Method for enhancing performance of LaNi4.8Al0.2 alloy to resist CO, CO2 and air poison and anti-pulverization performance of alloy

A technology of CO2 and alloy powder, applied in the direction of coating, etc., can solve the problems of poor anti-powdering ability, achieve the effects of increasing viscosity, shortening the time of process preparation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

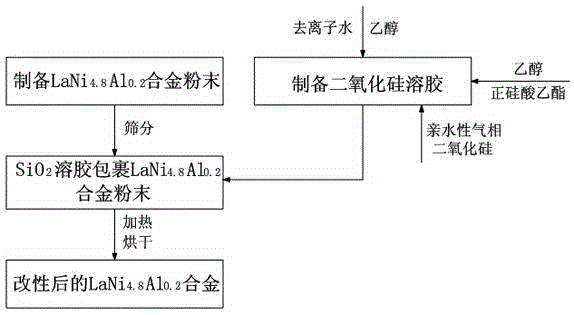

[0061] The present invention is mainly used for LaNi 4.8 Al 0.2 The alloy is modified to enhance its resistance to CO, CO 2 , Air poisoning and anti-powdering properties. Such as figure 1 Shown, the present invention is to LaNi 4.8 Al 0.2 The process flow of alloy powder modification can be divided into the preparation of LaNi 4.8 Al 0.2 Alloy powder, sieved LaNi 4.8 Al 0.2 Alloy powder, preparing silica sol, wrapping LaNi 4.8 Al 0.2 There are several major steps of alloy powder and heating and drying. The realization process of each major step is as follows:

[0062] Preparation of LaNi 4.8 Al 0.2 Alloy powder

[0063] The present invention can adopt existing technology to prepare LaNi 4.8 Al 0.2 Alloy powder, then it is modified, also can adopt the technology that the present invention designs to prepare LaNi 4.8 Al 0.2 Alloy powder, and then modify it. LaNi prepared by the process of the present invention 4.8 Al 0.2 alloy powder, and cooperate with other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com