Patents

Literature

1001 results about "Silicon oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon Oxidation Number. The Oxidation state of Silicon (Si) is +2, with atomic number 14. It is the second most abundant element in the earth, exceeded only by oxygen in the atmosphere.

Sorbent composition, process for producing same and use in desulfurization

Particulate sorbent compositions comprising a mixture of zinc oxide, silica, alumina and a substantially reduced valence nickel are provided for the desulfurization of a feedstream of cracked-gasoline or diesel fuels in a desulfurization zone by a process which comprises the contacting of such feedstreams in a desulfurization zone followed by separation of the resulting low sulfur-containing stream and sulfurized-sorbent and thereafter regenerating and activating the separated sorbent before recycle of same to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

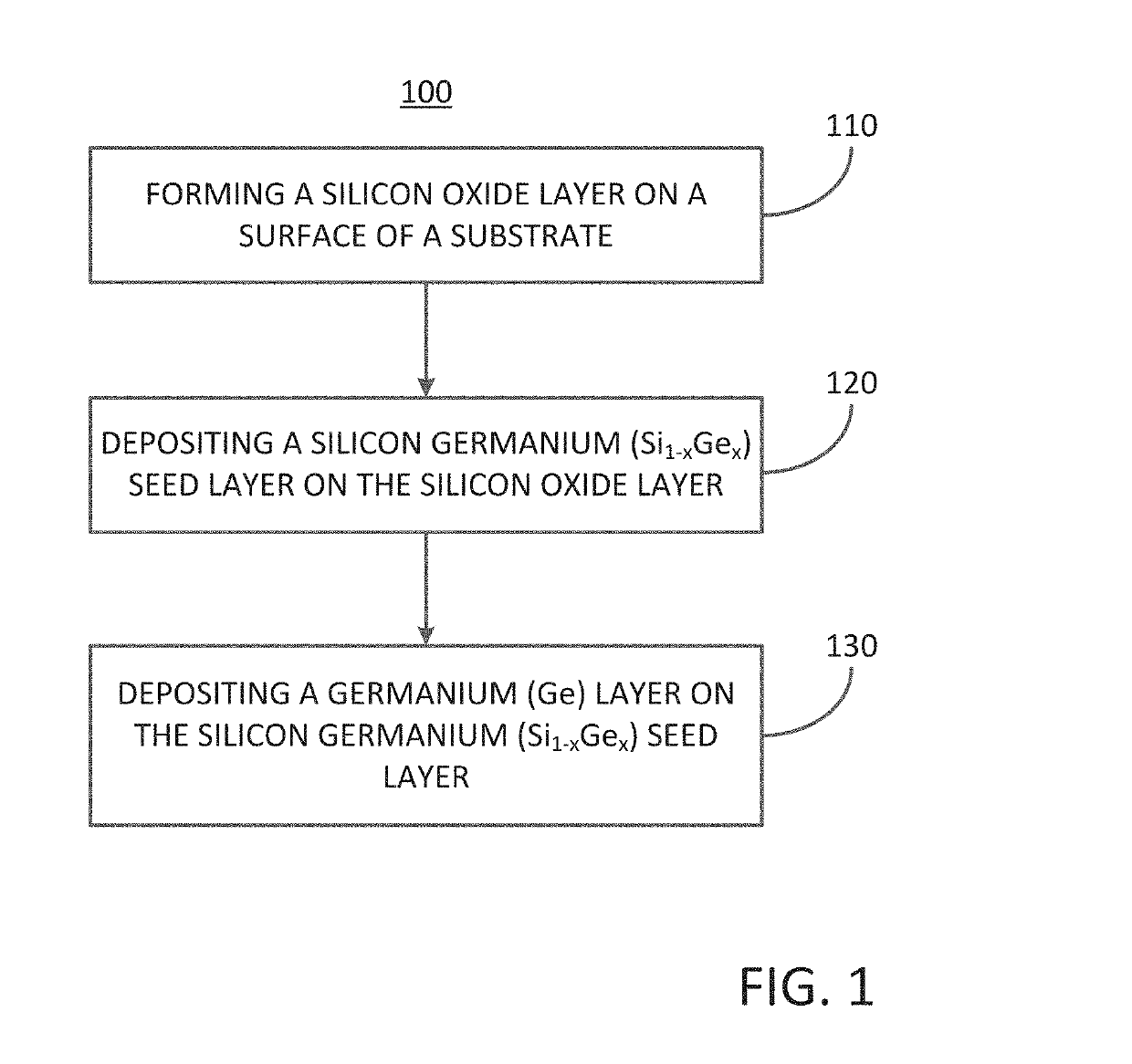

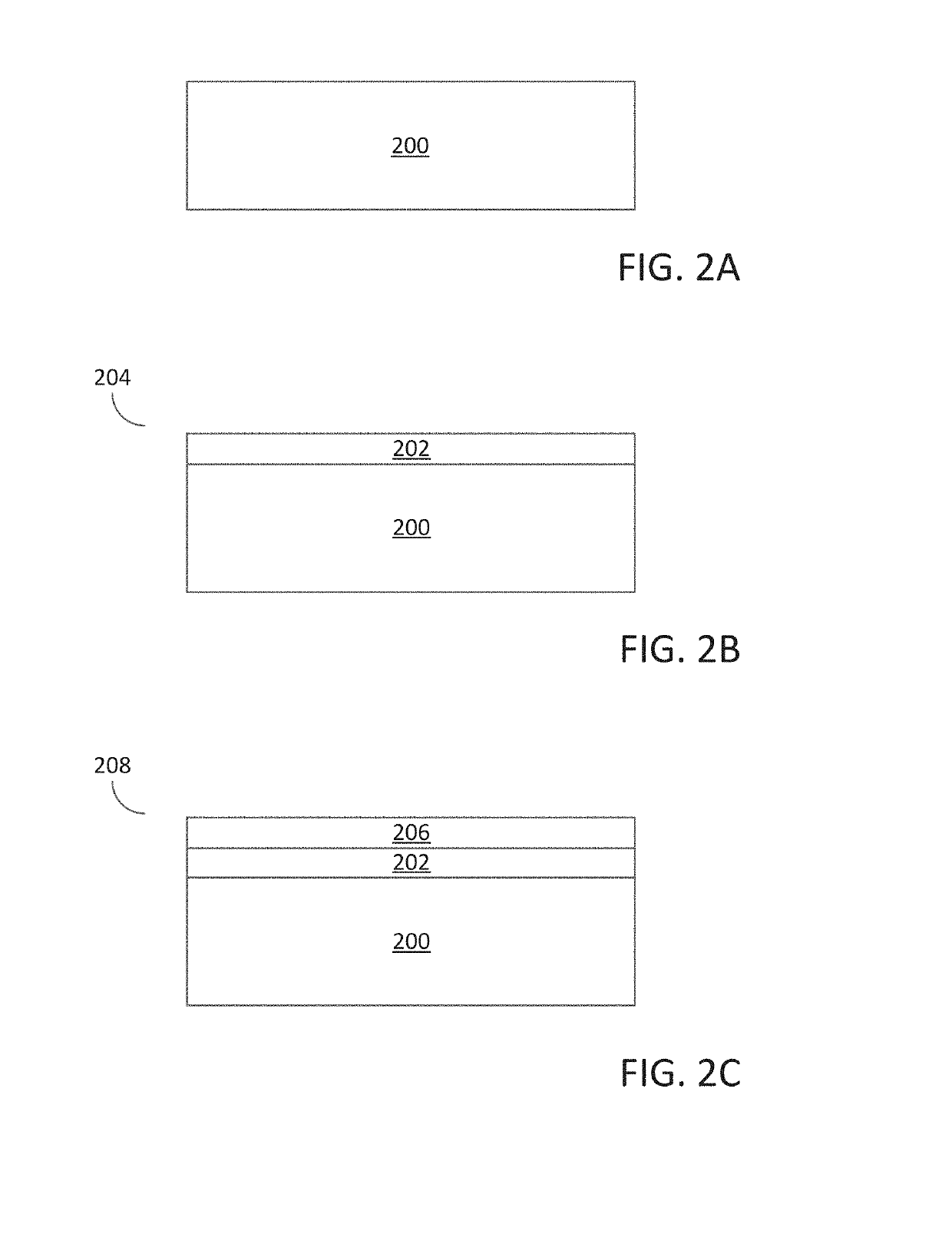

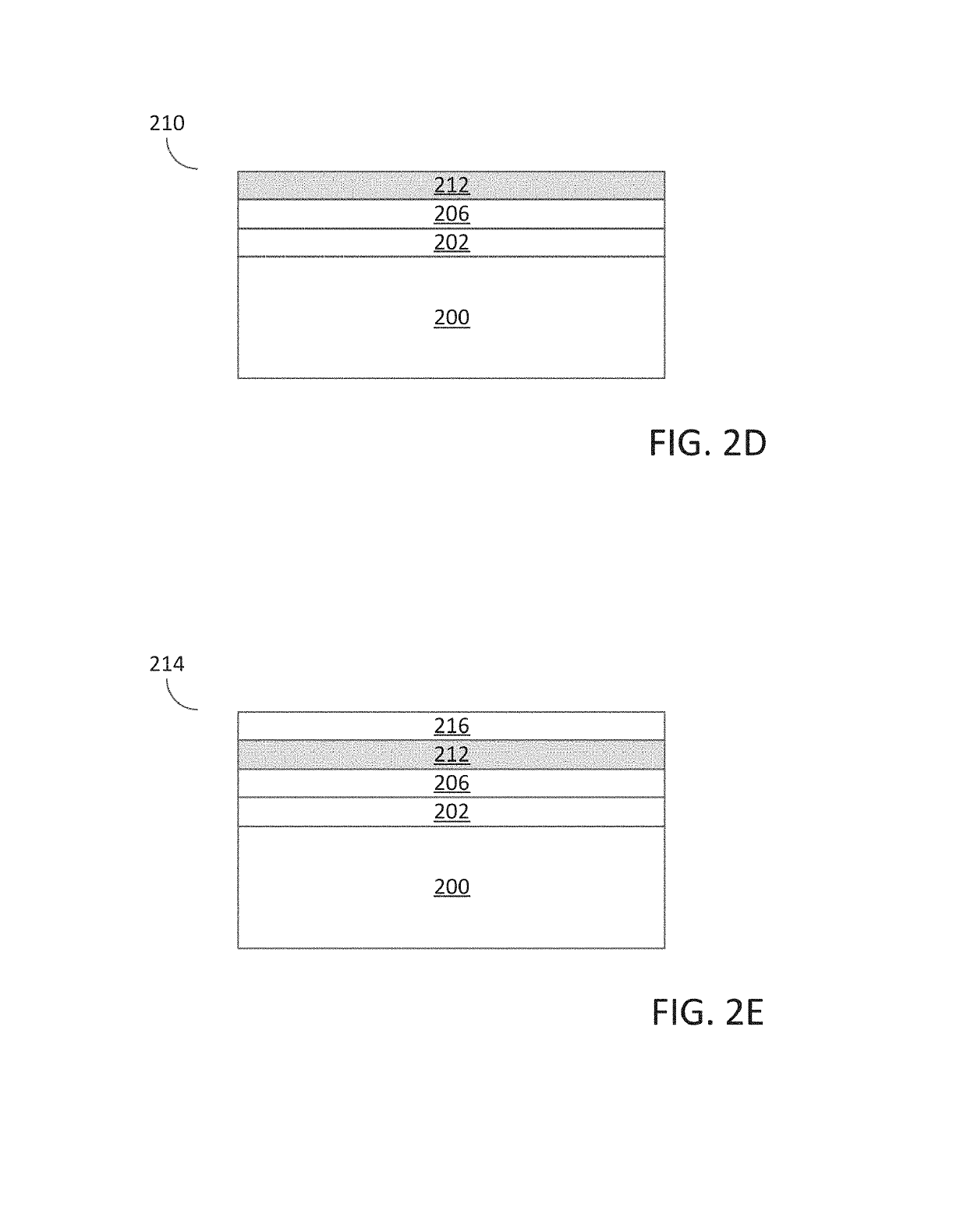

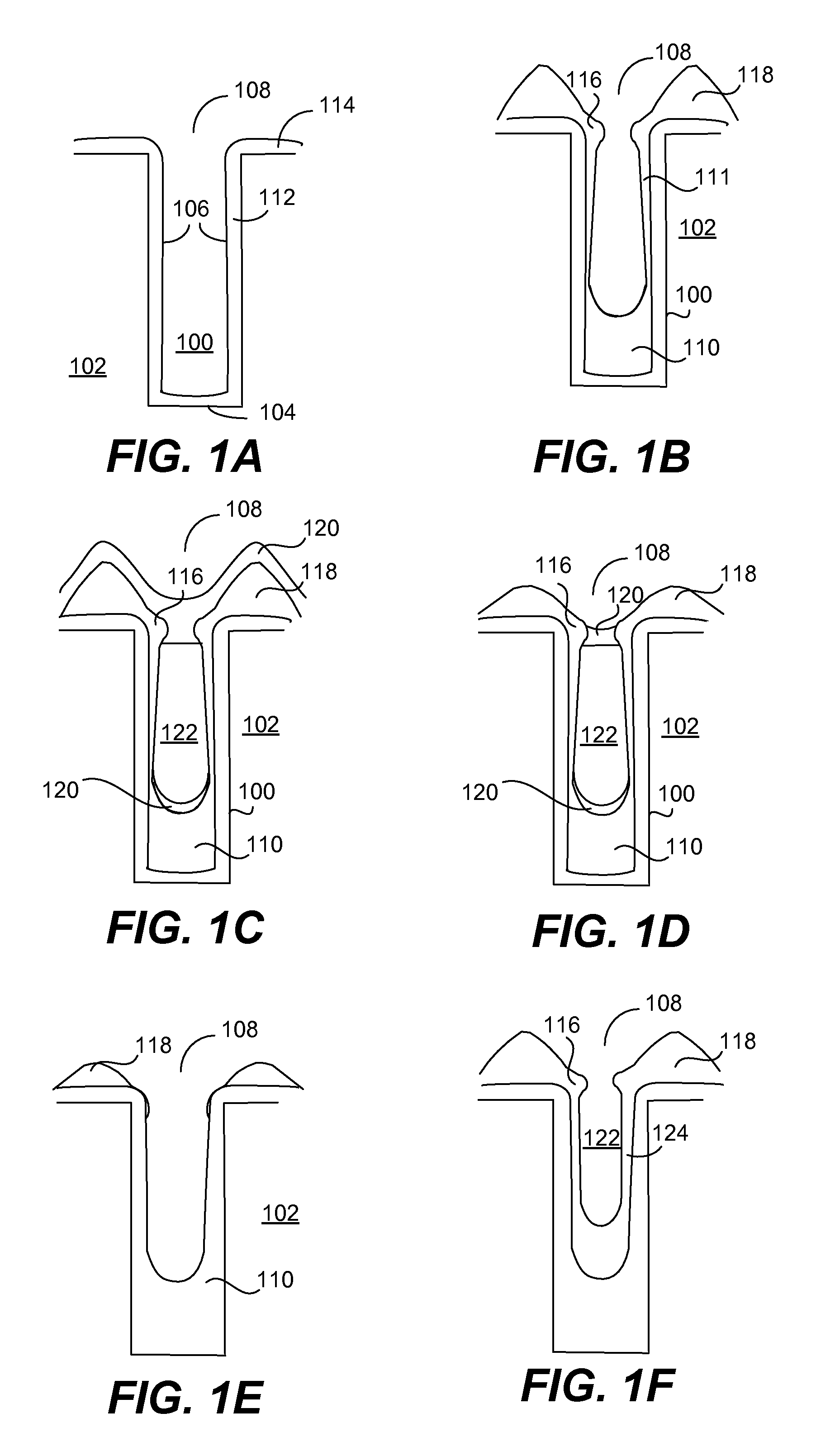

Methods for forming a semiconductor structure and related semiconductor structures

ActiveUS20190131124A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureSilicon oxide

A method for forming a forming a semiconductor structure is disclosed. The method may include: forming a silicon oxide layer on a surface of a substrate, depositing a silicon germanium (Si1-xGex) seed layer directly on the silicon oxide layer, and depositing a germanium (Ge) layer directly on the silicon germanium (Si1-xGex) seed layer. Semiconductor structures including a germanium (Ge) layer deposited on silicon oxide utilizing an intermediate silicon germanium (Si1-xGex) seed layer are also disclosed.

Owner:ASM IP HLDG BV

Sorbent composition, process for producing same and use in desulfurization

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

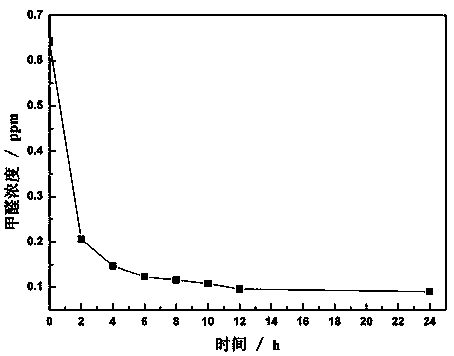

Preparation of room temperature formaldehyde catalyst

Belonging to the technical field of adsorption catalysis and air pollution control, the invention relates to preparation of a room temperature formaldehyde catalyst. The invention is characterized in that: zeolite, sepiolite, a porous activated carbon material, cordierite or a self-made carrier is adopted as the catalyst carrier, one or more non-noble metal oxides, like magnesium oxide, aluminum oxide, silicon oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide or cerium oxide are taken as active components, and an impregnation technique is employed to prepare the catalyst, which can be powdery, strip, blocky, spherical or honeycomb. The loading amount of the non-noble metal oxides is 2-15wt%, and the content of the catalyst carrier is 85-98%. Under normal temperature and ambient humidity conditions, the catalyst has the capacity of catalytic oxidation of formaldehyde into non-toxic and harmless CO2 and H2O up to over 95%, no intermediate product is generated, and the catalyst has the characteristics of high catalytic oxidation activity, strong moisture resistant ability, stable operation, long service life and the like, thus being suitable for formaldehyde purification treatment in offices, office buildings, living rooms, shopping malls, hospitals, hotels and other places.

