N-Fe2O3/nitrogen-sulfur double-doped graphene composite electrode material and preparation method thereof

A graphene composite and electrode material technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as hindering the development of electrode materials, poor cycle stability, etc., achieving a simple and pollution-free synthesis process and improving stability. , the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

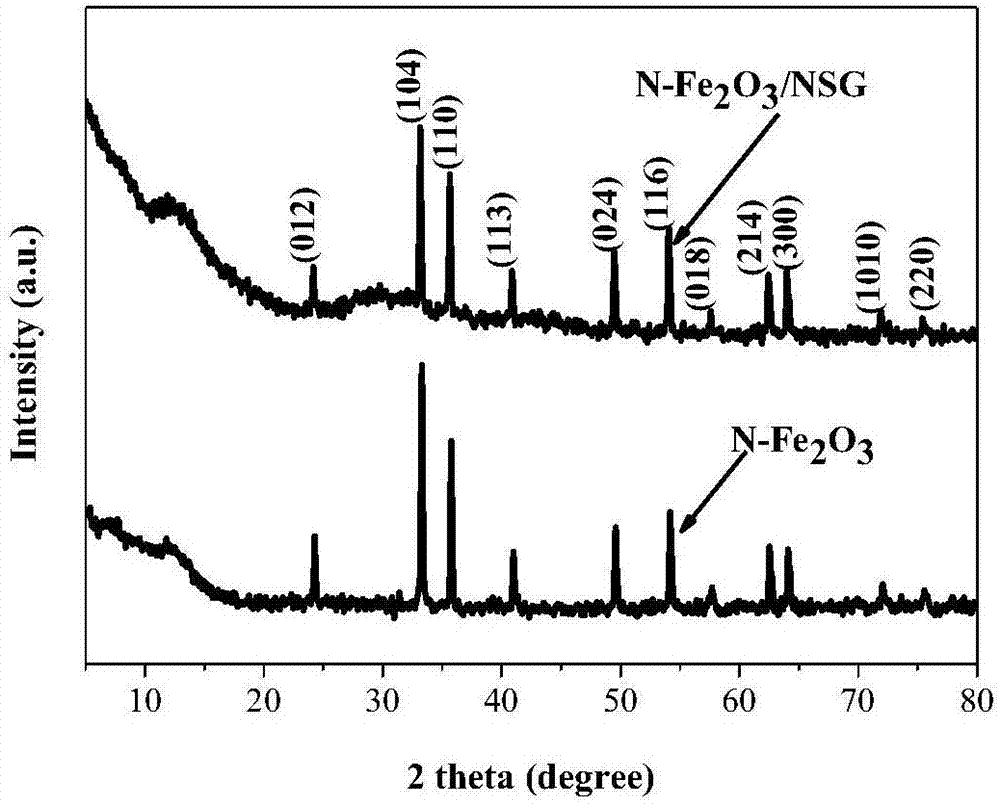

[0032] Weigh 1.6159g Fe(NO 3 ) 3 9H 2 O (0.004mol), 0.9134g NH 4 SCN (0.012mol) was ultrasonically dispersed in 70mL of a mixed solution of absolute ethanol and ethylene glycol (2:1 volume ratio), ultrasonically dispersed for 1h, and the mixed solution was transferred to a 100mL hydrothermal kettle, and reacted at 180°C for 24h. After the reaction was completed, it was naturally cooled to room temperature, washed with anhydrous ethanol and deionized water alternately for ten times, then dried in a vacuum oven at 60°C for 12 hours, and ground to obtain N-Fe 2 o 3 Nanoparticles. The samples have X-ray diffraction peaks at 2θ of 24.15°, 33.16°, 35.63°, 40.82°, 49.46°, 54.07°, 57.60°, 62.44°, 64.00°, 71.95° and 75.46°, which can be compared with Fe 2 o 3 (012), (104), (110), (113), (024), (116), (018), (214), (300), (1010) and (220) crystal planes and standard spectra of crystals corresponding, such as figure 1 , the diffraction peaks in the figure are the characteristic d...

Embodiment 2

[0034] Weigh 90mg graphene oxide, 0.9134g NH 4 SCN (0.012mol) was ultrasonically dispersed in 70mL of a mixed solution of absolute ethanol and ethylene glycol (2:1 volume ratio), ultrasonically dispersed for 1h, and the mixed solution was transferred to a 100mL hydrothermal kettle, and reacted at 180°C for 24h. After the reaction was completed, it was naturally cooled to room temperature, washed with absolute ethanol and deionized water by centrifugation for ten times, and then dried in a vacuum oven at 60° C. for 12 hours to obtain nitrogen-sulfur double-doped graphene. Nitrogen-sulfur double-doped graphene has a large specific surface area. The doping of nitrogen and sulfur activates the adjacent carbon atoms, increases the number of active sites, and facilitates the reaction between electrolyte ions and active materials. The nitrogen-sulfur double-doped graphene material prepared above was subjected to charge and discharge experiments, and the current density was 1Ag -1 , ...

