon particles can be avoided, so that the structural stability and cycling performance of the material can be further improved; and the prepared silicon carbon negative electrode material has the advantages of high initial coulombic efficiency, stable cycling performance, high compaction density and stable electrode structure.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

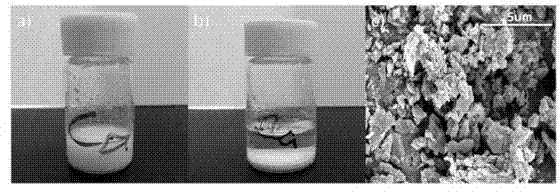

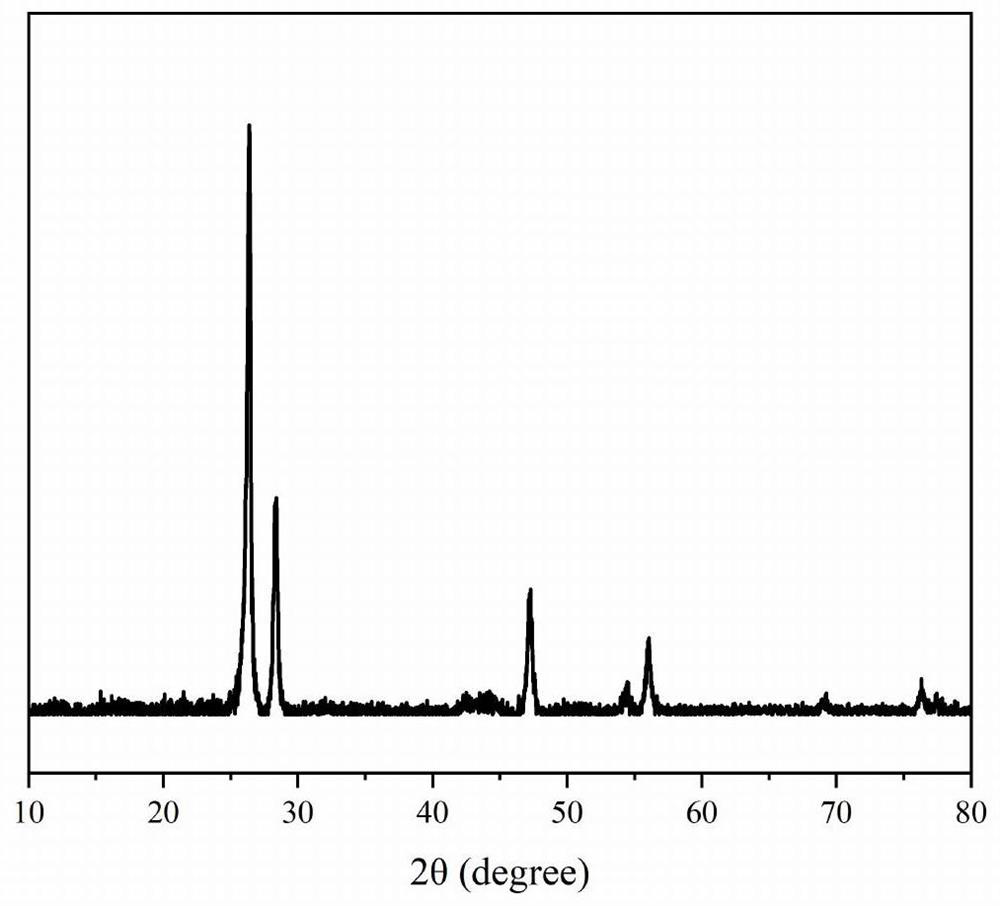

Nano silicon, preparation method thereof and application of nano silicon in silicon carbon composite cathode material and lithium ion battery

InactiveCN107634199AImprove electronic conductivityBuffer volume effectCell electrodesSecondary cellsCarbon compositesCyclic process

The invention provides nano silicon, a preparation method thereof and an application of the nano silicon in a silicon carbon composite cathode material and a lithium ion battery. The invention provides a method for preparing the pure silicon component nano silicon by a low-temperature molten salt method, the obtained nano silicon is the secondary particles with a particle size being 80-120 nm formed by assembling the primary silicon particles, which is very suitable for preparing the silicon carbon composite cathode material, the silicon carbon composite cathode material is employed for preparing the silicon carbon material by a machinery fusion and high-temperature pyrolysis method, the electronic conductivity of the silicon material is improved, the volume effect generated during an alloying and dealloying process of the silicon cathode can be effectively buffered, and the structural stability of the material during a cycle process is increased. The silicon carbon cathode material has the advantages of high initial coulomb efficiency, good cycle performance, high compacted density, and stable electrode structure, and the preparation process of the nano silicon and the silicon carbon composite cathode material is environment friendly and pollution-free.

Owner:EVE ENERGY CO LTD

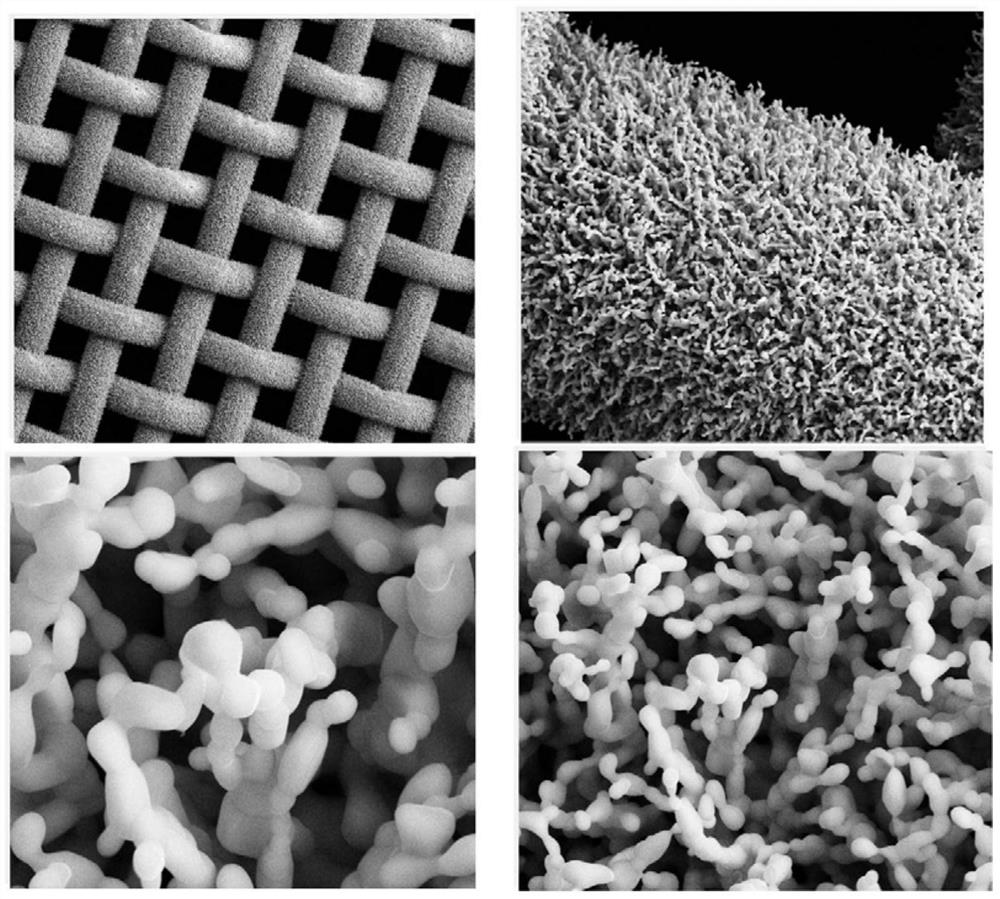

Method for preparing multilevel structure copper nitrate anode material

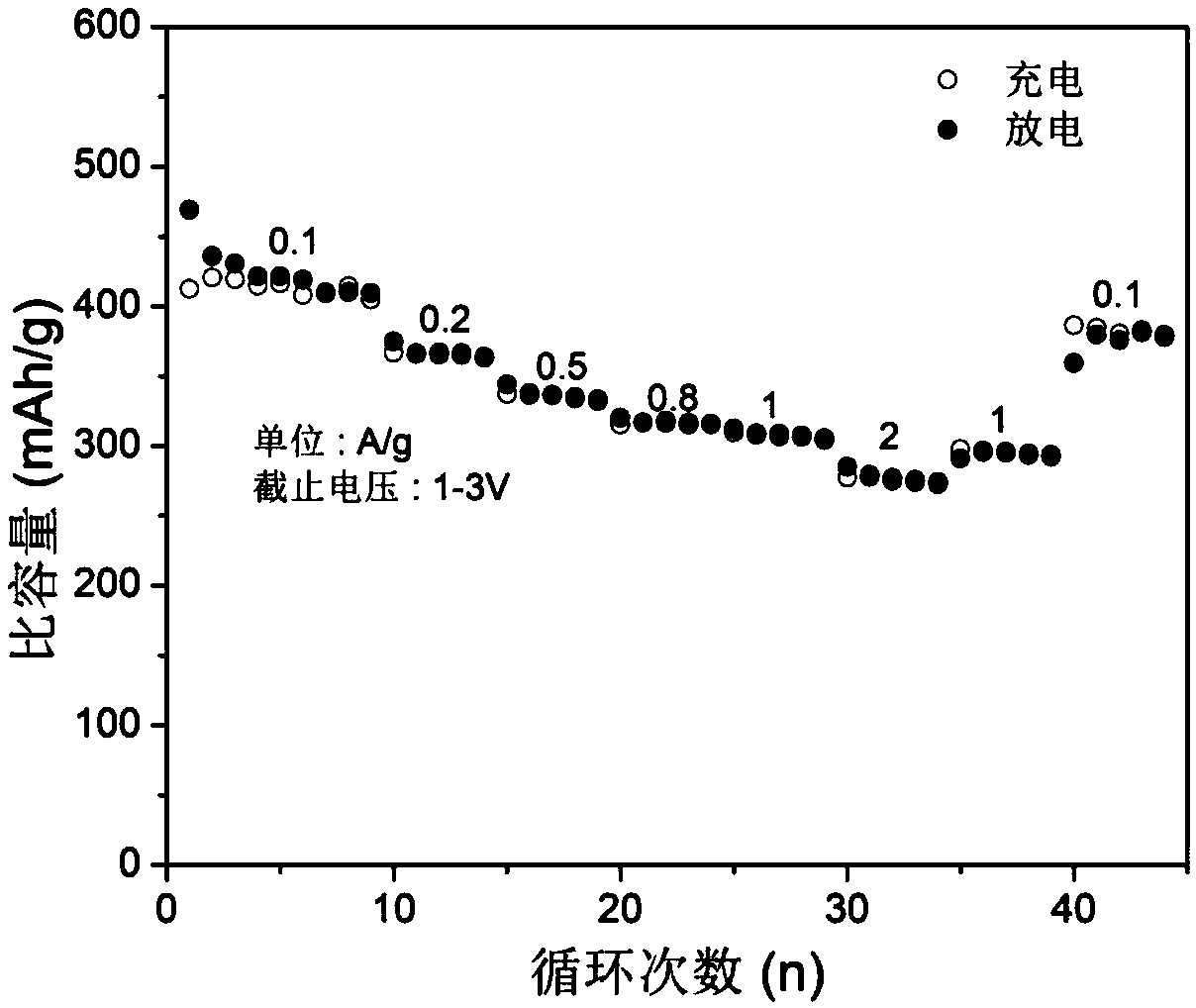

ActiveCN104993147AUniform particle sizeAct as a skeleton supportCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a method for preparing a multilevel structure copper nitrate anode material. The method comprises the steps of dissolving 100-200 g copper nitrate powder in 500 ml distilled water, adding 1-5 g carbon fiber after complete dissolution, stirring for 30 min at a high speed, then heating to 60-80 DEG C, adding 50-100 ml ethyl alcohol and 5 ml 1 mol / L glacial acetic acid, stirring for 3 min, then adding 1-2 g carbon black, and continuing to stir till complete volatilization; then, placing the obtained head product in an oven to be baked for 24 h at 60 DEG C, taking out the product, and grinding the product into powder, so that the multilevel structure copper nitrate anode material is obtained. The method has the advantage that the obtained copper nitrate anode material is of a stable multilevel composite structure, and the multilevel composite structure enables the copper nitrate anode material to have high capacity and long service life.