Owner:江苏瑞丰科技实业有限公司

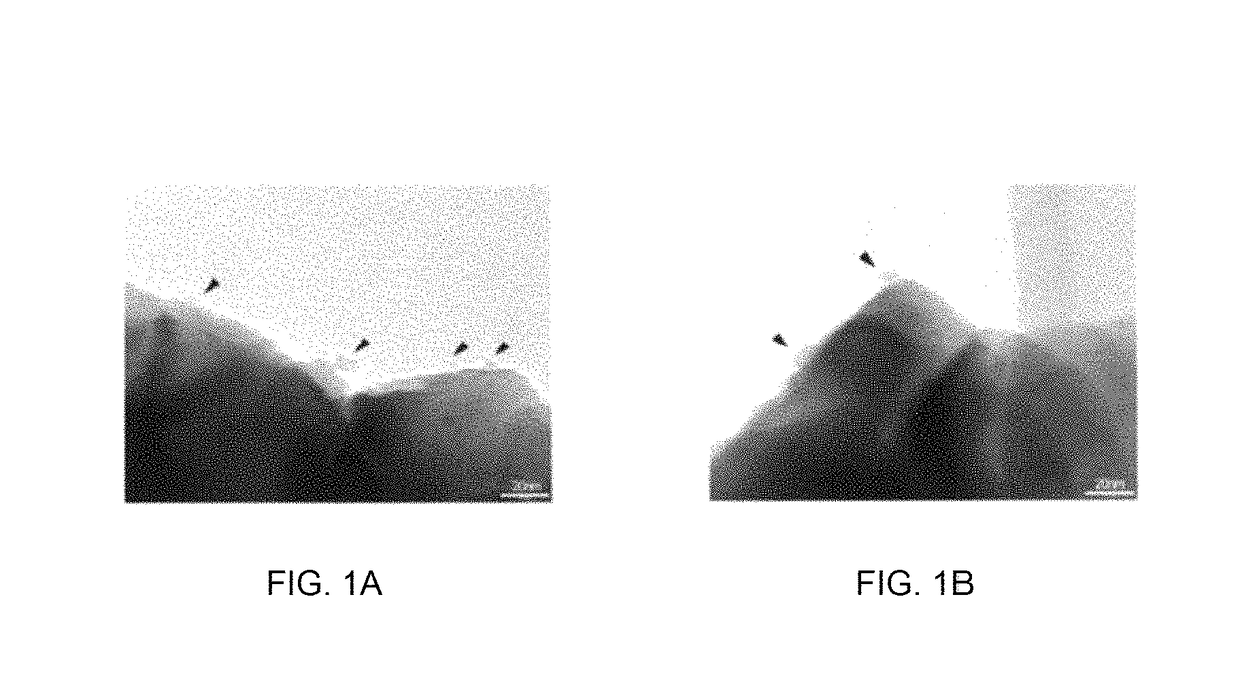

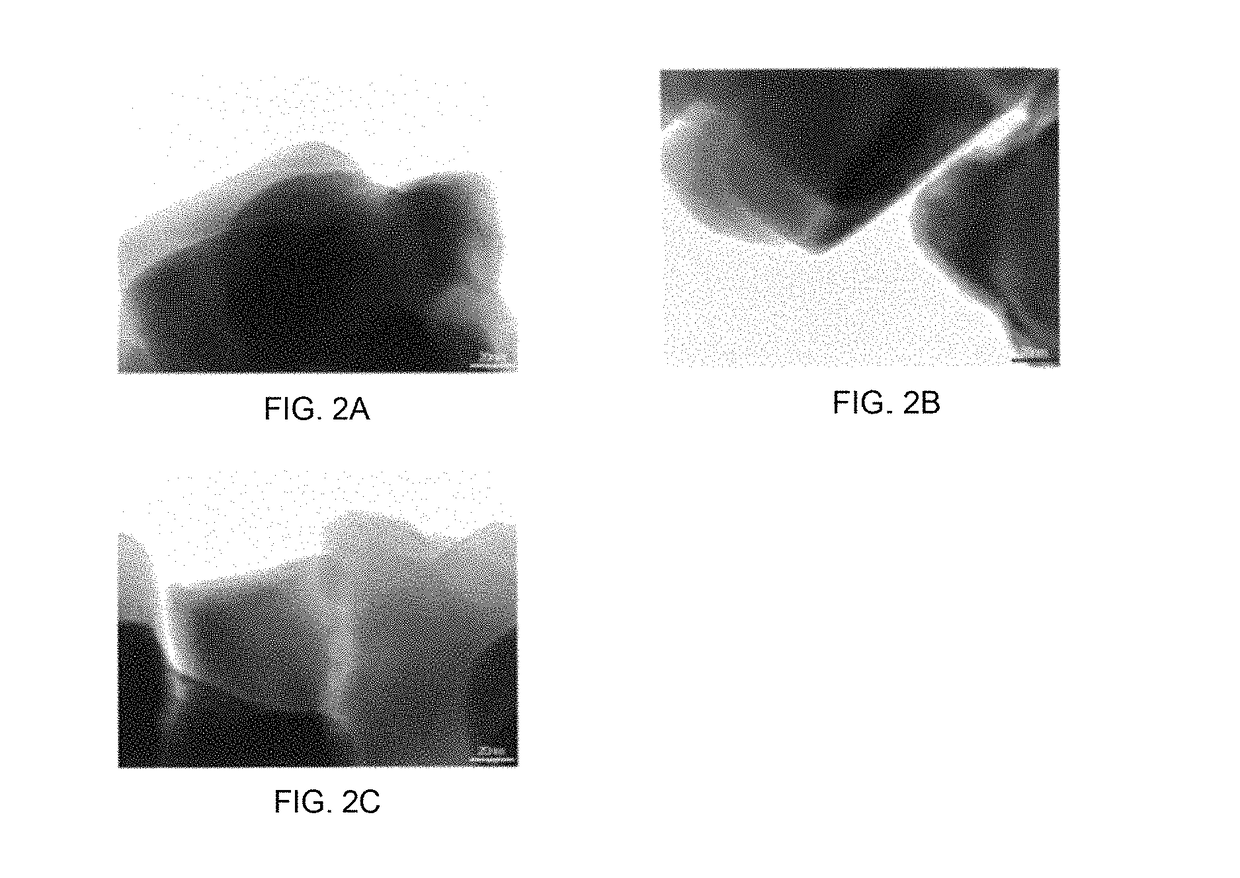

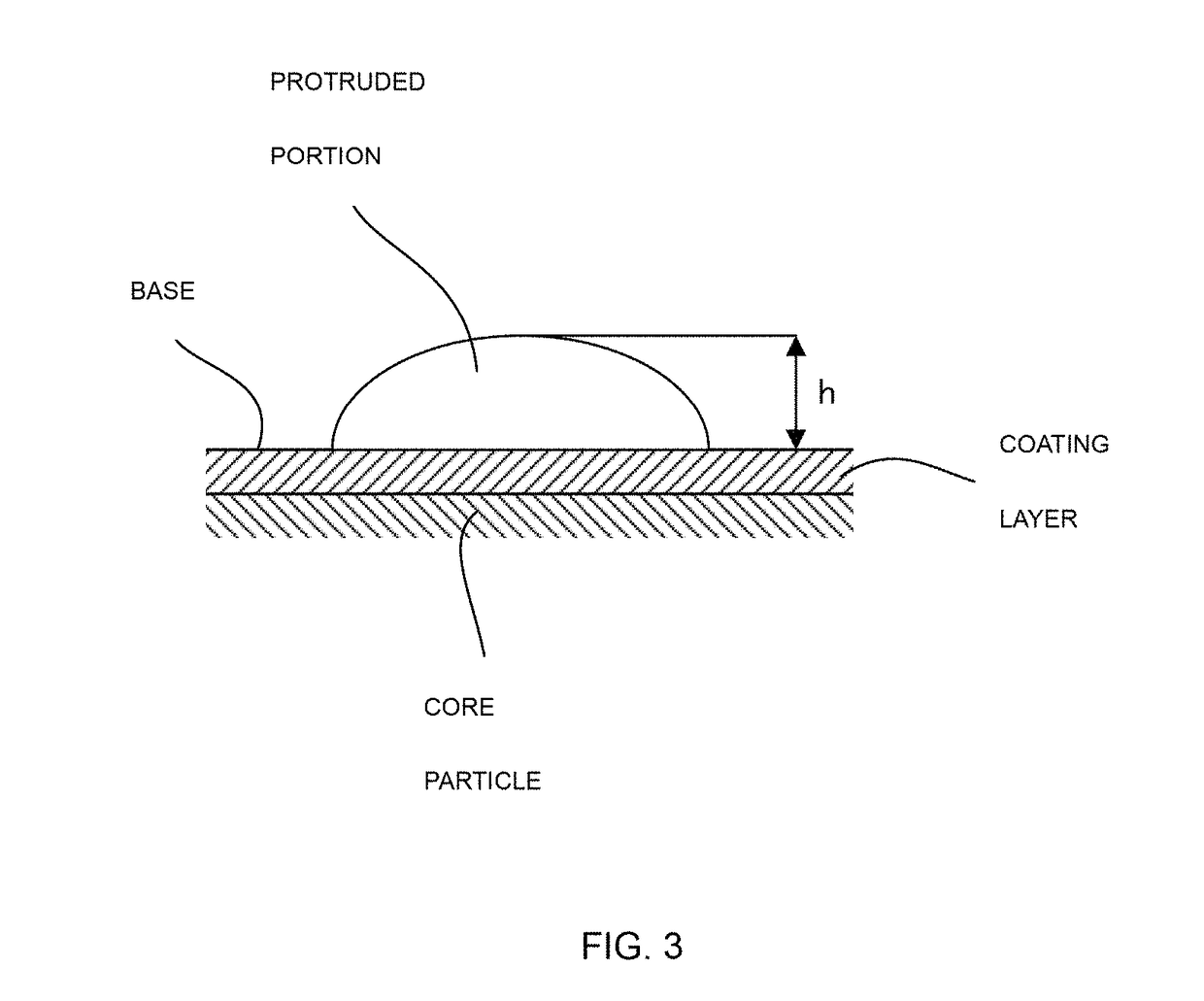

Anti-glare glass substrate

InactiveUS20070195419A1Improve visibilityWrite fluentlyLiquid crystal compositionsCoatingsArylPolymer science

An anti-glare glass substrate used for liquid crystal display devices is disclosed, which comprises a glass substrate; and a coating covering one side of said substrate, the coating having, on its surface, projection bodies which have round bottom surfaces and have an average bottom surface area ranging from 80 to 400 μm2, the projection bodies being randomly arranged on said coating at a density of 5 or more projection bodies per an area equivalent to one pixel of the liquid crystal display device, and the coating having a surface roughness from 0.1 to 0.4 μm. The anti-glare glass substrate can be prepared by the steps of (1) preparing a coating liquid by blending a silica sol (A) consisting of an oligomer whose crosslinks are formed from [SiO4 / 2] as crosslinking units and whose number average molecular weight ranges from 300 to 1000 (polystyrene conversion) and a silica sol (B) consisting of an oligomer in which silicon oxides having bonds between aryl groups and silicon atoms are formed as crosslinking units and whose number average molecular weight ranges from 500 to 1000 (polystyrene conversion); and (2) applying the resulting coating liquid onto the surface of a glass substrate according to the spin coating technique.

Owner:CENT GLASS CO LTD

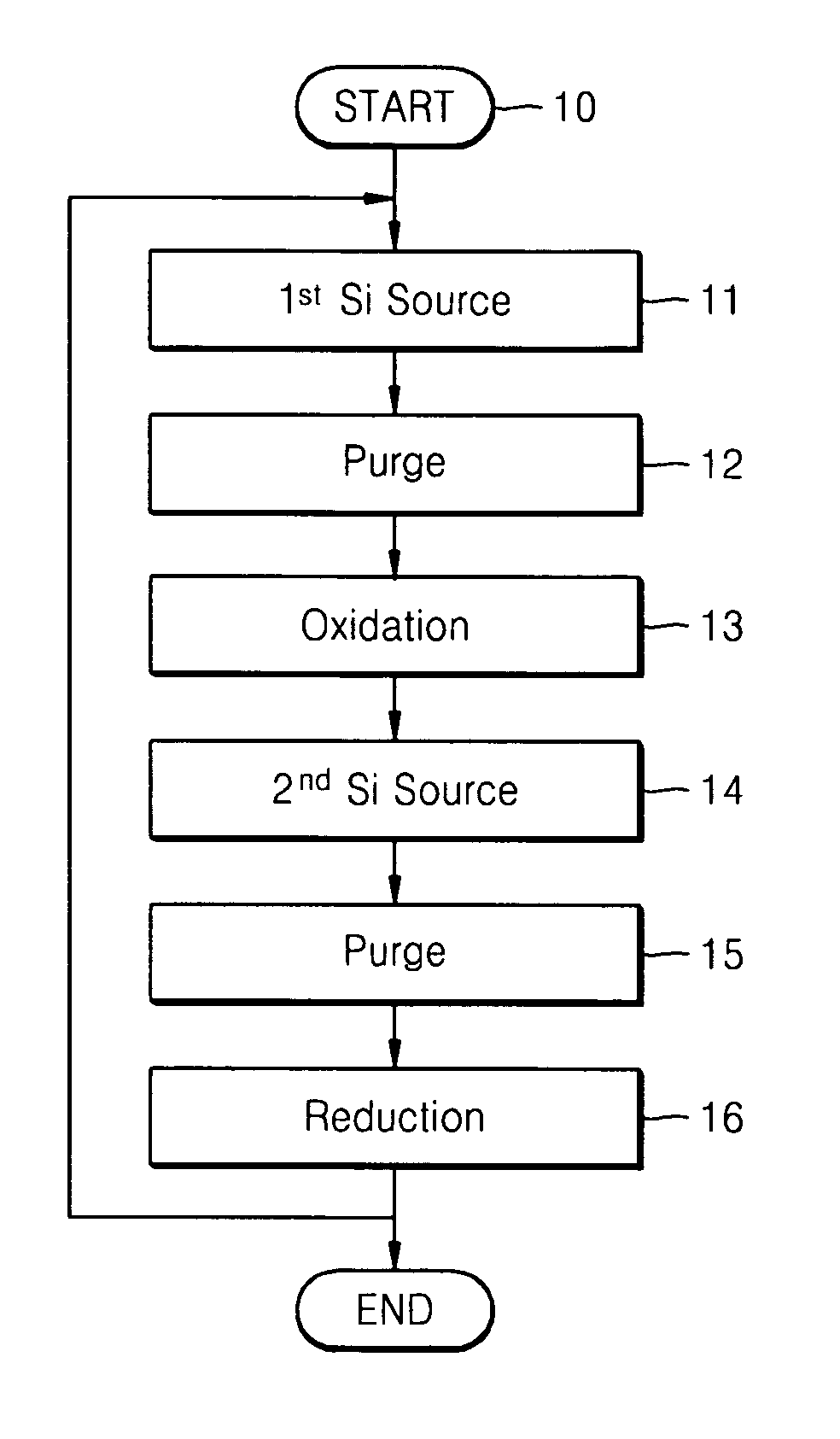

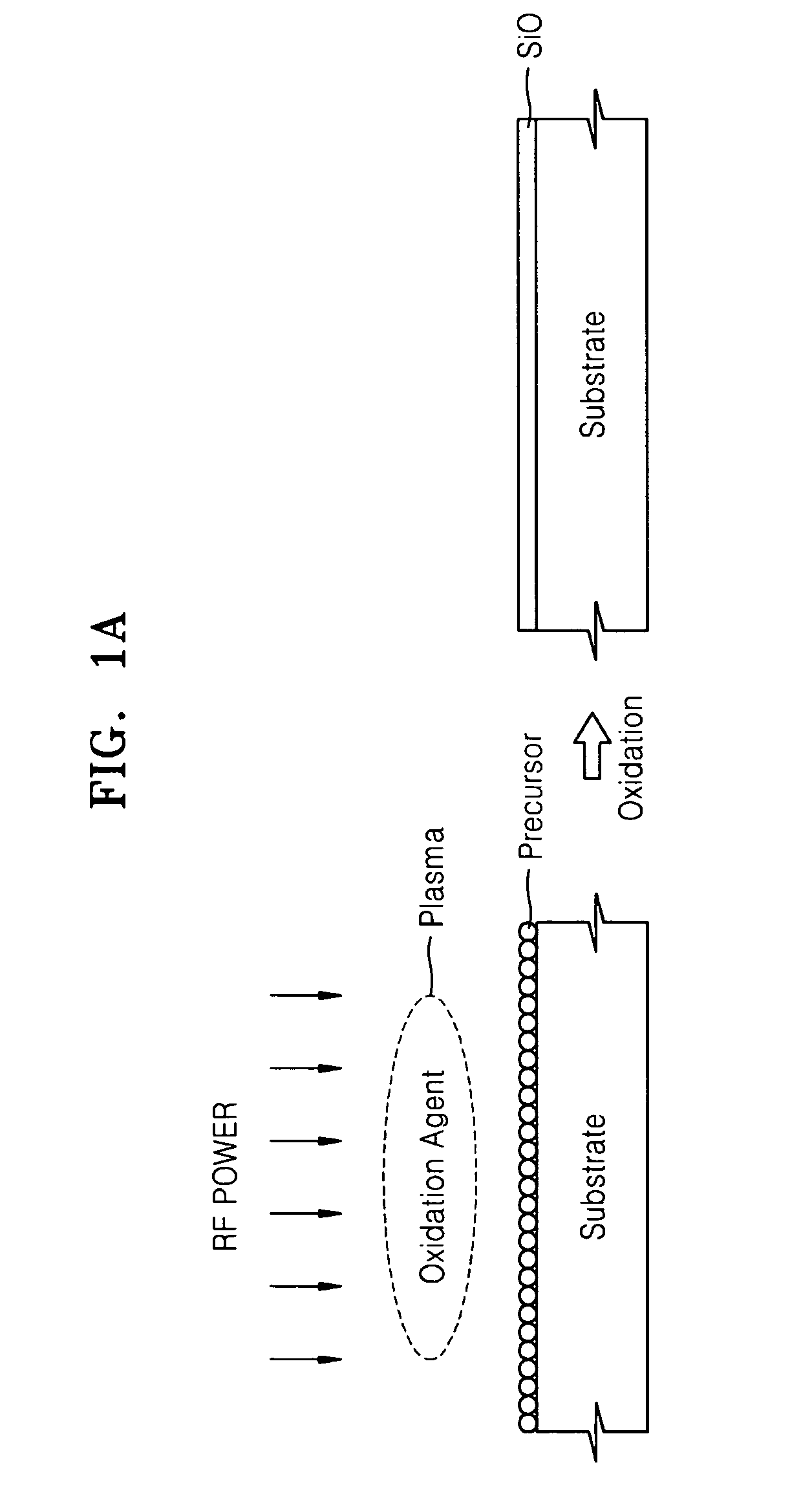

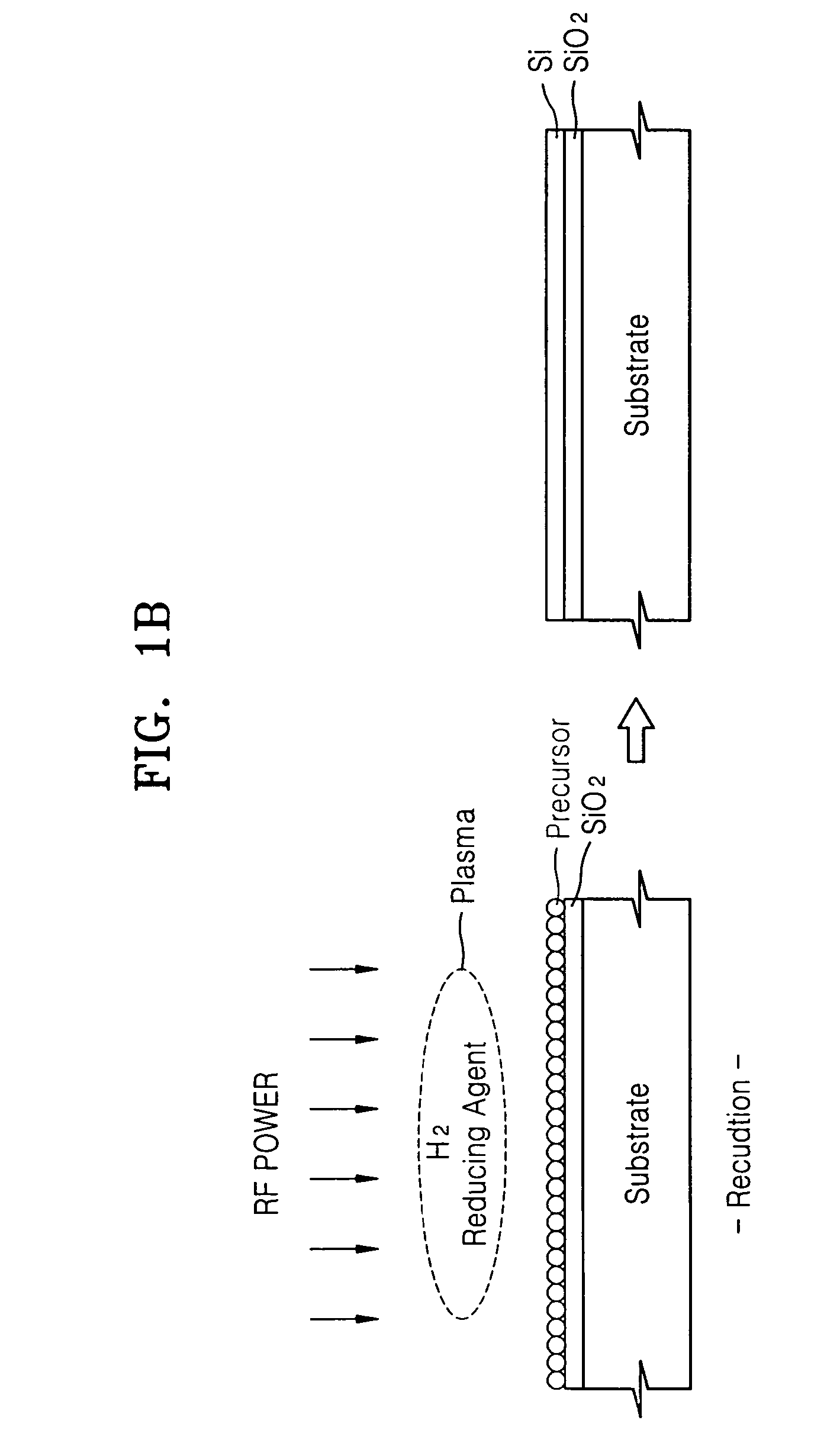

Method of manufacturing silicon rich oxide (SRO) and semiconductor device employing SRO

