Nano silicon metal composite material and preparation method thereof

A metal composite material, nano-silicon technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult process control, difficult mass production, complex process, etc. Simple, easy to operate, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the nano-silicon-metal composite material provided by the invention comprises the following steps:

[0037] 1. The porous block composed of metal, metal oxide and silicon dioxide is combined with a conductive cathode current collector as the cathode, graphite or an inert anode as the anode, placed at a certain temperature with CaCl 2 or as CaCl 2 In the main mixed salt melt electrolyte, a voltage is applied between the cathode and the anode, and the electrolysis power is used as a means of controlling the end of the electrolysis process, so that the silicon dioxide in the porous block is electrolytically reduced to nano-silicon, and nano-silicon metal is produced at the cathode composite material. The electrolysis time is when the electrolysis power reaches the theoretical required power and above. The theoretical required electricity is the electricity calculated based on the electrons consumed by SiO2 into simple Si, which changes with the ...

Embodiment 1

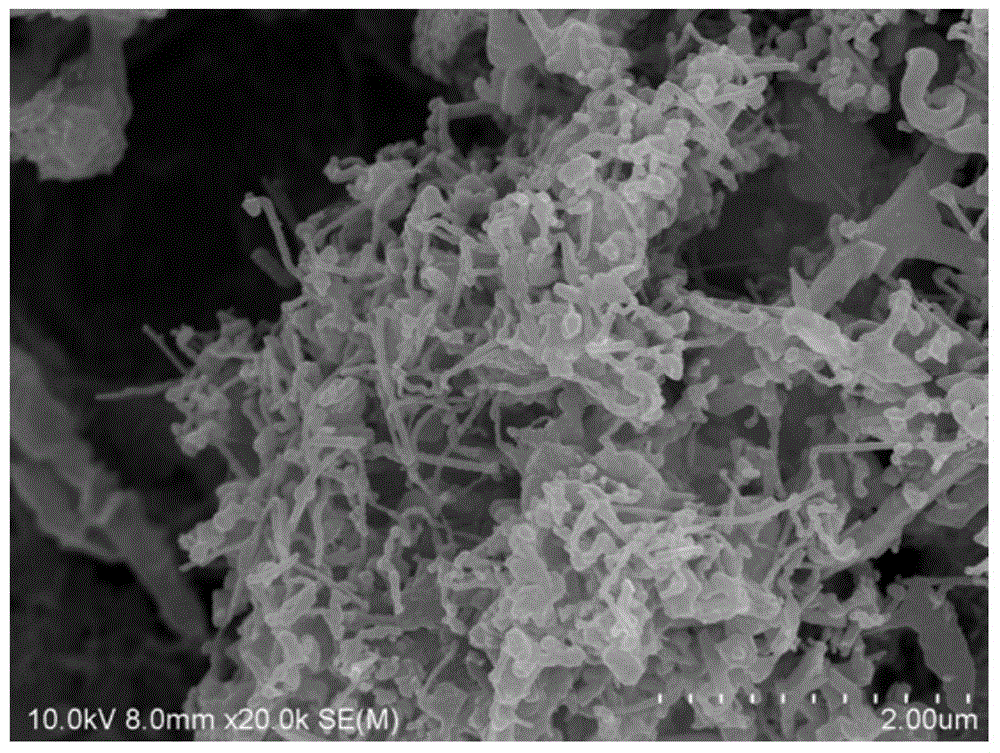

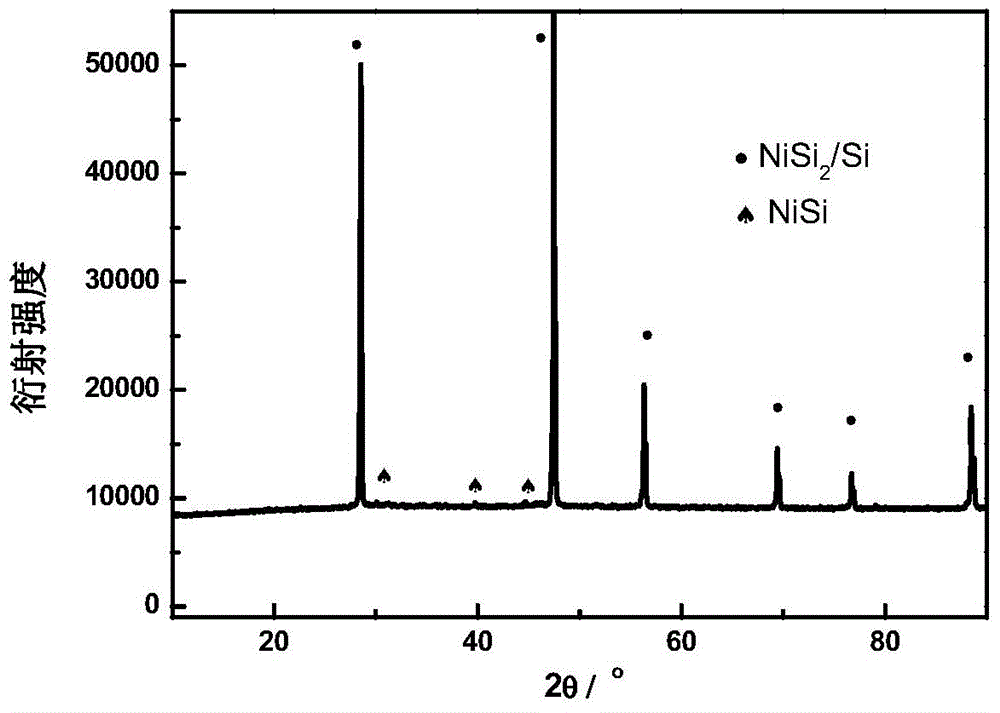

[0052] 60mol% of nano-SiO with a purity of 99.95wt% 2 The powder is stirred with water to form colloidal silica, the mass ratio of water to SiO2 is 2:1, and 30mol% of commercially available spherical nickel powder with a diameter of 2-10μm and 10mol% of commercially available nickel oxide with a purity of 98wt% are added In the colloid, a high-speed mechanical