Owner:NINGBO UNIV

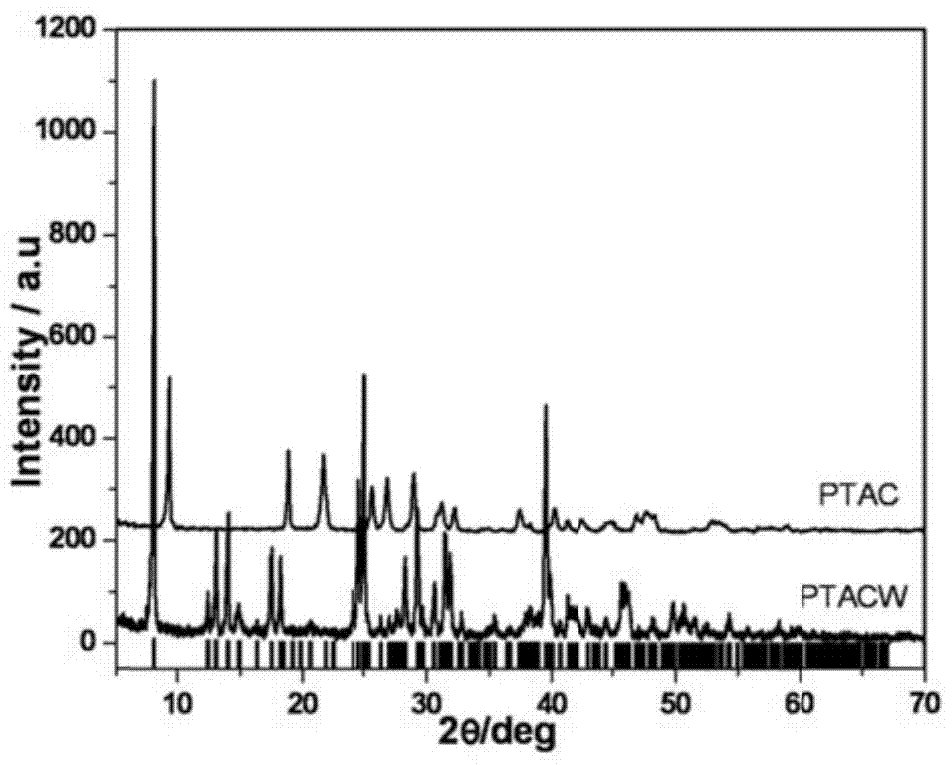

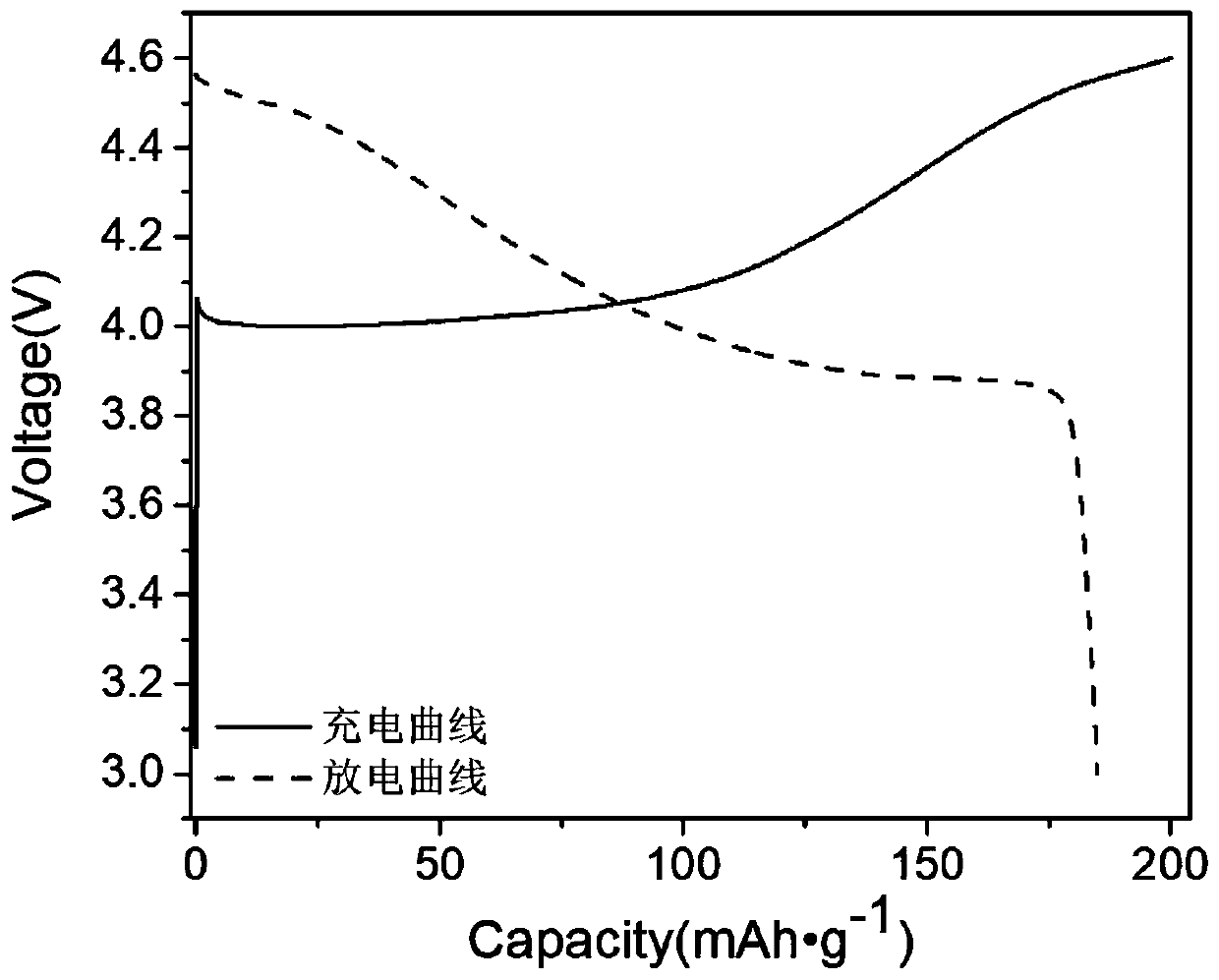

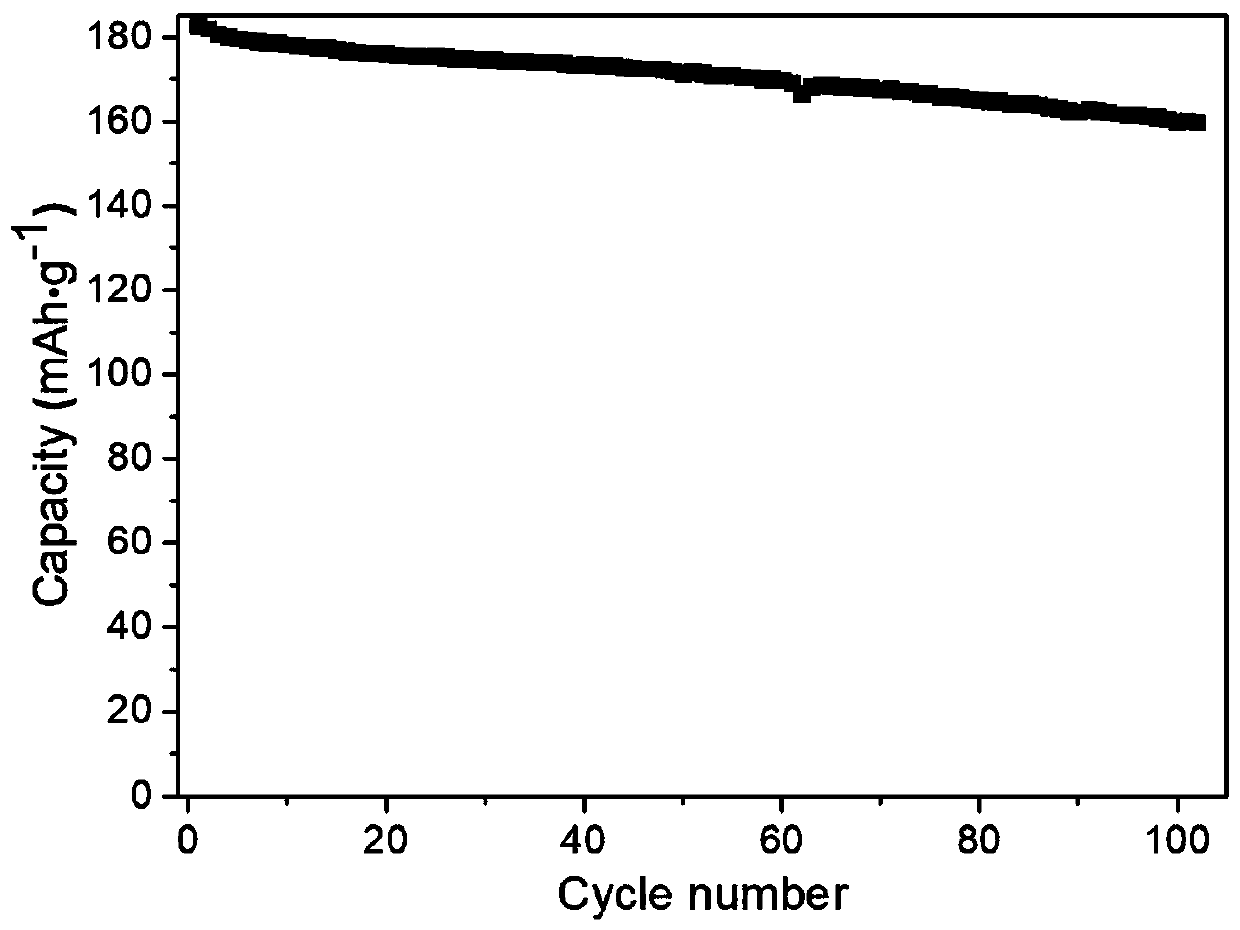

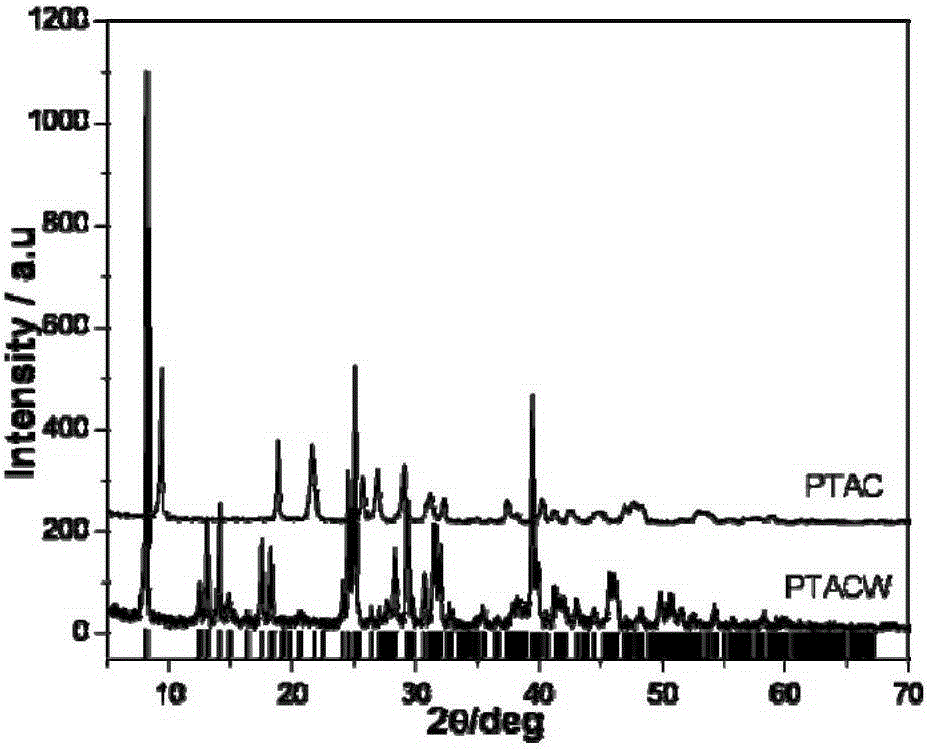

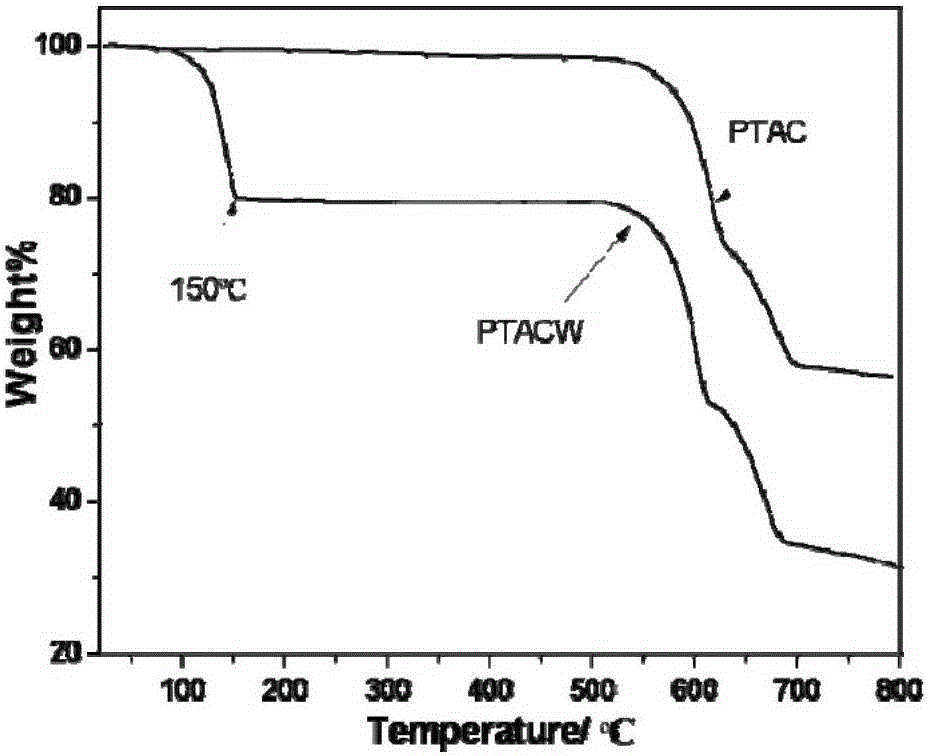

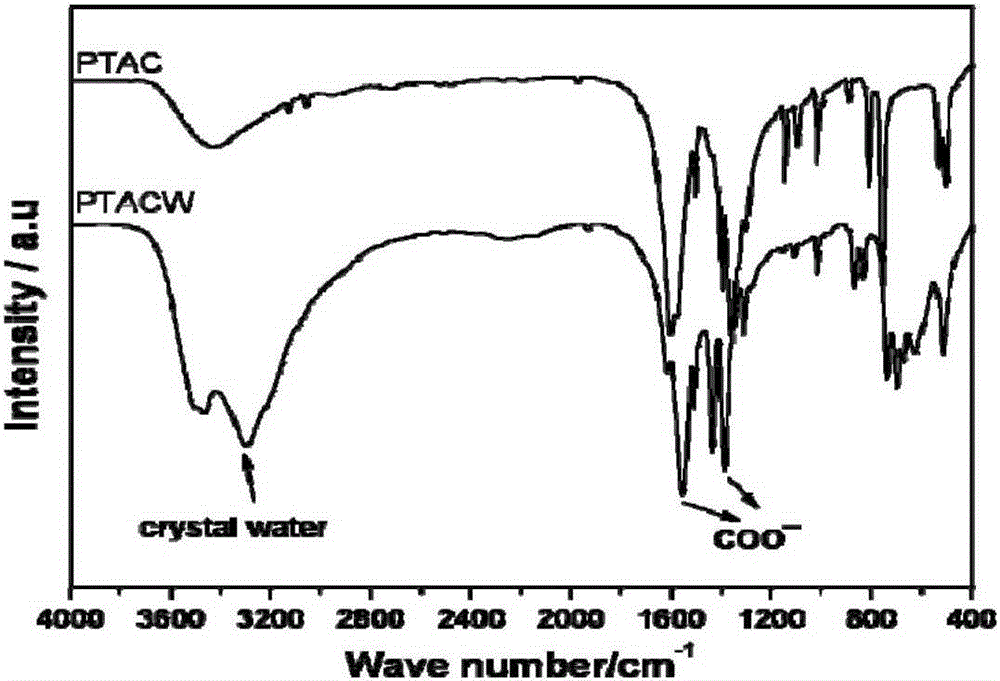

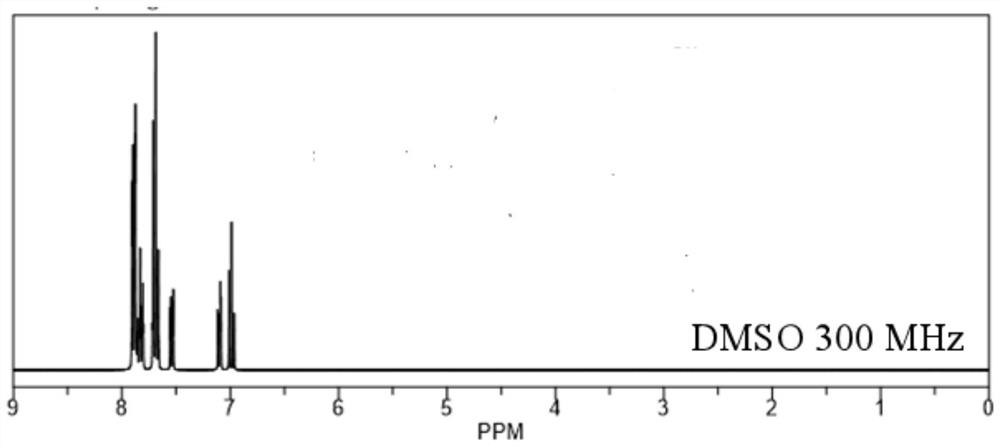

Preparation method of calcium terephthalate, and application of calcium terephthalate in lithium ion battery

