A kind of lithium secondary battery silicon-carbon-polymer composite electrode and preparation method thereof

A lithium secondary battery, composite electrode technology, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of unstable structure, deterioration of cycle performance, poor conductivity, etc., and achieve simple methods and improve electrochemical activity. , the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 0.9g of micro-silicon and 0.1g of polyacrylonitrile (PAN) and grind and mix evenly, place in a sealed ball mill jar under the protection of an argon atmosphere, and ball mill for 2h at a speed of 350 rpm to obtain Si-PAN. Composite material; weigh 0.8g of Si-PAN composite material and 9.2g of graphite and grind and mix uniformly to obtain mixture 1; weigh 0.2g of polyacrylonitrile and dissolve it in 20mL of dimethylformamide (DMF) solvent to form Transparent mixed solution 2; add mixture 1 to mixed solution 2 and stir evenly with a magnetic stirrer, evaporate the solvent and transfer it to a 60°C oven for vacuum drying for 24 hours to obtain brown mixture 3; then place mixture 3 in argon In a tube furnace protected by gas atmosphere, sinter at 300°C for 12h, cool to a suitable temperature and grind to obtain a brown final composite material.

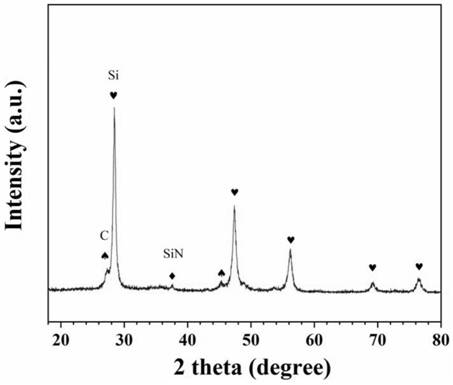

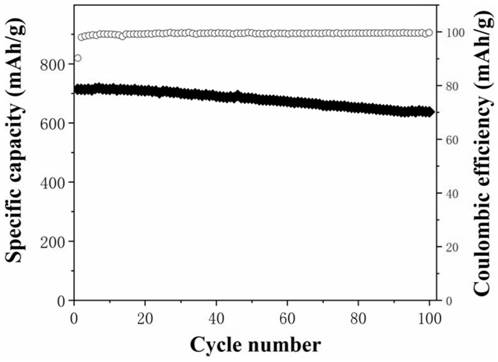

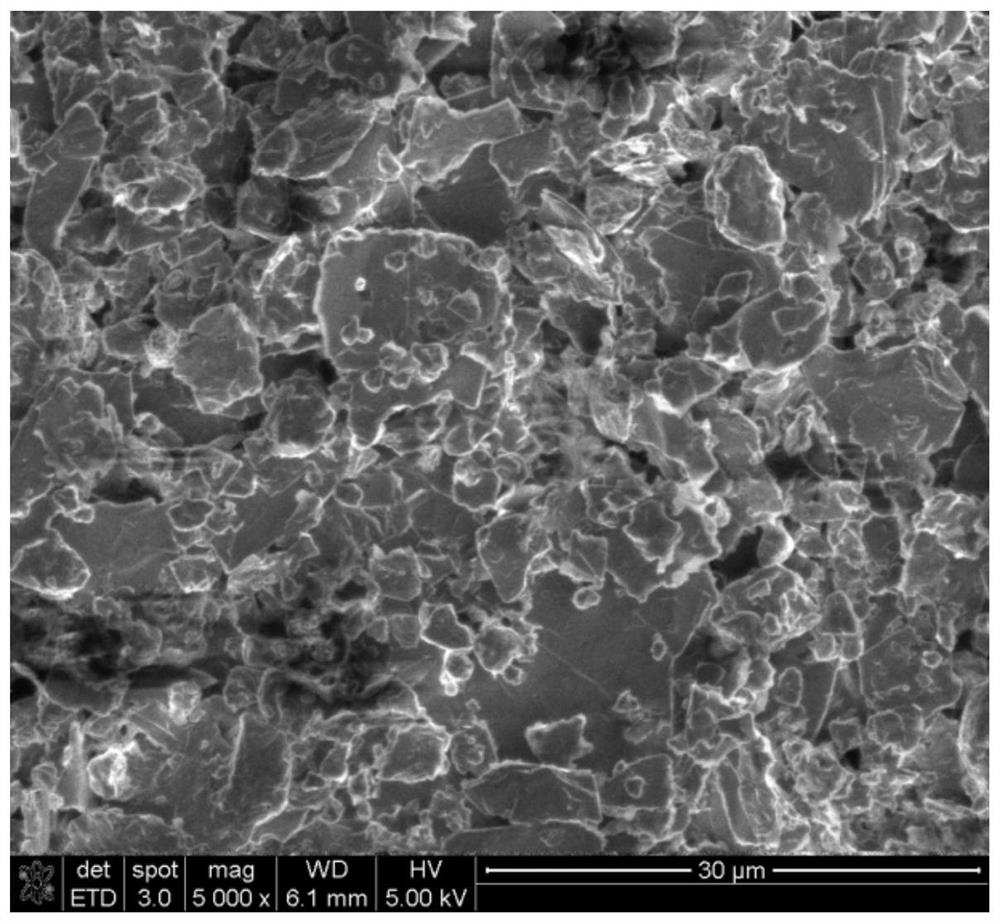

[0042] The XRD test shows that the silicon-carbon-polymer composite material prepared in Example 1 contains the characteri...

Embodiment 2

[0045] Weigh 0.9g of micro-silicon and 0.1g of polyacrylonitrile (PAN) and grind and mix evenly, place in a sealed ball mill jar under the protection of an argon atmosphere, and ball mill for 2h at a speed of 350 rpm to obtain Si-PAN. Composite material; weigh 0.8g of Si-PAN composite material and grind and mix with 6.48g of graphite to obtain mixture 1; weigh 0.2g of polyacrylonitrile and dissolve it in 20mL of dimethylformamide (DMF) solvent to form Transparent mixed solution 2; add mixture 1 to mixed solution 2 and stir evenly with a magnetic stirrer, evaporate the solvent and transfer it to a 60°C oven for vacuum drying for 24 hours to obtain brown mixture 3; then place mixture 3 in argon In a tube furnace protected by gas atmosphere, sinter at 300°C for 12h, cool to a suitable temperature and grind to obtain a brown final composite material.

[0046] The XRD test shows that the silicon-carbon-polymer composite material prepared in Example 1 contains the characteristic dif...

Embodiment 3

[0049]Weigh 0.9g of micro-silicon and 0.1g of polyacrylonitrile (PAN) and grind and mix evenly, place in a sealed ball mill jar under the protection of an argon atmosphere, and ball mill for 2h at a speed of 350 rpm to obtain Si-PAN. Composite material; weigh 0.8g of Si-PAN composite material and grind and mix with 4.0g of graphite to obtain mixture 1; weigh 0.2g of polyacrylonitrile and dissolve it in 20mL of dimethylformamide (DMF) solvent to form Transparent mixed solution 2; add mixture 1 to mixed solution 2 and stir evenly with a magnetic stirrer, evaporate the solvent and transfer it to a 60°C oven for vacuum drying for 24 hours to obtain brown mixture 3; then place mixture 3 in argon In a tube furnace protected by gas atmosphere, sinter at 300°C for 12h, cool to a suitable temperature and grind to obtain a brown final composite material.

[0050] The XRD test shows that the silicon-carbon-polymer composite material prepared in Example 1 contains the characteristic diffr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com