Porous silicon monoxide composite material and preparation and application thereof

A technology of silicon oxide and composite materials, applied in the preparation/purification of silicon oxide, silicon dioxide, carbon, etc., can solve the problems of complex preparation process and low first-time efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

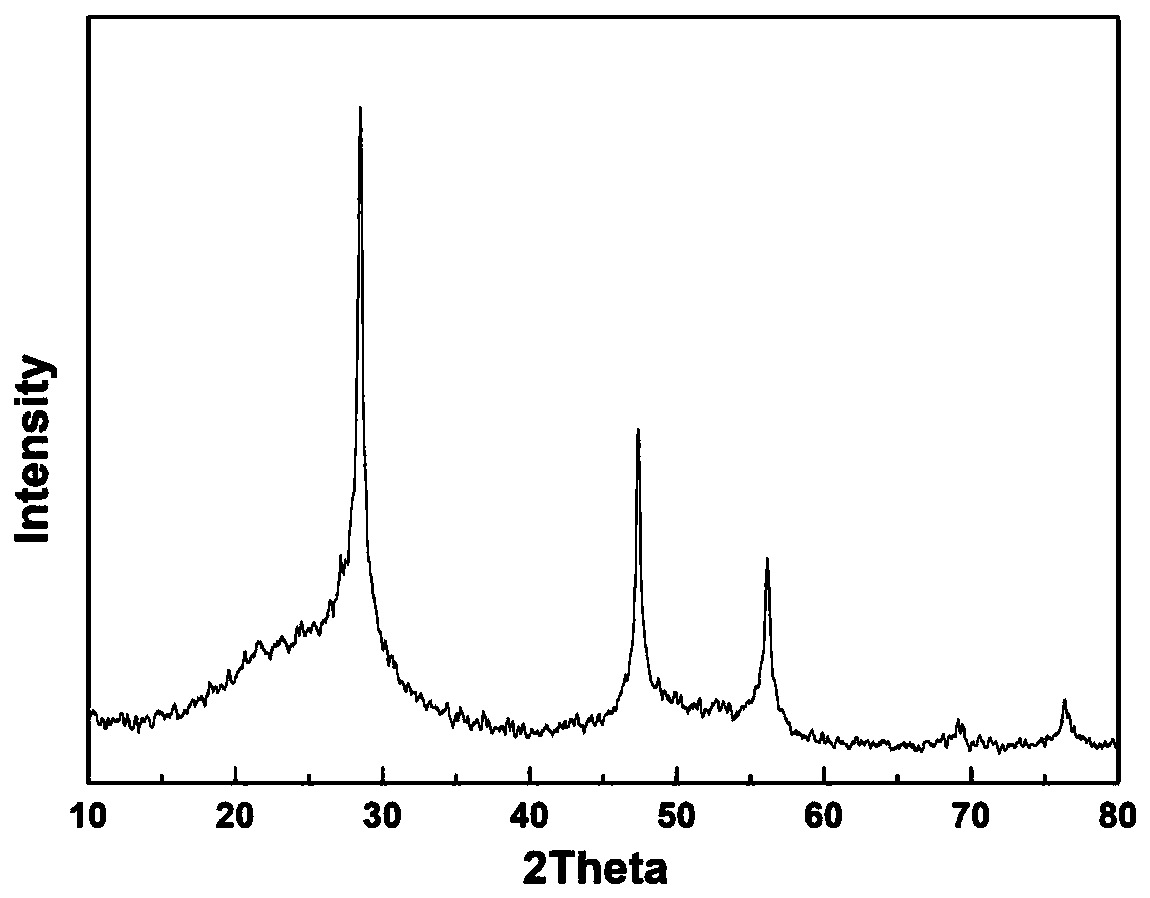

[0069] Put silicon particles with a silicon content of 99.5wt% and a particle size of 25mm into a roller ball mill with a filling factor of 25%; blow in air at 115°C and a humidity of 60%, the positive pressure of the ball mill is 750Pa, and the negative pressure of the collection device is 600Pa; at 60 rpm The ball milling reaction under the rotating speed produces silicon fine particles wrapped in silicon oxide, the particle size is 25 μm, and the oxygen content is 45 wt%. Granules, metal magnesium powder, mixed salt particles (the molar ratio of lithium chloride: sodium chloride is 7:3, eutectic point 570°C) and medium-temperature asphalt according to the ratio of 1:0.2:10:1 are processed by extrusion granulation Mix and granulate to obtain a composite precursor; put the composite precursor into a sintering boat and place it in a muffle furnace, and carry out a sintering reaction under an argon atmosphere, and raise the temperature to 700°C at a rate of 5°C / min, and react fo...

Embodiment 2

[0072] Put silicon particles with a silicon content of 99.5wt% and a particle size of 45mm into a roller ball mill with a filling factor of 30%; blow in air at 120°C and a humidity of 68%, the positive pressure of the ball mill is 760Pa, and the negative pressure of the collection device is 580Pa; at 50 rpm The ball milling reaction under the rotating speed produces silicon fine particles wrapped in silicon oxide, with a particle size of 32 μm and an oxygen content of 65 wt%. Granules, metal magnesium powder, mixed salt particles (the molar ratio of lithium chloride: sodium chloride is 7:3, eutectic point 570°C) and medium-temperature asphalt in the ratio of 1:0.3:10:1 are processed by extrusion granulation Mix and granulate to obtain a composite precursor; put the composite precursor into a sintering boat and place it in a muffle furnace, and carry out a sintering reaction under an argon atmosphere, and raise the temperature to 700°C at a rate of 5°C / min, and react for 6 hours...

Embodiment 3

[0075] Put silicon particles with a silicon content of 99.5wt% and a particle size of 10mm into a roller ball mill with a filling factor of 18%; blow in air at 110°C and a humidity of 55%, the positive pressure of the ball mill is 730Pa, and the negative pressure of the collection device is 620Pa; The ball milling reaction under the rotating speed produces silicon fine particles wrapped in silicon oxide, the particle size is 22 μm, and the oxygen content is 39 wt%. Granules, metal magnesium powder, mixed salt particles (the molar ratio of lithium chloride: sodium chloride is 7:3, eutectic point 570°C) and medium-temperature asphalt in the ratio of 1:0.15:10:1 are processed by extrusion granulation Mix and granulate to obtain a composite precursor; put the composite precursor into a sintering boat and place it in a muffle furnace, and conduct a sintering reaction under an argon atmosphere. Raise the temperature to 700°C at a rate of 5°C / min, and react for 6 hours. After cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com