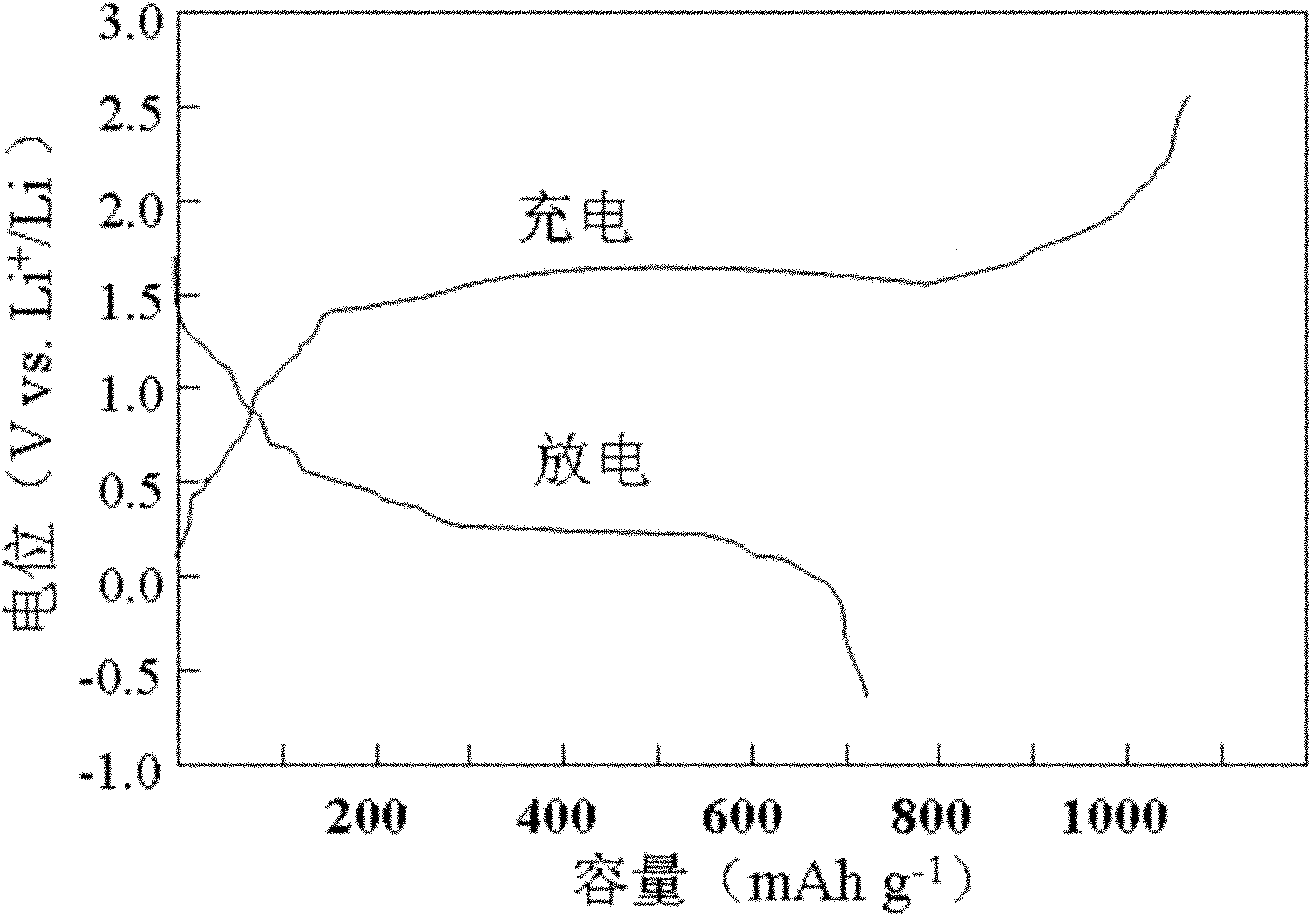

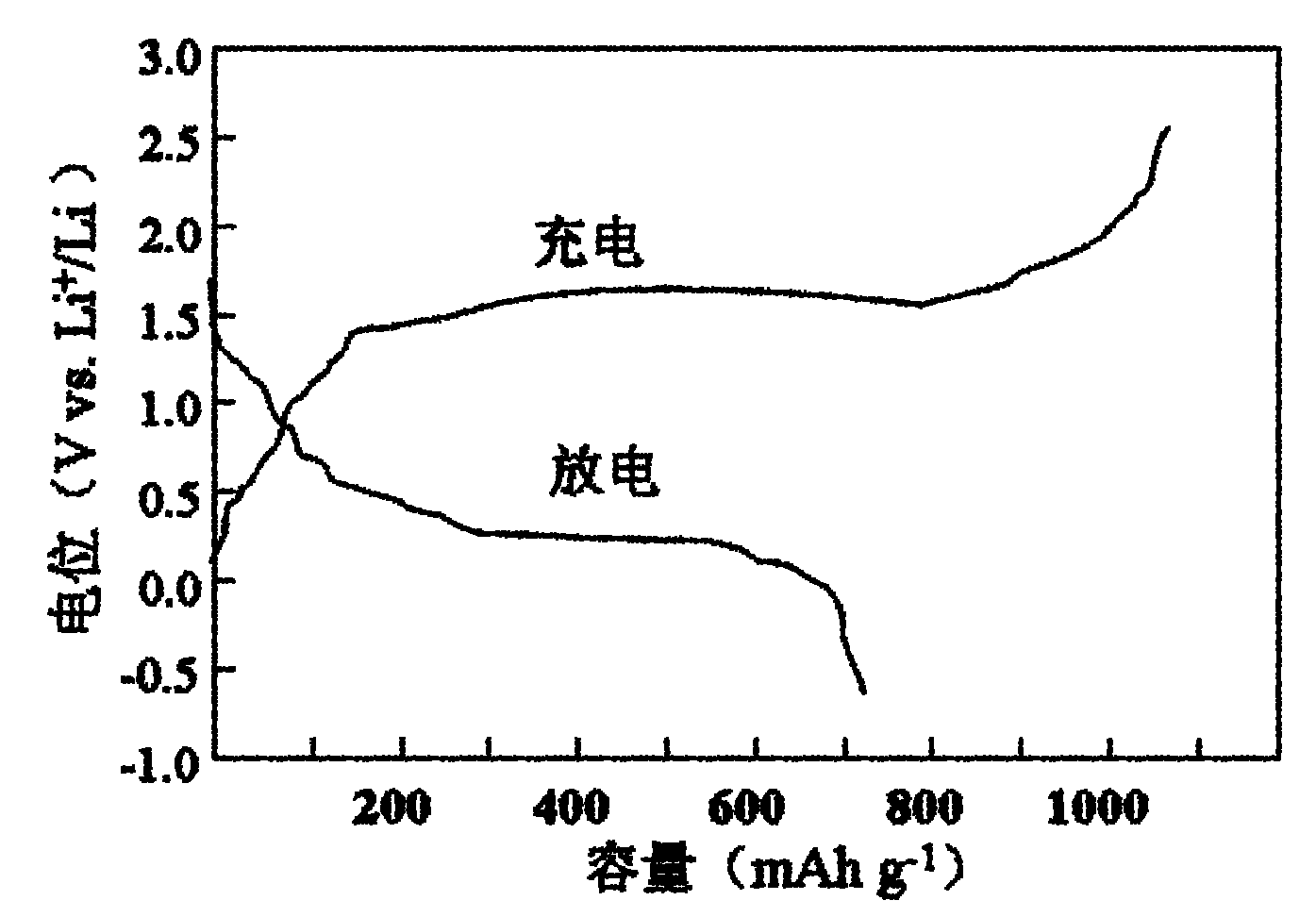

InactiveCN104292100AImprove stabilityReduce solubilityOrganic compound preparationCell electrodesLithium-ion batteryVacuum drying

The invention provides a preparation method of an organic negative material calcium terephthalate, and an application of the organic negative material calcium terephthalate in a lithium ion battery. The preparation method of calcium terephthalate comprises the following steps: 1, reacting terephthalic acid with LiOH or NaOH or KOH to obtain a terephthalate solution; 2, reacting the terephthalate salt solution with CaCl2 or Ca (NO3)2 to obtain a mixed solution containing calcium terephthalate; 3, separating the mixed solution, and drying the solid obtained separation to obtain calcium terephthalate trihydrate; and 4, drying the calcium terephthalate trihydrate in a vacuum drying box to remove crystal water in order to obtain calcium terephthalate. The calcium terephthalate has a reversible capacity of 231mAh / g, has the advantages of excellent stability in an electrolyte, good rate capability, slow specific capacity attenuation, and maintenance of high capacity of 93% after cycling for 120 weeks, and is a lithium ion battery organic negative material with excellent performances.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

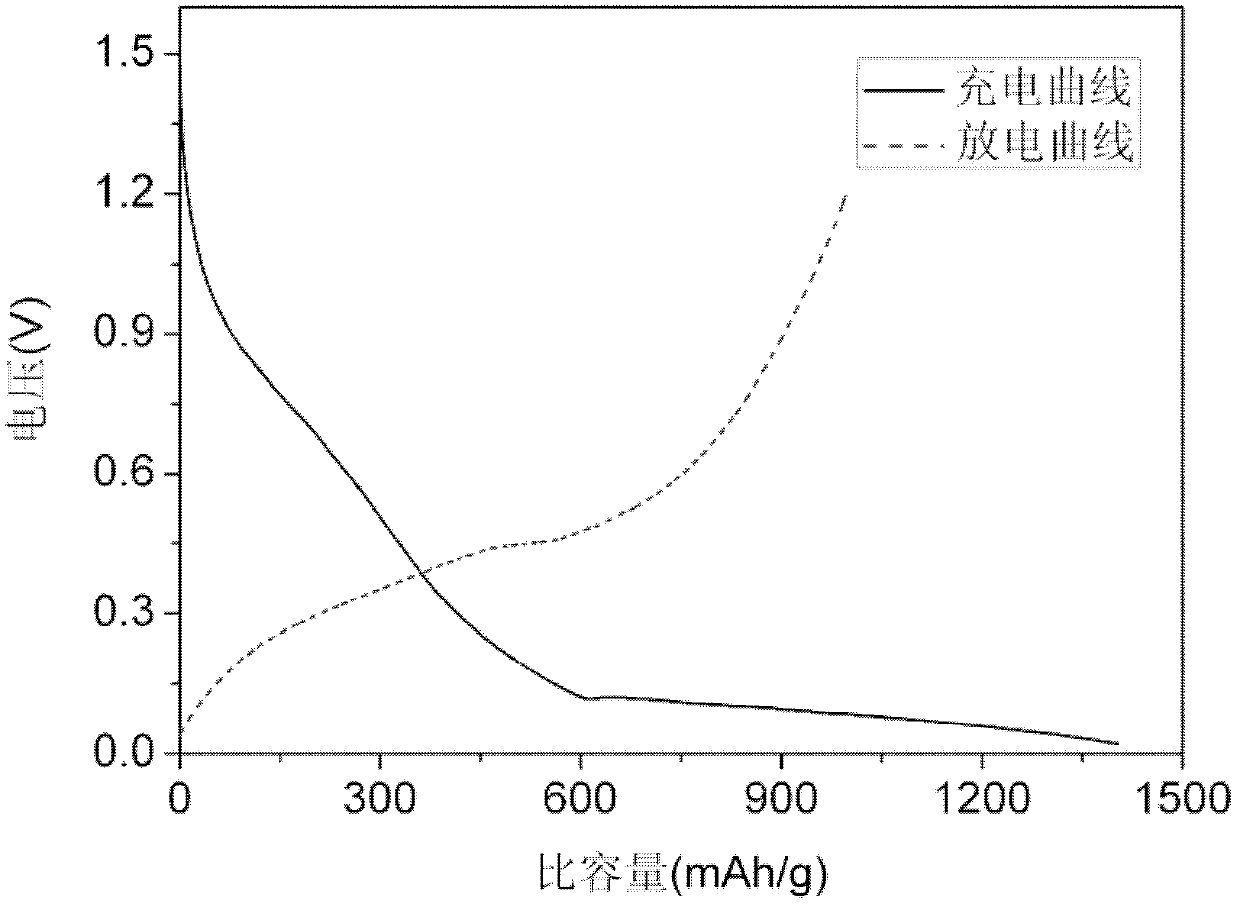

Preparation and application of conductive carbon film-coated calcium nitride compound serving as anode material of lithium battery

InactiveCN102082267ALow costGood thermal stabilityCell electrodesSecondary cellsCarbon filmNitrogen atmosphere

The invention relates to preparation and application of an anode material of a lithium battery and aims to provide preparation and the application of a conductive carbon film-coated calcium nitride compound serving as the anode material of the lithium battery. The preparation method comprises the following steps of: after calcium metal is molten, spraying into polyethylene glycol liquid by using high purity nitrogen, and performing a reaction of the calcium fog drops and nitrogen in an nitriding atmosphere to obtain Ca3N2 microspheres so as to obtain a carbon-coated calcium nitride material primary product; and after filtering out a carbon-coated calcium nitride material, calcining for 2 to 3 hours again in the high purity nitrogen atmosphere and carrying out refining to obtain carbon-coated Ca3N2, or calcining for 2 to 3 hours again in vacuum to obtain a carbon-coated Ca3N2-Ca2N mixture. In the invention, a conductive carbon film is formed on the surface of Ca3N2 or Ca3N2-Ca2N, is favorable for stability of an electrode structure, has high heat stability and low cost, is easy to prepare and has no pollution. The conductive carbon film prepared by a spraying method has the advantages of uniform thickness and high conductivity. The electrode polarization is reduced. The speed and the capacity of the lithium battery are improved.

Owner:ZHEJIANG UNIV

Silicon-based and tin-based composite particles for lithium ion battery and preparation method thereof and negative electrode and lithium ion battery containing silicon-based and tin-based composite particles

ActiveCN108807935AEasy to prepareRich sourcesMaterial nanotechnologyCell electrodesLithium intercalationMaterials science

The invention provides silicon-based and tin-based composite particles for a lithium ion battery and a preparation method thereof and negative electrode and a lithium ion battery containing the silicon-based and tin-based composite particles. The silicon-based and tin-based composite particles are characterized by being prepared from hollow tin particles or hollow tin oxide particles and a siliconlayer coating the outer surfaces of the hollow tin particles or hollow tin oxide particles. The invention also provides the negative electrode containing the composite particles and applied to a lithium ion secondary battery, and the lithium ion secondary battery with the negative electrode. The preparation method of the composite particles is simple; due to the hollow structure, the particles can effectively accommodate the volume expansion of silicon-based and tin-based materials in a lithium intercalation process, so as to maintain stability of the electrode structure. Moreover, an external silicon-based material can effectively prevent agglomeration of nano tin particles and maintain stability of a tin-based material, so as to obtain a lithium ion battery negative electrode compositematerial with great specific capacity and good cycle performance.

Owner:TSINGHUA UNIV

Conducting polymer film and positive pole piece modified by same

ActiveCN106229464AUniform thicknessInhibit side effectsElectrode carriers/collectorsSecondary cellsIn situ polymerizationConductive polymer

The invention discloses a conducting polymer film and a positive pole piece modified by the same. The conducting polymer film is prepared by a method comprising the following steps: (1) coating a film-forming base with an initiator and putting the film-forming base coated with the initiator into a closed container containing a conductive polymer monomer; and (2) controlling vacuum conditions of the closed container, evaporating the conductive polymer monomer, carrying out in-situ polymerization on the film-forming base coated with the initiator to form the film and then drying. The conducting polymer film disclosed by the invention is prepared by a vacuum evaporation coating process, so that the conducting polymer film with a uniform thickness can be formed without complicated and harsh condition control in the polymerization process; the obtained conducting polymer film is uniform in thickness and can be arranged between a positive electrode and a membrane; the side reaction between an electrode material and an electrolyte is inhibited; and the structure stability and the heat stability of the positive electrode material in battery charging and discharging processes are improved, thereby improving the electrochemical properties of the material.

