A silicon-based negative electrode material for a secondary battery, a method for preparing the same, and the secondary battery

A silicon-based negative electrode material and secondary battery technology, which is applied in secondary batteries, battery electrodes, electrode manufacturing, etc., can solve the problems of poor safety performance of lithium supplementation process, reduced electrode cycle life, and low initial Coulombic efficiency, etc., to achieve improved Effects of fast charging ability, enhanced electron mobility rate, and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

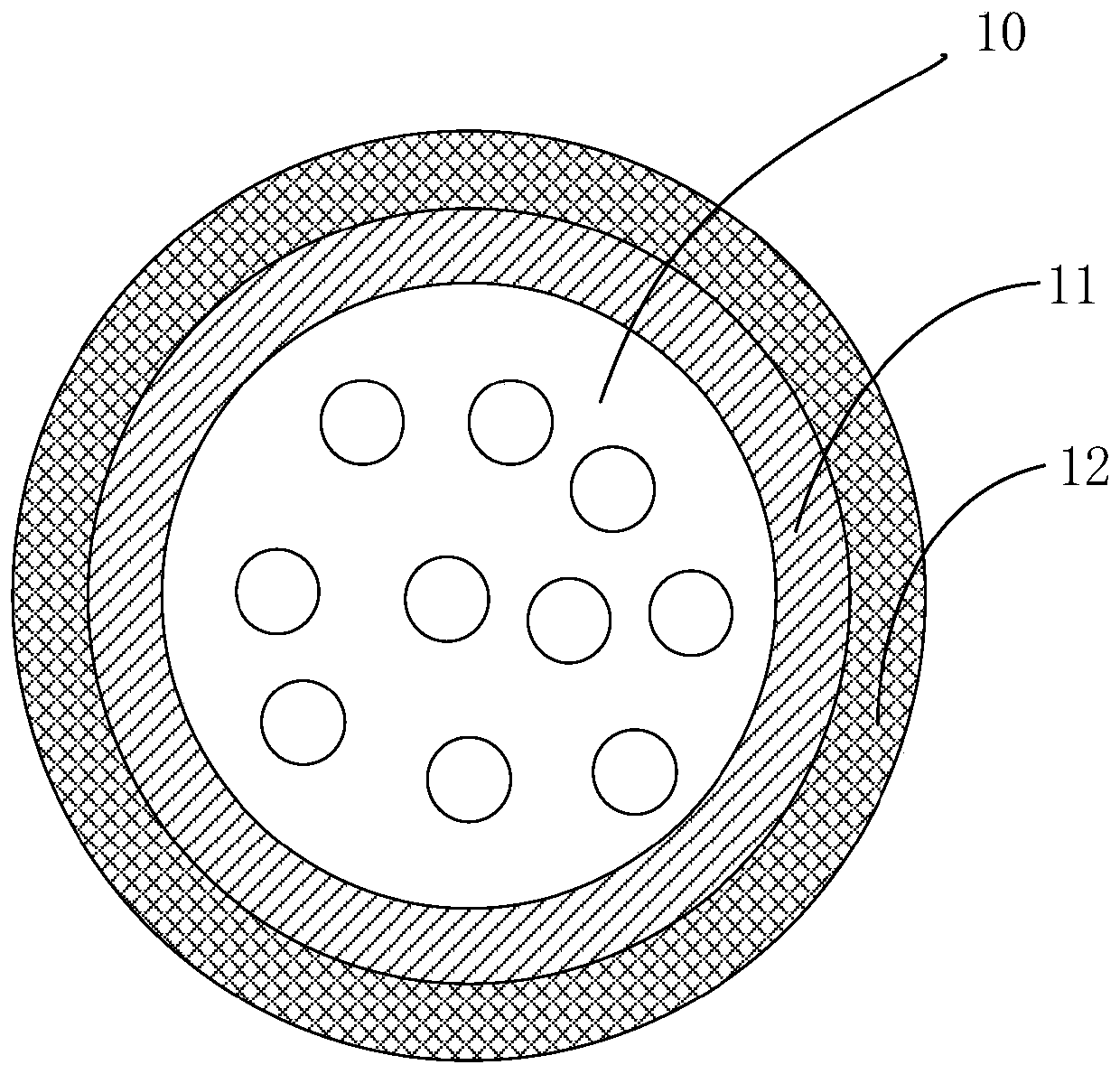

[0056] Another aspect of the present application provides a method for preparing a silicon-based negative electrode material for a secondary battery, comprising:

[0057] Step S1, preparing a first mixture, said first mixture including silicon oxygen raw material SiOx, metal source material and carbon source material (wherein 0<x<2);

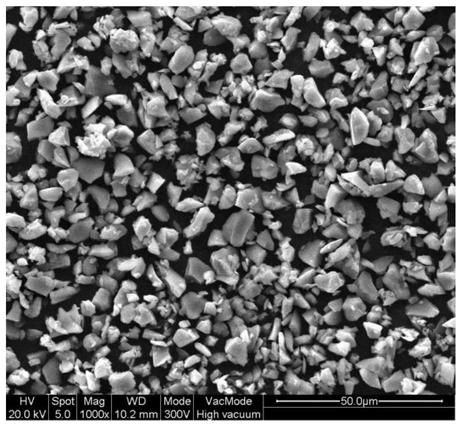

[0058] Wherein, the silicon-oxygen raw material SiOx is a powder with a median particle diameter D50 of 1-10 μm, and the method for forming the silicon-oxygen raw material SiOx powder is, for example, to obtain SiOx powder by coarsely crushing and pulverizing bulk SiOx. The primary crushing includes using a jaw crusher, a pair of roller crushers, a cone crusher, a hammer crusher or an impact crusher to perform primary crushing on the massive SiOx. The crushing includes further crushing the coarsely crushed SiOx by using any one of a jet mill, a mechanical mill, a ball mill or a vibration mill, so as to obtain a powder with a median particle size...

