Preparation method of calcium terephthalate, and application of calcium terephthalate in lithium ion battery

A technology of calcium terephthalate and terephthalic acid is applied in the field of preparation of organic negative electrode materials for lithium ion batteries, which can solve the problem that stability and solubility are not fundamentally improved, affecting the application process and modification of lithium ion batteries. The material capacity retention rate is low and other problems, to achieve the effect of excellent electrochemical cycle performance, low cost and slow specific capacity decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of calcium terephthalate comprises the following steps:

[0033] A, take by weighing 3.3226g purity and be 99% terephthalic acid C 8 h 6 o 4 Add 0.9576g of analytically pure LiOH to 100ml of deionized water, stir for 10min, ultrasonicate for 1h, and then stand in a constant temperature drying oven at 80°C for 12h to obtain a clear solution of lithium terephthalate (PTAL) with a concentration of 0.1mol / L;

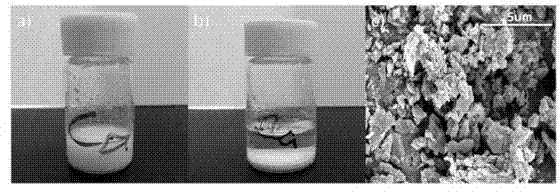

[0034] B, add 2.2196g anhydrous CaCl in the lithium terephthalate solution that step A obtains 2 , stirred and ultrasonicated for 6 hours, and then stood still in a constant temperature drying oven for 12 hours at a temperature of 80°C to obtain a mixed solution containing a white precipitate of calcium terephthalate;