Owner:HENAN NORMAL UNIV

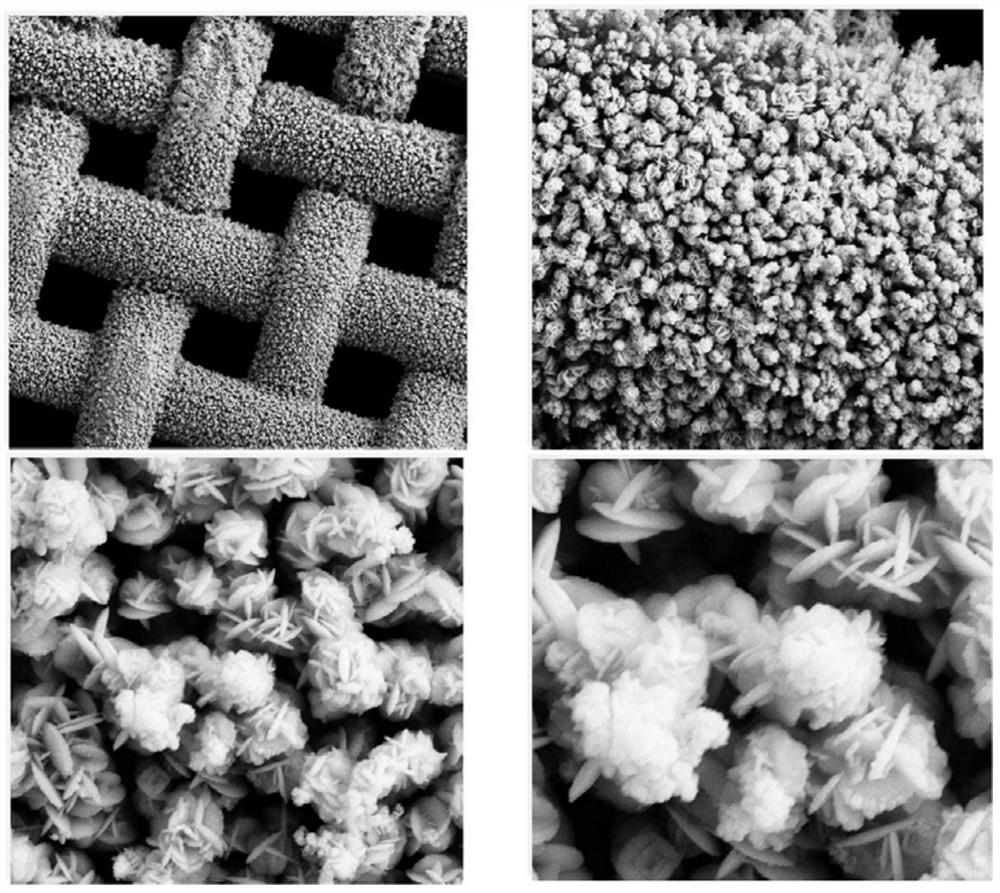

Preparation method of lithium sodium titanate negative electrode material with multistage structure

ActiveCN107742718AStable structureCompact structureCell electrodesSecondary cellsDispersityHigh rate

The invention discloses a preparation method of a lithium sodium titanate negative electrode material with a multistage structure, and belongs to the technical field of lithium ion batteries. The method comprises the following specific steps: dissolving tetrabutyl titanate, lithium acetate and sodium nitrate in an alcohol solution, adding citric acid to serve as a chelating agent, then adding an amine compound, stirring to form gel, and performing vacuum drying; then mixing gamma-LiAlO2 with the dried gel, performing ball milling, performing preheating treatment in the air, then performing ball milling and calcining to obtain a Na2Li2Ti6O14@gamma-LiAlO2 material; putting the Na2Li2Ti6O14@gamma-LiAlO2 material into distilled water, performing ultrasonic treatment and adding sodium dodecyl benzene sulfonate; and pouring a dissolved pyrrole solution into the mixture, stirring, adding an initiator, centrifuging, washing and drying to obtain a target product. The synthesized negative electrode material has the advantages of uniform and consistent particles, high dispersity and high degree of crystallinity; with a stable multistage composite structure, the negative electrode material hasconsiderable wide-potential-window reversible capacity, high rate performance and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

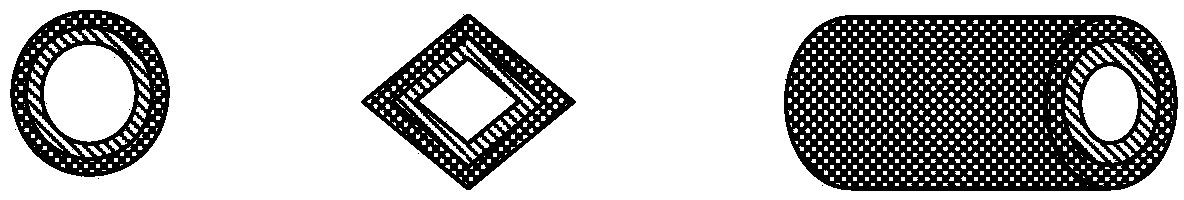

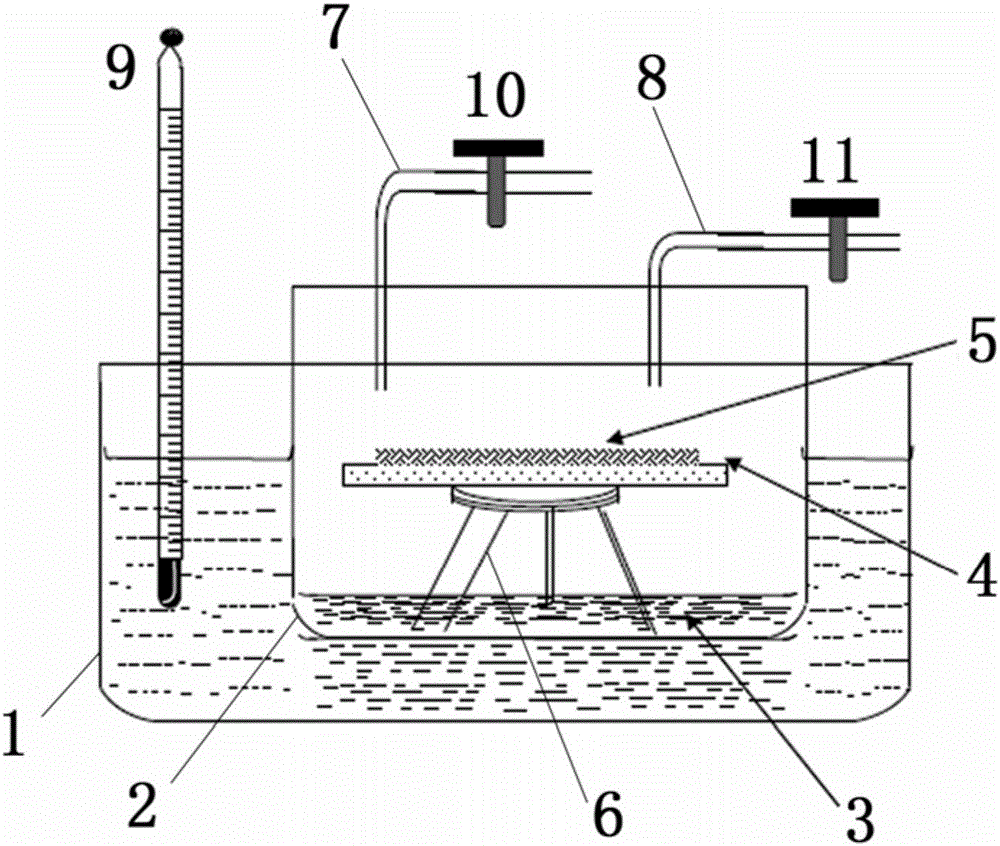

Preparation method of lithium-titanate-cladding sulfur composite lithium-ion battery positive material

InactiveCN103296251APrevent disengagementEase of mass productionCell electrodesFinal product manufactureHeat stabilityUltrasonic dispersion

The invention relates to the preparation technology of a lithium-ion battery, and aims at providing a preparation method of a lithium-titanate-cladding sulfur composite lithium-ion battery positive material. The preparation method comprises the following steps of: adding organic acid and tetrabutyl titanate into ethyl alcohol to be ultrasonically dispersed to obtain a solution A; adding the organic acid into the ethyl alcohol, and adding deionized water lithium acetate to obtain a solution B; dropping the solution B into the solution A to obtain sol; adding organic acid into the sol to obtain a precursor sol; spraying the precursor sol into the air to form erythrocyte-shaped lithium titanate material precursor; placing the lithium titanate material precursor into a muffle furnace to be insulated after reaching a set temperature, thus obtaining the erythrocyte-shaped lithium titanate material; grinding and mixing single sulfur with the erythrocyte-shaped lithium titanate material, placing the mixture into a reactor to be heated in vacuum to complete a sulfur storage process, and cooling a product to the room temperature to obtain the lithium-titanate-cladding sulfur composite material. By adopting the method, the organic electrolyte is safe to use in the battery; good electrode reaction reversibility can be realized; good chemical stability and heat stability can be realized; the material is cheap and easy to prepare; no pollution exists.

Owner:ZHEJIANG UNIV

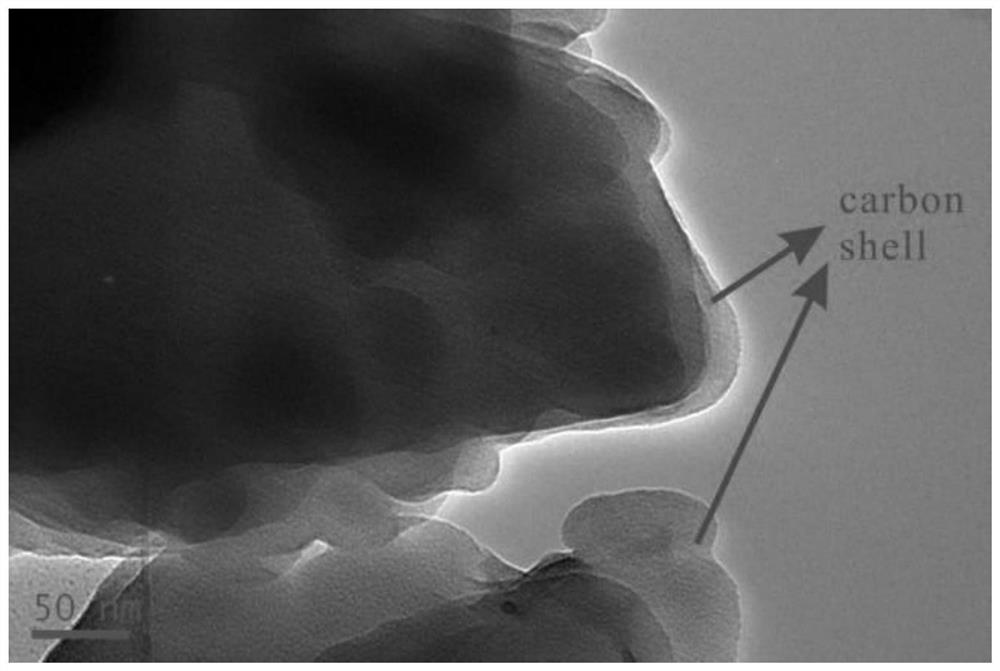

High-compaction silicon-carbon composite negative electrode material as well as preparation and application thereof

ActiveCN112028049AAchieving Controlled RestorationImprove electrochemical performanceCell electrodesSecondary cellsCarbon compositesCarbon coating

The invention belongs to the field of preparation of silicon-carbon negative electrode materials, and particularly discloses a silicon-carbon composite material based on low-oxygen-content porous silicon, which comprises silicon-carbon composite particles and a carbon component a, the silicon-carbon composite particles comprise amorphous carbon substrates, small-particle-size carbon particles b and low-oxygen-content porous silicon particles; the low-oxygen-content porous silicon particle comprises an inner core and a shell compounded on the surface of the inner core, wherein the inner core islocally non-crystallized silicon SiOy with a low oxygen-containing porous structure, and the shell is a thin carbon coating layer; 0 < y < 1; the thickness of the thin carbon coating layer is not more than 100nm the core and / or shell material is doped with a non-metallic element E; and the non-metallic element E is at least one of boron, nitrogen, phosphorus and sulfur. The invention also provides a preparation method of the material. Research finds that the material with the components and the morphological structure can show better reversible capacity, rate capability and cycling stability.

Owner:湖南宸宇富基新能源科技有限公司

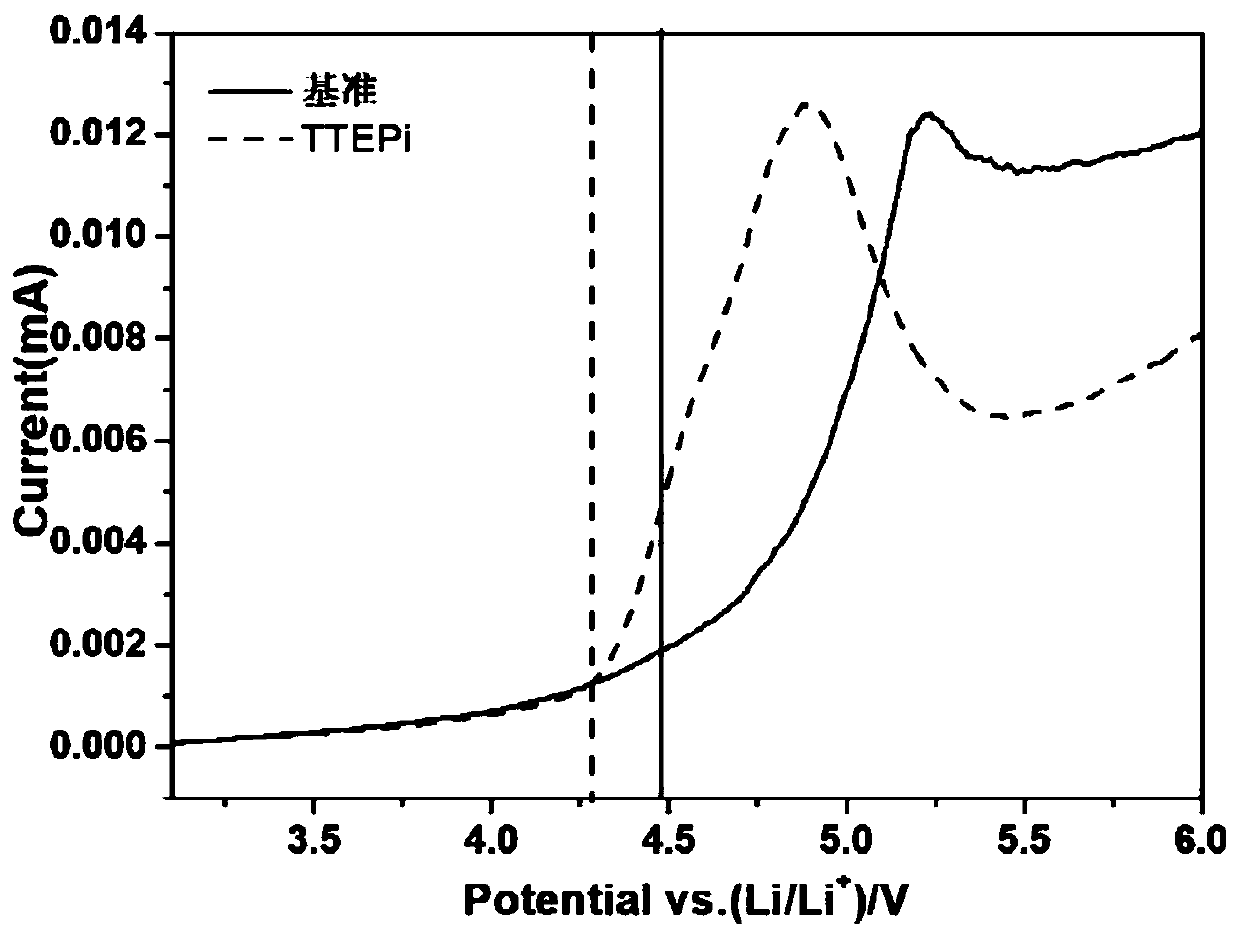

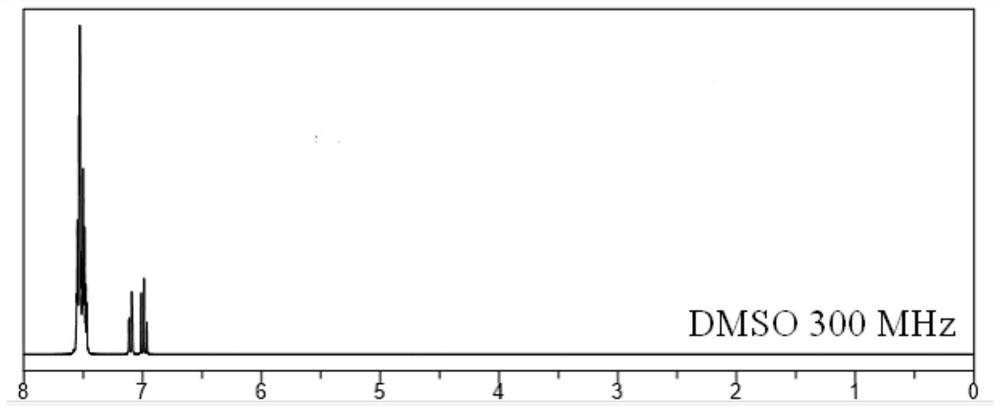

Thienyl-containing phosphite compound and application thereof

ActiveCN111116651ALower oxidation potentialImprove low temperature performanceGroup 5/15 element organic compoundsSecondary cellsElectrolytic agentElectrical battery

