Palladium/nitrogen-doped titanium dioxide electrocatalyst as well as preparation method and application thereof

A titanium dioxide and electrocatalyst technology, applied in the field of electrochemistry, can solve the problems of reducing the amount of Pd, expensive metal Pd, etc., and achieve the effect of improving the activity, optimizing the electronic structure of Pd, and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of Pd / N-TiO 2 electrocatalyst

[0029] (1) Weigh 3g of titanium nitride and 4.2g of sodium tetrachloropalladate in a crucible, place it in the center of the muffle furnace (without a cover), raise it to the set temperature at 2°C / min, and calcinate at 450°C 2h, naturally cool down to room temperature after processing;

[0030] (2) Disperse the composite material obtained in step (1) in a 2g / L NaCl solution, and conduct electroreduction at -8mA for 2h to obtain Pd / N-TiO 2 electrocatalyst.

[0031] In Example 1, TiN generates N-TiO during the calcination process 2 Support, electroreduction of sodium tetrachloropalladate to Pd nanoparticles supported on N-TiO 2 On the support, Pd nanoparticles and N-TiO 2 The mass ratio of the carrier is 0.2:1.

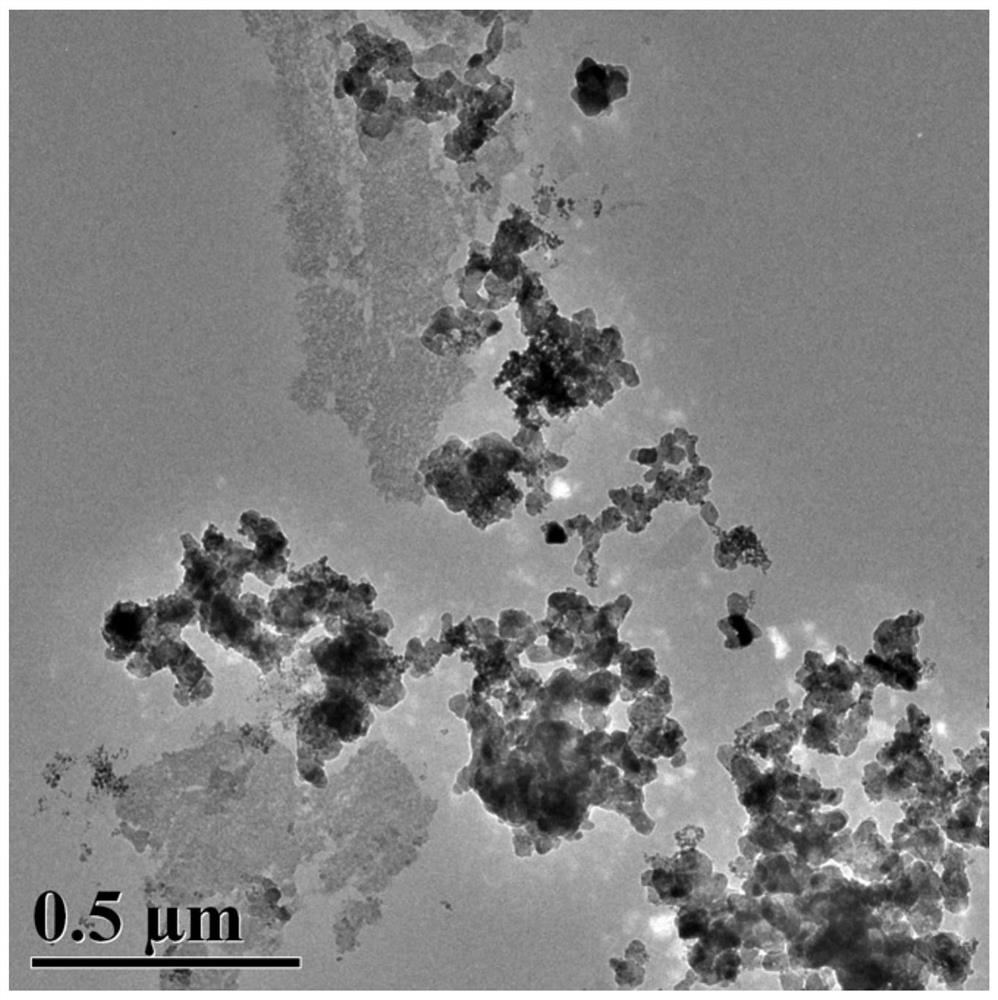

[0032] figure 1 For the Pd / N-TiO prepared in Example 1 2 TEM image of electrocatalyst, TEM image shows that Pd nanoparticles can be uniformly supported on N-TiO 2 , and the particle size of Pd na...

Embodiment 2

[0033] Embodiment 2: Preparation of Pd / N-TiO 2 electrocatalyst electrode

[0034] (1) Cut 3*3cm 2 Then cut off 2cm of copper glue, fold it in half, stick it on the edges of both sides of the carbon paper, and leave a length of 0.5cm, and apply silicone on the area of carbon paper with copper glue on it. The silicone smearing area is 3 *1cm 2 , with a thickness of 1mm;

[0035] (2) Weigh 8 mg of Pd / N-TiO prepared in Example 1 2 Electrocatalyst and 8mg carbon powder, mixed with 0.4mL isopropanol and 3.6mL ethanol solution, added 40uL Nafion as a binder, and ultrasonically dispersed the mixture; pipette the suspension and drop it slowly onto the carbon paper at a uniform speed On the blank area (that is, the area without copper glue and silica gel), it is necessary to wait for the last applied liquid to evaporate completely before each drop coating; after the drop coating is completed, dry it to get Pd / N-TiO 2 electrocatalyst electrodes.

