Preparation method of lithium sodium titanate negative electrode material with multistage structure

A negative electrode material, sodium lithium titanate technology, applied in the direction of structural parts, battery electrodes, electrical components, etc., can solve the problems of limitations, poor conductivity of sodium lithium titanate, poor capacity performance, etc., to achieve uniform particles and good dispersion , The effect of stabilizing the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

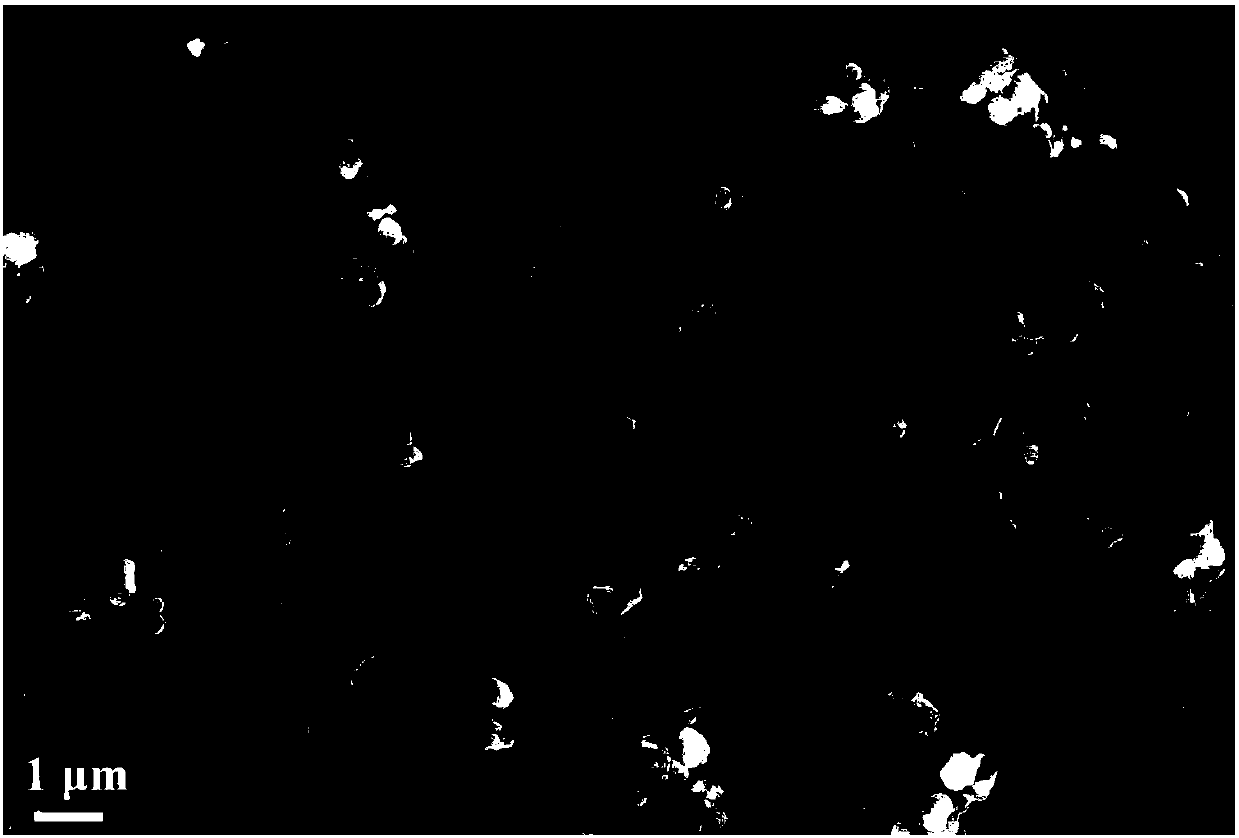

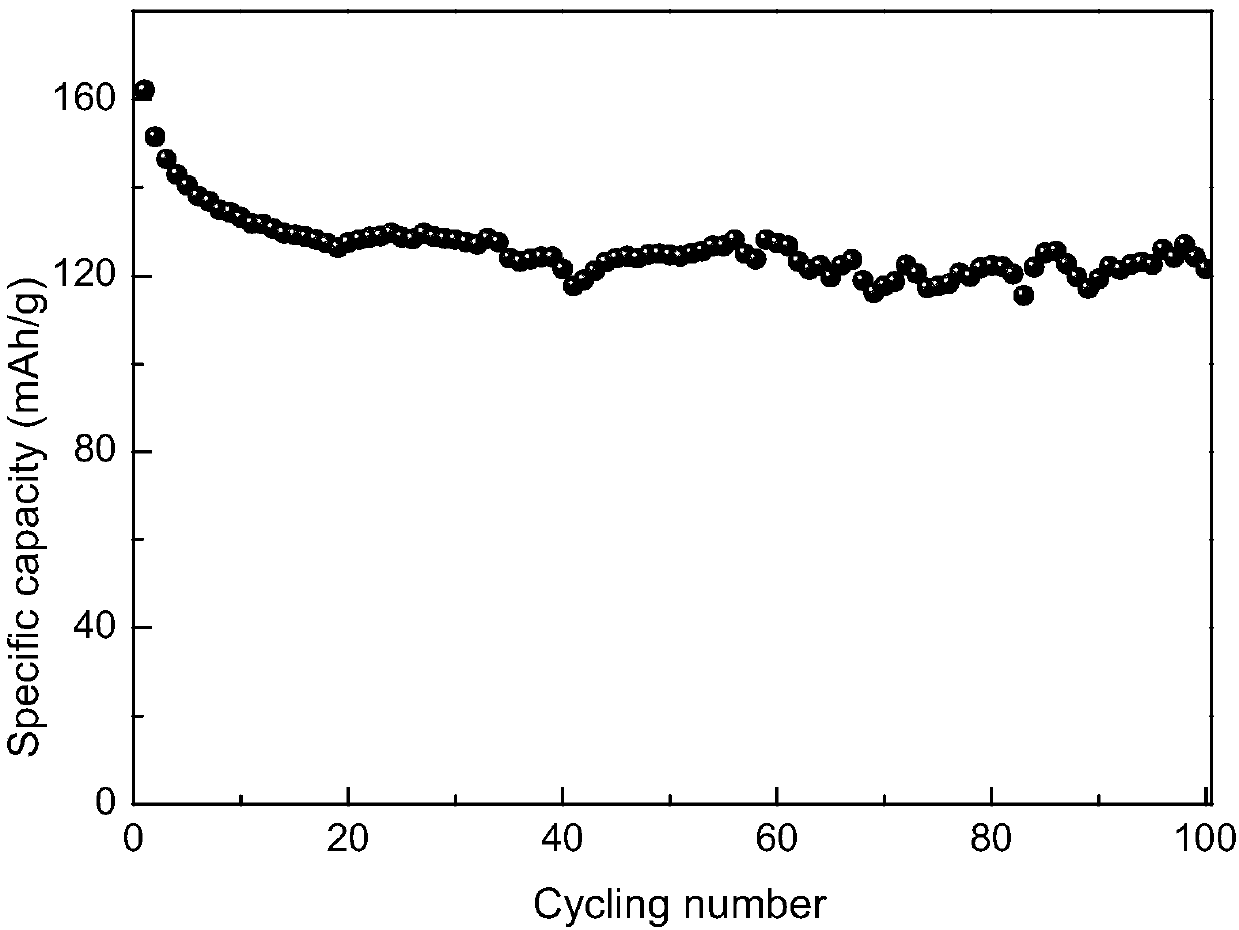

Embodiment 1

[0017] Put 0.05mol lithium nitrate and 0.05mol aluminum nitrate in a ball mill, use acetone as dispersant, ball mill for 4h, then place in a muffle furnace and bake at 750°C for 18h, after cooling to room temperature, pass through a fine sieve to obtain γ-LiAlO 2 powder. Dissolve 0.06mol tetrabutyl titanate, 0.02mol lithium acetate and 0.02mol sodium nitrate in a mixed solution of ethanol, ethylene glycol and glycerol, the volume ratio is 5:3:1, add citric acid as a chelating agent, of which lemon The molar ratio of acid to metal cation is 1.3:1, then add 24 grams of N,N-acrylamide and acrylamide mixture (the mass ratio of the two is 1:5), and stir in a constant temperature water bath at 80°C To form a gel, then place the gel at room temperature for 12 hours, then put the gel in a vacuum oven at 160°C and dry it for 24 hours to obtain a precursor; then 0.1713 grams of γ-LiAlO 2 The powder is mixed with the precursor, the precursor is ball milled for 4 hours, put into a muffle...

Embodiment 2