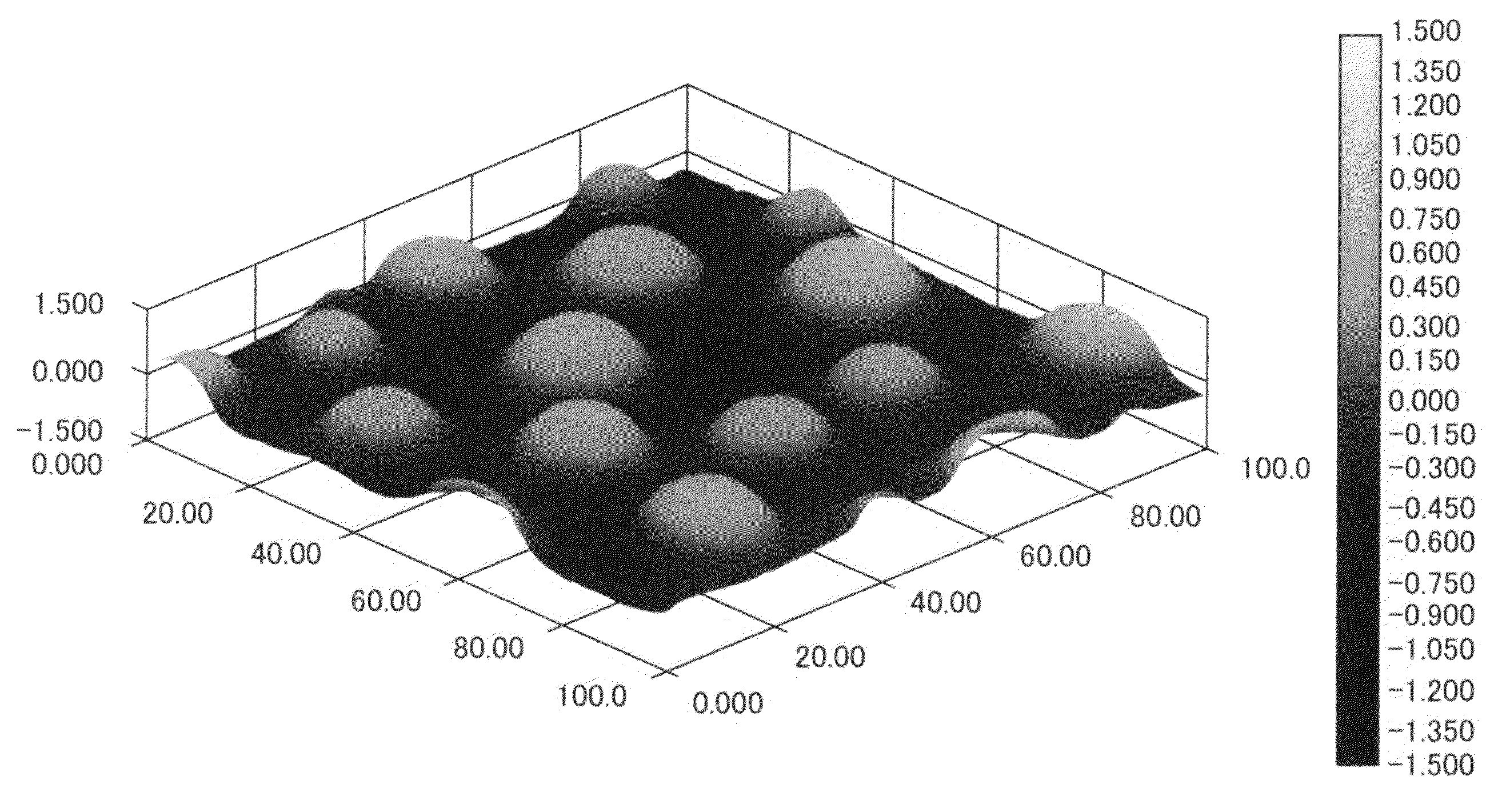

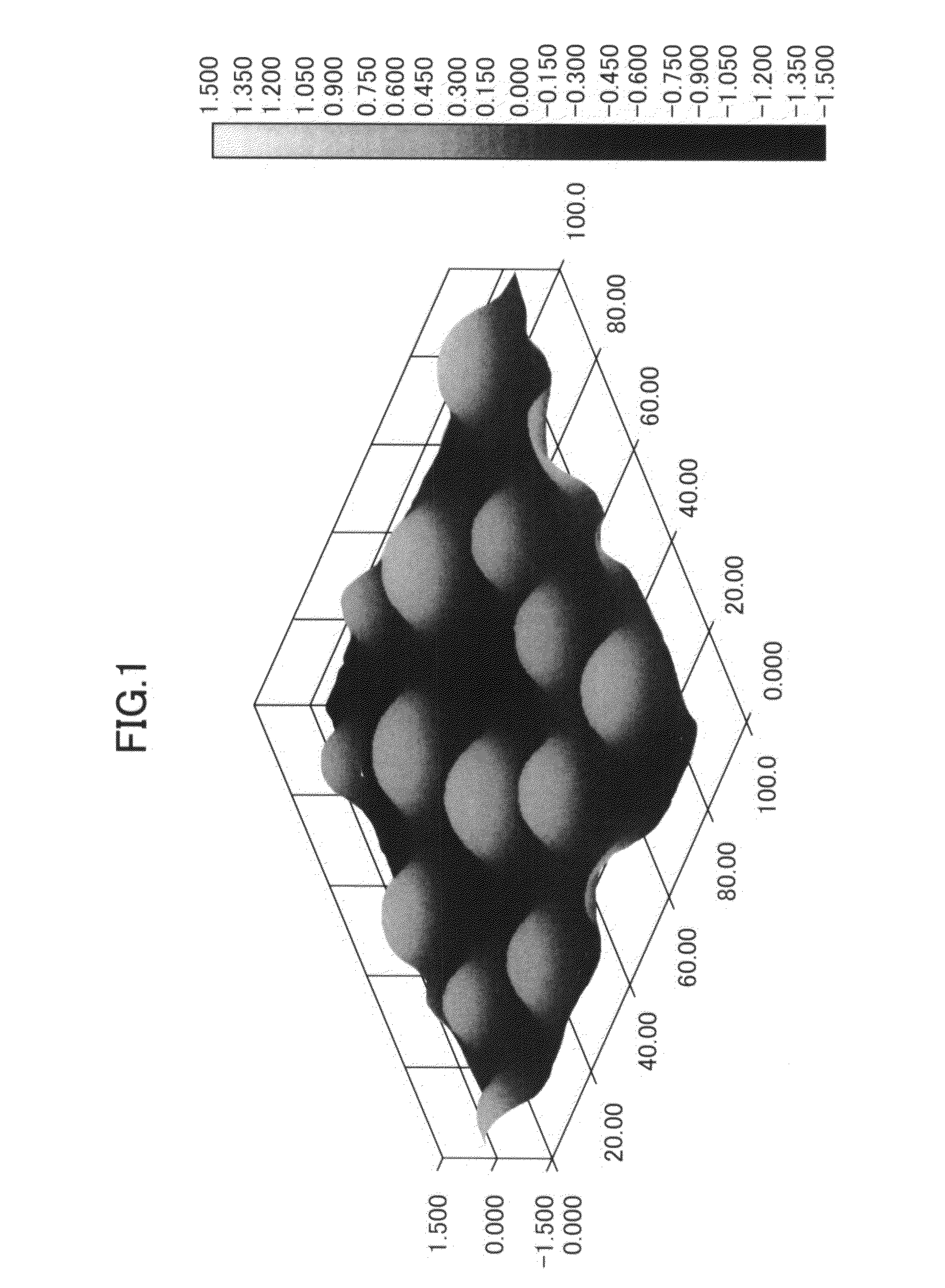

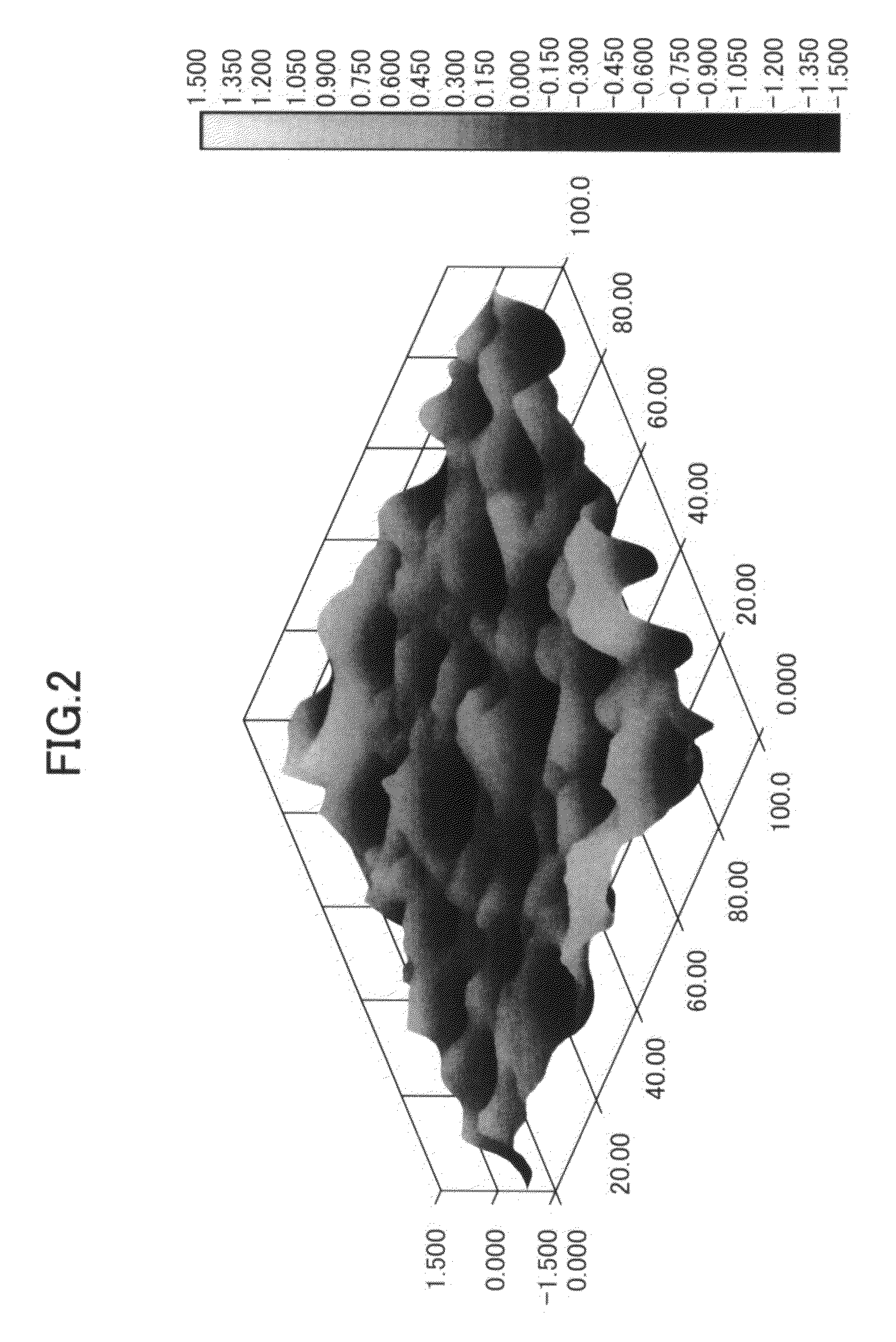

ActiveUS7410913B2Good step coverageImproved control over the silicon:oxygen ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialPhysical chemistry

Provided are methods for manufacturing silicon rich oxide (SRO) layers useful in the fabrication of semiconductor devices, for example, non-volatile memory devices, and methods for fabricating semiconductor devices incorporating such SRO layers. The methods include absorbing a first silicon source gas onto the substrate, oxidizing the first absorbed layer to form a silicon oxide layer, absorbing a second silicon source gas onto the substrate and reducing the second absorbed layer to form a silicon layer. The combination of the silicon oxide layer(s) and the silicon layer(s) comprise, in turn, a composite SRO layer. These manufacturing methods facilitate control of the oxygen concentration in the SRO, the relative thicknesses of the silicon oxide and silicon layers, and provides improved step coverage, thus allowing the manufacturing of high quality semiconductor devices.

Owner:SAMSUNG ELECTRONICS CO LTD

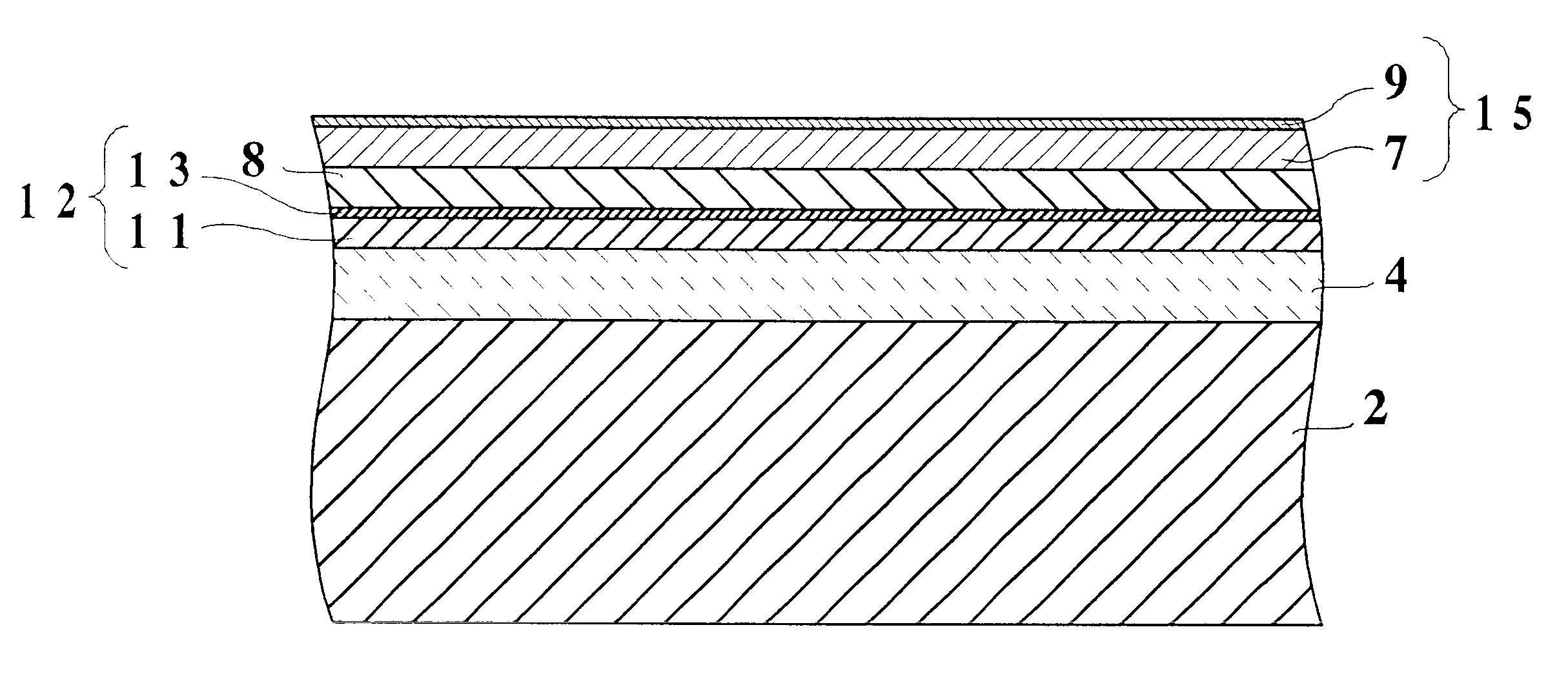

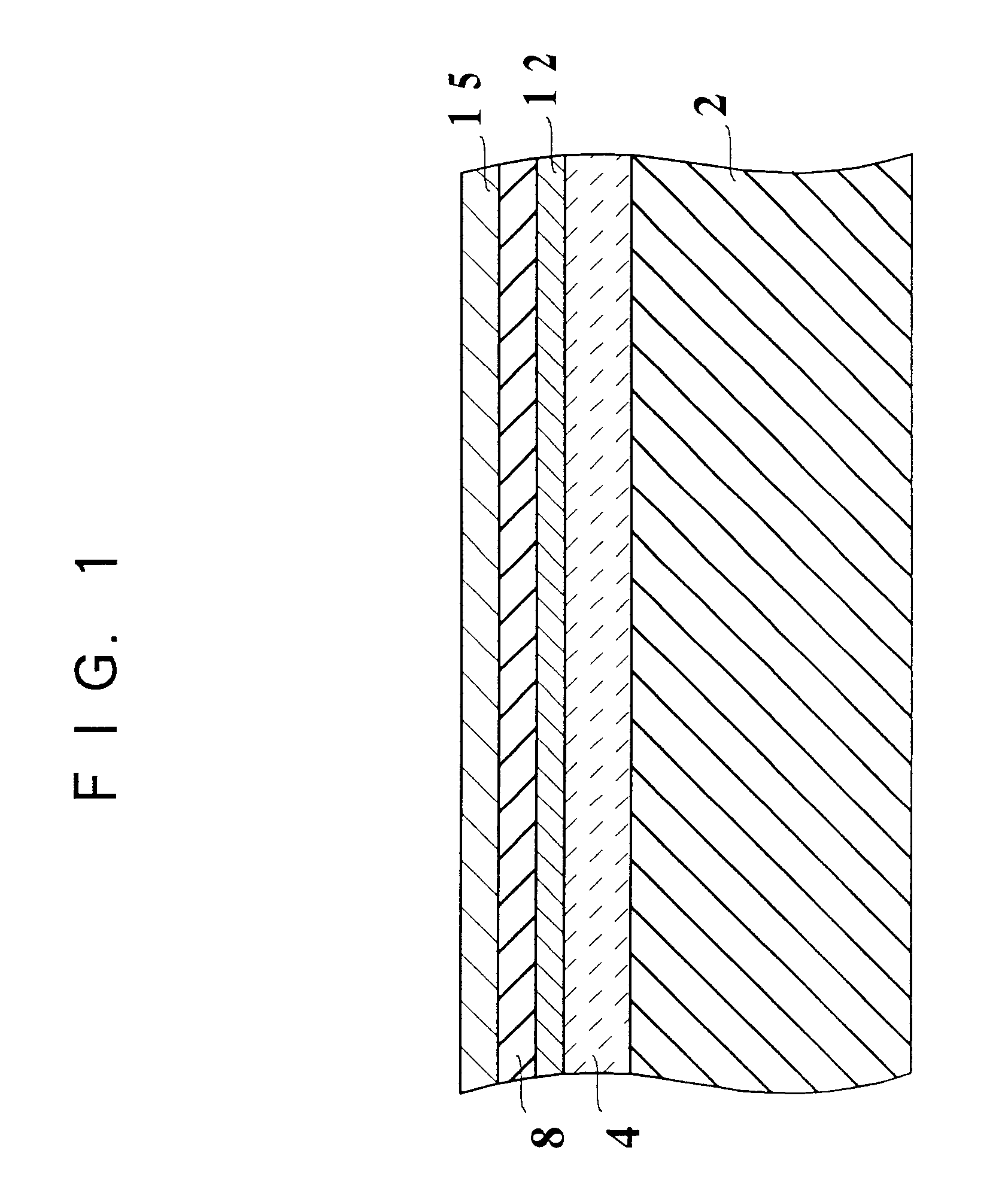

Ferroelectric capacitor and a method for manufacturing thereof

InactiveUS6454914B1Reduce degradationHigh dielectric constantThin/thick film capacitorStacked capacitorsOxygenPalladium oxide

An object of the present invention is to provide a ferroelectric capacitor which shows excellent ferroelectricity. A silicon oxidation layer 4, a lower electrode 12, a ferroelectric layer 8 and an upper electrode 15 are formed on a silicon substrate 2. The lower electrode 12 is made of palladium oxide. Also, the upper electrode 15 is made by palladium oxide, since palladium oxide prevents leakage of oxygen contained in the ferroelectric layer 8. Thus, the ferroelectric capacitor of the present invention offers excellent ferroelectricity can be realized.

Owner:ROHM CO LTD

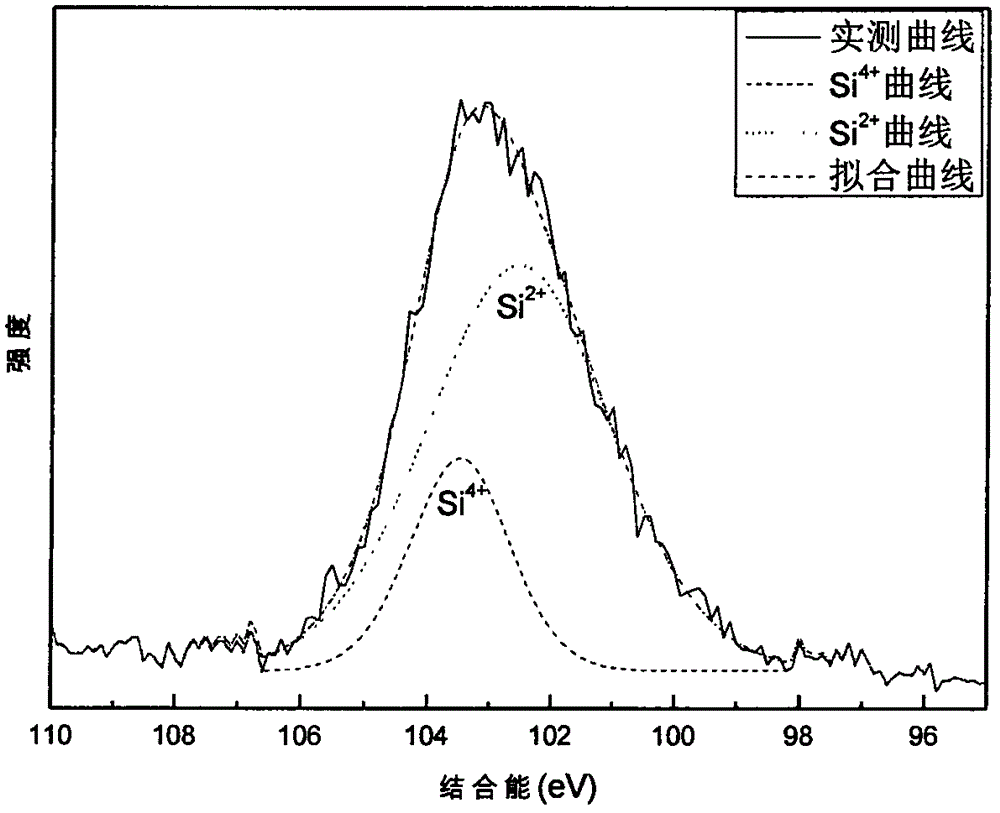

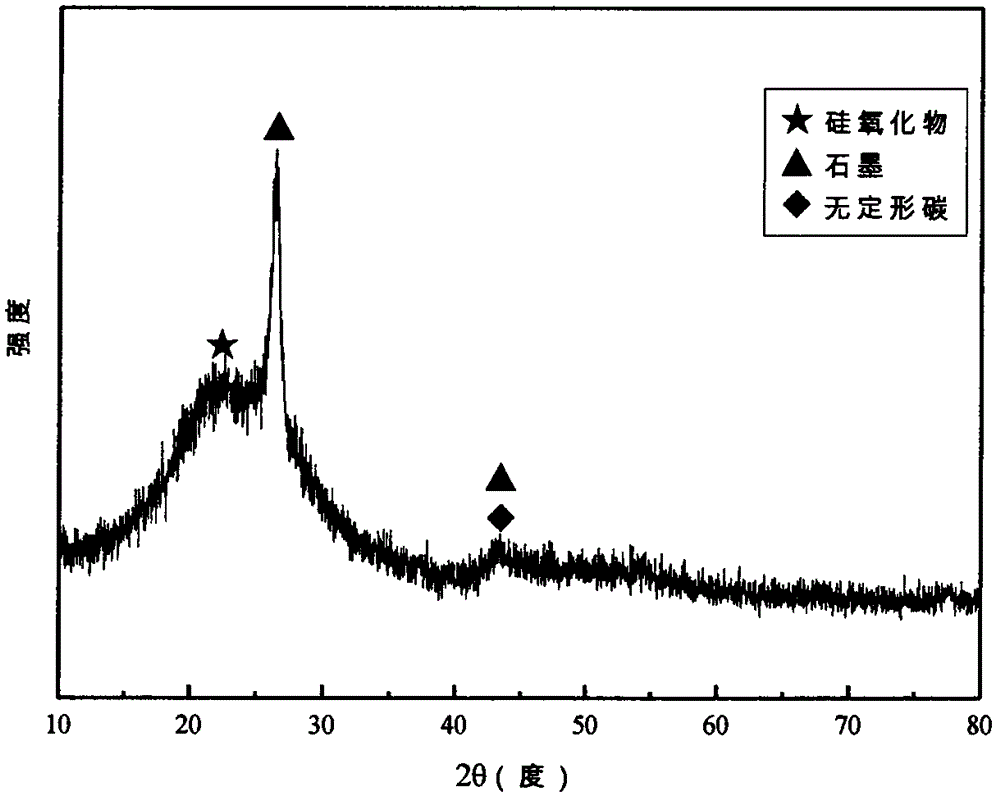

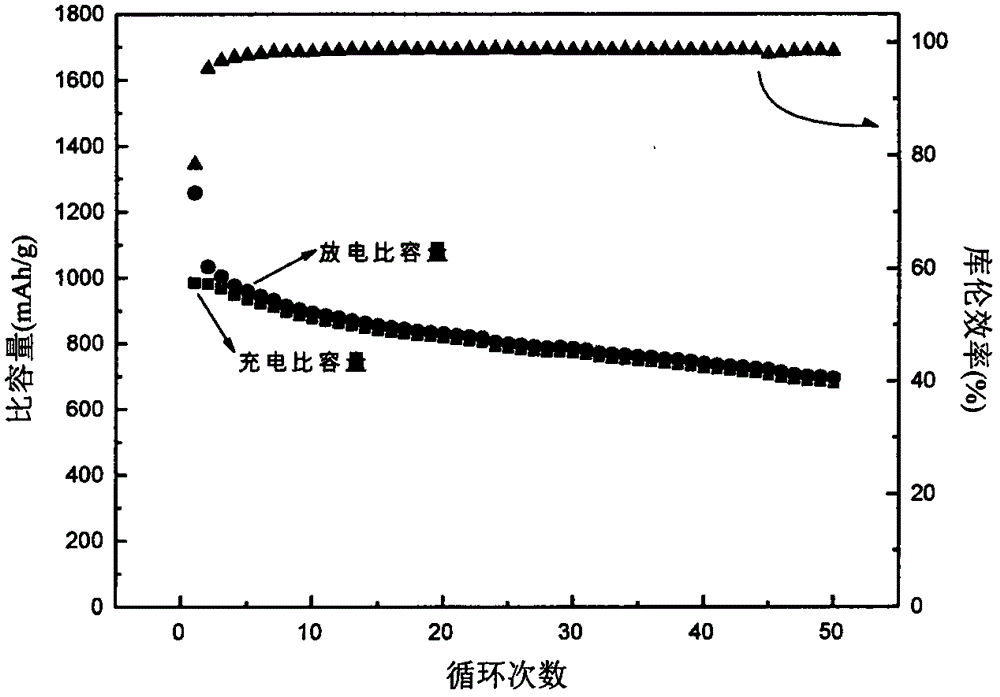

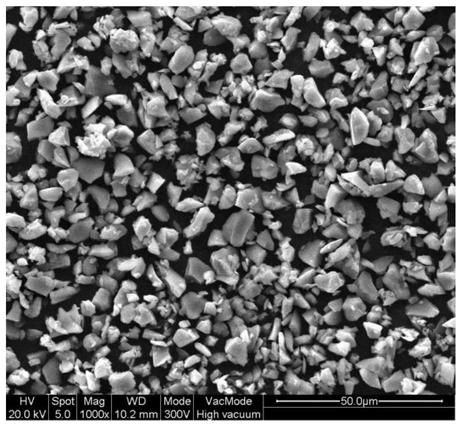

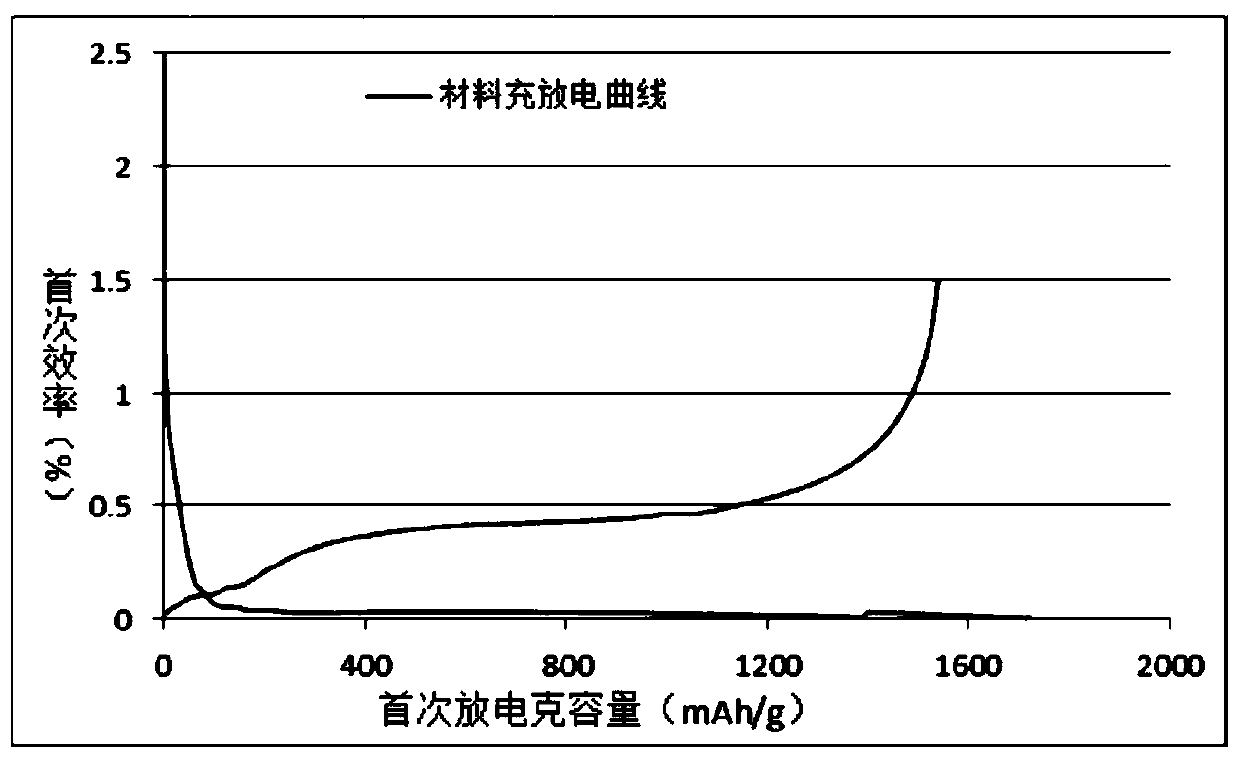

Silicon oxide composite negative pole material for lithium ion secondary battery and preparation method thereof

ActiveCN104577066AReduce manufacturing costImprove the first Coulombic efficiencyCell electrodesFiltrationSilicon oxide

The invention relates to a silicon oxide composite negative pole material for a lithium ion secondary battery and a preparation method thereof. The composite material consists of silicon oxide, graphite type carbon materials and amorphous carbon materials. The preparation method comprises the following steps: performing magnesiothermic reduction on silicon dioxide so as to generate the silicon oxide by using alkaline(soil) metal chloride as a heat absorbent; after performing acid corrosion, sucking filtration, washing and vacuum drying on the silicon oxide, performing pre-ball milling on the dried silicon oxide and graphite; then complementing an organic carbon source, performing secondary ball milling, and then performing high-temperature heat treatment so as to obtain the silicon oxide composite negative pole material. The oxygen content of the silicon oxide is controlled by regulating the proportion of the silicon dioxide to magnesium, and then the silicon oxide is uniformly mixed with the graphite type carbon materials and the organic carbon source. The silicon oxide composite negative pole material disclosed by the invention has the characteristics of a higher first-time Kulun efficiency, a high specific capacity, a better cycle performance and the like; the preparation method adopted by the invention is easy in operation, simple in technology, low in cost and suitable for the industrial mass production.

