Conducting polymer film and positive pole piece modified by same

A technology of conductive polymers and positive plates, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of complex preparation process and poor electrochemical performance of positive plates, and improve structural stability and thermal stability. Stability, improved electrochemical performance, uniform thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

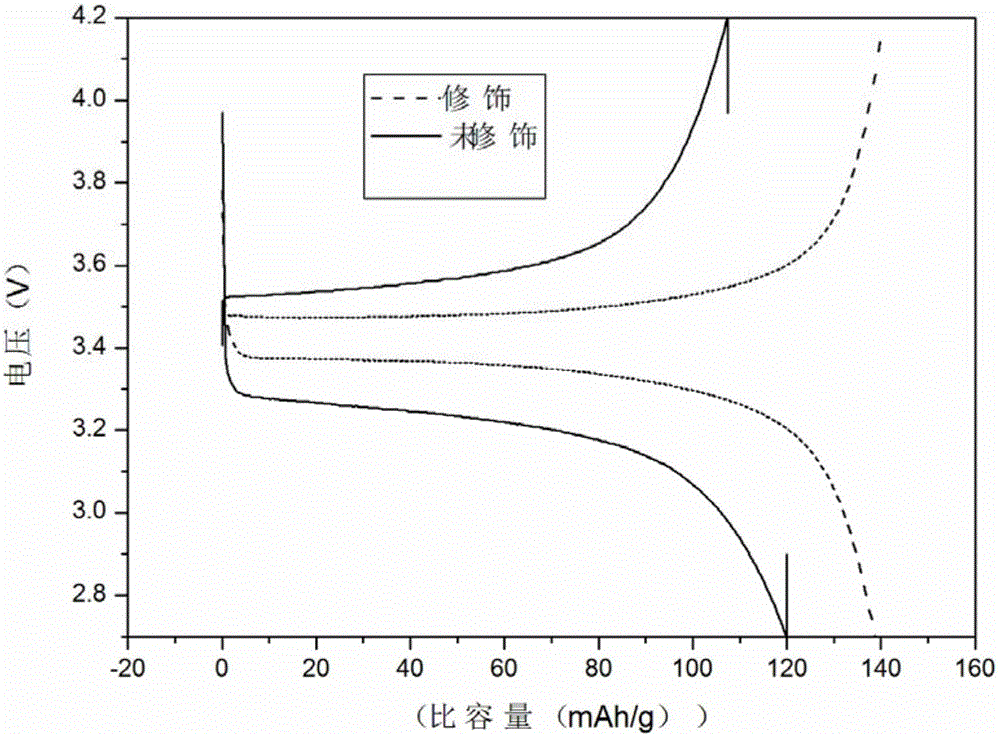

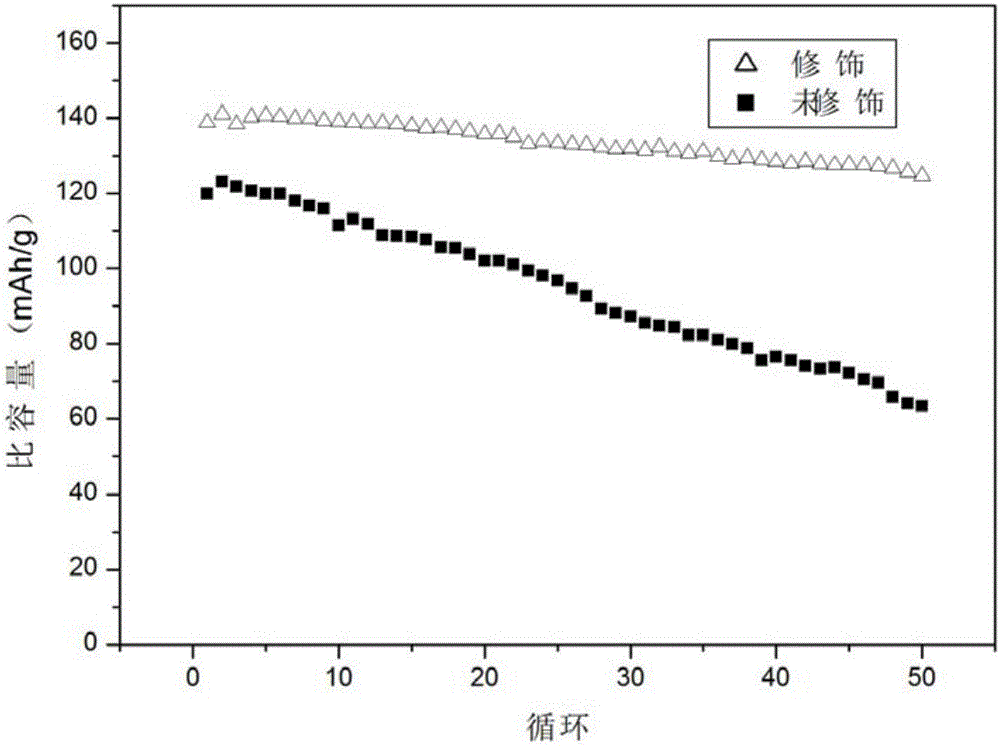

[0056] The positive electrode sheet of this embodiment includes a positive electrode plate formed by a current collector and a positive electrode material layer attached to one side of the current collector, and a conductive polymer film is attached to the outer side of the positive electrode material layer on the positive electrode plate.