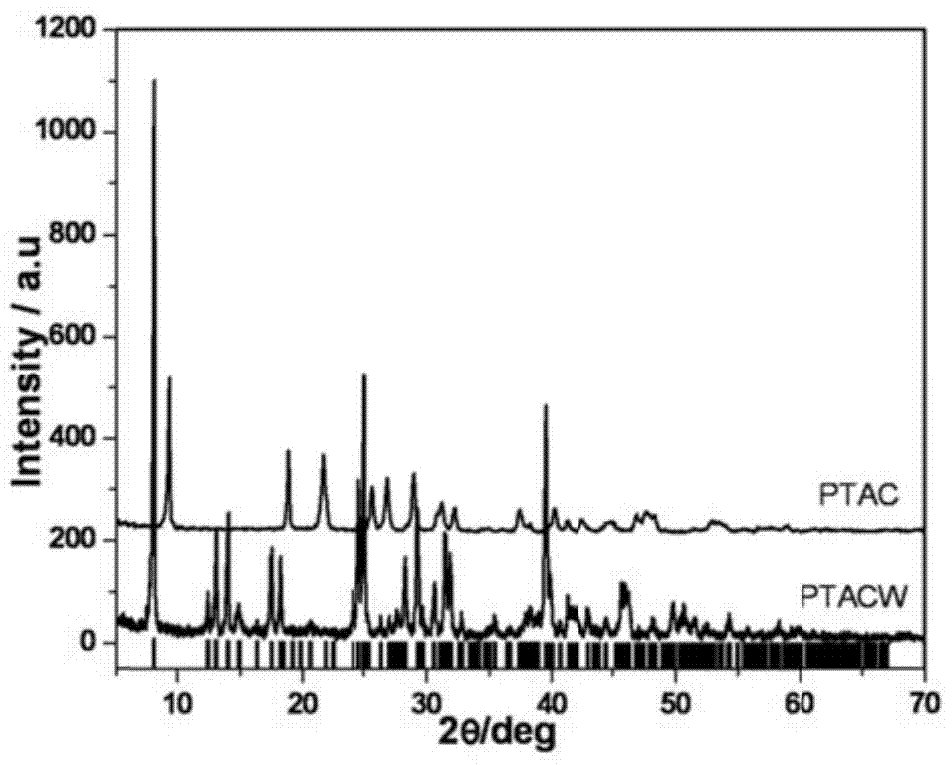

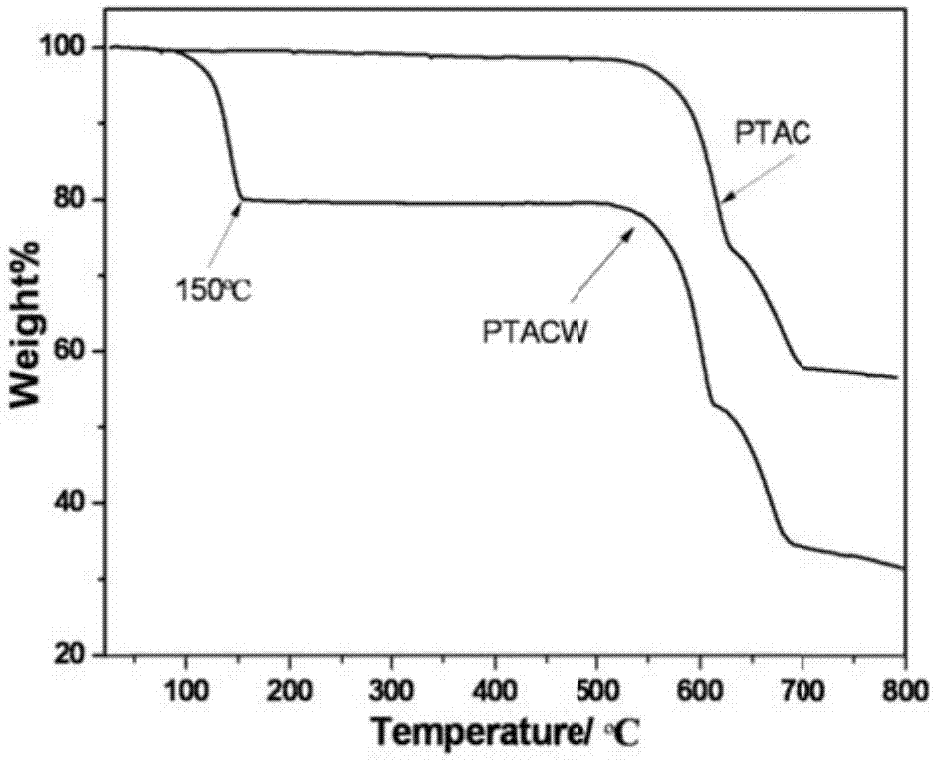

[0035] C. The mixed solution containing calcium terephthalate obtained in step B is centrifuged and washed 3 times with deionized water, and the solid obtained by centrifugation is placed in a thermostat and dried for 6 hours ...

Embodiment 2

[0044] The PTAC and graphite obtained in Example 1 were ball milled, wherein the mass ratio of PTAC to graphite was 100:10, deionized water was used as solvent, the time was 5 hours, the rotating speed was 400r / min, and finally dried in a vacuum oven at 110°C 6h to get the sample PTACG10. The obtained sample was subjected to the same half-cell assembly as in Example 1, and its electrochemical performance was tested. Figure 8 It is the rate performance diagram of PTACG10. It can be seen from the figure that the average discharge specific capacity when the current density is 20mA / g is 231mAh / g, which is about 80mAh / g higher than that of the pure sample, and the ratio when the current density is 243mA / g The capacity is 164mAh / g. It shows that the mixed grinding treatment with graphite can improve the electrical conductivity of the electrode material, improve its reversible capacity and rate performance.

Embodiment 3

[0046] The PTAC obtained in Example 1 was coated by CVD. In a tube furnace with two temperature zones, put urea at the inlet end, the temperature is 200°C, put the sample at the outlet end, the temperature is 400°C, and the coating time is 6h. The final sample is marked as PTACU6. The obtained sample was subjected to the same half-cell assembly as in Example 1, and its electrochemical performance was tested. Figure 9 It is the rate performance diagram of PTACU6. It can be seen from the figure that the average discharge specific capacity when the current density is 13mA / g is 210mAh / g, which is about 60mAh / g higher than that of the pure sample, and the specific capacity when the current density is 244mA / g 95mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com