fusion is added to make the silica evenly coated on the metal nickel to form a mixture, and then the mixture is made into a block green body, and the block green body forms a porous block under a certain mechanical pressure or a certain temperature , the mechanical pressure of the porous block is 14MPa, the temperature of the porous block is 900°C, the porosity of the obtained porous block is 30% by volume, and the density is 1.3g / cm 3 , the conductivity is 0.8Ω·cm, the porous block is combined with the conductive cathode current collector as the cathode, the graphite rod is used as the anode, and the CaCl 2 As an elect...

Embodiment 2

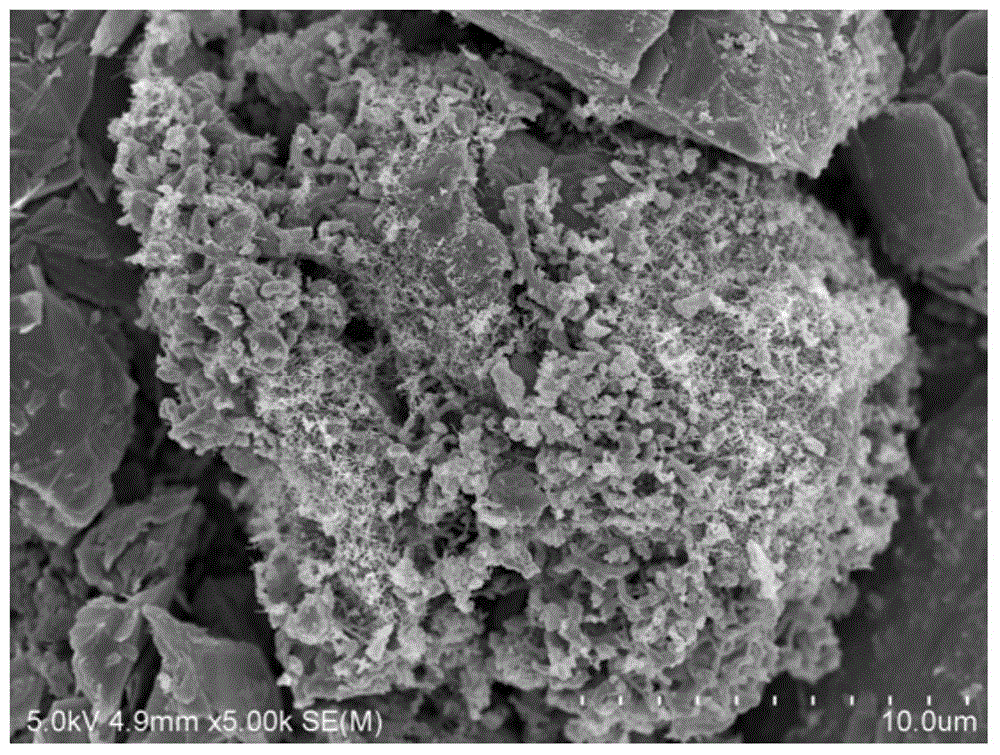

[0055] 60mol% of nano-SiO with a purity of 99.95wt% 2 The powder is stirred with water to form colloidal silica, the mass ratio of water to SiO2 is 2:1, 20mol% of commercially available spherical nickel powder with a diameter of 2-10μm and 20mol% of commercially available nickel oxide with a purity of 98wt% Add it to the colloid, and combine it with high-speed machinery, so that the silicon dioxide is uniformly coated on the metal nickel to form a mixture, and then the mixture is made into a block green body, and the block green body forms a porous block under a certain mechanical pressure or a certain temperature The mechanical pressure of the porous block is 14MPa, the temperature of the porous block is 900°C, the porosity of the obtained porous block is 23% by volume, and the density is 1.4g / cm 3 , the electrical conductivity is 1.2Ω2 cm, the porous block is combined with the conductive cathode current collector as the cathode, the graphite rod is used as the anode, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com