Owner:NANKAI UNIV

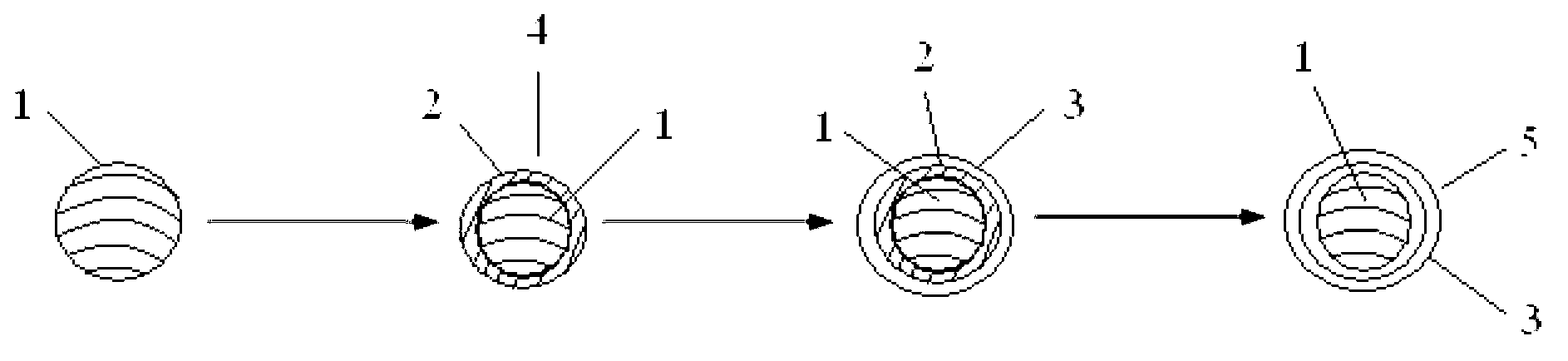

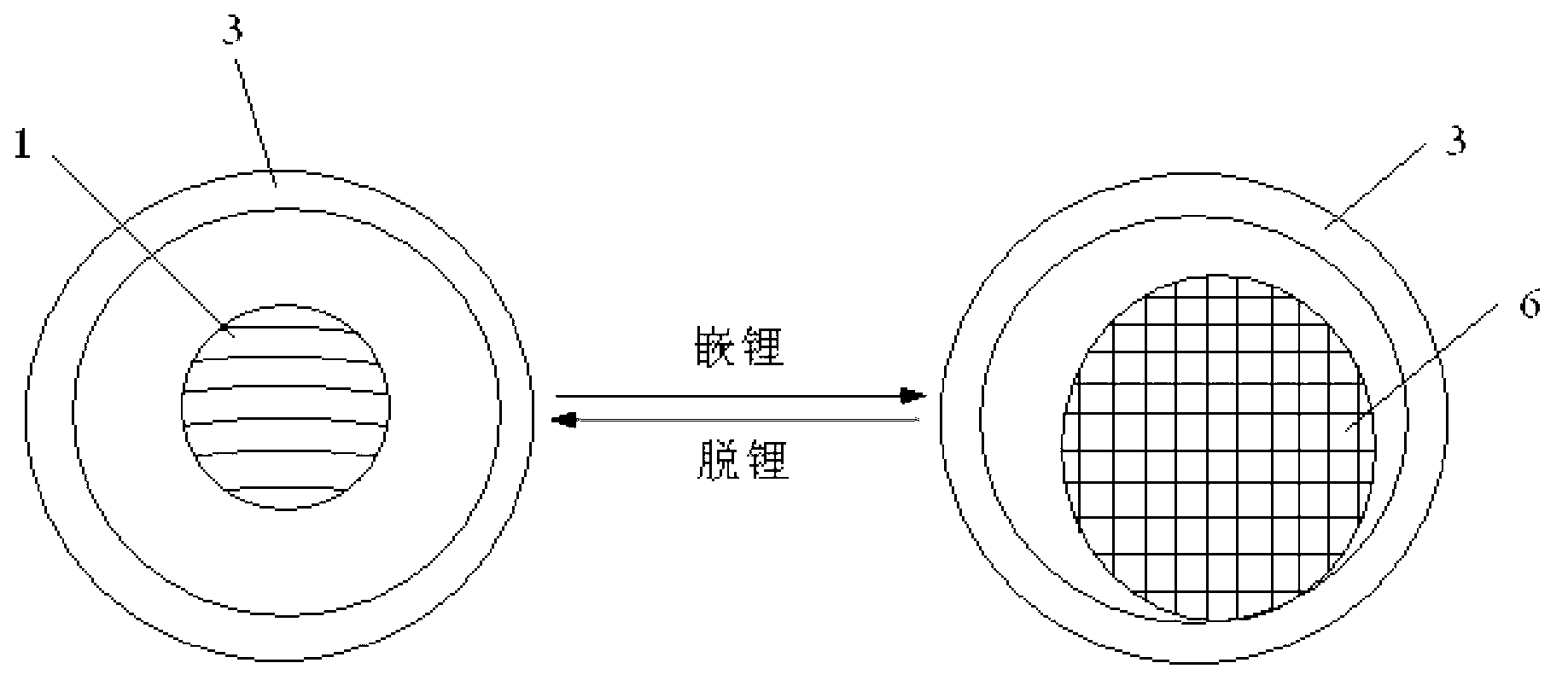

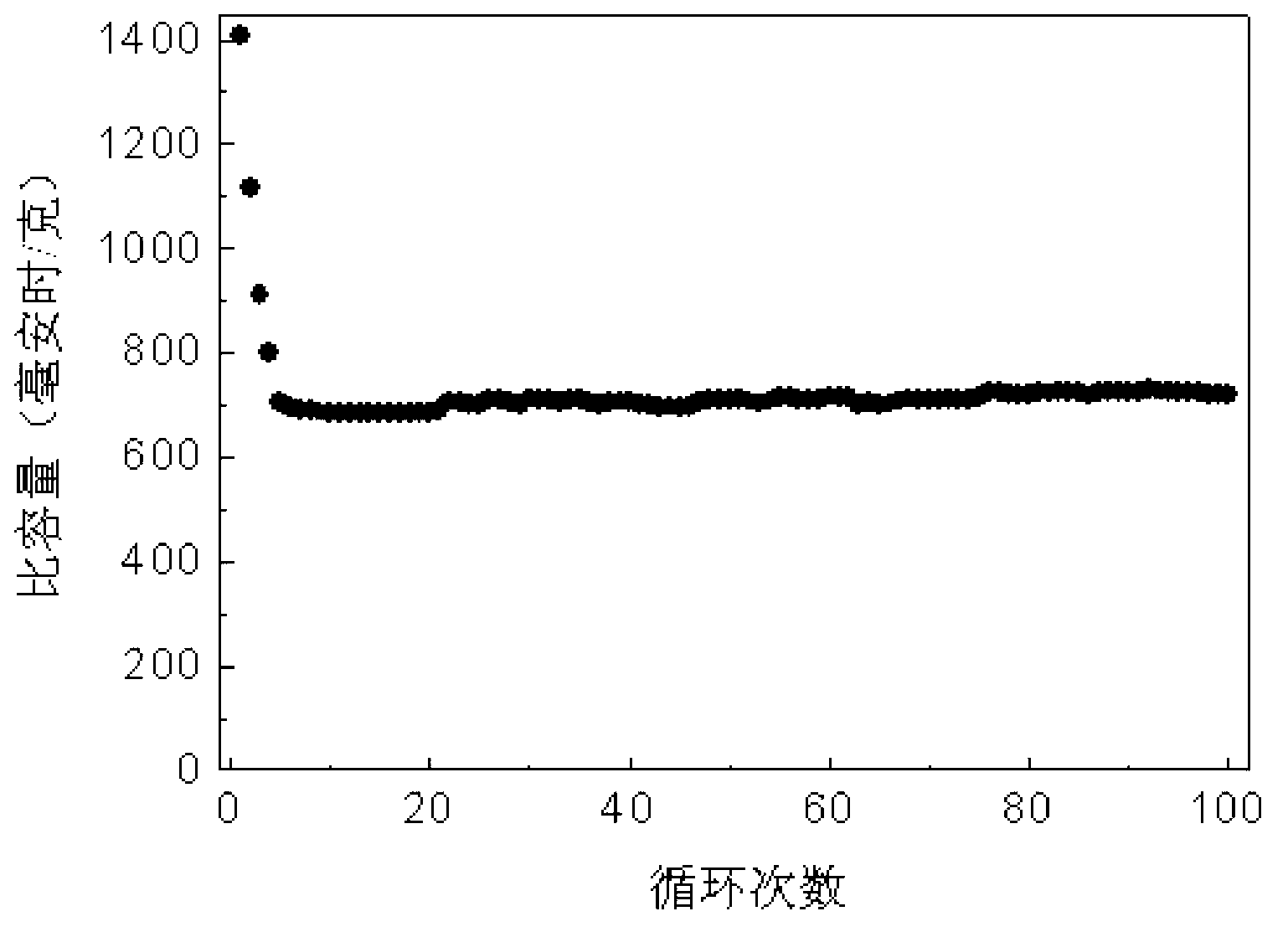

Silicon carbon composite material and preparation method thereof, lithium ion battery containing same

InactiveCN102800851AEasy to makeWith lithium storage capacityMaterial nanotechnologyCell electrodesCarbon layerCarbon composites

The invention discloses a silicon carbon composite material and a preparation method thereof, and a lithium ion battery containing the material. The preparation method of the silicon carbon composite material comprises the following steps: (1) calcining silicon powder in oxygen-containing atmosphere to obtain a composite material with silica-coated silicon; (2) coating the composite material with silica-coated silicon by carbon; (3) corroding the silica with excessive hydrofluoric acid to obtain the silicon carbon composite material. The preparation process of the silicon carbon composite material is simple; the preparation of the composite material with silica-coated silicon by partial oxidation of silicon is simple, and controllable in silicon oxidation degree; the silica layer of the material obtained after coating the composite material with silica-coated silicon by carbon is easy to remove; and a core shell structure with a certain gap between the carbon layer and the silicon is obtained. The preparation process is simple; the silicon carbon composite material prepared by the preparation method has better electrochemical properties; batteries prepared by the silicon carbon composite material have better cycle performance.

Owner:CHERY AUTOMOBILE CO LTD

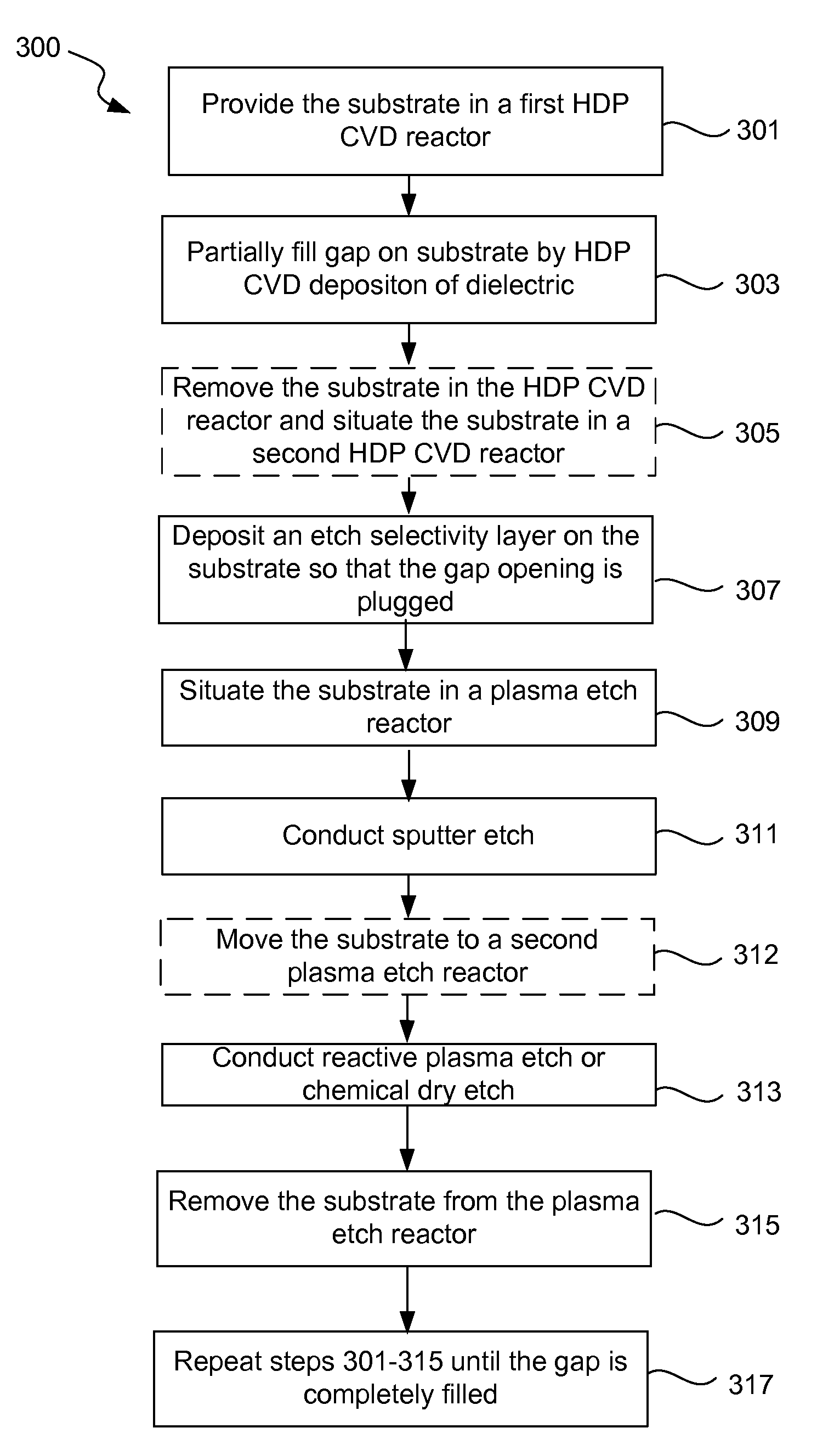

In-situ process layer using silicon-rich-oxide for etch selectivity in high AR gapfill

ActiveUS7951683B1Reduce morbiditySmall sizeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densityReactive plasma

In-situ semiconductor process that can fill high aspect ratio (typically at least 6:1, for example 7:1 or higher), narrow width (typically sub 0.13 micron, for example 0.1 micron or less) gaps with significantly reduced incidence of voids or weak spots is provided. This deposition part of the process may involve the use of any suitable high density plasma chemical vapor deposition (HDP CVD) chemistry. Prior to etch back, the feature gap is plugged with an etch selectivity layer. The etch back part of the process involves multiple steps including a sputter etch to reduce the top hat formations followed by a reactive plasma etch to open the gap. This method improves gapfill, reduces the use of high cost fluorine-based etching and produces interim gaps with better sidewall profiles and aspect ratios.