The invention relates to a thienyl-containing phosphite compound and an application thereof in a lithium ion battery electrolyte. The phosphite compound at least comprises one thiophene alkoxy C4H3(C2H4)nOS<->. The synthesis process of the phosphite compound is simple. The thienyl-containing phosphite compound is used for preparing a lithium ion battery electrolyte. Thienyl in the compound has thecharacteristic of being polymerized into a film at a positive electrode, trivalent P can react with O2 and HF in a battery to form a CEI film at the positive electrode, the formed polymer film contains a P element which is beneficial to the low-temperature performance of the battery, and the formed polymer film contains an S element which is beneficial to the high-temperature performance and thelow-temperature performance of the battery. The polymer film can stabilize the electrode structure, inhibit the dissolution of a transition metal, reduce the side reaction between the positive electrode and the electrolyte interface, and improve the electrochemical performance and safety performance of the battery.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

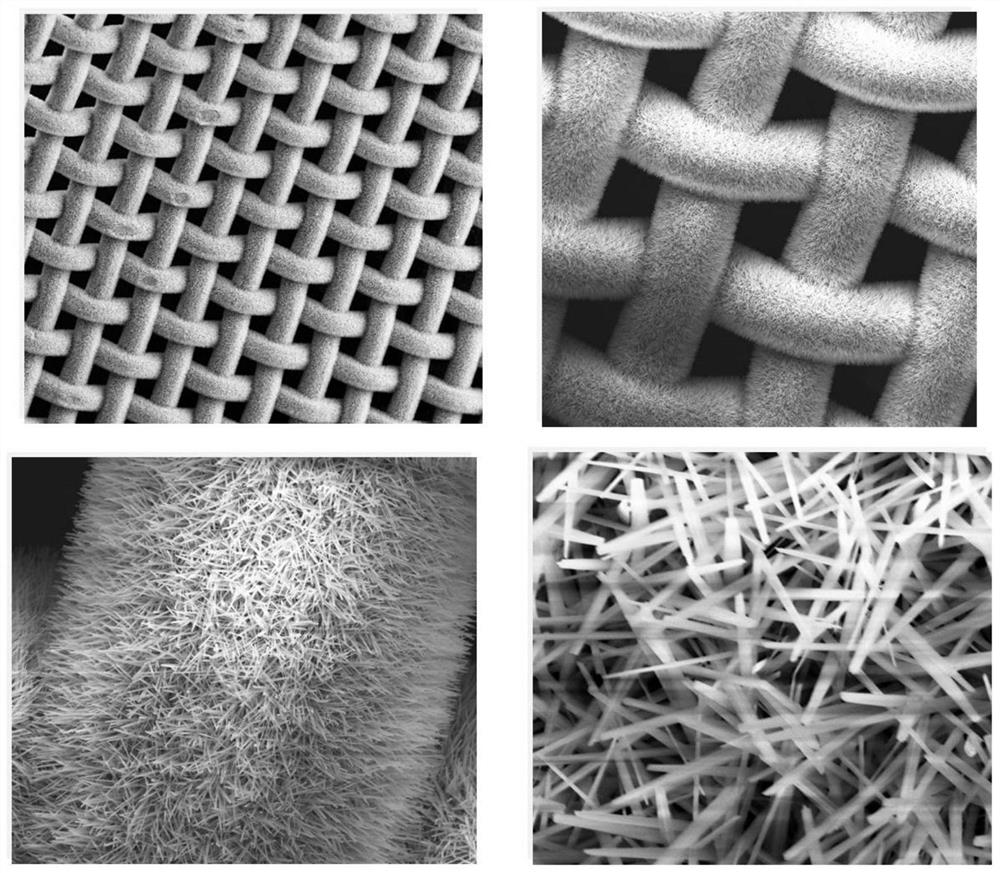

Array type metal sulfide composite electrode material and preparation method thereof

ActiveCN111900334AHigh specific surface areaImprove conductivityCell electrodesElectrolytic agentConductive polymer

The preparation method of the array type metal sulfide composite electrode material comprises the following steps: step 1, taking a copper mesh substrate, slicing, ultrasonically cleaning, and dryingfor later use; 2, adopting an electrochemical workstation, adopting a constant current mode, taking foamy copper as a working electrode, taking mercury oxide as a reference electrode, taking a platinum sheet as a counter electrode and taking NaOH as an electrolyte, and electroplating to prepare a Cu(OH)2 nano array; 3, putting the prepared Cu(OH)2 nano array into a tubular furnace for annealing treatment to prepare a copper peroxide CuO2 nano array; 4, carrying out vulcanization treatment on the annealed copper peroxide CuO2 nano array sample to prepare a Cu9S5 nano array; and 5, coating a layer of conductive polymer ppy outside the Cu9S5 nano array by adopting an electroplating method to prepare a Cu9S5@ppy nano array. Therefore, the vertical Cu9S5 nanosheet is prepared on the surface ofthe foamy copper, and a layer of polypyrrole is coated outside the Cu9S5 nanosheet, so that the stability of the electrode material is improved, and the obtained electrode material has excellent electrochemical performance.

Owner:东营睿港招商服务有限责任公司

Preparation method of multilevel structure titanate negative electrode material for lithium ion battery

ActiveCN107749471AStable structureEvenly dispersedMaterial nanotechnologyCell electrodesMuffle furnaceCarbon nanotube

The invention discloses a preparation method of a multilevel structure titanate negative electrode material for a lithium ion battery, and belongs to the technical field of lithium ion batteries. Themethod concretely comprises the following steps: dispersing a sodium source and a titanium source in a glycol and anhydrous ethanol mixed solution to form a solution A; dissolving a barium source in an aqueous solution of anhydrous ethanol to form a solution B; mixing and stirring the solution A and the solution B, heating the obtained solution until evaporative drying is achieved, placing the obtained precursor in a muffle furnace, and carrying out pre-calcining, ball milling and calcining to obtain a BaNa2Ti6O14 material; dispersing the material in an acetone solution, adding carbon nano-tubes, and stirring and heating the obtained solution until the solution is completely volatilized in order to obtain BaNa2Ti6O14-CNT; and carrying out mixing and ball-milling on the BaNa2Ti6O14-CNT andcarbon fibers, and sintering the obtained mixture in nitrogen to obtain the target product. The titanate negative electrode material obtained in the invention has a stable multilevel composite structure, so the titanate negative electrode material has the advantages of considerable wide potential window reversible capacity, excellent rate performances and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

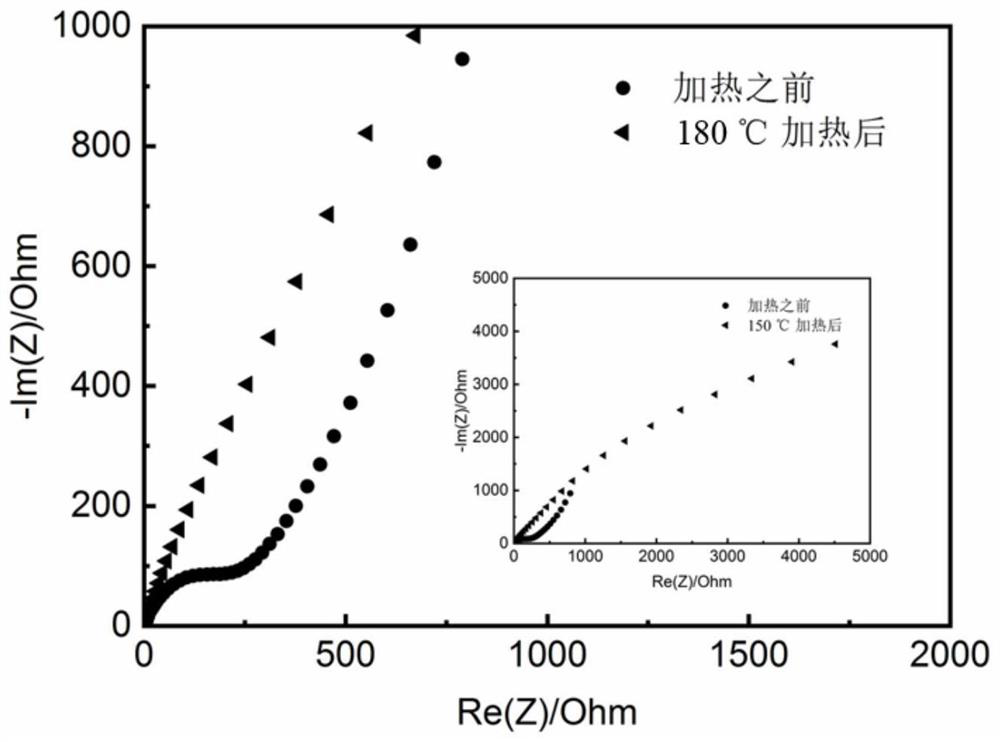

Polymer electrolyte and preparation method and application thereof

ActiveCN112979875AImproved thermal dimensional stabilityAvoid destructionSolid electrolytesFinal product manufacturePolymer electrolytesPolymer science

The invention discloses a polymer electrolyte and a preparation method and application thereof. The polymer electrolyte comprises a polymer matrix, the polymer matrix is a polymer formed by self-polymerization of a polymeric monomer composed of three building blocks of acryloyl, carbamate and phosphate, or a polymer formed by copolymerizing a polymeric monomer and other monomers, wherein the polymeric monomer is composed of three building blocks, namely acryloyl, carbamate and phosphate. The polymer electrolyte can be used in a battery, the polymer matrix can be subjected to a self-crosslinking reaction at a high temperature of 130-190 DEG C to generate a compact thermosetting polymer which can cut off ion transmission and prevent thermal runaway of the battery; the self-crosslinking reaction is an endothermic reaction, so that the temperature of the battery can be quickly reduced, and the thermal runaway of the battery can be prevented; the polymer electrolyte can capture free radicals and has intrinsic flame retardance; and the characteristics of the polymer matrix are synergistic, so that the thermal runaway of the battery can be effectively prevented.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

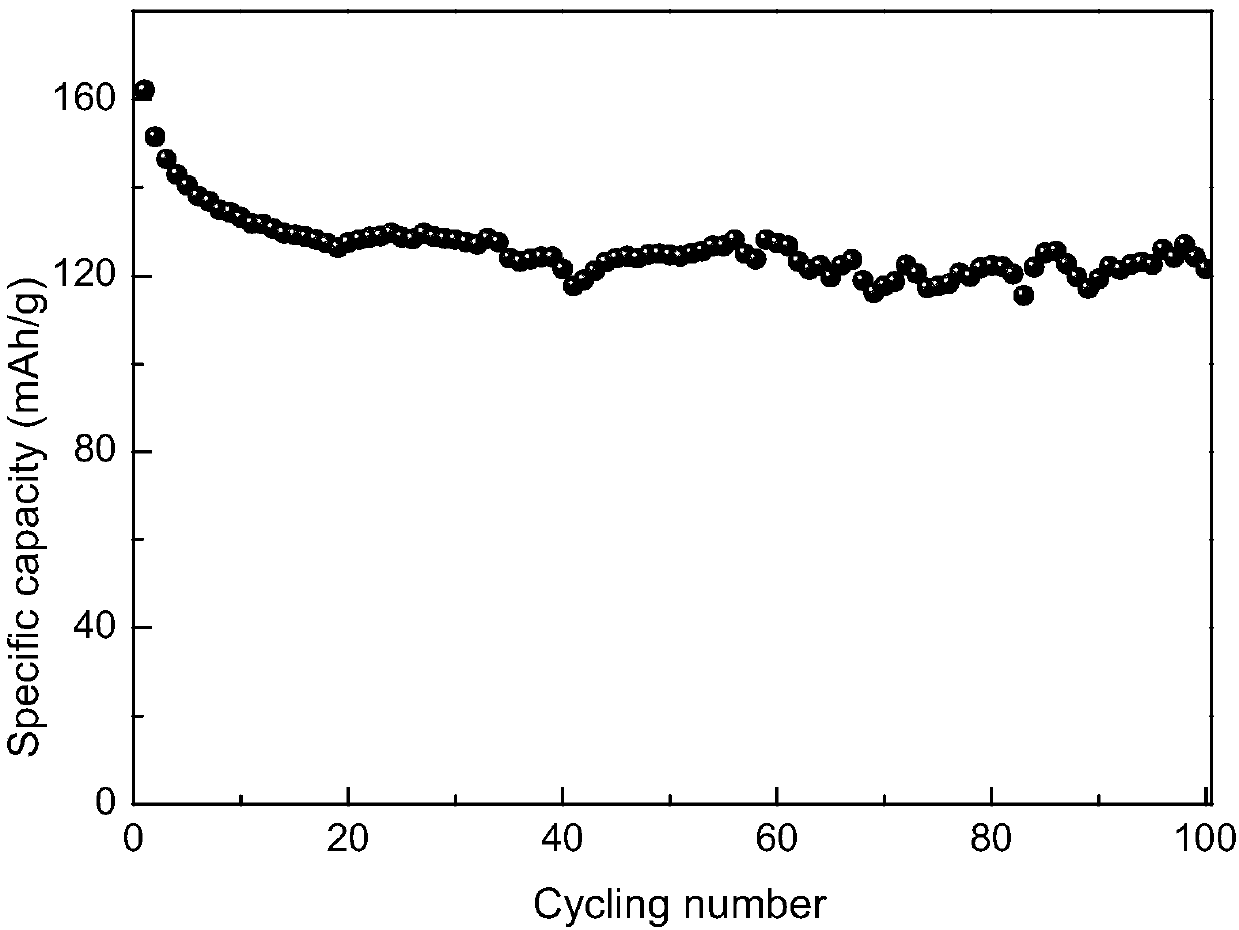

Application of Calcium Terephthalate as Lithium-ion Battery Anode Material

InactiveCN104292100BImproved magnification performanceNo apparent damageOrganic compound preparationCell electrodesLithium-ion batteryVacuum drying