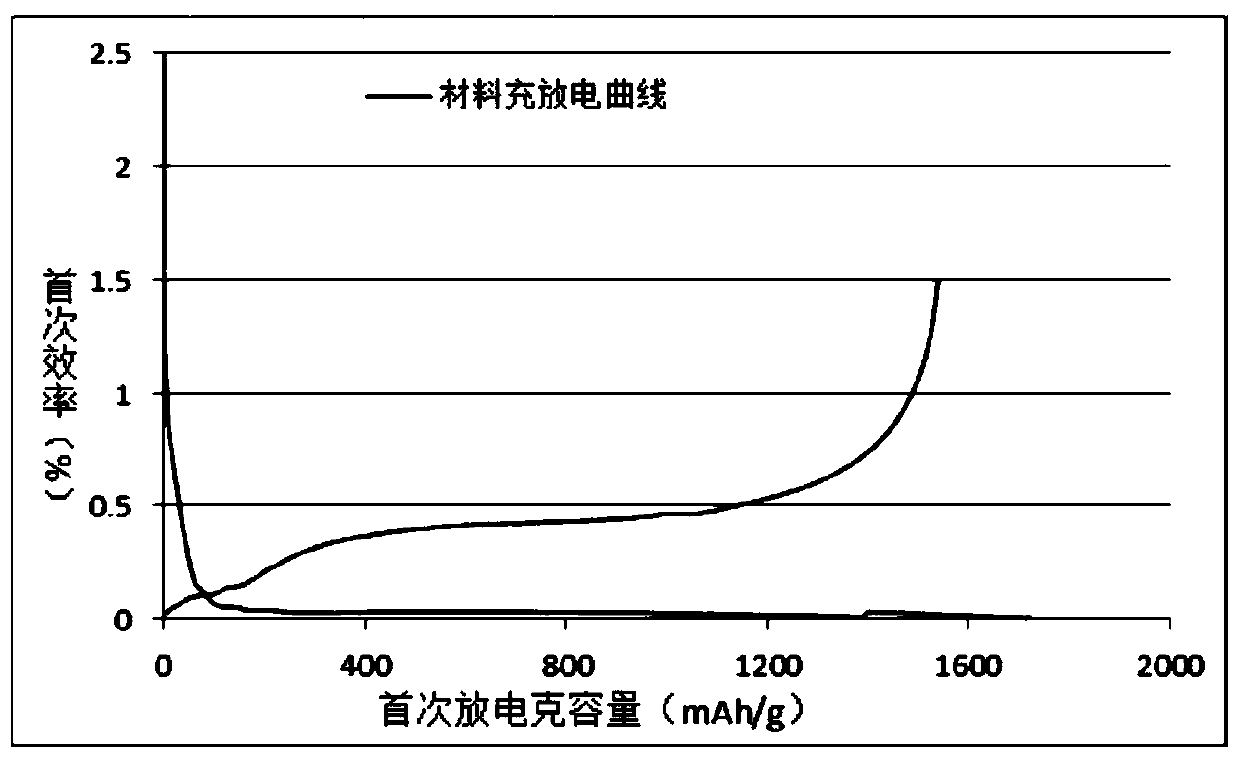

Embodiment 1

[0075] The bulk SiOx (x=0.9) is coarsely crushed by a roller crusher, and the coarsely crushed raw material is pulverized by a jet mill to obtain a SiOx powder with a particle diameter D50 of 5 μm, and the SiOx powder is mixed with carbonic acid Lithium and citric acid are thoroughly mixed in a high-speed stirring mill to prepare a first mixture comprising lithium carbonate, citric acid and SiOx. Wherein, the quality of the silicon oxygen raw material SiOx is 1Kg, the quality of the lithium carbonate is 476.8g, and the quality of the citric acid is 5g.

[0076] The first mixture is calcined by a rotary kiln in an argon atmosphere, the calcination temperature is 750°C, and the reaction time is 12h, to obtain the inner core including SiOx 1 and Si particles, the first shell consists of Li 2 SiO 3 and the first product of the C particle.

[0077] The first product is passed through a pitch doped with conductive graphite for a coating reaction in a coating kettle. The coating r...

Embodiment 2

[0080] The bulk SiOx (x=0.9) is coarsely crushed by a roller crusher, and the coarsely crushed raw material is pulverized by a jet mill to obtain a SiOx powder with a particle diameter D50 of 5 μm, and the SiOx powder is mixed with carbonic acid Lithium and citric acid are thoroughly mixed in a high-speed stirring mill to prepare a first mixture comprising lithium carbonate, citric acid and SiOx. Wherein, the quality of the silicon oxygen raw material SiOx is 1Kg, the quality of the lithium citrate is 286.1g, and the quality of the citric acid is 5g.

[0081] The first mixture is calcined by a rotary kiln in an argon atmosphere, the calcination temperature is 750°C, and the reaction time is 12h, to obtain the inner core including SiOx 1 and Si particles, the first shell consists of Li 2 SiO 3 and the first product of the C particle.

[0082] The first product is coated with pitch doped with conductive graphite in a coating kettle, the coating reaction is carried out in an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com