Preparation of room temperature formaldehyde catalyst

A catalyst and formaldehyde technology, applied in the direction of catalyst carrier, molecular sieve catalyst, physical/chemical process catalyst, etc., can solve the problems of unfavorable commercial application, high price, cumbersome catalyst preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Vector preparation

[0021] Accurately weigh 51 g of silicon oxide, 35 g of aluminum oxide and 14 g of magnesium oxide, mix and stir evenly, and add 10 g of kaolin, 1.0 g of carboxymethyl cellulose, 0.5 ml of paraffin oil and a certain amount of water, stir to form a slurry, squeeze Pressed into a honeycomb shape, aged for 24 h, 80 o C, 4h dry, 1350 o C, 4h high-temperature calcination to obtain cordierite honeycomb carrier;

[0022] (2) Carrier modification treatment

[0023] The above-mentioned honeycomb cordierite carrier was immersed in a solution containing 10% nitric acid for 2 hours, and after taking it out, it was washed for 60 o C, 2h to dry.

[0024] (3) Preparation of catalyst

[0025] According to the water absorption of the carrier, prepare a mixed solution of manganese nitrate and lanthanum nitrate with a certain concentration, soak the above carrier in the solution for 4 hours, take it out, dry it naturally, and mix with 80 o C, 2h dry, with 500...

Embodiment 2

[0027] (4) Vector preparation

[0028] Accurately weigh 51 g of silicon oxide, 35 g of aluminum oxide and 14 g of magnesium oxide, mix and stir evenly, and add 10 g of kaolin, 1.0 g of carboxymethyl cellulose, 0.5 ml of paraffin oil and a certain amount of water, stir to form a slurry, squeeze Pressed into a honeycomb shape, aged for 24 h, 80 o C, 4h dry, 1350 o C, 4h high-temperature calcination to obtain cordierite honeycomb carrier;

[0029] (5) Carrier modification treatment

[0030] The above-mentioned honeycomb cordierite carrier was immersed in a solution containing 10% nitric acid for 6 hours, and after taking it out, it was subjected to 100o C, 1h to dry.

[0031] (6) Preparation of catalyst

[0032] According to the water absorption rate of the carrier, prepare a mixed solution of tetraethyl orthosilicate and nickel nitrate with a certain concentration, soak the above carrier in the solution for 6 hours, take it out, dry it naturally, and mix it with 100 o C, 1h...

Embodiment 3

[0034] (1) Vector preparation

[0035] Accurately weigh 100 g of zeolite powder, add 20 g of kaolin, 1.5 g of carboxymethyl cellulose, 0.5 ml of paraffin oil and a certain amount of water, mix and stir evenly into mud, extrude into strips, and age for 24 h. 80 o C, 4h dry, 500 o C, 4h high temperature roasting;

[0036] (2) Carrier modification treatment

[0037] The above-mentioned strip-shaped zeolite carrier was immersed in 10% hydrogen peroxide solution for 4 hours, and after taking it out, it was heated at 80 o C, 2h to dry;

[0038] (3) Preparation of catalyst

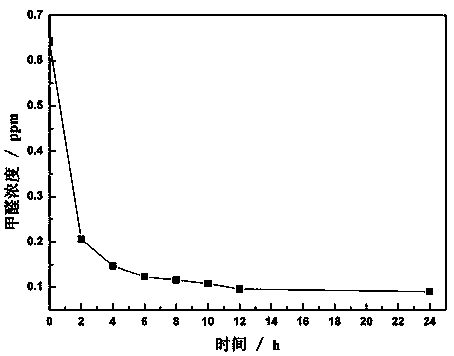

[0039] According to the water absorption rate of the carrier, prepare a mixed solution of copper nitrate and ferric nitrate with a certain concentration, soak the above carrier in the solution for 2 hours, take it out, dry it naturally, and mix with 60 o C, 2h dry, with 350 o C, 2h calcination in air atmosphere to produce CuO-FeO x / Zeolite catalyst. The metal oxide loading of the catalyst is 15.0 wt%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com