The invention provides a preparation method of calcium terephthalate, an organic negative electrode material, and its application in lithium ion batteries. The preparation method of calcium terephthalate comprises the following steps: 1) terephthalic acid reacts with LiOH or NaOH or KOH to generate terephthalate solution; 2) terephthalate solution and CaCl2 or Ca(NO3) 2 reactions to obtain a mixed solution containing calcium terephthalate; 3) separate the mixed solution, and dry the separated solid to obtain calcium terephthalate containing three waters of crystallization; 4) mix the solution containing three waters of crystallization Calcium terephthalate is dried in a vacuum drying oven to remove crystal water to obtain calcium terephthalate. The reversible specific capacity of calcium terephthalate obtained by the present invention is as high as 231mAh / g, and it has excellent stability in the electrolyte, good rate performance, slow specific capacity decay, and a capacity retention rate of up to 93% after 120 cycles of circulation, which is a performance Excellent organic anode materials for lithium-ion batteries.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

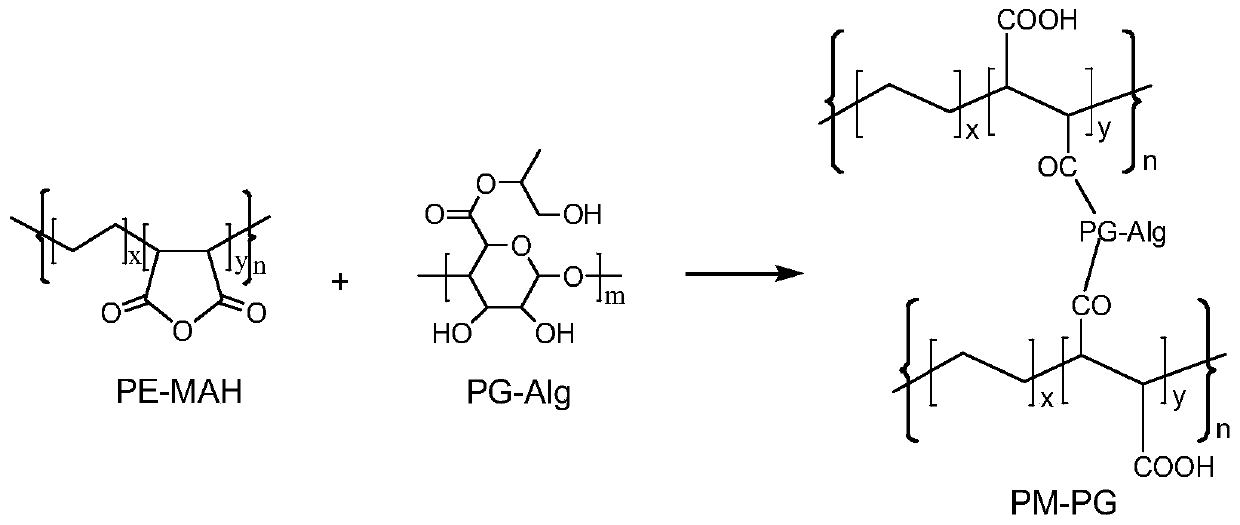

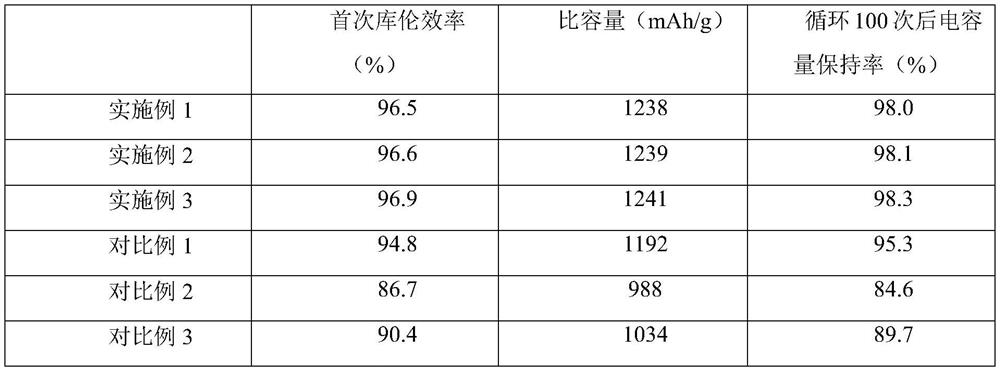

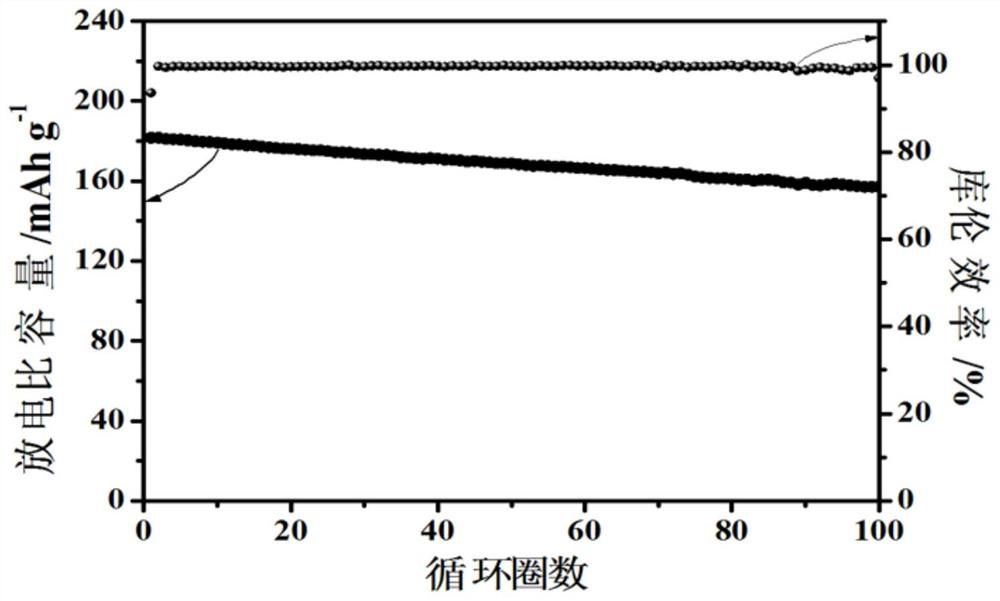

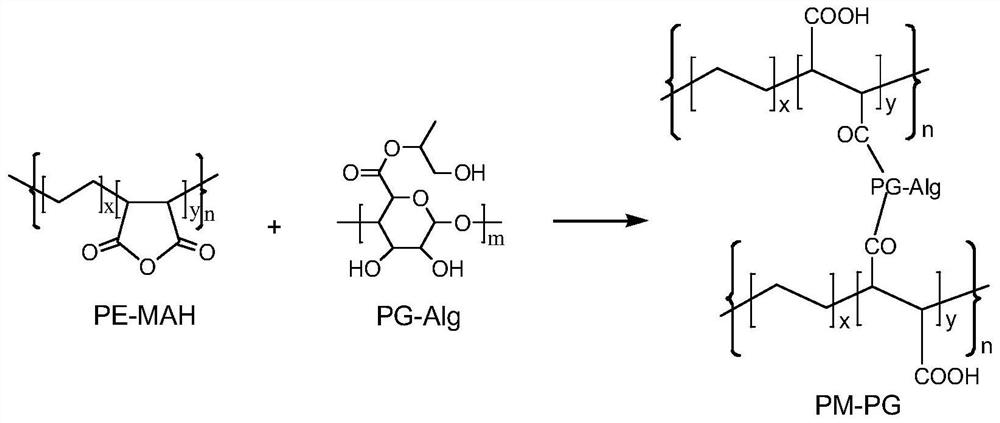

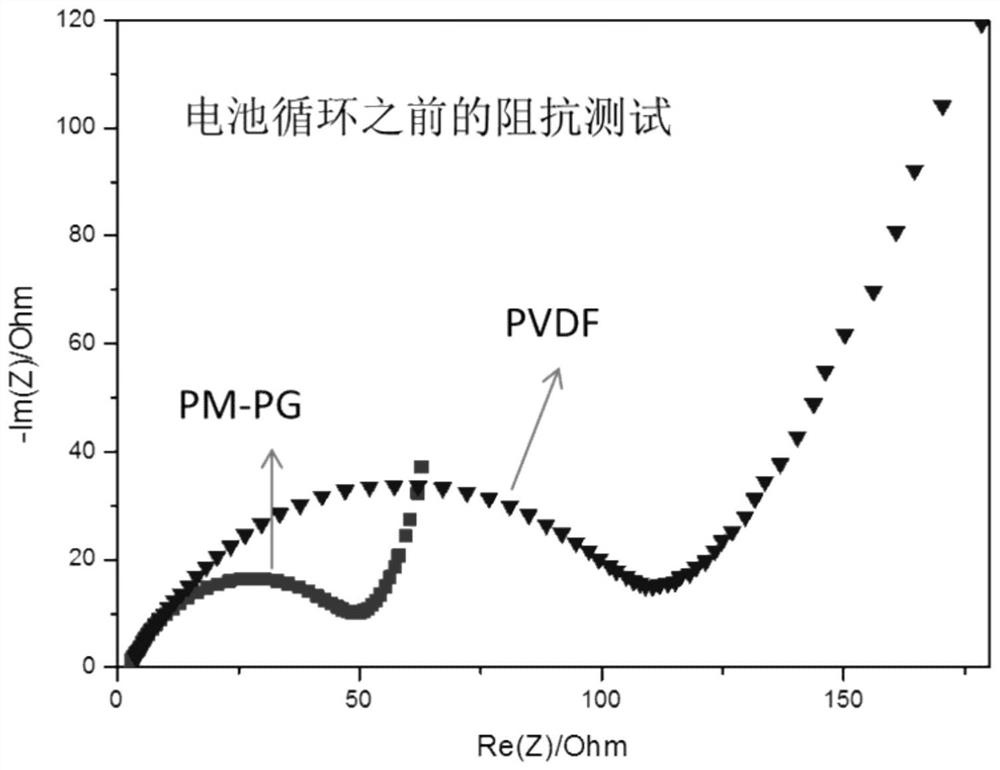

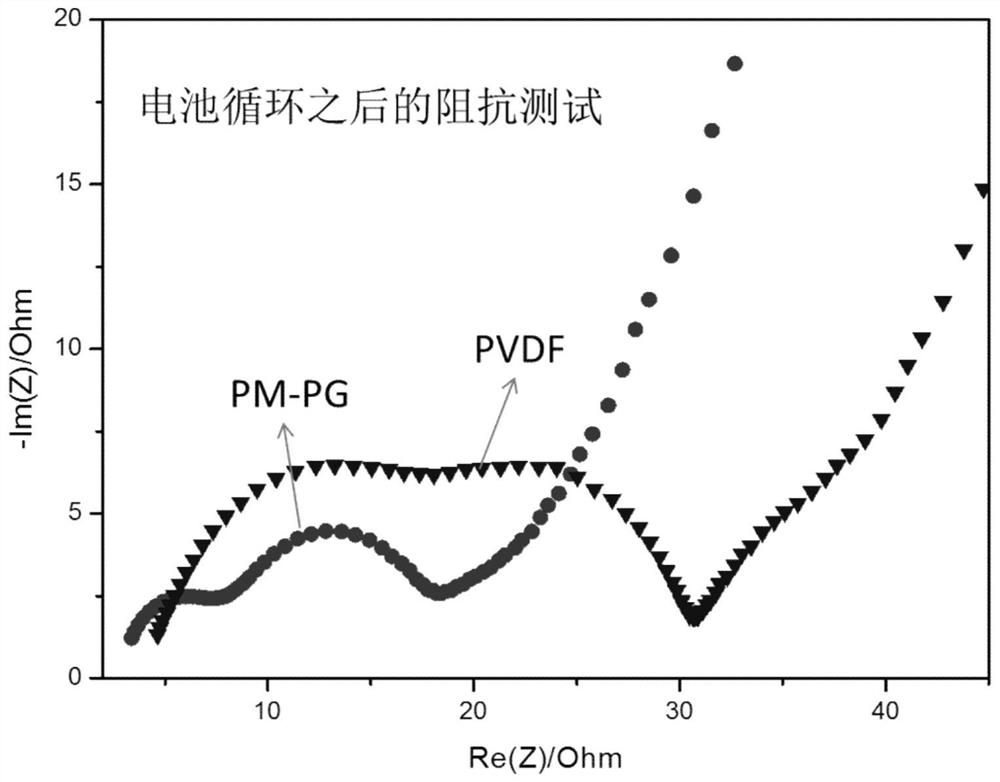

In-situ generated cross-linked type lithium ion battery anode material adhesive as well as preparation method and lithium ion secondary battery thereof