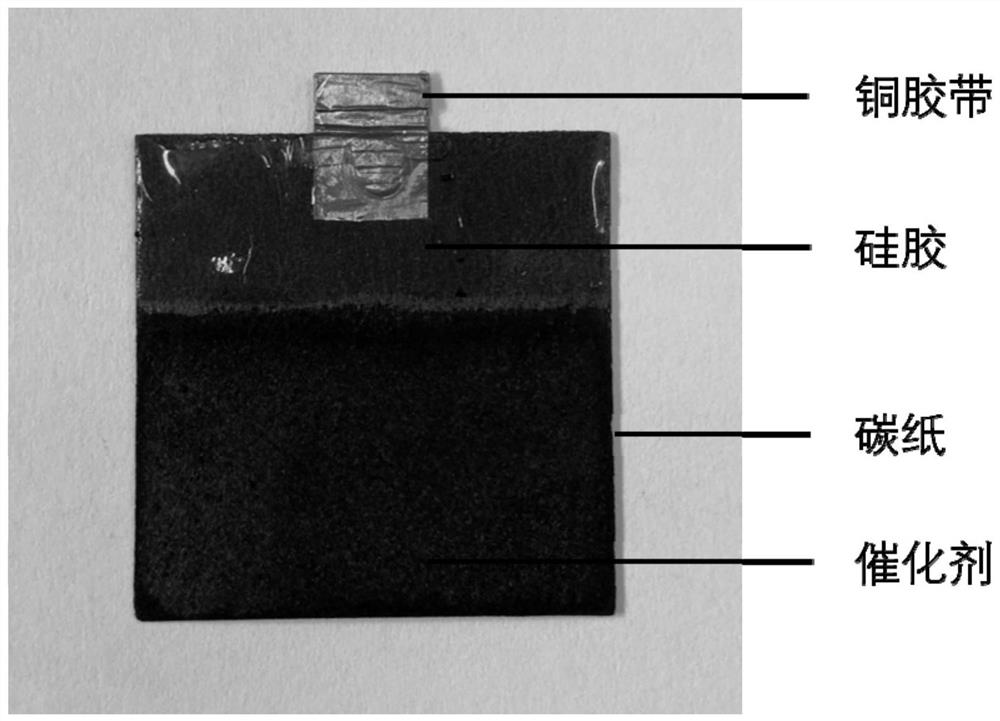

[0036] figure 2 For the Pd / N-T...

Embodiment 3

[0037] Embodiment 3: use the Pd / N-TiO prepared in embodiment 2 2 Electrocatalyst electrode, to investigate its dechlorination effect on the pollutant 2,4-dichlorophenol

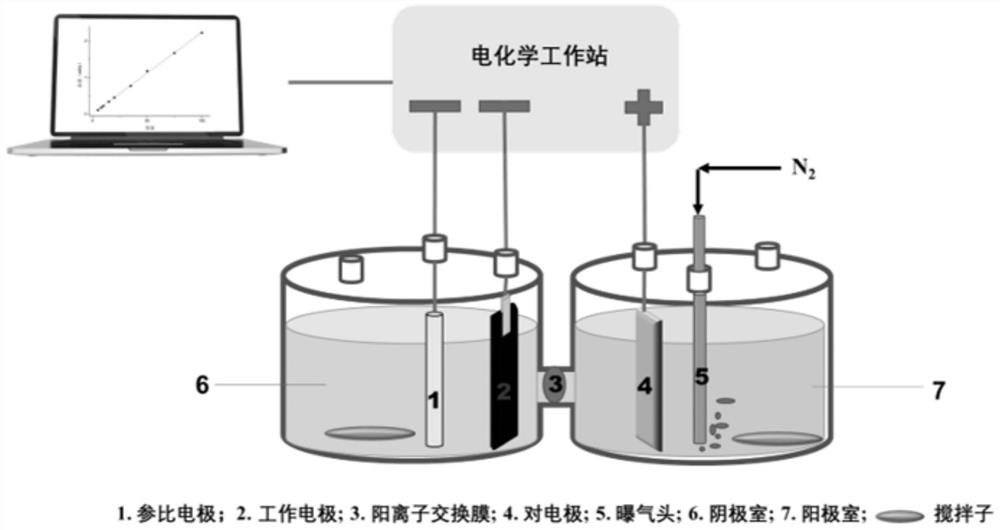

[0038] (1) The construction of the dechlorination reaction device, such as image 3 As shown, the steps are as follows:

[0039] a) The electrolytic cell for dechlorination reaction is an H-type electrolytic cell. The anode chamber and the cathode chamber are separated by a cation exchange membrane (Nafion-117). Before the reaction, it is necessary to pass nitrogen gas for 15 minutes; then use a 1mL pipette to add 2,4-dichlorophenol stock solution into the cathode electrolysis chamber, the initial concentration is 50mg / L, and then add a B-type magnetic stirrer to stir;

[0040] b) According to the principle of the three-electrode system, build the circuit of the electrocatalytic dechlorination device. Wherein the counter electrode is a platinum sheet electrode (30mm × 30mm), the reference electrode is Ag / Ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com