[0019] Put 0.05mol lithium nitrate and 0.05mol aluminum nitrate in a ball mill, use acetone as dispersant, ball mill for 4h, then place in a muffle furnace and bake at 750°C for 18h, after cooling to room temperature, pass through a fine sieve to obtain γ-LiAlO 2 powder. Dissolve 0.06mol tetrabutyl titanate, 0.02mol lithium acetate and 0.02mol sodium nitrate in a mixed solution of ethanol, ethylene glycol and glycerol, the volume ratio is 5:3:1, add citric acid as a chelating agent, of which lemon The molar ratio of acid to metal cation is 1.3:1, then add 24 grams of N,N-acrylamide and acrylamide mixture (the mass ratio of the two is 1:5), stir in a constant temperature water bath at 70°C To form a gel, then place the gel at room temperature for 10 hours, then put the gel in a vacuum oven at 120°C and dry it for 24 hours to obtain a precursor; then 0.1713 grams of γ-LiAlO 2 The powder is mixed with the precursor, the precursor is ball milled for 4 hours, put into a muffle fur...

Embodiment 3

[0021] Put 0.05mol lithium nitrate and 0.05mol aluminum nitrate in a ball mill, use acetone as dispersant, ball mill for 4h, then place in a muffle furnace and bake at 750°C for 18h, after cooling to room temperature, pass through a fine sieve to obtain γ-LiAlO 2 powder. Dissolve 0.06mol tetrabutyl titanate, 0.02mol lithium acetate and 0.02mol sodium nitrate in a mixed solution of ethanol, ethylene glycol and glycerol, the volume ratio is 5:3:1, add citric acid as a chelating agent, of which lemon The molar ratio of acid to metal cation is 1.3:1, then add 24 grams of N,N-acrylamide and acrylamide mixture (the mass ratio of the two is 1:5), and stir in a constant temperature water bath at 100°C To form a gel, then place the gel at room temperature for 15 hours, then put the gel in a vacuum oven at 180°C and dry it for 24 hours to obtain a precursor; then 0.1713 grams of γ-LiAlO 2 The powder is mixed with the precursor, the precursor is ball milled for 4 hours, put into a muffl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com