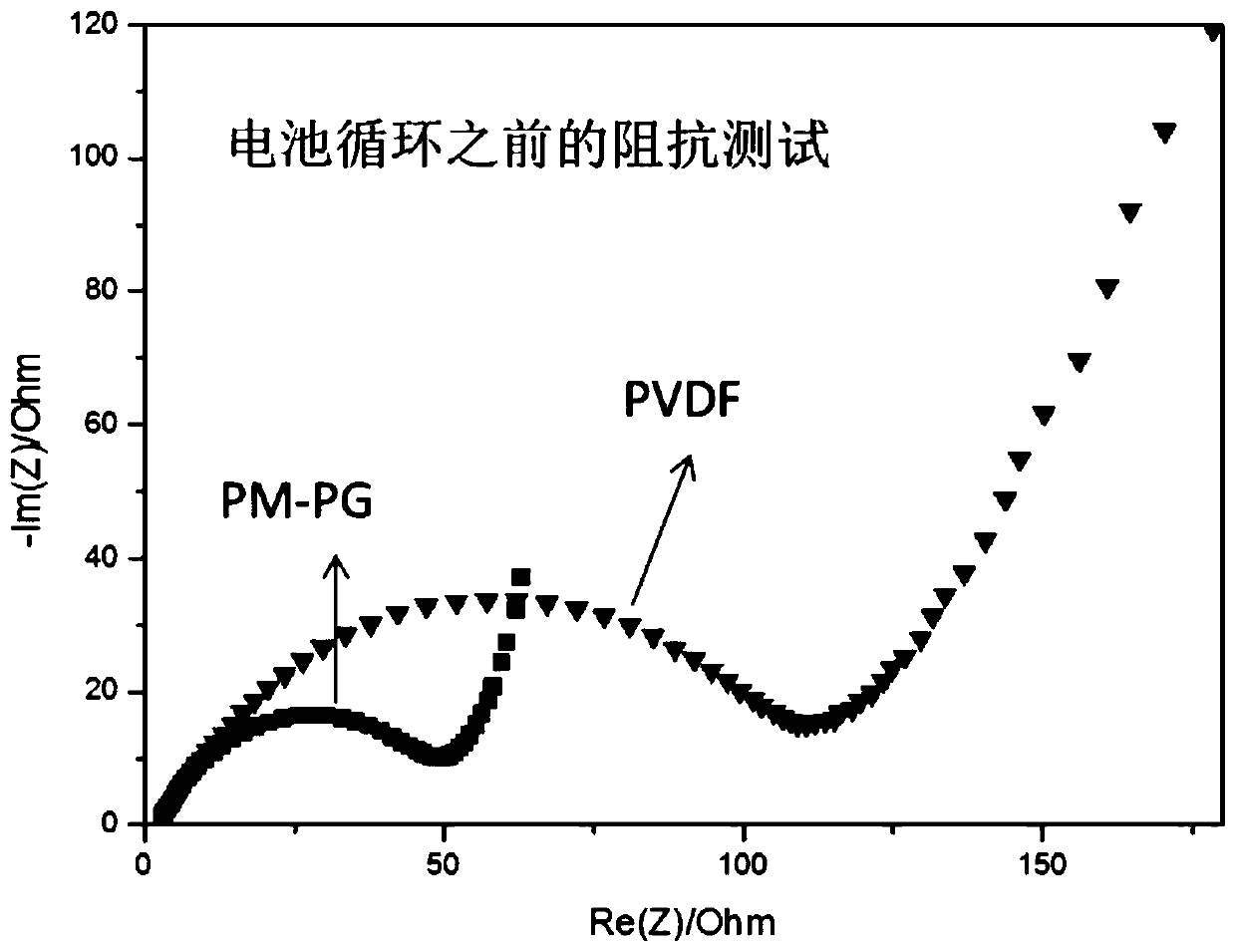

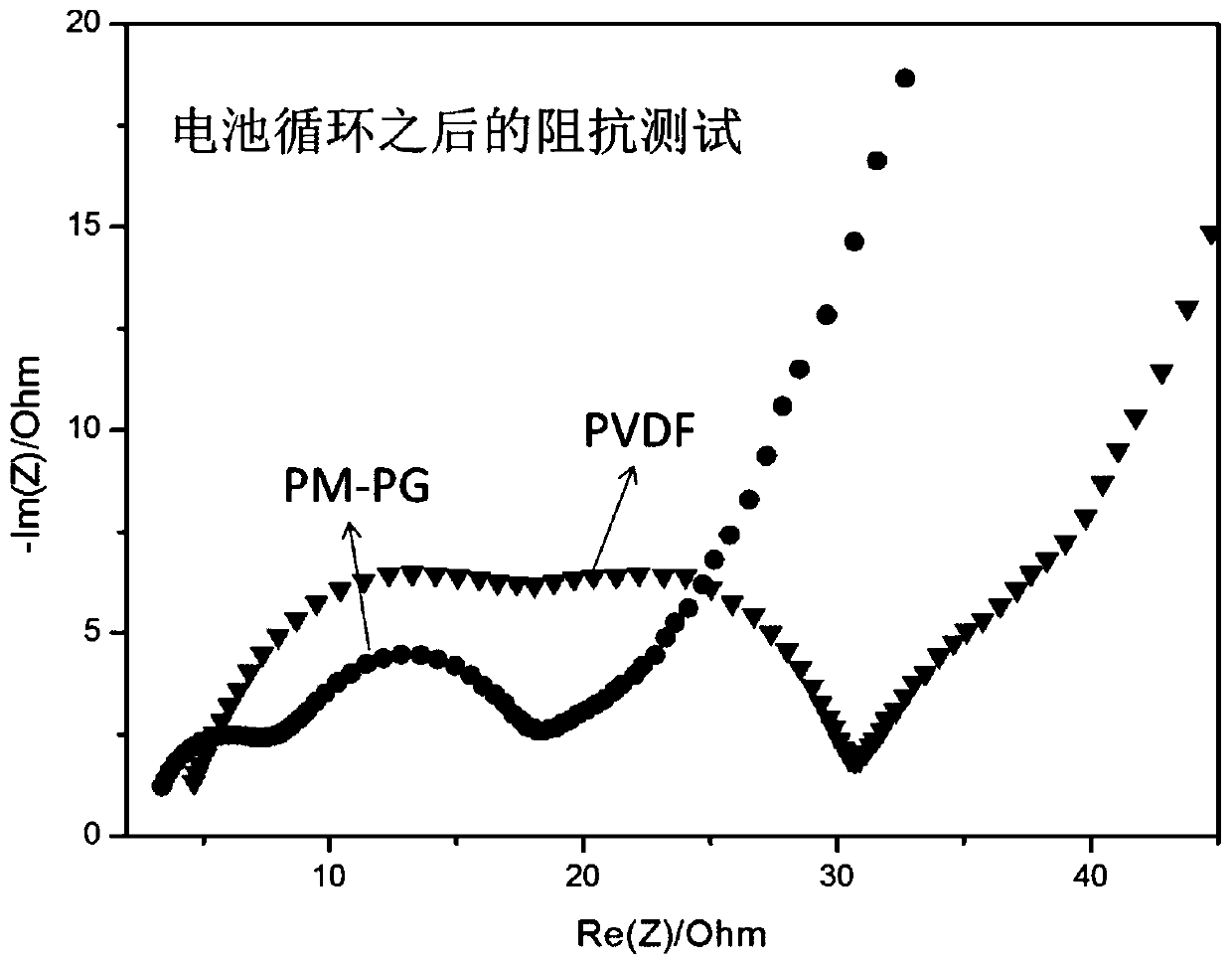

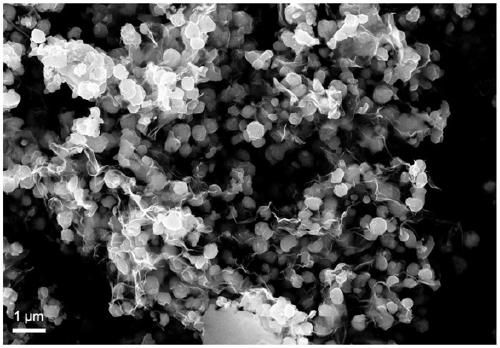

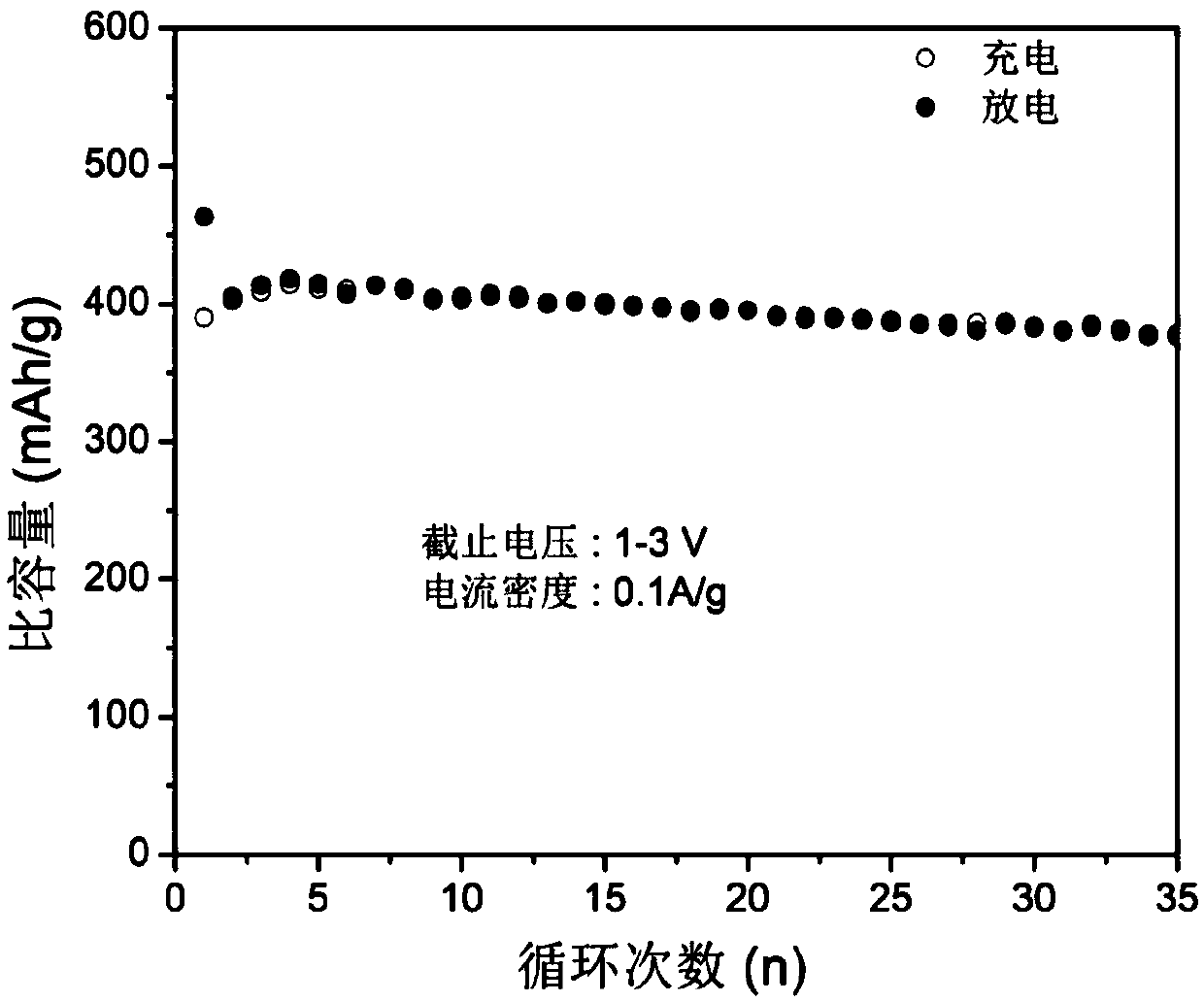

The invention provides an in-situ generated cross-linked type lithium ion battery anode material adhesive which is a cross-linking product PM-PG of polyethylene maleic anhydride and propylene glycol alginate. The invention furthermore provides a preparation method of the cross-linked type lithium ion battery anode material adhesive. The preparation method comprises the following steps: dissolvingpolyethylene maleic anhydride and propylene glycol alginate into a solvent, and carrying out stirring at the room temperature to carry out a reaction, so as to obtain an adhesive solution. The invention furthermore provides a lithium ion battery anode material which consists of an active component, a conductive material and the cross-linked type lithium ion battery anode material adhesive. The invention furthermore provides a lithium ion secondary battery which comprises the lithium ion battery anode material. The cross-linked type lithium ion battery anode material adhesive provided by the invention comprises multiple polar bonds such as hydroxyl and carboxyl, and has good adhesiveness; and the cross-linked type lithium ion battery anode material adhesive provided by the invention has a 3D cross-linking network, and is capable of well covering active materials and conductive materials, and thus an electrode structure can be stabilized.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

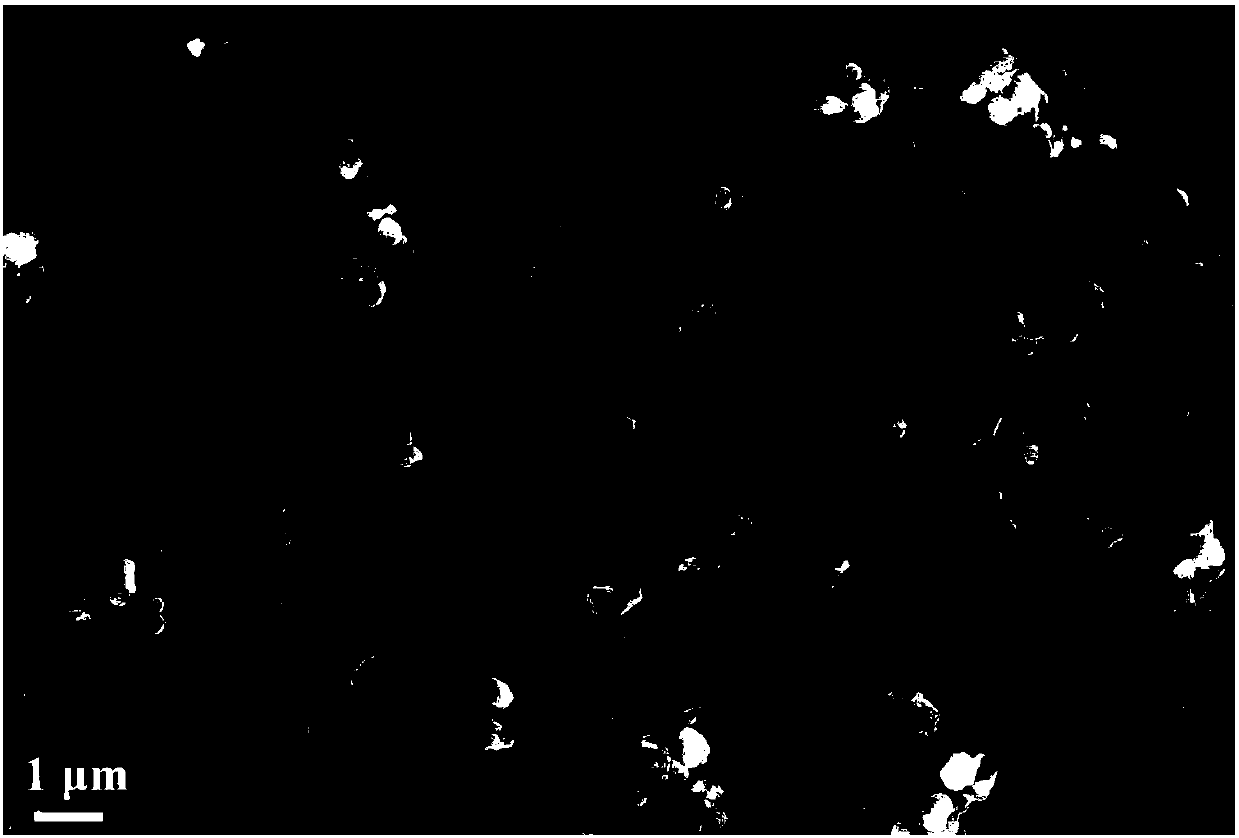

Preparation method of nano ferrous sulfide/graphene composite positive electrode material

InactiveCN109546128AInhibition of dissolutionEvenly dispersedCell electrodesGrapheneDissolutionLithium-ion battery

The invention discloses a preparation method of a nano ferrous sulfide / graphene composite positive electrode material. The ferrous sulfide / graphene composite material is prepared by using a ferroferric oxide / graphene composite material as a reaction product and introducing a sulfur source based on a chemical vapor deposition method. ferrous sulfide particles are uniformly dispersed on the surfaceof the graphene and are combined with the graphene stably, thereby preventing agglomeration of the nanoparticles during charging and discharging processes effectively, buffering the volume expansion,suppressing the dissolution of the reaction product in the electrolyte and thus guaranteeing the electrode structure stability during the charging and discharging processes. Meanwhile, the graphene provides a good conductive network to accelerate electron transport. Moreover, the preparation process is simple; the time is shortened; the cost is lowered; and the industrial production is easy to implement. The ferrous sulfide / graphene composite material prepared based on the method has the excellent electrochemical performance and is an ideal positive electrode material for a lithium ion battery. Therefore, the nano ferrous sulfide / graphene composite positive electrode material can be widely applied to portable electronic equipment, electric vehicles and aerospace and other fields.