Owner:NOVELLUS SYSTEMS

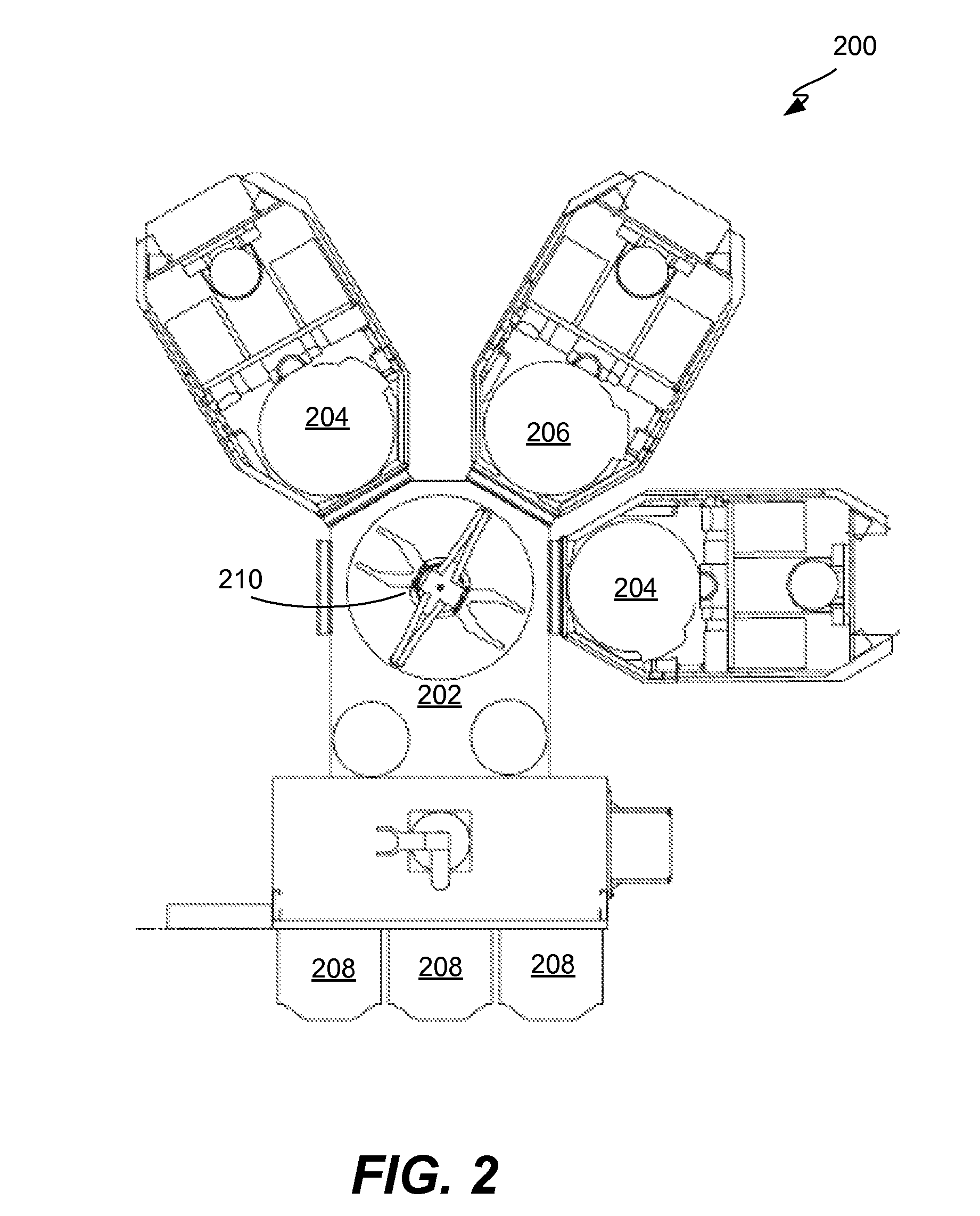

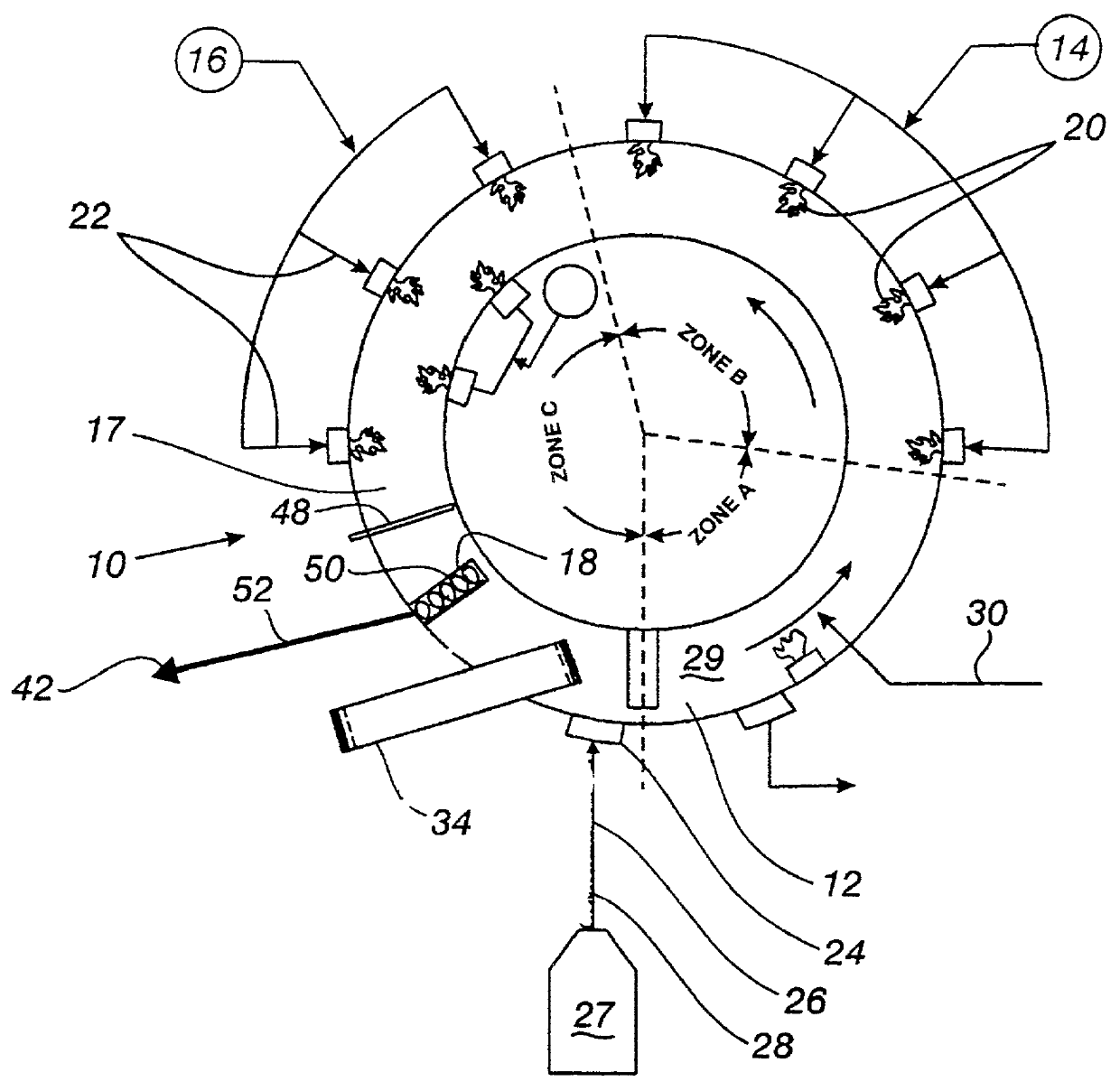

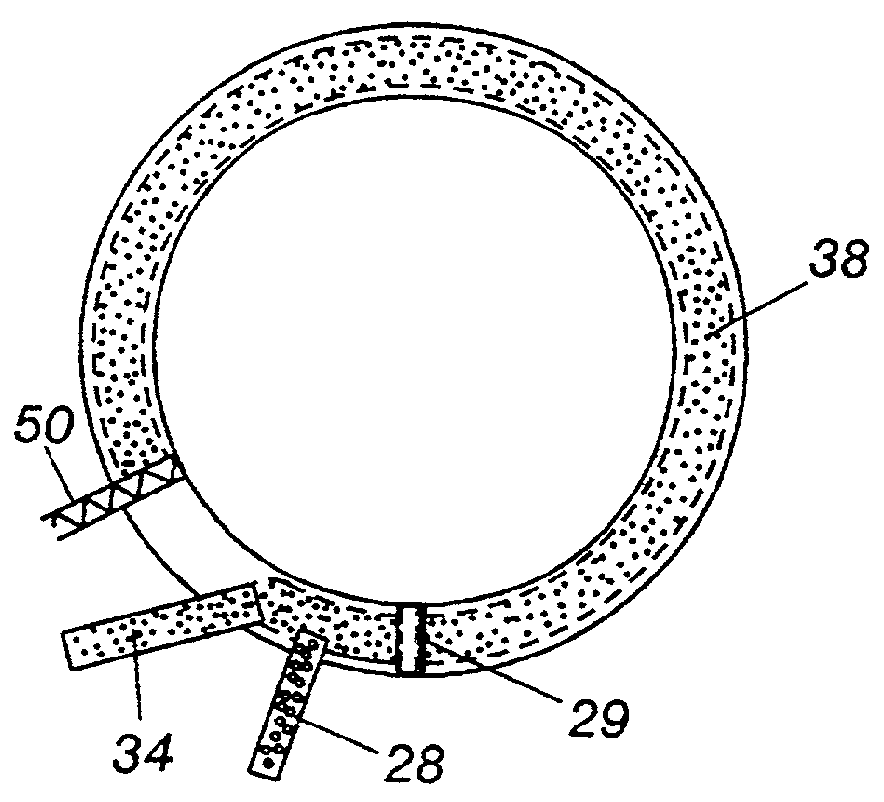

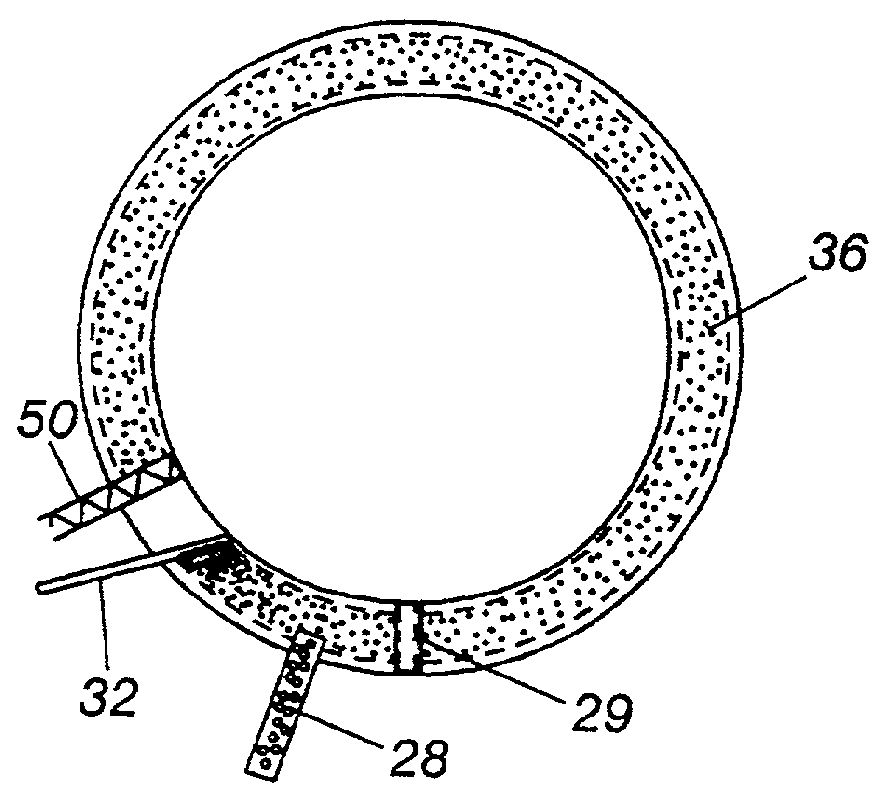

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

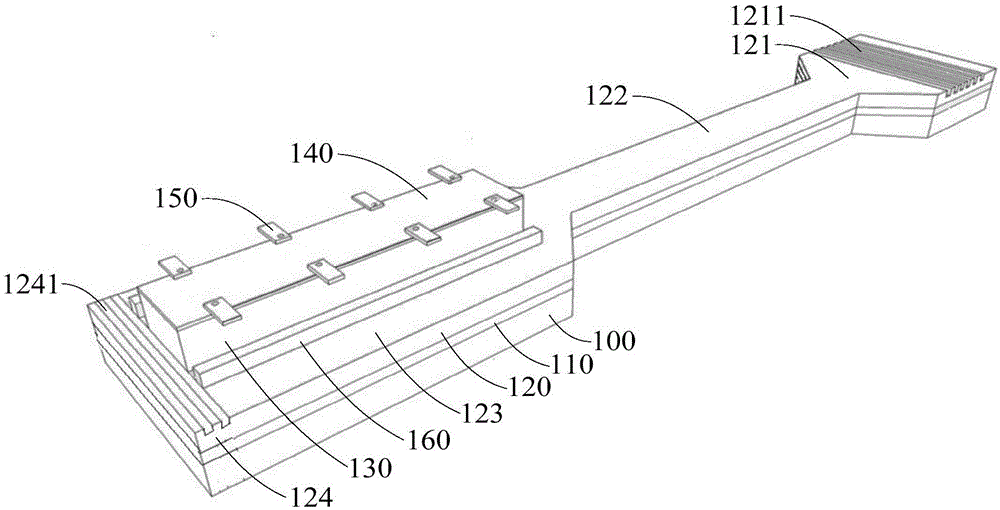

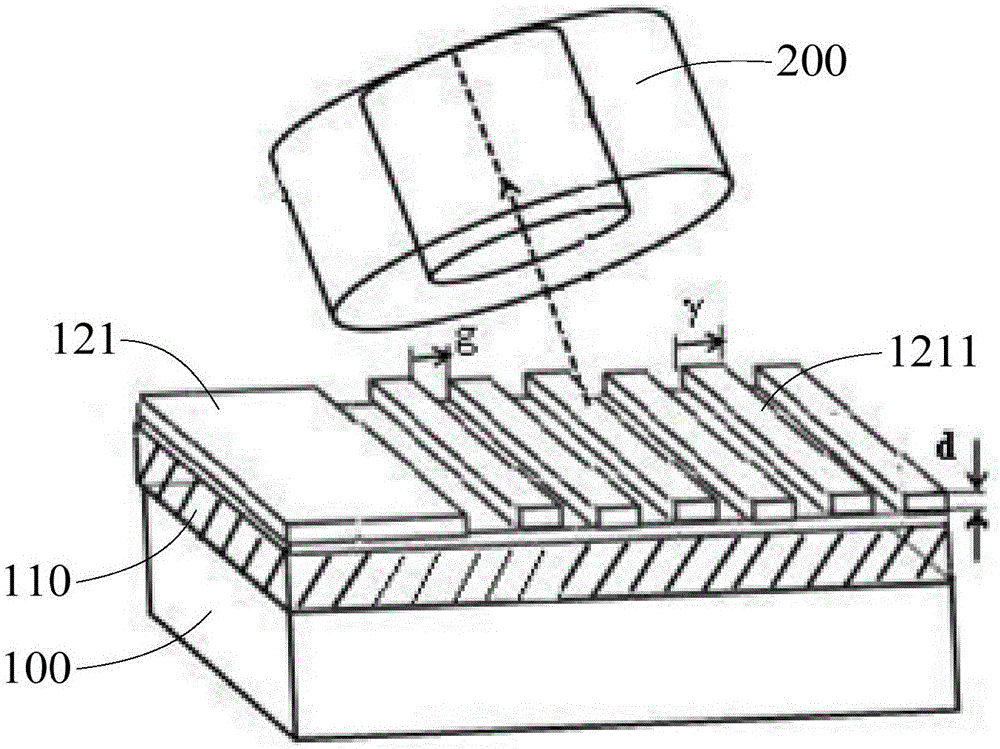

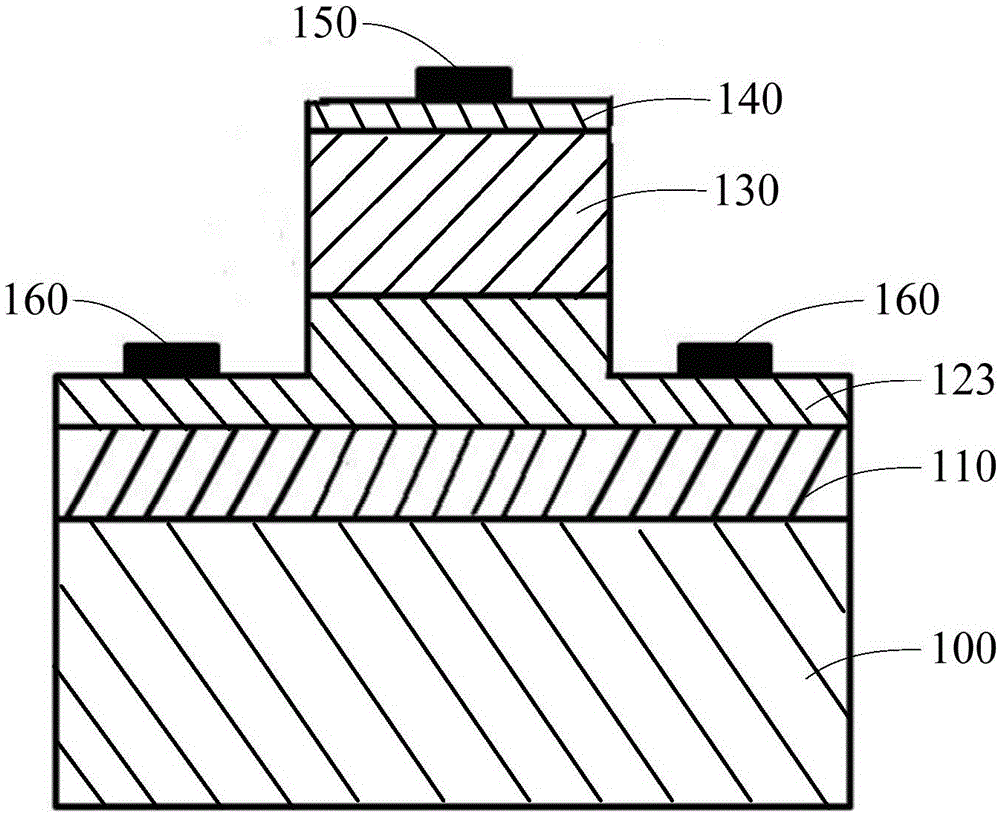

Silicon-based germanium photodetector

The present invention discloses a silicon-based germanium photodetector. The silicon-based germanium photodetector comprises an optical waveguide layer, a silicon oxide layer and a silicon substrate which are sequentially stacked from top to bottom; the optical waveguide layer includes an optical coupling region, a planar optical waveguide region and an optical output region which are distributed sequentially along the propagation direction of optical signals; a coupling grating for receiving the optical signals and guiding the optical signals to the planar optical waveguide region is formed in the coupling region; and the silicon-based germanium photodetector further comprises a germanium layer stacked on the optical output region, a silicon covering layer stacked on the germanium layer, a first electrode formed on the silicon covering layer, and a second electrode formed on the optical output region, wherein the germanium layer receives the optical signals from the optical output region and converts the optical signals into electrical signals. According to the silicon-based germanium photodetector of the invention, the silicon covering layer is adopted, so that bandwidth is greatly improved, the dark current of the device is greatly reduced, and therefore, the comprehensive performance index of the device can be improved, and the requirements of high-speed optical communication and optical interconnection systems can be better satisfied.

Owner:ZTE CORP

Preparation method of furnace transmutation sorghum red-flower glaze

The invention relates to the technical field of ceramic glaze and particularly relates to a preparation method of furnace transmutation sorghum red-flower glaze. A ground coat is prepared from feldspar, quartz, Soochow soil, calcite, glass dust, dolomite, chromic oxide, cobaltous oxide, ferric oxide and vanadium pentoxide; overglaze is prepared from feldspar, quartz, zinc oxide, Soochow soil, boron frits, cadmium-selenium haematochrome, silicon carbide and copper oxide. The preparation method comprises the following steps: firstly applying the ground coat on a green body after biscuiting; then applying the overglaze; and firing by adopting oxidizing flames of a roller kiln. By adopting formulae of the ground coat which is matte black with metallic luster and the bright-red overglaze as well as a special firing process, particularly control of the temperature-raising rate, the ground coat which is matte black with metallic luster is low in initial melting point, the green body and the glaze are compactly combined, the glaze is level and smooth, and the product is smooth, flexible, vigorous and decent in surface.

Owner:江苏省宜兴彩陶工艺厂

Polishing Composition and Polishing Method Using The Same

InactiveUS20110223840A1Improve polishing ratePigmenting treatmentOther chemical processesZeta potentialIndium

Owner:FUJIMI INCORPORATED

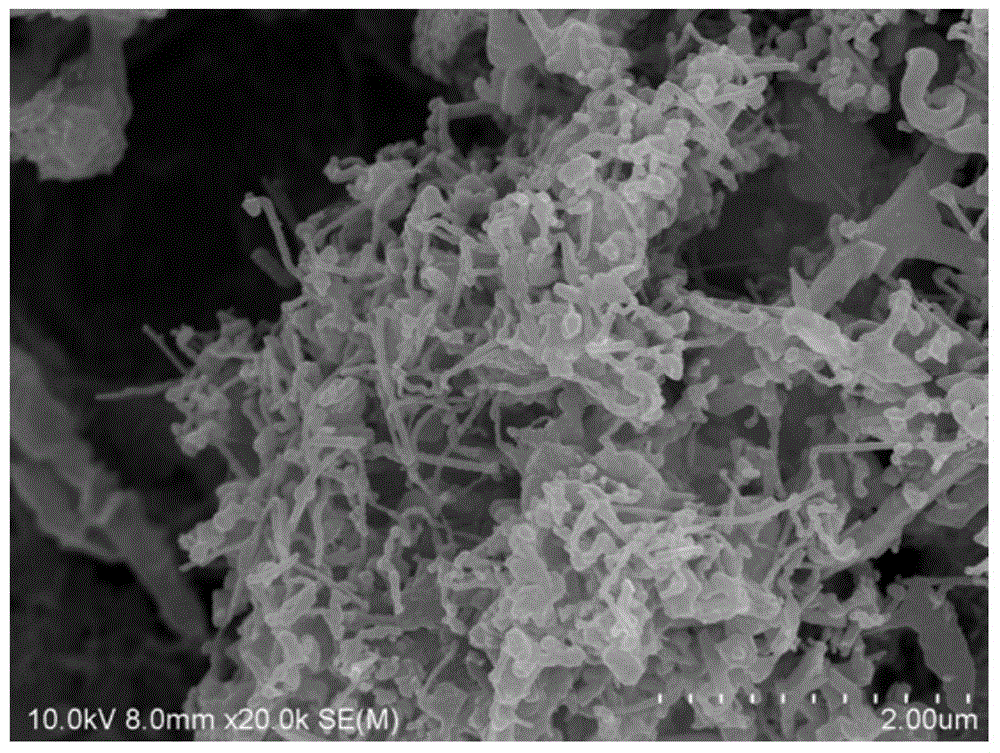

High-performance silicon/graphene oxide negative electrode material based on chemical bond and preparation method thereof

InactiveCN103441247AInhibit sheddingAvoid reunionMaterial nanotechnologyCell electrodesMicro nanoElectrical battery

The invention discloses high-performance silicon / graphene oxide negative electrode material based on chemical bond and a preparation method thereof. The chemical bond effect between micron and nano silica powder and graphene oxide is realized by performing surface modification to micron and nano silica powder, so that the micron and nano silica powder and the graphene oxide can be uniformly compounded, and the purpose of effectively improving the cycle performance is achieved. The silicon / graphene oxide composite material has the advantages of high specific discharge capacity, excellent rate performance and cycle performance and the like, and belongs to potential lithium ion battery negative electrode material.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