example 3

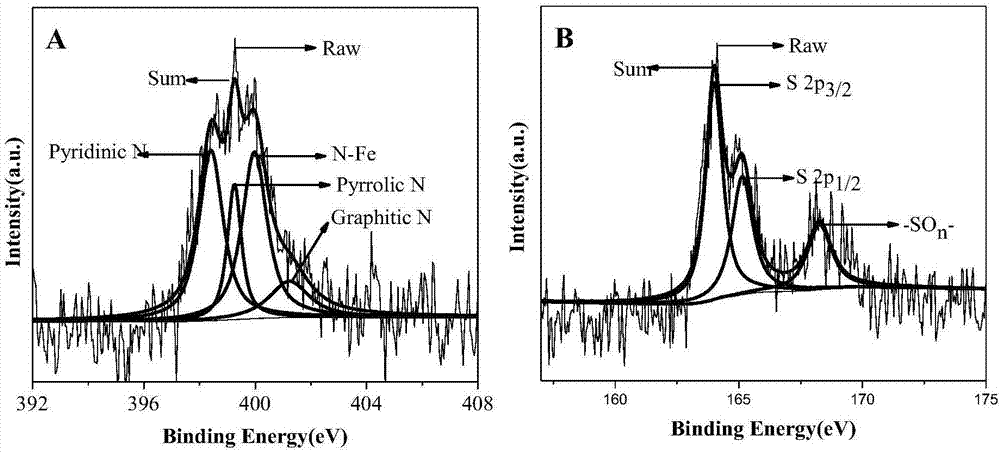

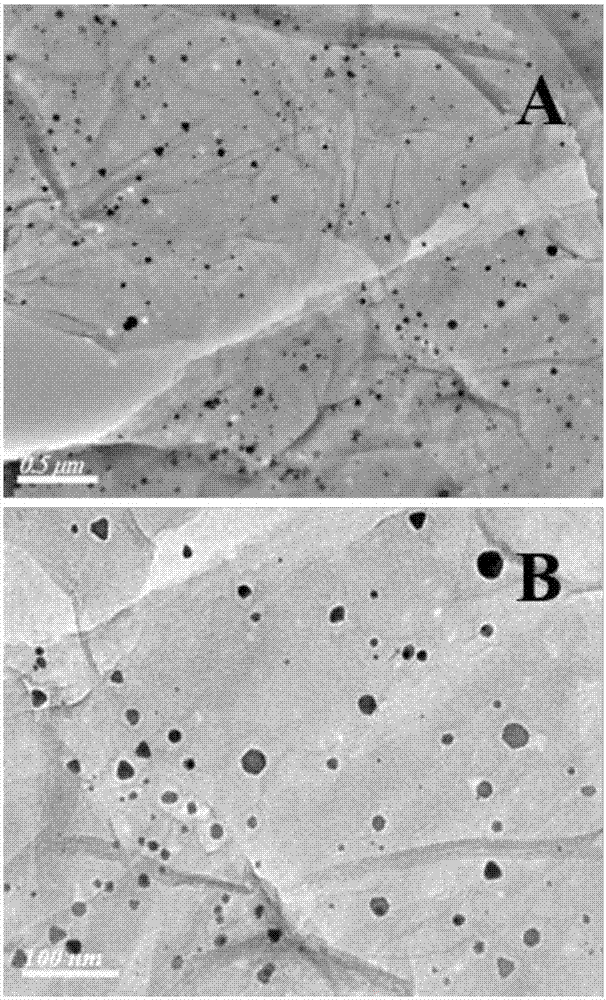

[0036] Weigh 90mg graphene oxide, 1.6159g Fe(NO 3 ) 3 9H 2 O (0.004mol), 1.8269g NH 4 SCN (0.024mol) was ultrasonically dispersed in 70mL of a mixed solution of absolute ethanol and ethylene glycol (volume ratio 0.5:1), ultrasonically dispersed for 1h, and the mixed solution was transferred to a 100mL hydrothermal kettle, and reacted at 180°C for 24h. After the reaction was completed, it was naturally cooled to room temperature, washed with absolute ethanol and deionized water alternately for ten times, and then dried in a vacuum oven at 60°C for 12 hours to obtain N-Fe 2 o 3 / Three-dimensional nitrogen-sulfur double-doped graphene. The product is analyzed by X-ray photoelectron spectroscopy (XPS). Nitrogen exists in the form of graphite nitrogen, pyridine nitrogen, pyrrole nitrogen and N-Fe, and sulfur exists in the form of S 2p 3 / 2 , S 2p 1 / 2 and-SO n - forms exist, indicating successful doping of nitrogen atoms to Fe 2 o 3 On the lattice surface of graphene, nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com