Owner:UNIV OF SCI & TECH BEIJING

Silicon-carbon composite cathode material with three-dimensional preformed hole structure and preparation method thereof

ActiveCN102623680BGood lithium removal/intercalation performanceWith dispersionCell electrodesCarbon compositesComposite cathode

The invention discloses a silicon-carbon composite cathode material with a three-dimensional preformed hole structure and a preparation method thereof. According to the composite cathode material, a carbon material having high electric conductivity and a stable structure is used as a matrix for dispersedly containing high-volume silicon particles, and proper three-dimensional expansion spaces are reserved around one or several silicon particles. The preparation method comprises the following steps of: carrying out surface modification on the silicon particles; coating the silicon particles by silicon dioxide; coating the silicon dioxide / silicon composite particles by carbon source precursors; carrying out high-temperature carbonization treatment; and removing a silicon dioxide template, and the like. When the composite material prepared by the preparation method is used for a lithium ion battery, the reversible specific capacity is high, and the cycle performance is excellent. The silicon-carbon composite cathode material has the advantages of simple preparation process and wide raw material resource and is suitable for industrial production.

Owner:湖南宸宇富基新能源科技有限公司

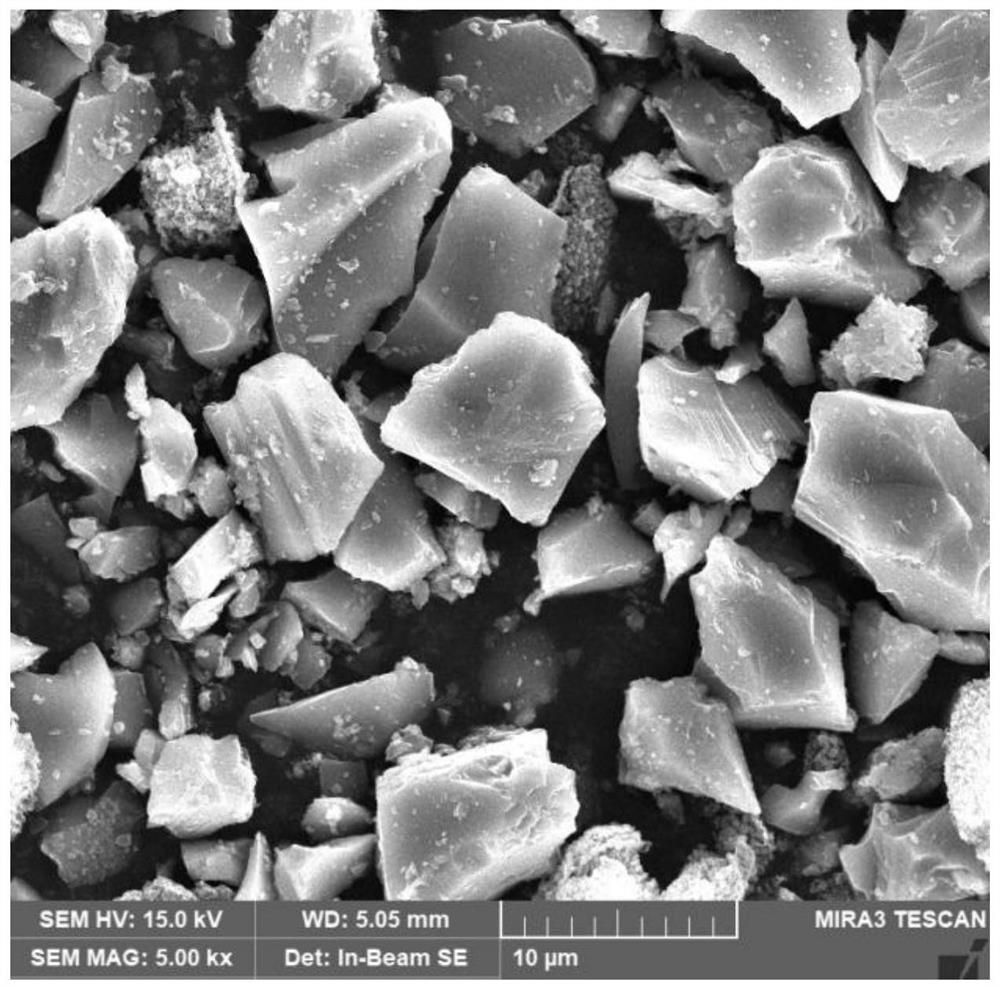

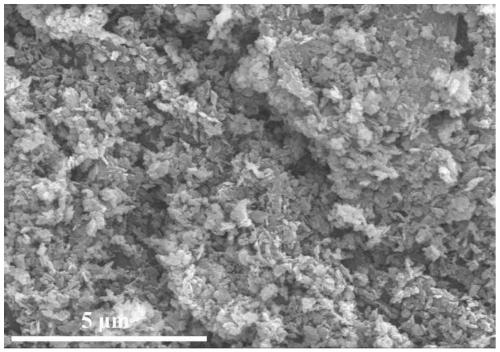

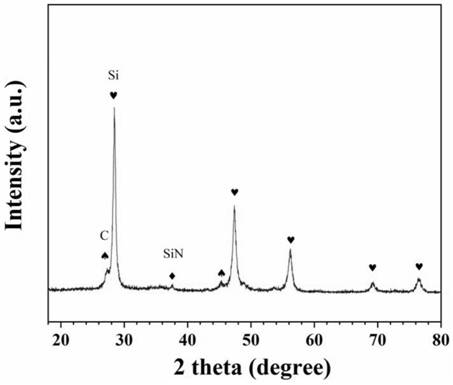

Low-oxygen-content porous silicon composite powder material as well as preparation and application thereof

ActiveCN112054180AControl hypoxicExcellent first lap efficiencyCell electrodesSecondary cellsCarbon coatingLithium-ion battery

The invention belongs to the technical field of lithium-ion battery materials, and particularly discloses a low-oxygen-content porous silicon composite material which comprises an inner core and a shell compounded on the surface of the inner core, wherein the inner core is locally non-crystallized silicon SiOy with a low oxygen-containing porous structure; the shell is a thin carbon coating layer;wherein y is larger than 0 and smaller than 1; and the thickness of the thin carbon coating layer is not more than 100nm. In addition, the invention also discloses a preparation method of the material. Research finds that the composite material has the characteristics of large reversible capacity, excellent rate capability, high first efficiency, stable circulation and the like.

Owner:湖南宸宇富基新能源科技有限公司

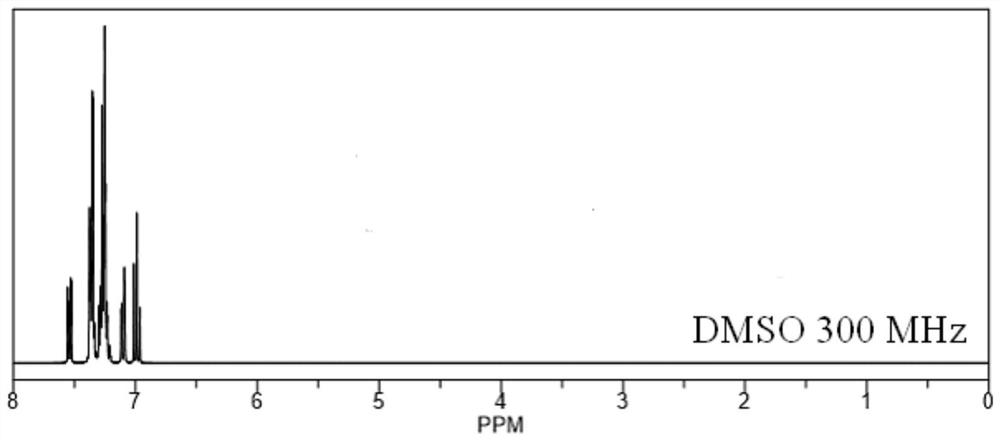

A kind of borate compound and preparation method thereof and electrolyte containing same

ActiveCN111574545BLower oxidation potentialImprove low temperature performanceGroup 3/13 element organic compoundsSecondary cells servicing/maintenanceElectrolytic agentAryl

The present invention provides a borate compound and a preparation method thereof, and a lithium ion battery electrolyte including the borate compound. The S-containing heterocycles in the boric acid ester compound provided by the present invention, such as thienyl and aryl groups, have the characteristics of being polymerized into a film at the positive electrode. High temperature performance of the battery. In addition, the polymer film can stabilize the electrode structure, inhibit the dissolution of transition metals, reduce side reactions at the interface between the positive electrode and the electrolyte, and improve the electrochemical performance and safety performance of the battery.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

Lithium ion battery anode material based on metal oxide and preparation method thereof

ActiveCN111969191AHigh tap densityStable electrode structureCell electrodesSecondary cellsLithium hydrideLithium electrode

The invention relates to a lithium ion battery anode material based on a metal oxide and a preparation method thereof. The preparation method comprises the following steps: firstly, taking hydroxyethyl methacrylate, [alpha]-bromo isobutyryl bromide and mercaptoethanol as raw materials to react to generate hydroxyl-terminated hyperbranched polyacrylate; then enabling the hydroxyl-terminated hyperbranched polyacrylate to react with aluminum nitrate nonahydrate and copper nitrate hexahydrate to prepare aluminum and copper oxide microspheres; mixing and ball-milling the aluminum and copper oxide microspheres and lithium hydride in a carbon dioxide gas atmosphere, and performing heating to release hydrogen, so as to obtain pretreated aluminum and copper oxide microspheres; and finally, using the pretreated aluminum and copper oxide microspheres and 2-vinylthiophene as raw materials, performing a polymerization reaction, obtaining the lithium ion battery negative electrode material, and therefore, the initial coulombic efficiency is high, and the cycling stability is good.

Owner:山东兴丰新能源科技有限公司

Preparation method of lithium titanate negative electrode material of lithium ion battery

ActiveCN111403721AStable structureCompact structureCell electrodesSecondary cells servicing/maintenancePhysical chemistryMixed gas

The invention provides a preparation method of a lithium titanate negative electrode material of a lithium ion battery. The invention belongs to the technical field of lithium-ion batteries. The method comprises the following steps: preparing porous Li4Ti5O12 nanosheets by utilizing LiOH.H2O, Ti (OC4H9) 4 and the like; then preparing nitrogen-doped carbon nanosheets by utilizing medium-temperaturecoal pitch and the like; then, grinding and transferring the porous Li4Ti5O12 nanosheets, the nitrogen-doped carbon nanosheets and a sulfur-containing substance into a tubular furnace; and carrying out continuous heat treatment in a mixed gas at 500-600 DEG C for 3 hours, and naturally cooling to room temperature to obtain a coal pitch-based sulfur and nitrogen-doped carbon nanosheet modified sulfur-doped lithium titanate negative electrode material with a hierarchical structure. The negative electrode material prepared by the invention is in a nanosheet shape, is stable and compact in structure, maintains the stability and high conductivity of an electrode structure, and has excellent high-rate performance and cycling stability.

Owner:JIANGSU AOXIN TECH DEV

A kind of polymer electrolyte and its preparation method and application

ActiveCN112979875BImproved thermal dimensional stabilityAvoid destructionSolid electrolytesFinal product manufacturePolymer electrolytesPolymer science

The invention discloses a polymer electrolyte and a preparation method and application thereof, wherein the polymer electrolyte comprises a polymer matrix, and the polymer matrix is composed of three blocks of acryl, urethane and phosphate. The polymer formed by the self-polymerization of the polymerized monomer, or the polymer formed by the copolymerization of the polymerized monomer composed of the three building blocks of acryl, urethane and phosphate ester and other monomers. The polymer electrolyte can be used in a battery, and the polymer matrix can undergo a self-crosslinking reaction at a high temperature of 130-190° C. to generate a dense thermosetting polymer that can cut off ion transport and prevent the occurrence of thermal runaway of the battery; and The self-crosslinking reaction is an endothermic reaction, which helps to quickly reduce the battery temperature and prevent the battery from thermal runaway; the polymer electrolyte can also capture free radicals and has intrinsic flame retardancy; the above characteristics of the polymer matrix act synergistically , which can effectively prevent the occurrence of thermal runaway of the battery.

Owner:中科深蓝汇泽新能源(青岛)有限责任公司

A cross-linked lithium-ion battery positive electrode material binder generated in situ, its preparation method and lithium-ion secondary battery

ActiveCN110229344BEasy to prepareEasy to operateSecondary cellsPositive electrodesCarboxyl radicalElectrical battery

The invention provides an in-situ generated cross-linked type lithium ion battery anode material adhesive which is a cross-linking product PM-PG of polyethylene maleic anhydride and propylene glycol alginate. The invention furthermore provides a preparation method of the cross-linked type lithium ion battery anode material adhesive. The preparation method comprises the following steps: dissolvingpolyethylene maleic anhydride and propylene glycol alginate into a solvent, and carrying out stirring at the room temperature to carry out a reaction, so as to obtain an adhesive solution. The invention furthermore provides a lithium ion battery anode material which consists of an active component, a conductive material and the cross-linked type lithium ion battery anode material adhesive. The invention furthermore provides a lithium ion secondary battery which comprises the lithium ion battery anode material. The cross-linked type lithium ion battery anode material adhesive provided by the invention comprises multiple polar bonds such as hydroxyl and carboxyl, and has good adhesiveness; and the cross-linked type lithium ion battery anode material adhesive provided by the invention has a 3D cross-linking network, and is capable of well covering active materials and conductive materials, and thus an electrode structure can be stabilized.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A kind of preparation method of multi-level structure titanate negative electrode material for lithium ion battery

ActiveCN107749471BStable structureCompact structureMaterial nanotechnologyCell electrodesLithium-ion batteryMuffle furnace

The invention discloses a preparation method of a multilevel structure titanate negative electrode material for a lithium ion battery, and belongs to the technical field of lithium ion batteries. Themethod concretely comprises the following steps: dispersing a sodium source and a titanium source in a glycol and anhydrous ethanol mixed solution to form a solution A; dissolving a barium source in an aqueous solution of anhydrous ethanol to form a solution B; mixing and stirring the solution A and the solution B, heating the obtained solution until evaporative drying is achieved, placing the obtained precursor in a muffle furnace, and carrying out pre-calcining, ball milling and calcining to obtain a BaNa2Ti6O14 material; dispersing the material in an acetone solution, adding carbon nano-tubes, and stirring and heating the obtained solution until the solution is completely volatilized in order to obtain BaNa2Ti6O14-CNT; and carrying out mixing and ball-milling on the BaNa2Ti6O14-CNT andcarbon fibers, and sintering the obtained mixture in nitrogen to obtain the target product. The titanate negative electrode material obtained in the invention has a stable multilevel composite structure, so the titanate negative electrode material has the advantages of considerable wide potential window reversible capacity, excellent rate performances and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of high compacted silicon carbon composite negative electrode material and its preparation and application

ActiveCN112028049BAchieving Controlled RestorationImprove electrochemical performanceCell electrodesSecondary cellsCarbon compositesCarbon coating

The invention belongs to the field of preparation of silicon-carbon negative electrode materials, and specifically discloses a silicon-carbon composite material based on low-oxygen porous silicon, which includes silicon-carbon composite particles and carbon component a; the silicon-carbon composite particles include amorphous carbon Substrate and small-diameter carbon particles b and low-oxygen porous silicon particles compounded in the substrate; the low-oxygen porous silicon particles include a core and a shell compounded on the surface of the core; wherein the core is locally amorphized Low-oxygen porous silicon SiO y ;The shell is a thin carbon coating; where, 0

Owner:湖南宸宇富基新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com