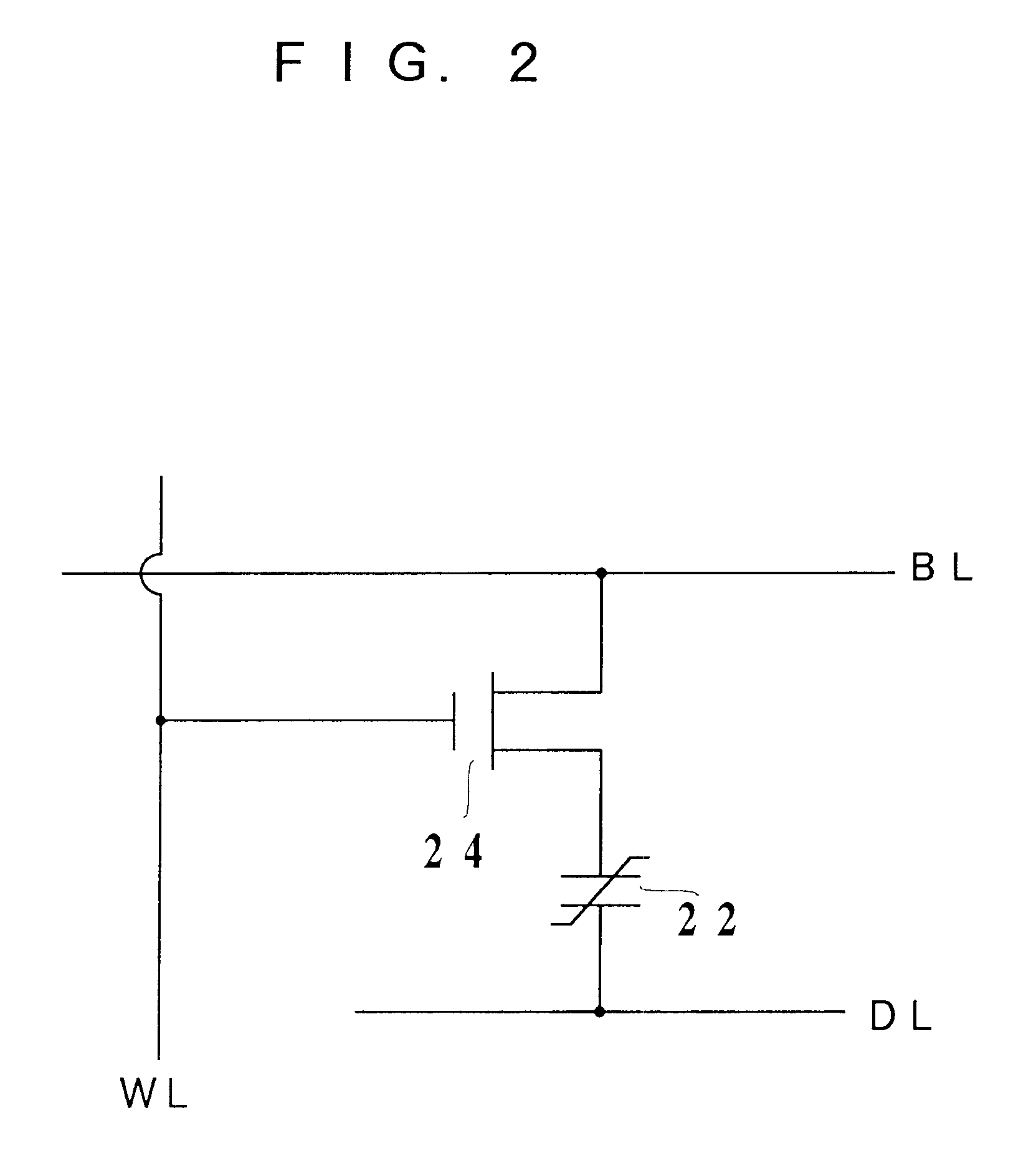

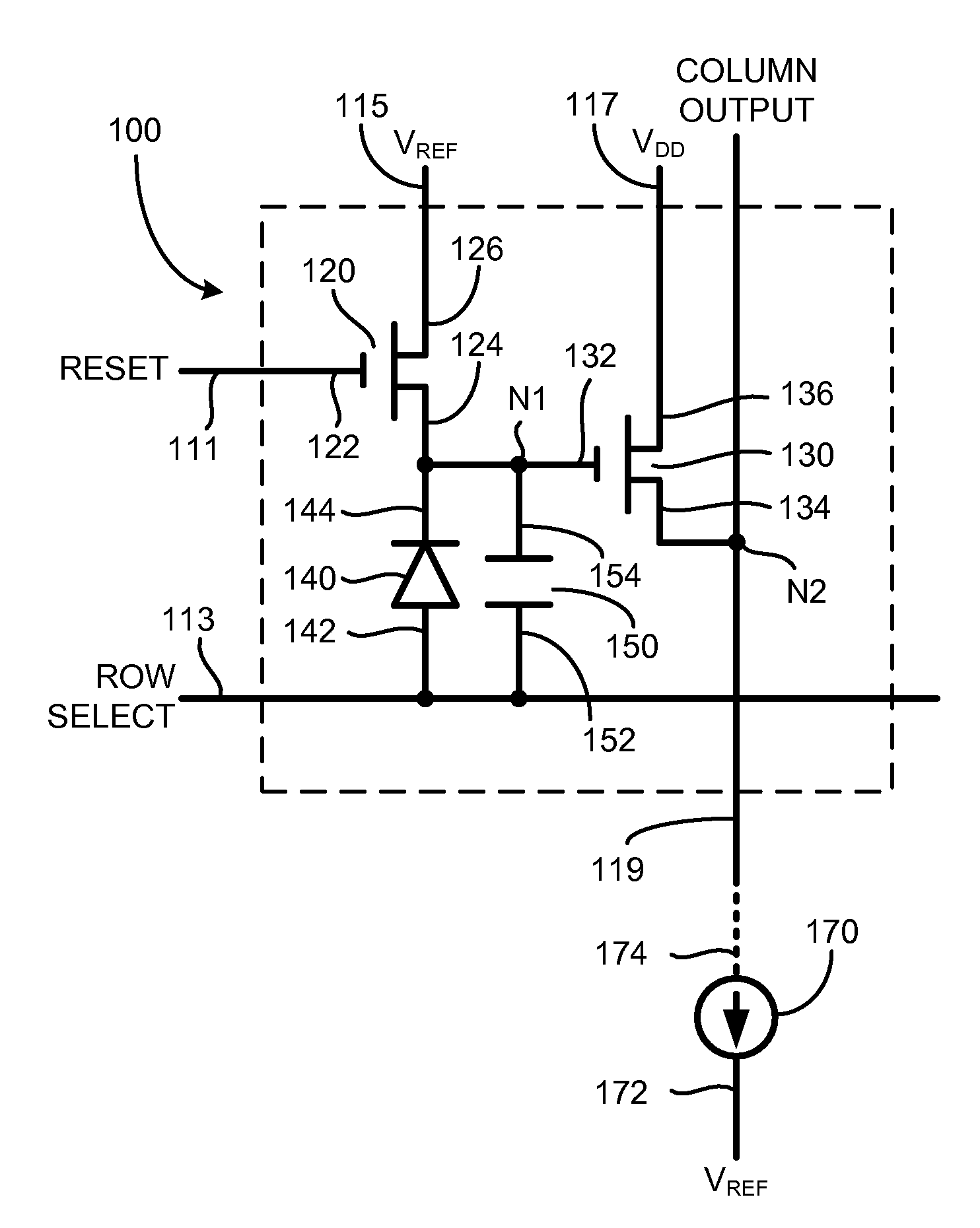

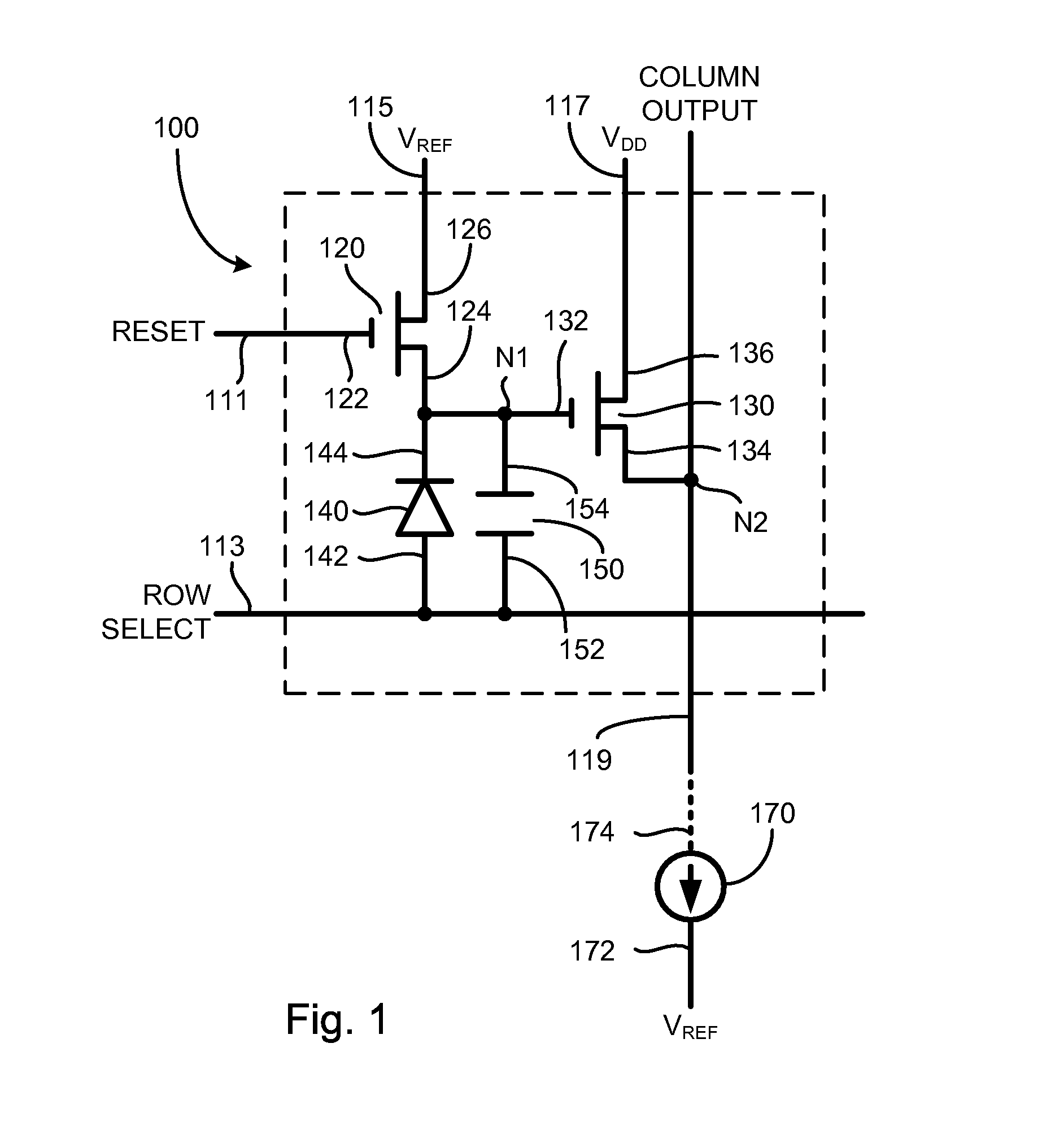

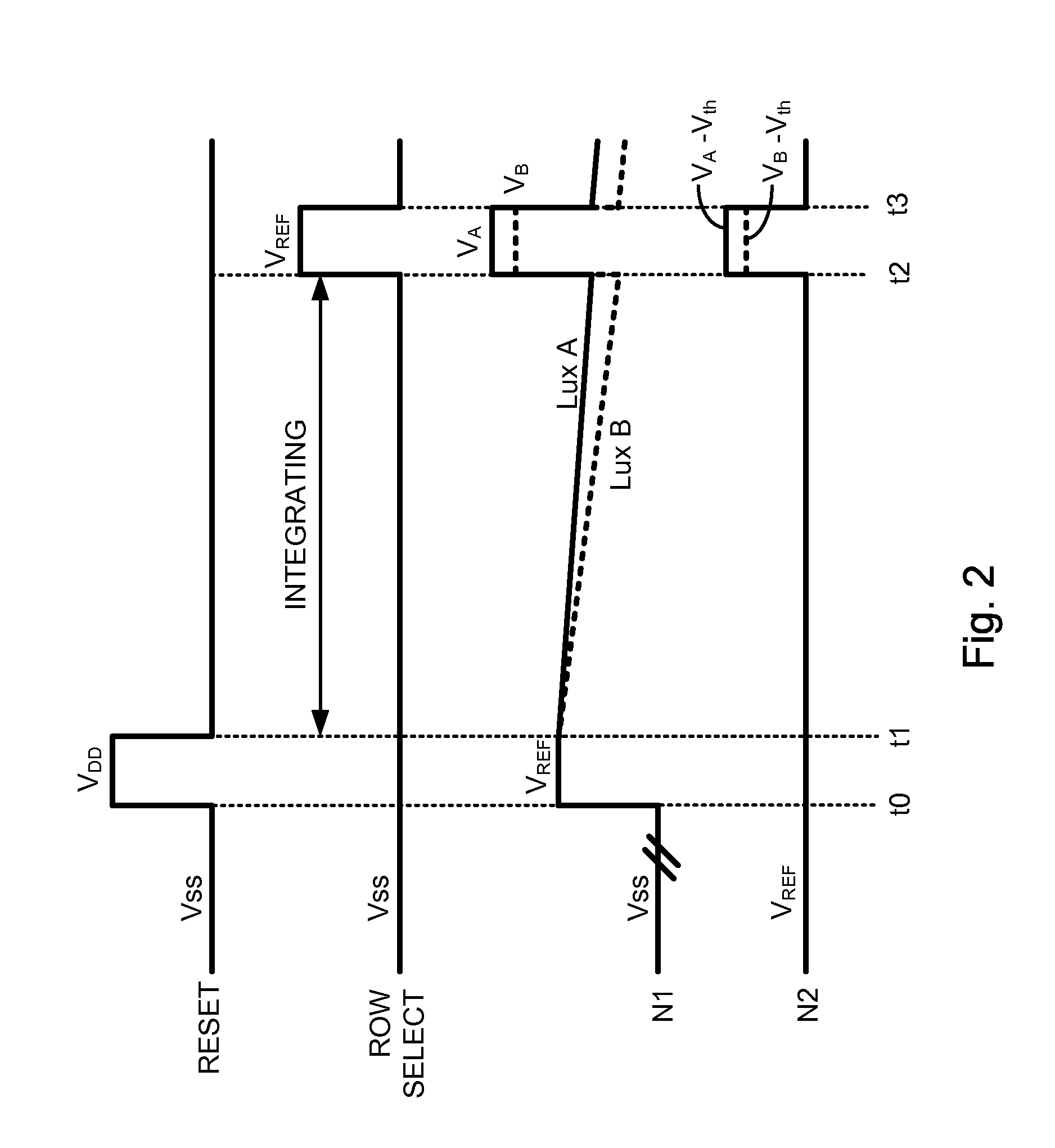

Active pixel senor circuit

ActiveUS20100091162A1Cancel noiseTelevision system detailsTelevision system scanning detailsCMOS sensorEngineering

The present invention relates to an active pixel sensor circuit and a method of operating same. In one embodiment, the active pixel sensor circuit includes a reset transistor having a gate, a source and a drain, a silicon rich oxide (SRO) photosensor having an anode and a cathode electrically coupled to the source of the reset transistor, and a readout transistor having a gate electrically coupled to the cathode of the SRO photosensor, a source and a drain.

Owner:AU OPTRONICS CORP

Toughened low-radiation coated glass with double-silver composite structure and technique thereof

InactiveCN101531471AQuality is not affectedControl and barrier infiltrationDielectric layerTitanium oxide

The invention provides a membranous layer composite structure of toughened low-radiation coated glass with a double-silver composite structure; toughening processing technique can be carried out after coating without influence on quality of products; silicon nitride (Si3N4) + ZnO is used as a composite dielectric layer of a base layer; one or more of tin oxide (SnO2), titanium oxide (TiO2), silicon nitride (Si3N4), and an absorbing layer of niobium oxide (Kb2O5) with ZnO are selected to form a composite dielectric layer of a middle layer; and the thicknesses and membranous components of other layers are reasonably selected, so as to prepare the toughened low-radiation coated glass with the double-silver composite structure which can undergo high-temperature heat processing.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP +3

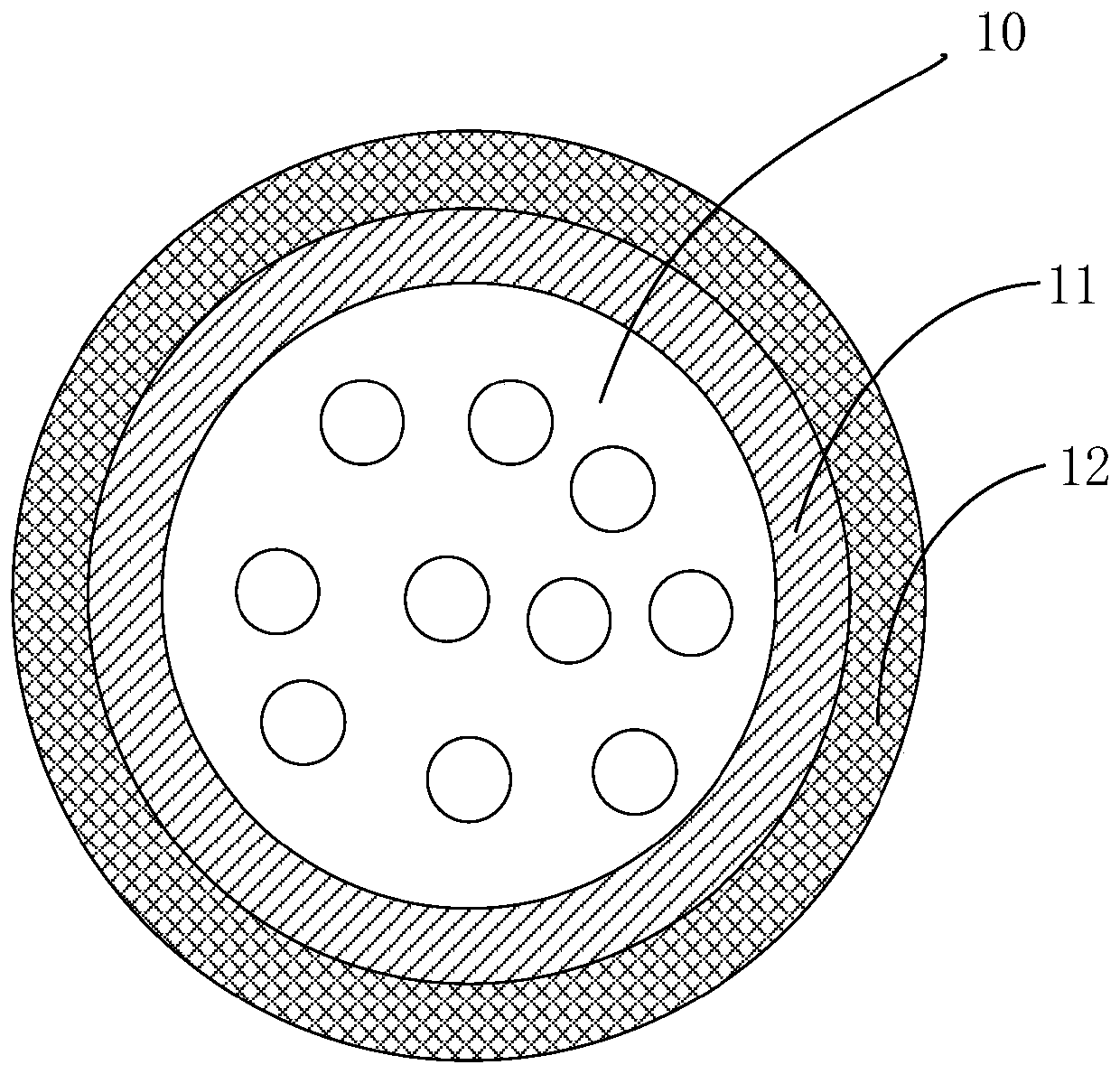

A silicon-based negative electrode material for a secondary battery, a method for preparing the same, and the secondary battery

ActiveCN111164803AImprove cycle performanceHigh electron mobilityElectrode thermal treatmentNegative electrodesCarbon filmSilicon oxide

The present application provides a silicon-based negative electrode material for a secondary battery, a method for preparing the same, and a secondary battery; the silicon-based negative electrode material for a secondary battery comprising: an inner core comprising Si particles and a silicon oxide SiOx1, wherein 0<x1<2; the first shell layer that comprises a compound with a general formula of MySiOz (y is more than 0 and less than or equal to 4, z is more than 0 and less than or equal to 5, and z is more than or equal to x1) and C particles, the first shell layer covers the inner core, and the contents of M and C in the first shell layer are gradually increased from one side close to the inner core to one side far away from the inner core; and the second shell layer that comprises a carbon film layer or a composite film layer formed by the carbon film layer and a conductive additive, and the second shell layer wraps the first shell layer. The first charge-discharge cycle capability ofthe silicon-based negative electrode material is improved, and the manufacturing cost is reduced.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Toner

ActiveUS9971263B2Excellent low temperature fixabilityBroad fixing marginDevelopersPolymer sciencePolymer chemistry

Owner:CANON KK

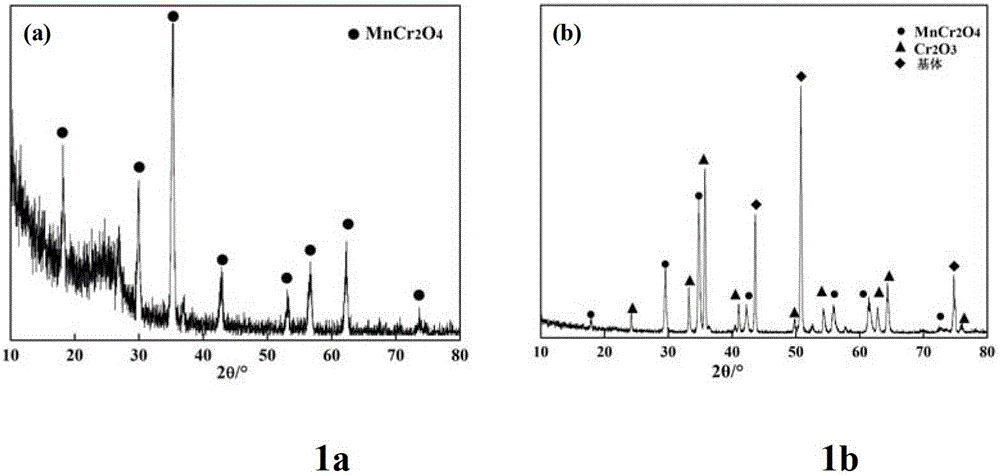

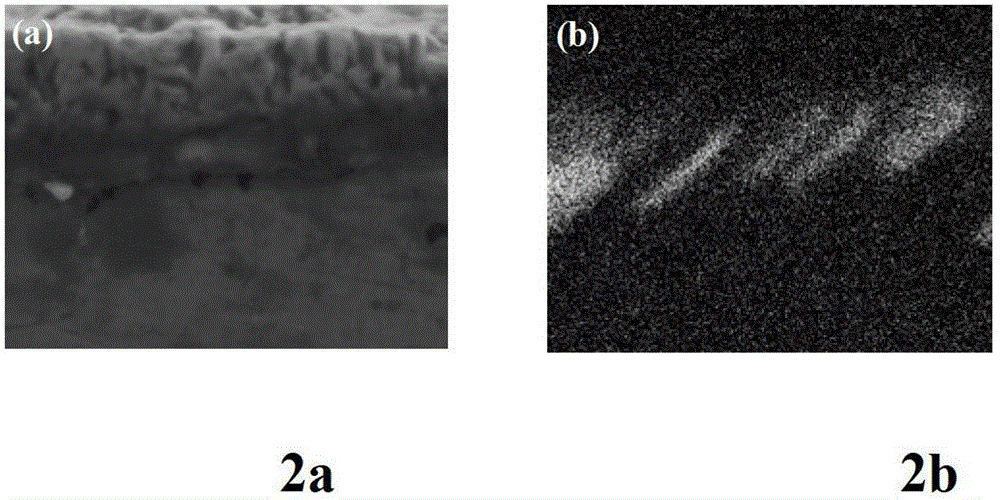

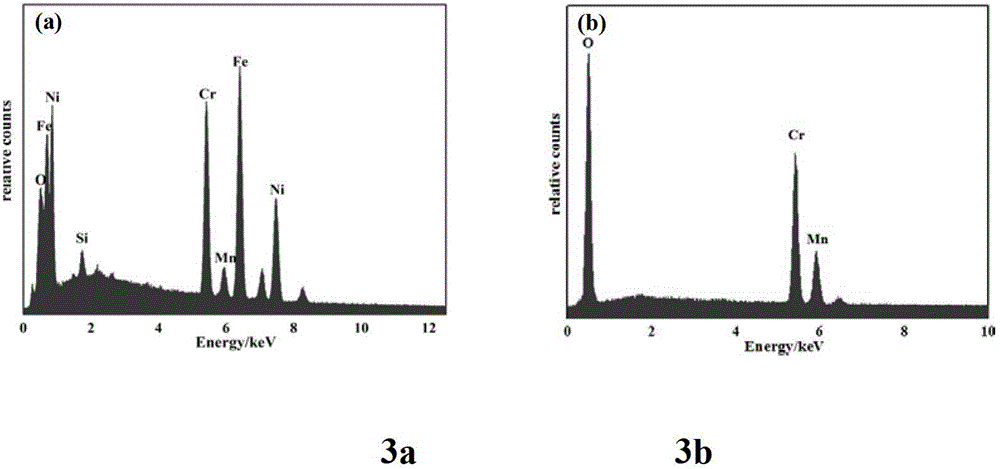

Preparation method forming protective film by alloy surface in-situ oxidation reaction

InactiveCN102719783AControl oxidation reactionSelf-healingSolid state diffusion coatingTectorial membraneSurface oxidation

The invention relates to a preparation method forming a protective film by an alloy surface in-situ oxidation reaction by means of precision control. The compact and stable oxide protective film of a three-layer structure is formed on the surfaces of materials by means of control of oxygen partial pressure and oxidation temperature in an oxidation atmosphere, and comprises a MnxCr3-xO4 (0.5< / =x< / =1.5) spinel layer, a chromic oxidation layer and a silicon oxidation layer from outside to inside, wherein the spinel layer mainly plays a role in protection, the chromic oxidation layer can provide Cr oxides for self repair of the spinel layer, and the silicon oxidation layer serves as a protective layer and a diffusion barrier for elements among substrates. The protective film can effectively inhibit surface oxidation, carburization or coking of the materials in service, and the service life or decoking period of the materials is prolonged.

Owner:EAST CHINA UNIV OF SCI & TECH

Nano polyester powder coating

InactiveCN1450133AGood weather resistanceRich and mysterious color effectPowdery paintsPolyester coatingsPolyesterUltraviolet

The composition of nano polyester powder coating material is composed of (wt%) 20-50% of unsaturated polyester resin, 2-5% of inorganic nano powder, 5-10% of solidifying agent, 30-50% of inorganic filling material and 0-10% of other adjuvant, in which the inorganic nano powder is titanium oxide, silicon oxide or zinc oxide, and said invented nano polyester coating layer has the advantages of goodlevelling property, uniform coating layer colour, strong resistance to UV-ray and long time for resisting ageing.

