Silicon-based and tin-based composite particles for lithium ion battery and preparation method thereof and negative electrode and lithium ion battery containing silicon-based and tin-based composite particles

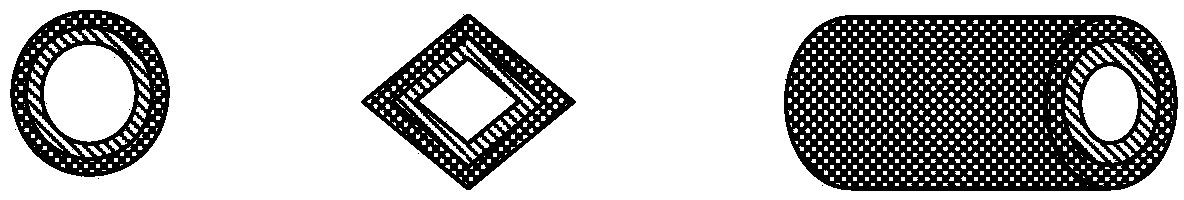

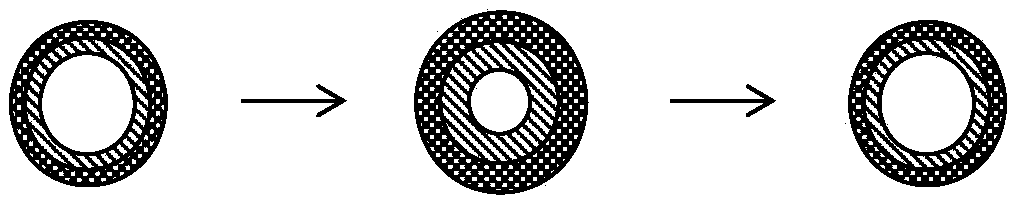

一种锂离子电池、复合颗粒的技术,应用在电池电极、二次电池、用于材料和表面科学的纳米技术等方向,能够解决电极结构不稳定、循环性能差、体积膨胀等问题,达到制备方法简单、比容量高、阻止团聚的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

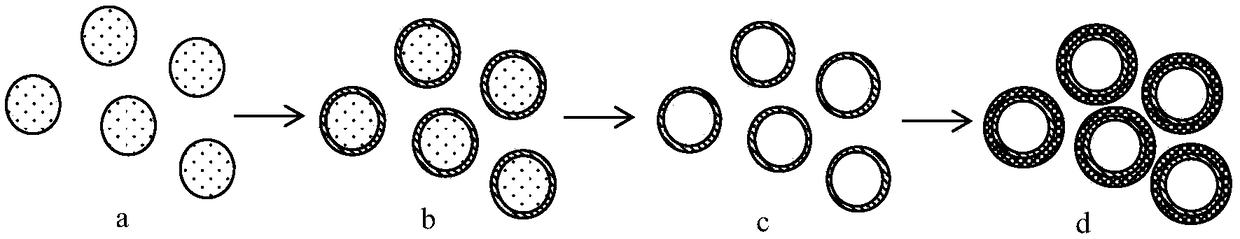

[0063] (1) Mix 60ml of deionized water, 150ml of ethanol and 15ml of 25% ammonia water in a beaker, add 10ml of tetraethyl orthosilicate and stir at room temperature for 50min. Centrifuge and wash with deionized water to obtain a silica template with a particle size of 130 nm.

[0064] (2) Add 1 g of the product in step (1) to 100 ml of deionized water, and ultrasonically disperse for 30 min. Add 50ml of 1mol / L sodium stannate solution, stir and react at 70°C for 2h. Centrifuge and wash with deionized water to obtain the product.

[0065] (3) Prepare a 1.5 mol / L potassium hydroxide solution, add the product in step (2), stir and react at 75 degrees for 1 h. Centrifuge and wash with deionized water to obtain tin dioxide hollow spheres with a particle size of 150 nm.

[0066] (4) Put 0.5 g of the product of step (3) into a tube furnace, and react at 450 degrees for 2 hours at a flow rate of 100 sccm by silane gas cracking under the protection of argon. Silicon / tin dioxide ho...

Embodiment 2

[0069] (1) With ethylene glycol methyl ether as the solvent, configure 100ml of 2mol / L ferric nitrate solution. Stir and add 10ml of sodium dodecylsulfonate, butyl titanate and ethyl silicate respectively at 70°C. After forming a uniform and stable brown sol, the sol was aged at 70°C for 2h, and dried under reduced pressure at 90°C for 3h. The product was taken out and calcined in a muffle furnace at 600°C for 3 hours to obtain nano-block particles of ferric oxide with a particle size of 50 nm.

[0070] (2) Add 2 g of the product in step (1) into 100 ml of deionized water, and ultrasonically disperse for 30 min. Add 30ml of 1mol / L potassium stannate solution, stir and react at 60°C for 2h. Centrifuge and wash with deionized water to obtain the product.

[0071] (3) Prepare 1 mol / L potassium hydroxide solution, add the product in step (2), stir and react at 80 degrees for 2 hours. Centrifuge and wash with deionized water to obtain tin dioxide hollow particles with a particl...

Embodiment 3

[0075](1) With ethylene glycol methyl ether as the solvent, configure 100ml of 2mol / L zinc nitrate solution. Stir and add 20ml of sodium dodecylsulfonate, butyl titanate and ethyl silicate respectively at 80°C. After forming a uniform and stable brown sol, the sol was aged at 80°C for 2h, and dried under reduced pressure at 90°C for 3h. The product was taken out and calcined in a muffle furnace at 600°C for 3 hours to obtain nano-spherical particles of zinc oxide with a particle size of 100 nm.

[0076] (2) Add 3 g of the product in step (1) into 100 ml of deionized water, and ultrasonically disperse for 30 min. Add 40ml of 1mol / L sodium stannate solution, stir and react at 60°C for 0.5h. Centrifuge and wash with deionized water to obtain the product.

[0077] (3) Prepare a 2mol / L potassium hydroxide solution, add the product in step (2), stir and react at 80°C for 2h. Centrifuge and wash with deionized water to obtain stannous oxide hollow spheres with a particle size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com