Methanation catalyst for removing trace amounts of oxycarbide

A methanation catalyst and carbon oxide technology are applied in the field of catalysts for methanation reaction of carbon oxides and the field of preparation thereof, which can solve the problems of not mentioning hydrotreating catalysts and the like, and achieve high anti-poisoning ability and thermal stability, Effects of high and low temperature activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

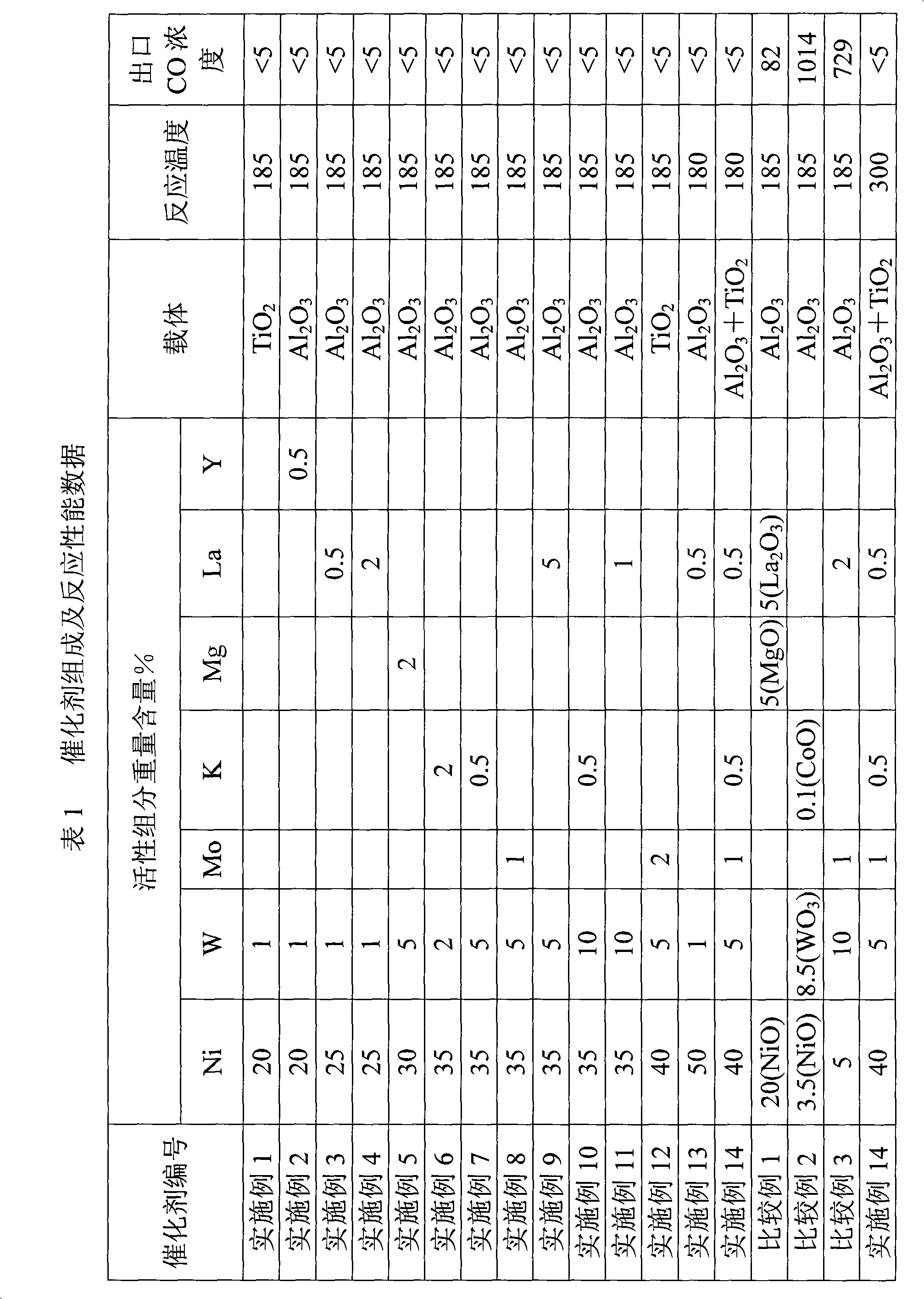

Examples

Embodiment 1

[0043] Example 1 Ni-W / TiO 2

[0044] Weigh the titanium dioxide (TiO 2 ) 100 grams of carrier, denoted as A.

[0045] 125 grams of nickel nitrate [Ni(NO 3 ) 2 ·6H 2 O], 1.7 grams of ammonium metatungstate [(NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O] Dissolved with deionized water to form a 200ml mixed aqueous solution, dipped into A. Bake at 110°C for 5 hours to obtain B.

[0046] Decompose B in an air atmosphere at 300° C. and 450° C. for 2 hours each by using a temperature-programmed heating decomposition method to obtain a catalyst containing 20% by weight of nickel and 1.0% by weight of tungsten.

Embodiment 2

[0047] Embodiment 2Ni-W-Y / Al 2 o 3

[0048] Weigh the alumina (γ-Al 2 o 3 ) 100 grams of carrier, denoted as A.

[0049] 126 grams of nickel nitrate [Ni(NO 3 ) 2 ·6H 2 O], 1.7 grams of ammonium metatungstate [(NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O] and 2.7 g of yttrium nitrate [YNO 3 ·6H 2 O] Dissolved with deionized water and configured to form a 200ml mixed aqueous solution, and dipped it into A. Bake at 110°C for 5 hours to obtain B.

[0050] Decompose B in an air atmosphere at 300° C. and 450° C. for 2 hours each by temperature-programmed thermal decomposition method to obtain a catalyst containing 20% by weight of nickel, 1.0% by weight of tungsten, and 0.5% by weight of yttrium.

Embodiment 3

[0051] Embodiment 3Ni-W-La / Al 2 o 3

[0052] Weigh the alumina (γ-Al 2 o 3 ) 100 grams of carrier, denoted as A.

[0053] 169 grams of nickel nitrate [Ni(NO 3 ) 2 ·6H 2 O], 1.8 grams of ammonium metatungstate [(NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O] and 2.1 grams of lanthanum nitrate [La(NO 3 ) 3 ·6H 2 O] Dissolved with deionized water and configured as a 200ml mixed aqueous solution, impregnated on the calcined carrier A.

[0054] The steps of drying and roasting are the same as in Example 2, and the obtained catalyst (weight %) contains 25% nickel, 1.0% tungsten, and 0.5% lanthanum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com