Owner:宁波市鄞州东海粉末涂料有限公司

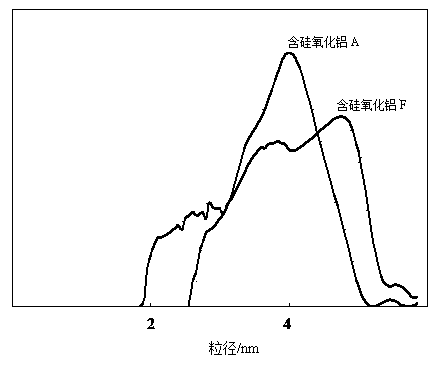

Preparation method of alumina dry glue containing silicon

ActiveCN103769232ASmall apertureUniform particle sizeCatalyst carriersHydrocarbon oils treatmentPtru catalystDry glue

The invention discloses a preparation method of an alumina dry glue containing silicon. The preparation method comprises the following steps: mixing original clay with a weak acid and a dispersant, then carrying out a hydrothermal treatment on the mixture so as to obtain modified clay; using an acidic solution containing aluminum and an alkaline solution containing aluminum to carry out a glue-forming reaction in the modified clay slurry by adopting a combined method of a pH swing method and a parallel-flow method, and after the glue-forming process, subjecting the glue-forming reaction product to processes of filtering, washing, and drying so as to obtain the alumina dry glue containing silicon. The alumina dry glue containing silicon has the advantages of uniform particle size, concentrated pore distribution, and proper acidity, and is especially suitable for being used to prepare a heavy oil or residual oil hydro-treatment catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

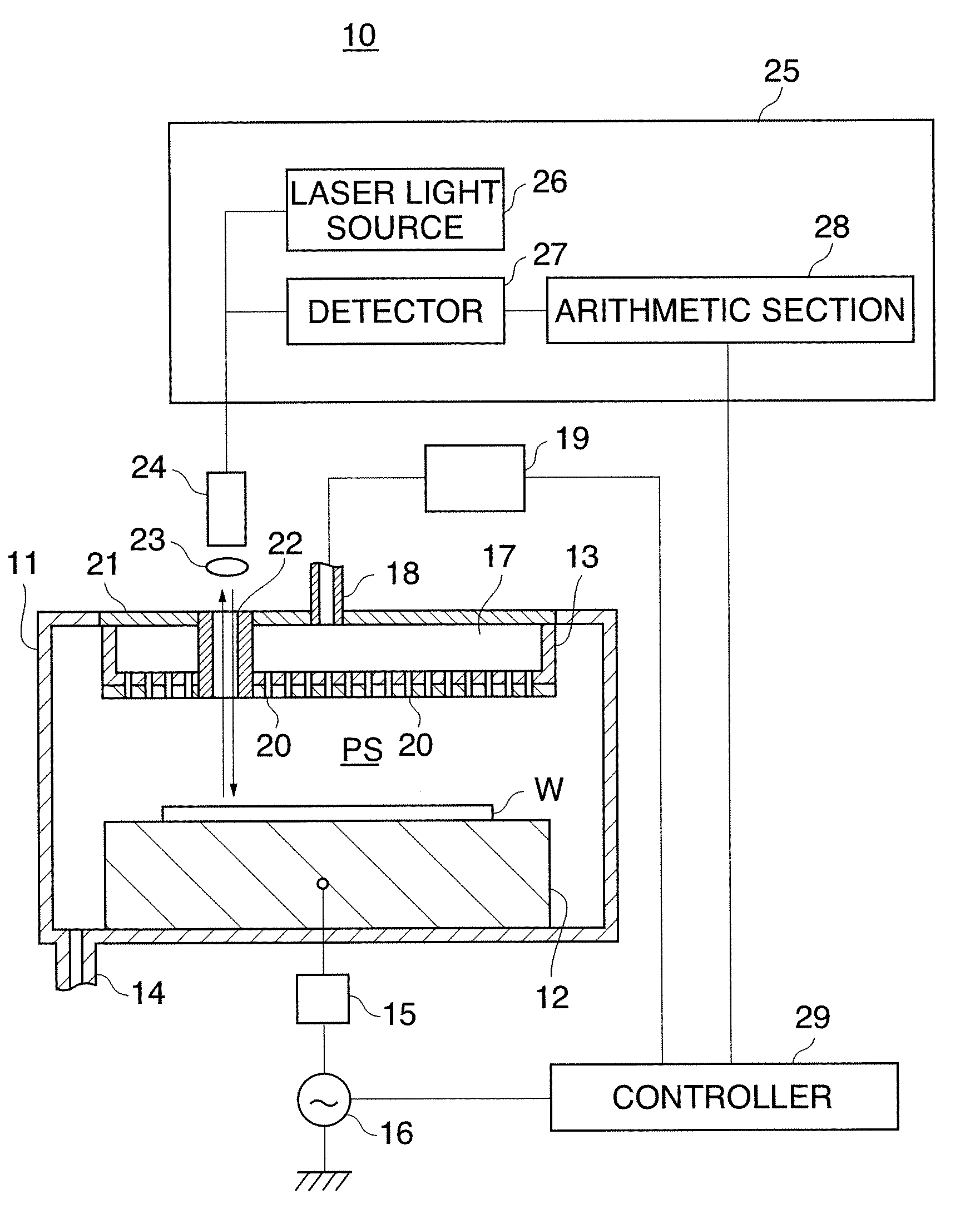

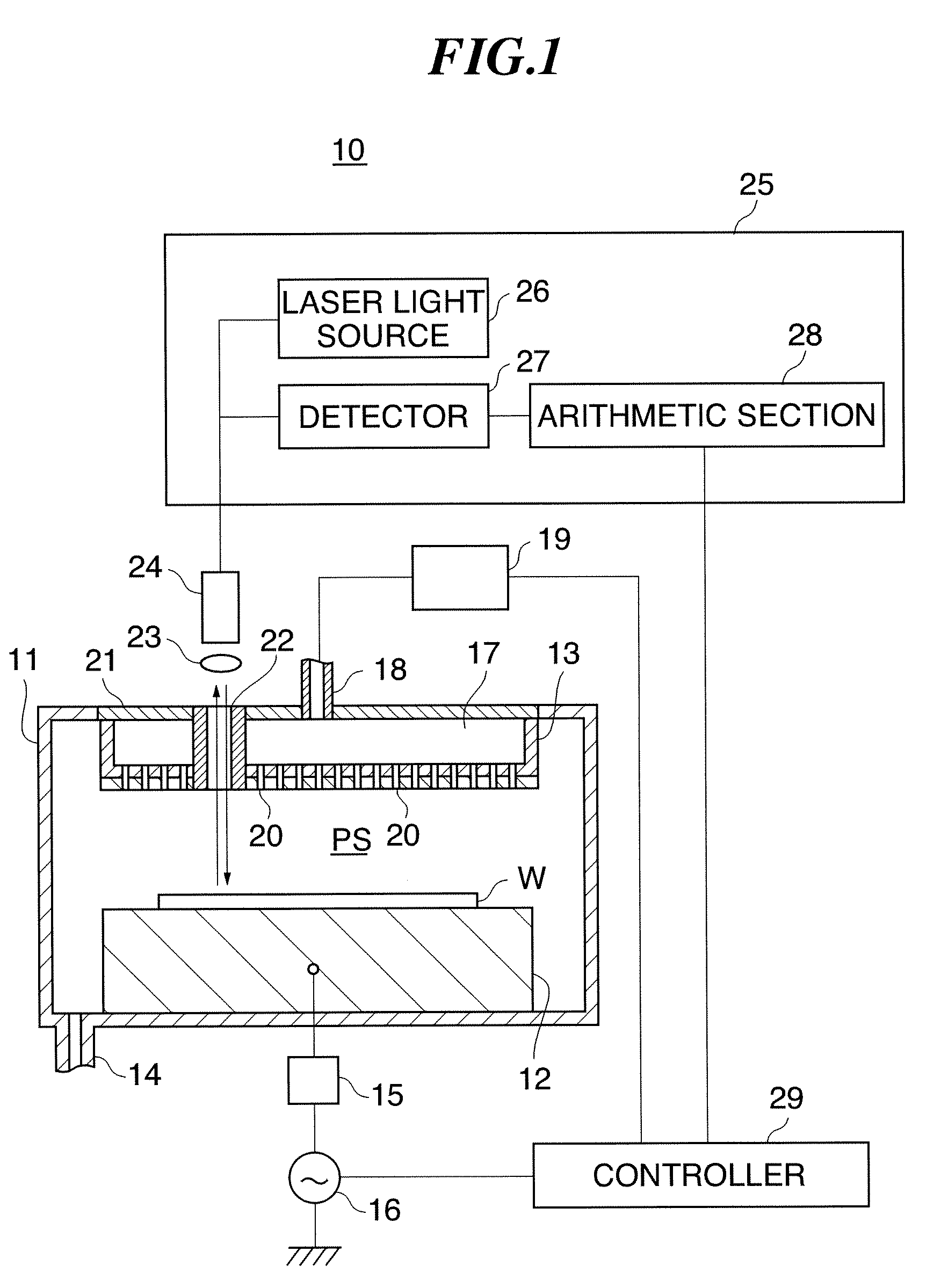

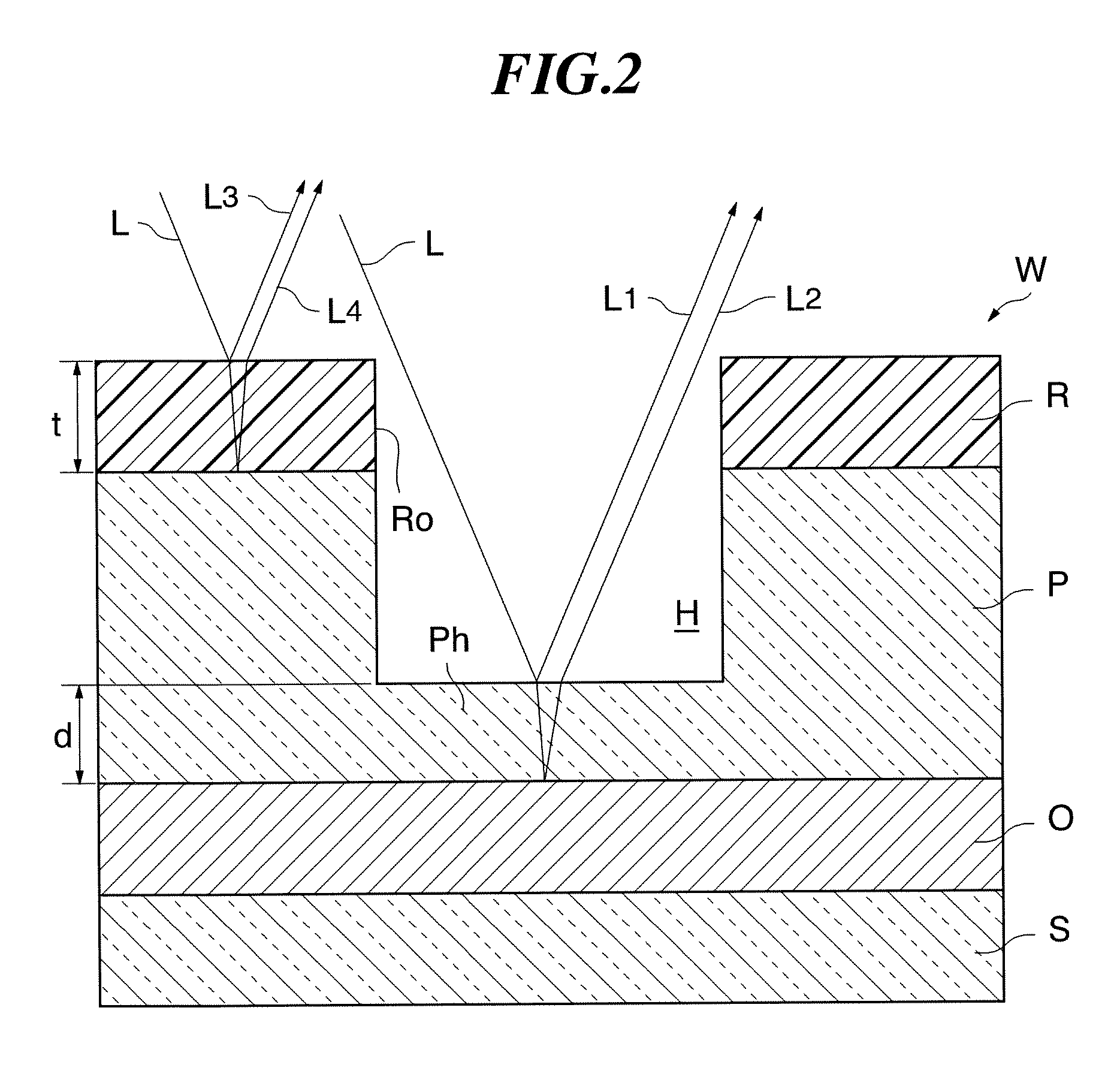

Processing termination detection method and apparatus

InactiveUS20080078948A1Precise processPrecise changeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSilicon oxideLaser light

A processing termination detection method capable of accurately performing changeover of etch rates when a residual film thickness of a to-be-processed layer decreases to a predetermined value. A substrate processing apparatus starts first etching to form a through-hole in a single crystal silicon layer of a wafer. A processing termination detection apparatus irradiates laser light comprised of red to near-infrared light onto the wafer and performs a frequency analysis of reflected light received from the wafer. When the intensity, represented in a result of the frequency analysis, in a frequency band corresponding to residual layer interference light has exceeded a threshold value, second etching is started to remove a through hole formation portion of the single crystal silicon layer to cause a silicon oxide layer to be exposed.

Owner:TOKYO ELECTRON LTD

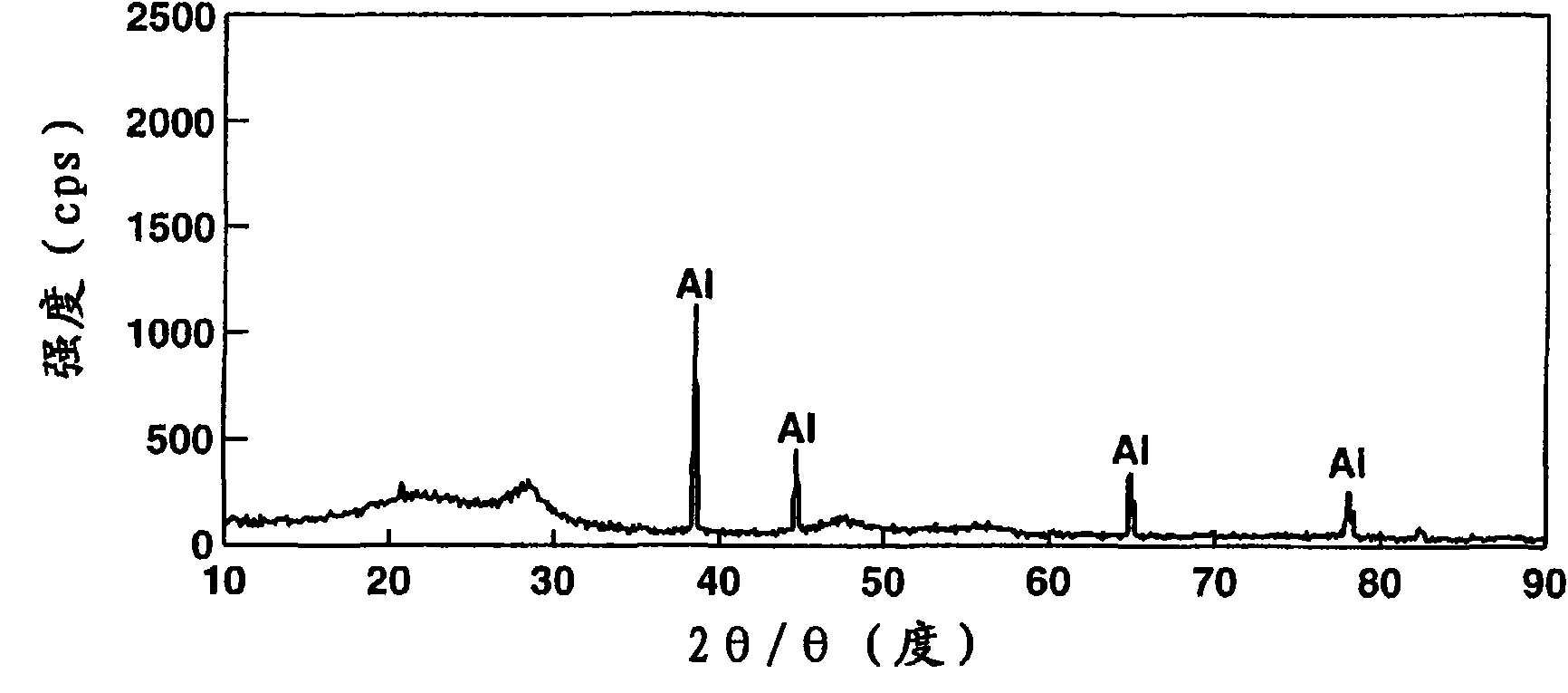

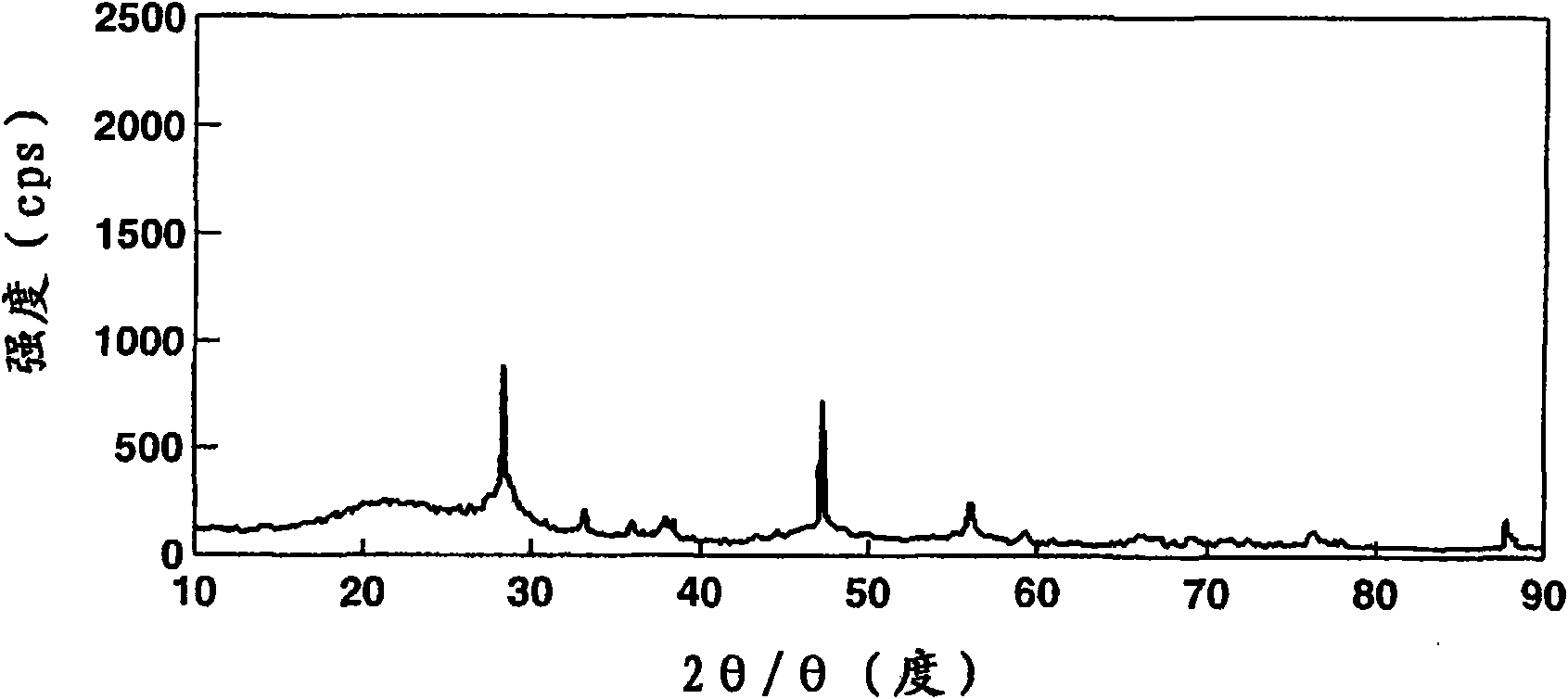

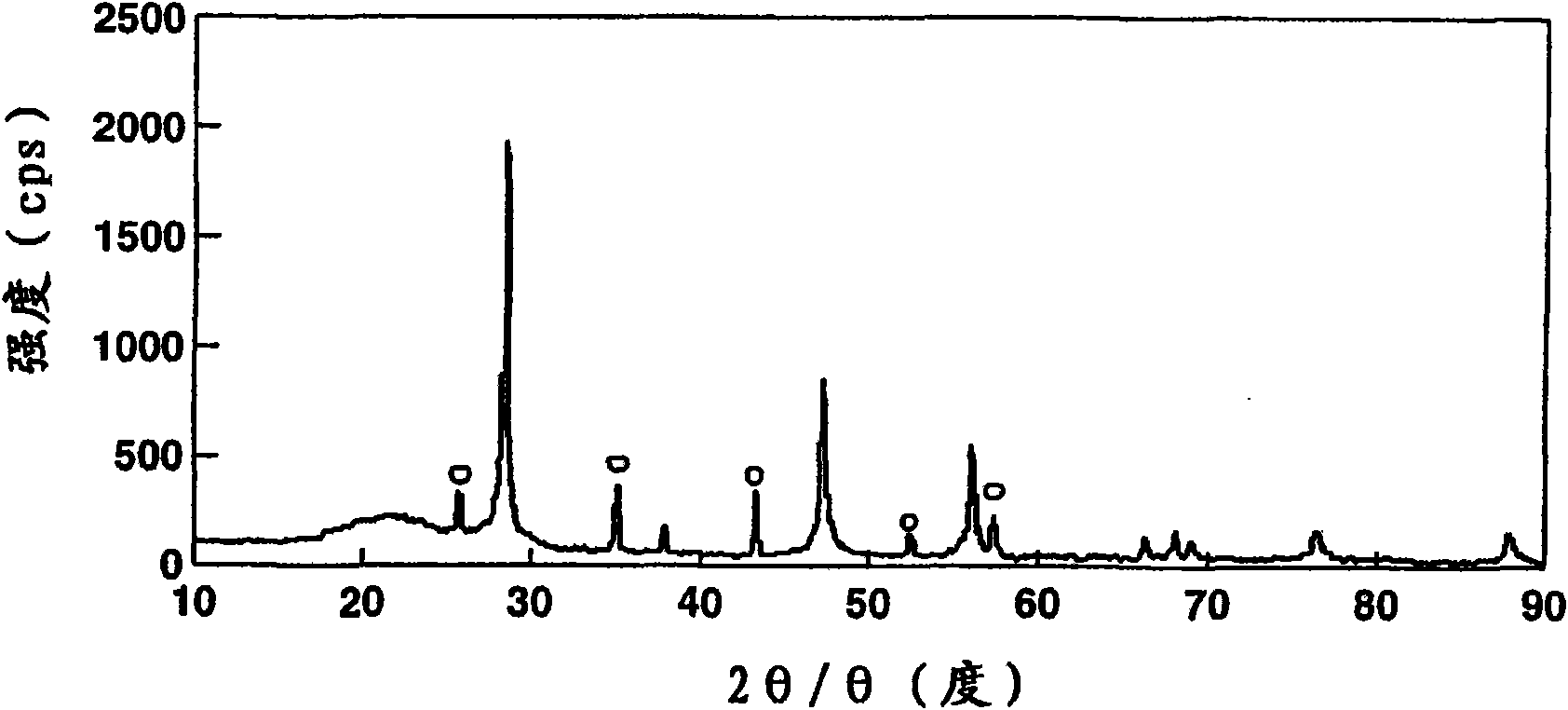

Non-aqueous electrolyte secondary battery, negative electrode, negative electrode material, and preparation of si-o-al composite

InactiveCN101662013AHigh 1st cycle charge/discharge efficiencyImprove cycle performanceElectrode manufacturing processesActive material electrodesDischarge efficiencyElectrical battery

The invention relates to a non-aqueous electrolyte secondary battery, a negative electrode, a negative electrode material and a preparation of Si-O-Al composite. An Si-O-Al composite comprising silicon, silicon oxide, and aluminum oxide exhibits a powder XRD spectrum in which the intensity of a signal of silicon at 28.3 DEG is 1-9 times the intensity of a signal near 21 DEG. A negative electrode material comprising the Si-O-Al composite is used to construct a non-aqueous electrolyte secondary battery which is improved in 1st cycle charge / discharge efficiency and cycle performance while maintaining the high battery capacity and low volume expansion upon charging of silicon oxide.