[0057] The preparation method of the positive pole piece of the present embodiment comprises the following steps:

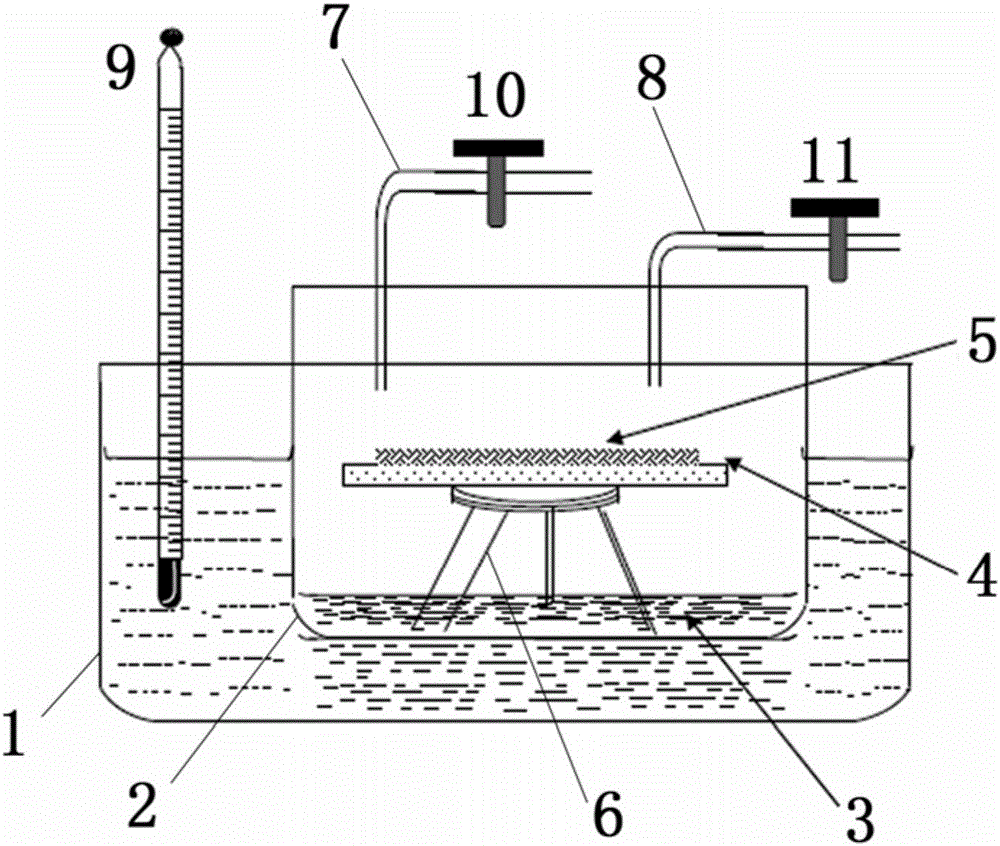

[0058] a) Preparation of positive plate: olivine-type pure LiFePO 4 It is the positive electrode active material, acetylene black is the conductive agent, and polytetrafluoroethylene is the binder. According to the mass ratio of the positive electrode active material, the conductive agent and the binder is 80:10:10, mix evenly, and add an appropriate amount of NMP as the solvent A slurry was made, and the slurry was evenly coated on one side surface of an aluminum foil (the thickness of the current collector was 0.02 mm), the...

Embodiment 2

[0064] The positive electrode sheet of this embodiment includes a positive electrode plate formed by a current collector and a positive electrode material layer attached to both sides of the current collector, and a conductive polymer film is attached to the outer side of the positive electrode material layer on the positive electrode plate.

[0065] The preparation method of the positive pole piece of the present embodiment comprises the following steps:

[0066] a) Preparation of positive plate: olivine-type pure LiFePO 4It is the positive electrode active material, acetylene black is the conductive agent, polyvinylidene fluoride is the binder, according to the mass ratio of the positive electrode active material, conductive agent and binder is 89:7:4, mix evenly, and use NMP as the solvent to prepare Form a slurry, and use a coating machine to evenly coat the slurry on both sides of the aluminum foil (the thickness of the current collector is 0.02mm). The coating thickness ...

Embodiment 3

[0072] The positive electrode sheet of this embodiment includes a positive electrode plate formed by a current collector and a positive electrode material layer attached to one side of the current collector, and a conductive polymer film is attached to the outer side of the positive electrode material layer on the positive electrode plate.

[0073] The preparation method of the positive pole piece of the present embodiment comprises the following steps:

[0074] a) Preparation of positive plate: S / C composite positive electrode material is used as positive electrode active material, polytetrafluoroethylene is used as water-based binder, superconducting carbon black is used as conductive agent, according to the mass ratio of positive electrode active material, binder and conductive agent Mix evenly at a ratio of 7:3:1, add an appropriate amount of NMP as a solvent to make a slurry, apply the slurry evenly on an aluminum foil, and dry it in vacuum at 60°C for 12 hours. A positive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com