Owner:SHIN ETSU CHEM CO LTD

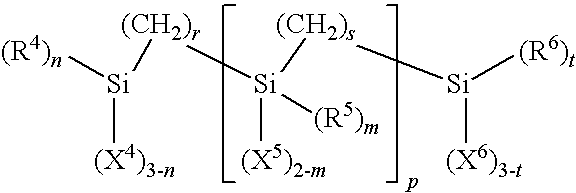

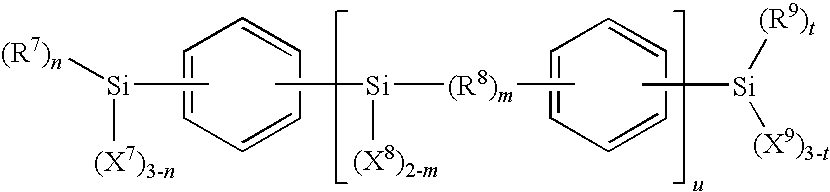

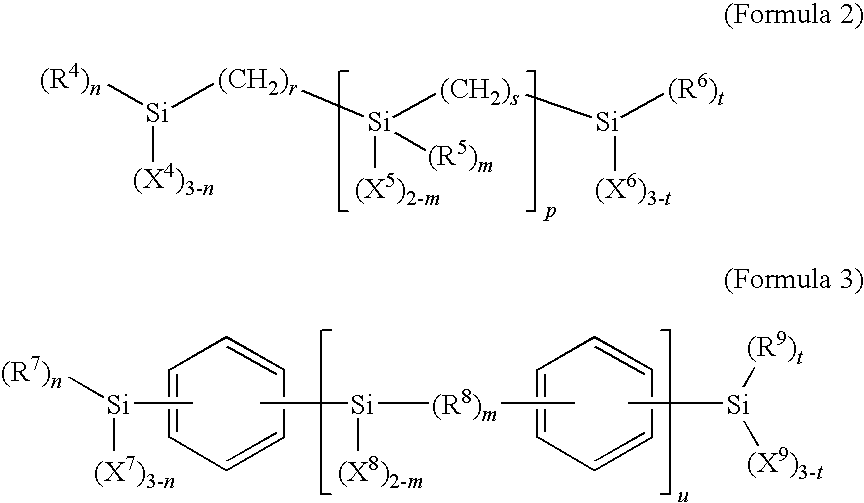

Organic silicon oxide core-shell particles and preparation method thereof, porous film-forming composition, porous film and formation method thereof, and semiconductor device

InactiveUS7754330B2Increasing the thicknessImprove reliabilityOther chemical processesElectric discharge tubesSilanesCarbon chain

Owner:SHIN ETSU CHEM CO LTD +1

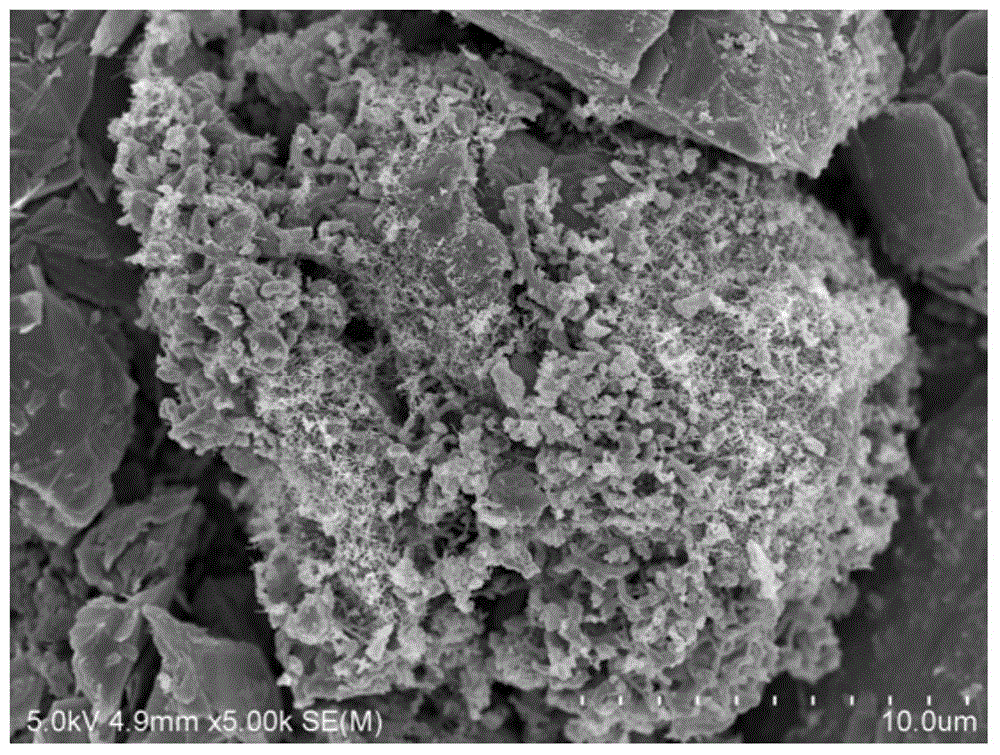

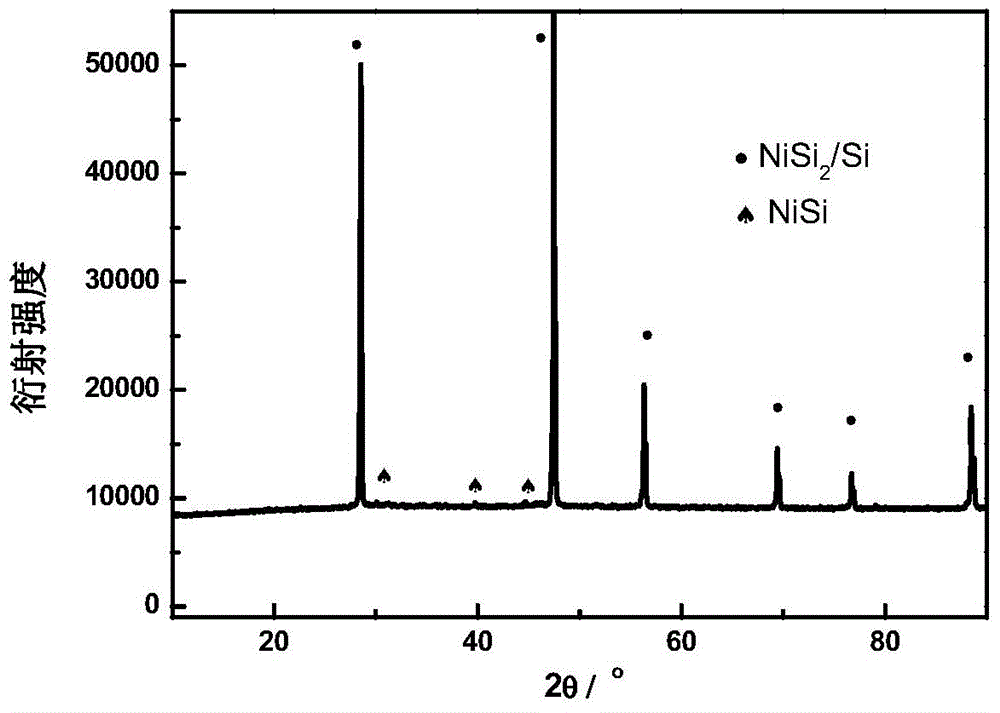

Nano silicon metal composite material and preparation method thereof

ActiveCN104617278AControl the degree of metallurgical bondingImprove electrochemical cycle stabilityMaterial nanotechnologyCell electrodesElectrolysisSilicon oxygen

A nano silicon metal composite used for a negative electrode of a lithium ion battery comprises the following parts: (a) the first component part is simple substance silicon with the content accounting for 5-75mol% of the nano silicon metal composite; (b) the second component part contains a metal element, a compound formed and a silicon oxygen compound formed by the metal element and silicon, the second component part content accounts for 25 to 95mol% of the nano silicon metal composite; and (c) the third component part is simple substance carbon with the content accounting for 0-70mol% of the nano silicon metal composite. The preparation method is as follows: a porous block, comprising silica and metal or metal oxide and the like, and a conductive negative electrode current collector are compounded as a negative electrode, graphite or an inert positive electrode is used as a positive electrode, the negative electrode and the positive electrode are placed in a mixed salt melt electrolyte using CaCl2 or CaCl2 as the main components, voltage is applied between the negative electrode and the positive electrode, current density and electrolytic quantity are controlled, silica in the porous block is electrolyzed and reduced into nano silicon, and a nano silicon metal composite material is prepared on the negative electrode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Preparation method and application of a compound carrier metal nanometer catalyst

InactiveCN101143326AHigh activityLarge specific surface areaCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsCyclohexanoneNano catalyst

The invention relates to a preparation method of composite carrier metal nanometer catalyst and the application. Copper is used as the main activity catalytic component; one or a plurality of the elements, cobalt, nickel, iron, cerium and lanthanum is / are used as an auxiliary activity catalytic component or components; alumina is used as the main carrier; one or a plurality of the compounds, magnesium oxide or magnesium nitrate, silica, calcium oxide or calcium nitrate, zirconia, molecular sieve is / are used as composite carrier or carriers. The composite carrier metal nanometer catalyst is prepared in the following procedures: 1.the preparation of the catalyst solution; 2. catalyst gel preparation; 3. extruded catalyst preparation. When applied in catalytic dehydrogenation method to prepare cyclohexanone, the catalyst of the invention has the advantages that: the roasted catalyst has greater specific surface area, thereby improving the activity of the catalyst; that high temperature activity and stability is greatly improved; that cyclohexanone yield reaches above 90 percent; that the conversion rate and the selectivity reaches the highest point reported in documents; and that the catalyst performs good effects in service life experiment.

Owner:HEBEI UNIVERSITY

Hydroprocessing catalyst and preparing method thereof

InactiveCN1488716AIncrease acidityImprove denitrification activityRefining to eliminate hetero atomsNano siliconHigh activity

The present invention discloses a hydrogenation treatment catalyst and its preparation method. It is applicable to hydrogenation treatment of heavy oil, specially hydrogenation treatment of heavy fraction. Said catalyst is prepared by loading molybdenum, nickel and phosphorus on silicon-contained aluminium oxide carrier prepared by adopting a special method, and said silicon-contained aluminium oxide carrier is prepared by adding nano silicon-containing compound, for example nano silicon dioxide. As compared with existent catalyst it has higher activity for hydrodesulfurization and hydro-denitrification.

Owner:CHINA PETROLEUM & CHEM CORP +1

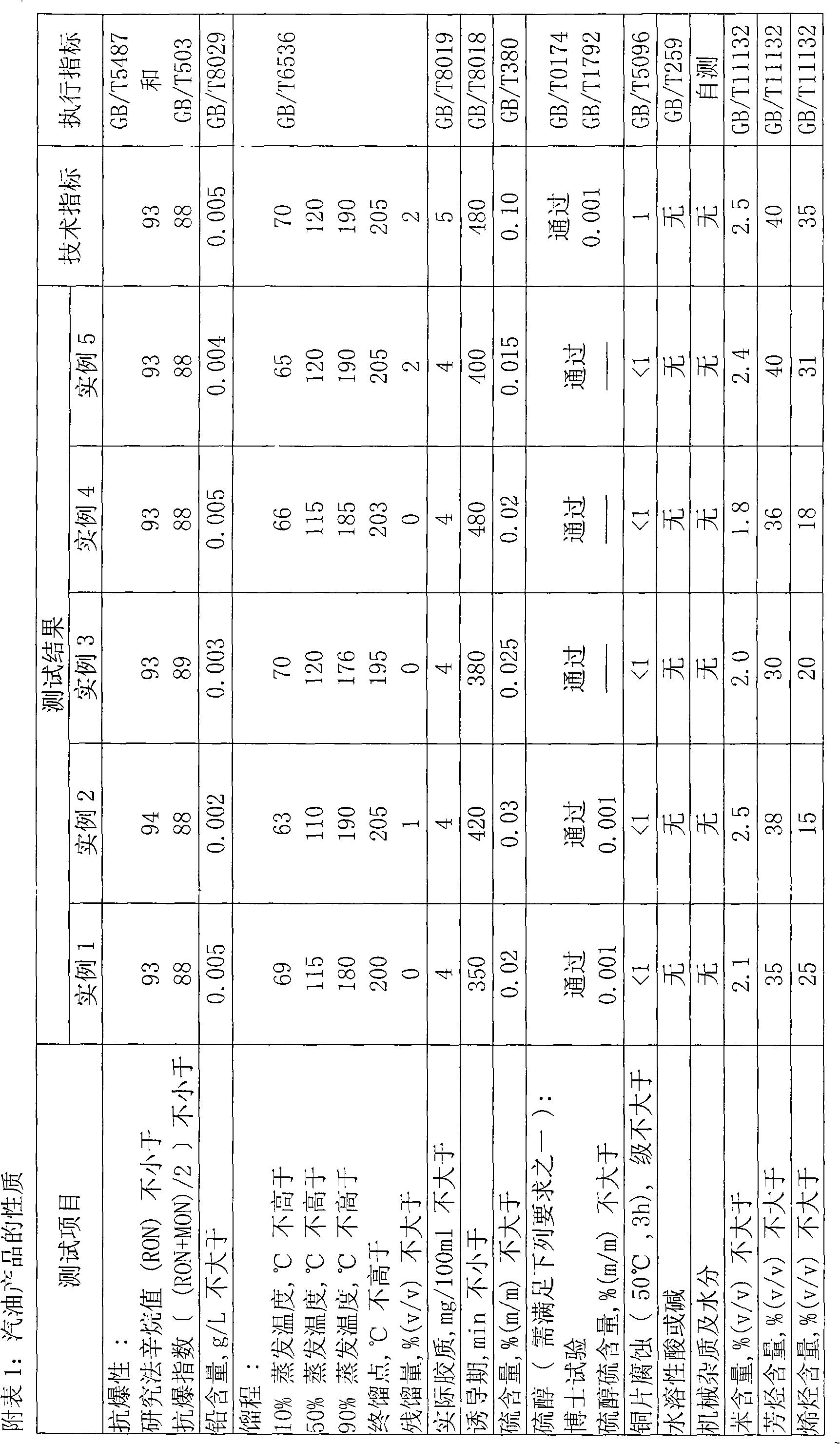

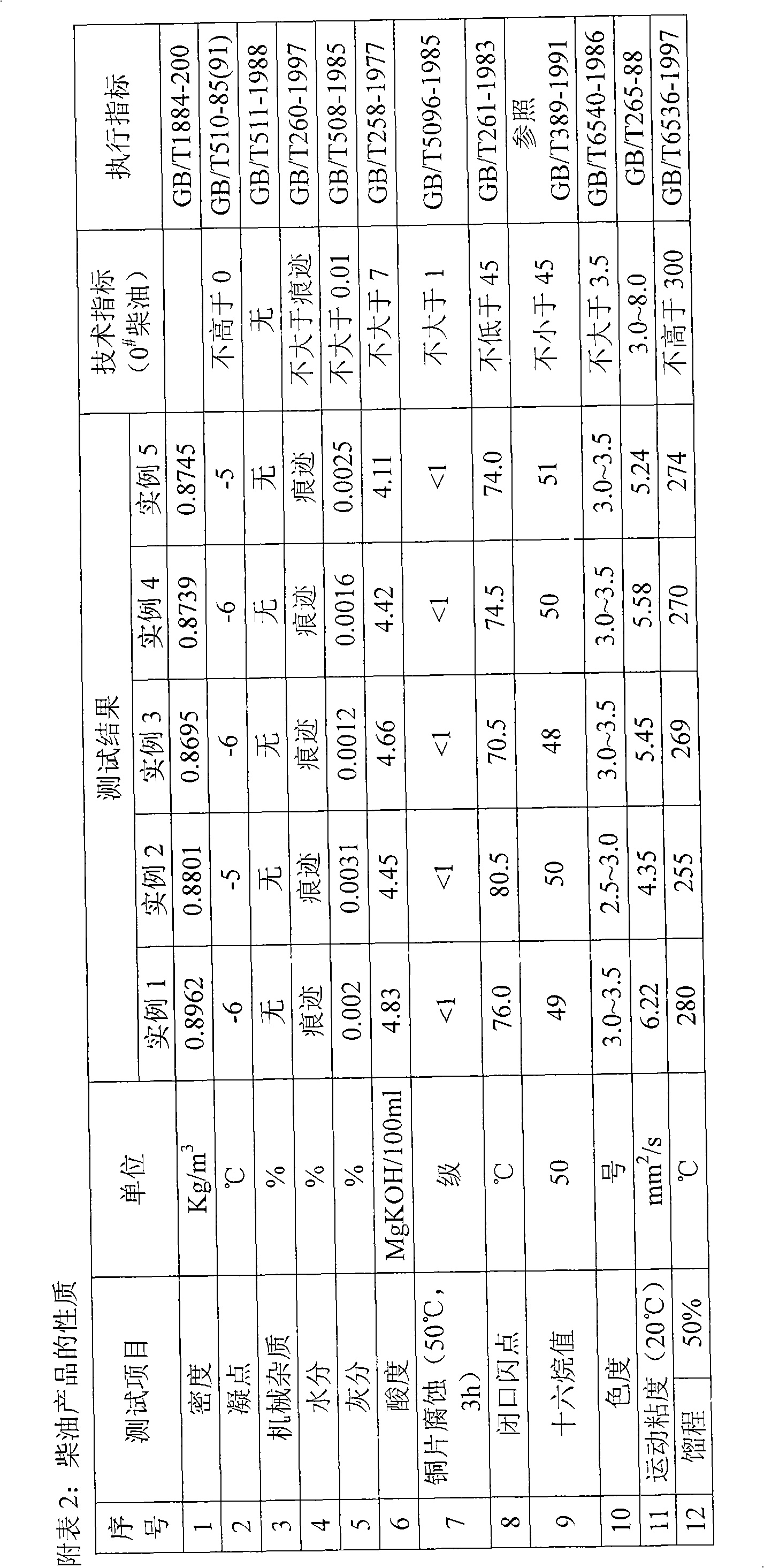

Catalyst for using coal tar to prepare clean fuel oil by catalytic hydrogenation, preparation method and applications

InactiveCN101574659AHigh activityHigh selectivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFuel oilSilicon oxide

The invention relates to a catalyst for using coal tar to prepare clean fuel oil by catalytic hydrogenation, comprising the following components in percentage by mass: 4 to 15 percent of molybdenum oxide, 3 to 9 percent of nickel oxide, 0.1 to 5 percent of cobalt oxide, 10 to 25 percent of tungsten oxide, 2.5 to 40 percent of silicon oxide and 26 to 65 percent of aluminium oxide. The preparation method of the catalyst comprises the following steps of: firstly, preparing a silicon oxide-aluminium oxide carrier, loading active components of Co, Mo, Ni and W on the carrier by an isosteric dipping method, drying, baking and forming. The catalyst can be used for the preparation of the clean fuel oil by catalytic hydrogenation of the coal tar, gasoline and diesel oil obtained from the prepared fuel oil after being separated respectively meet the national standard of 93# gasoline and 0# diesel oil.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

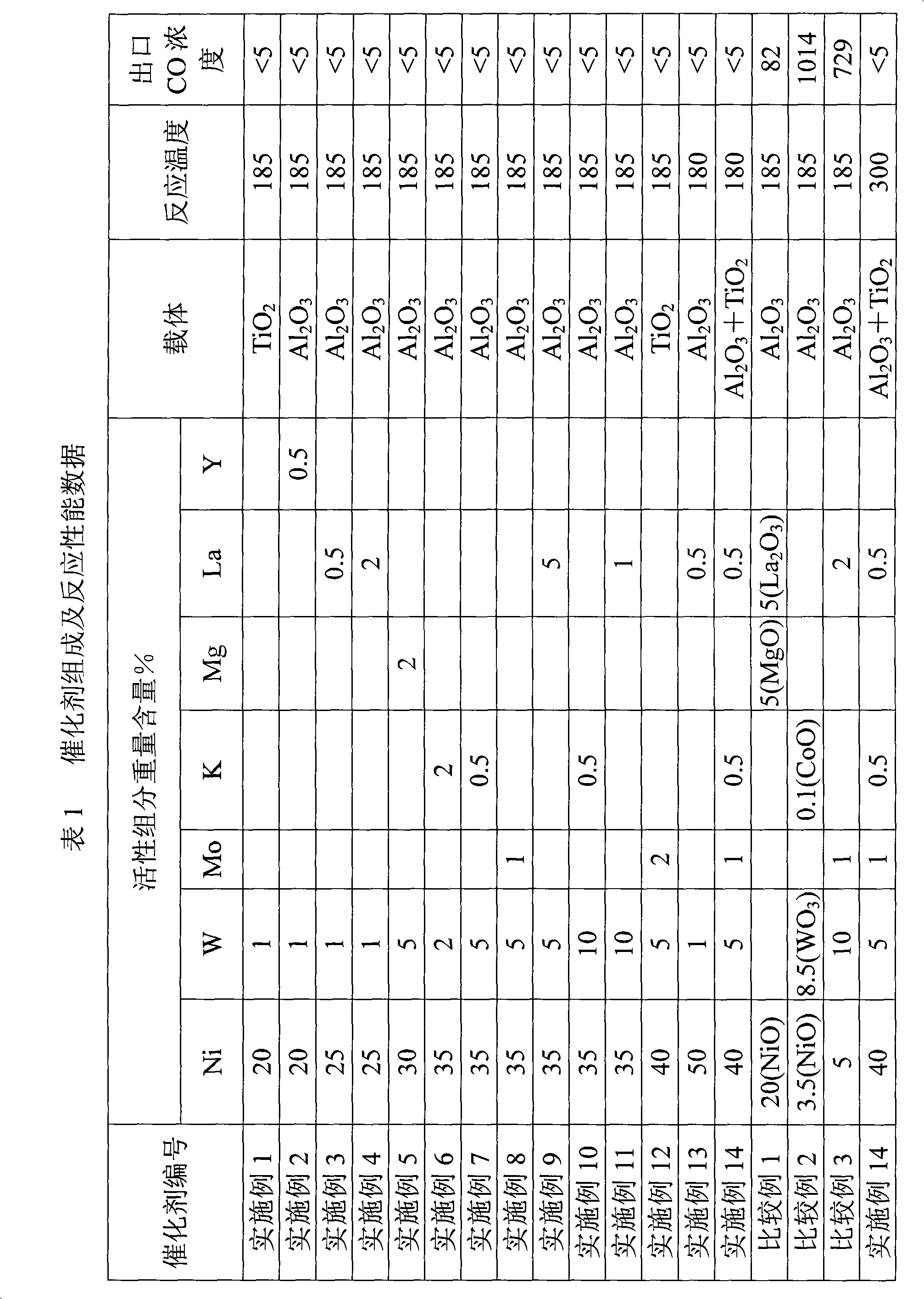

Methanation catalyst for removing trace amounts of oxycarbide

ActiveCN101347735AImprove anti-toxic performanceImprove thermal stabilityHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationAlkali metal oxide

The invention discloses a methanation catalyst of carbon oxides containing nickel, the methanation catalyst contains active components of a) nickel oxide, b) tungsten oxide and / or molybdenum oxide, and c) at least one active component which is selected from alkali metal oxides, alkaline earth metal oxides and rare earth metal oxides which are loaded on a carrier of the oxides, and the carrier of the oxides is aluminium oxide, silicon oxide, titanium oxide, zirconium oxide or the mixture thereof. The catalyst of the invention has very high activity at low temperature, high anti-poisoning capacity and thermal stability and broad application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com